SSANGYONG KORANDO 1997 Service Repair Manual

Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1141 of 2053

5A-46 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

AFTER TEARDOWN FAULTS

Condition

C2 burntPossible Causes

Gear shift lever linkage out of

adjustment.

S6 foiled - stuck low.

Overdrive/output shaft sealing

rings damaged.

C2 piston cracked.

Incorrect C4 pack clearance.

C4 wave plate not lined up

properly.

Overdrive or output shaft sealing

rings damaged.

C2 piston cracked.

Over-run Clutch (OC) /low-1st

ball misplaced.

B1R spring broken.

Input shaft sealing ring cut.

C1/B1R ball misplaced.

B1R spring left out.

Overdrive or input shaft sealing

rings damaged.

C1 piston cracked.

Ball capsule jammed.

4-3 sequence valve in backwards.

Clutch Apply Feed (CAF) /B1R

ball left out.

Rear band incorrectly adjusted

or damaged.

Reverse-low/first ball misplaced.Action

Inspect, repair C2 and adjust

the linkage as necessary.

Repair C2. Inspect, repair or

replace S6 as necessary.

Repair C2. Inspect, replace the

sealing rings and/or shaft as

necessary.

Repair C2. Inspect, repair or

replace the C2 piston as

necessary.

Inspect C4 and repair as

necessary.

Inspect and adjust the C4 pack

clearance as necessary.

Repair C4. Inspect and realign

the wave plate as necessary.

Repair C4. Inspect and realign

the sealing rings and/or shaft as

necessary.

Repair C4. Inspect and replace

the C2 piston as necessary.

Repair C4. Inspect and refit the

ball as necessary.

Inspect and repair B1 and

replace the spring as necessary.

Replace sealing ring.

Repair B1. Refit the ball as

necessary.

Inspect and repair C1 and

replace the spring.

Repair C1. Inspect and replace

the sealing tongs and/or shaft

as necessary.

Repair C1. Inspect and replace

the C1 piston as necessary.

Repair C1. Inspect and refit the

capsule as necessary.

Repair C1. Inspect and refit the

valve as necessary.

Repair C1. Inspect and replace

the ball as necessary.

Inspect and adjust the band as

necessary.

Inspect and refit the ball as

necessary.

C4 burnt

B1 burnt

C1 burnt

B2 burnt

(Slips in reverse - no manual 1st )

Page 1142 of 2053

AUTOMATIC TRANSMISSION 5A-47

SSANGYONG MY2002

Condition

Firm converter lock or unlockPossible Causes

Input shaft 'O' ring missing or

damaged.

Converter clutch regulator valve

in backwards.

Input shaft 'O' ring missing or

damaged.

C1 bias valve in backwards.Action

Inspect and replace the 'O' ring

as necessary.

Inspect and refit the valve as

necessary.

Inspect and replace the 'O' ring

as necessary.

Inspect and refit the valve as

necessary.

No lock up at light throttle

Page 1143 of 2053

5A-48 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

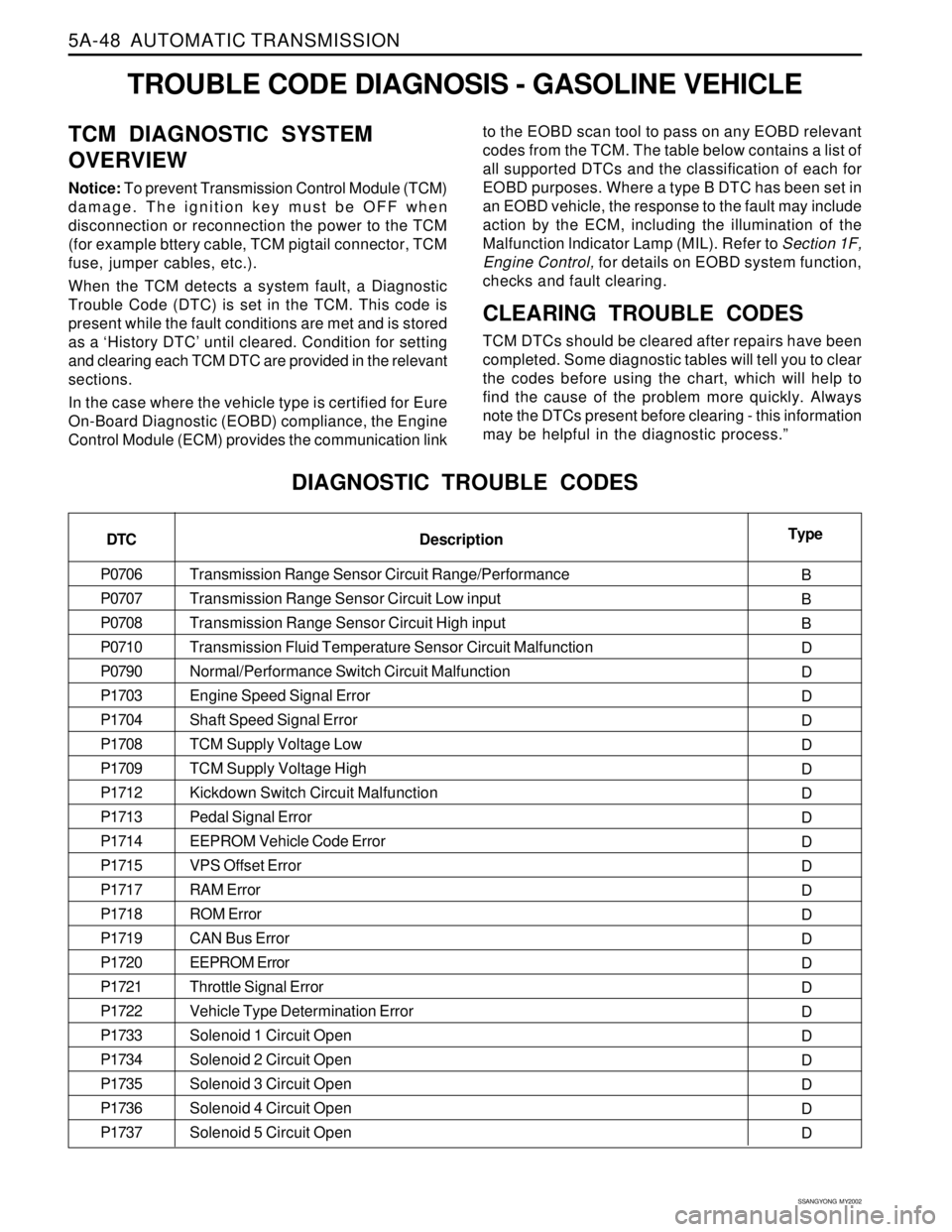

TROUBLE CODE DIAGNOSIS - GASOLINE VEHICLE

TCM DIAGNOSTIC SYSTEM

OVERVIEW

Notice: To prevent Transmission Control Module (TCM)

damage. The ignition key must be OFF when

disconnection or reconnection the power to the TCM

(for example bttery cable, TCM pigtail connector, TCM

fuse, jumper cables, etc.).

When the TCM detects a system fault, a Diagnostic

Trouble Code (DTC) is set in the TCM. This code is

present while the fault conditions are met and is stored

as a ‘History DTC’ until cleared. Condition for setting

and clearing each TCM DTC are provided in the relevant

sections.

In the case where the vehicle type is certified for Eure

On-Board Diagnostic (EOBD) compliance, the Engine

Control Module (ECM) provides the communication linkto the EOBD scan tool to pass on any EOBD relevant

codes from the TCM. The table below contains a list of

all supported DTCs and the classification of each for

EOBD purposes. Where a type B DTC has been set in

an EOBD vehicle, the response to the fault may include

action by the ECM, including the illumination of the

Malfunction lndicator Lamp (MIL). Refer to Section 1F,

Engine Control, for details on EOBD system function,

checks and fault clearing.

CLEARING TROUBLE CODES

TCM DTCs should be cleared after repairs have been

completed. Some diagnostic tables will tell you to clear

the codes before using the chart, which will help to

find the cause of the problem more quickly. Always

note the DTCs present before clearing - this information

may be helpful in the diagnostic process.”

DIAGNOSTIC TROUBLE CODES

DTC

P0706

P0707

P0708

P0710

P0790

P1703

P1704

P1708

P1709

P1712

P1713

P1714

P1715

P1717

P1718

P1719

P1720

P1721

P1722

P1733

P1734

P1735

P1736

P1737Type

B

B

B

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D Description

Transmission Range Sensor Circuit Range/Performance

Transmission Range Sensor Circuit Low input

Transmission Range Sensor Circuit High input

Transmission Fluid Temperature Sensor Circuit Malfunction

Normal/Performance Switch Circuit Malfunction

Engine Speed Signal Error

Shaft Speed Signal Error

TCM Supply Voltage Low

TCM Supply Voltage High

Kickdown Switch Circuit Malfunction

Pedal Signal Error

EEPROM Vehicle Code Error

VPS Offset Error

RAM Error

ROM Error

CAN Bus Error

EEPROM Error

Throttle Signal Error

Vehicle Type Determination Error

Solenoid 1 Circuit Open

Solenoid 2 Circuit Open

Solenoid 3 Circuit Open

Solenoid 4 Circuit Open

Solenoid 5 Circuit Open

Page 1144 of 2053

AUTOMATIC TRANSMISSION 5A-49

SSANGYONG MY2002

DIAGNOSTIC TROUBLE CODES (Cont'd)

DTC Types

Each DTC is directly related to a diagnostic test. The

Diagnostic management system sets DTCs based on

the failure of the tests during a driving cycle or cycles.

The following are the two types of DTCs and the charac-

teristics of those codes;

Type B

Emissions related.

EOBD system “Armed” after one driving cycle with

a fail.

EOBD system “Disarmed” after one driving cycle

with a pass.

Illuminates the MIL on the second con-secutive

driving cycle with a fail.

TCM stores a history DTC on the first driving cycle

with a fail.

EOBD system stores a history DTC on the second

consecutive driving cycle with a fail, (the DTC will

be armed after the first fail).

EOBD system stores a freeze frame on the second

consecutive driving cycle with a fail, (if empty).

Type D

Non-Emissions related.

Does not request illumination of any lamp.

Stores a history DTC on the first driving cycle with

a fail.

EOBD system does not store a freeze frame. DTC

P1738

P1739

P1741

P1742

P1743

P1744

P1745

P1746

P1747

Type

D

D

D

D

D

D

D

D

D Description

Solenoid 6 Circuit Open

Solenoid 7 Circuit Open

Solenoid 1 Circuit Short

Solenoid 2 Circuit Short

Solenoid 3 Circuit Short

Solenoid 4 Circuit Short

Solenoid 5 Circuit Short

Solenoid 6 Circuit Short

Solenoid 7 Circuit Short

Page 1145 of 2053

5A-50 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Transmission Range Sensor Circuit Low Input

Transmission Range Sensor Circuit High Input

Transmission Fluid Temperature Sensor Circuit Malfunction

Normal/Performance Switch Circuit Malfunction

Engine Speed Signal Error

Shaft Speed Signal Error

TCM Supply Voltage Low

TCM Supply Voltage High

Air Conditioning Switch Circuit Malfunction

Kickdown Switch Circuit Malfunction

EEPROM Vehicle Code Error

VPS Offset Error

Throttle Not Learnt Error

RAM Error

ROM Error

EEPROM Error

Throttle Signal Error

Vehicle Type Determination Error

Solenoid 1 Circuit Open

Solenoid 2 Circuit Open

Solenoid 3 Circuit Open

Solenoid 4 Circuit Open

Solenoid 5 Circuit Open

Solenoid 6 Circuit Open

Solenoid 7 Circuit Open

Solenoid 1 Circuit Short

Solenoid 2 Circuit Short

Solenoid 3 Circuit Short

Solenoid 4 Circuit Short

TROUBLE CODE DIAGNOSIS - DIESEL VEHICLE

TCM DIAGNOSTIC SYSTEM

OVERVIEW

Notice: To prevent Transmission Control Module (TCM)

damage. The ignition key must be OFF when

disconnection or reconnection the power to the TCM

(for example bttery cable, TCM pigtail connector, TCM

fuse, jumper cables, etc.).

When the TCM detects a system fault, a Diagnostic

Trouble Code (DTC) is set in the TCM. This code is

present while the fault conditions are met and is storedas a ‘History DTC’ until cleared. Condition for setting

and clearing each TCM DTC are provided in the relevant

sections.CLEARING TROUBLE CODES

TCM DTCs should be cleared after repairs have been

completed. Some diagnostic tables will tell you to clear

the codes before using the chart, which will help to

find the cause of the problem more quickly. Always

note the DTCs present before clearing - this information

may be helpful in the diagnostic process.

DIAGNOSTIC TROUBLE CODES

DTC

P0707

P0708

P0710

P0790

P1703

P1704

P1708

P1709

P1710

P1712

P1714

P1715

P1716

P1717

P1718

P1720

P1721

P1722

P1733

P1734

P1735

P1736

P1737

P1738

P1739

P1741

P1742

P1743

P1744Description

Page 1146 of 2053

AUTOMATIC TRANSMISSION 5A-51

SSANGYONG MY2002

DIAGNOSTIC TROUBLE CODES (Cont'd)

DTC

P1745

P1746

P1747Description

Solenoid 5 Circuit Short

Solenoid 6 Circuit Short

Solenoid 7 Circuit Short

Page 1147 of 2053

5A-52 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Transmission Control Module (TCM) Diagnistic

System Check is the starting point for any driveability

complaint diagnosis. Before using this procedure,

perform a careful visual/physical check of the

Transmission Control Module (TCM) and the

transmission grounds for cleanliness and tightness.

The TCM Diagnostic System Check is an organized

approach to identifying a problem created by an

electronic transmission control system malfunction.

TCM DIAGNOSTIC SYSTEM CHECK

Diagnostic Aids

An intermittent fault may be caused by a poor connec-

tion, rubbed-through wire insulation or a wire broken

inside the insulation. Check for poor connections or a

damaged harness. Inspect the TCM harness and con-

nections for improper mating, broken locks, improperly

formed or damaged terminals, poor terminal-to-wire

connection, and damaged harness.

TCM Diagnostic System Check

1

StepAction Value(s) Yes No

21 Turn the ignition OFF.

2. Install the scan tool.

3. Turn the ignition ON, with the engine OFF.

4. Attempt to display the Transmission Control

Module (TCM) Data List with the scan tool.

Does the scan tool display the TCM data?

Select the Trouble Code with the scan tool.

Are any Diagnostic Trouble Codes (DTCs) stored?

- Go to Step 2 Go to Step 3

Go to

applicable

DTC table -System OK,

Check

Complete

KAA5A5KA

Page 1148 of 2053

AUTOMATIC TRANSMISSION 5A-53

SSANGYONG MY2002

TCM Diagnostic System Check (Cont'd)

3

StepAction Value(s) Yes No

4

5

6

71. Turn the ignition OFF.

2. Disconnect the TCM connector B.

3. Turn the ignition ON.

4. Check the serial data line from TCM connector

terminal B22 to Data Link Connector (DLC) connec-

tor terminal 14 for an open, short to ground, or

short to voltage. Also, check the DLC ignition feed

circuit for an open or short to ground and the DLC

ground circuit for an open.

Is a problem found?

Repair the open, short to ground or short to voltage in

the serial data circuit or the DLC ignition feed circuit

or the DLC ground circuit.

Is a repair complete?

Check the TCM ignition feed circuit for an open or

short to ground and the TCM ground circuit for an

open.

Is a problem found?

Repair the open or short to ground in the TCM ignition

feed circuit or the TCM ground circuit.

Is a repair complete?

1. Turn the ignition OFF.

2. Disconnect the TCM connector.

- Go to Step 6 Go to Step 7

- Go to Step 1-

- Go to Step 1 -

- Go to Step 4 Go to Step 5

- Go to Step 1 -

Page 1149 of 2053

5A-54 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

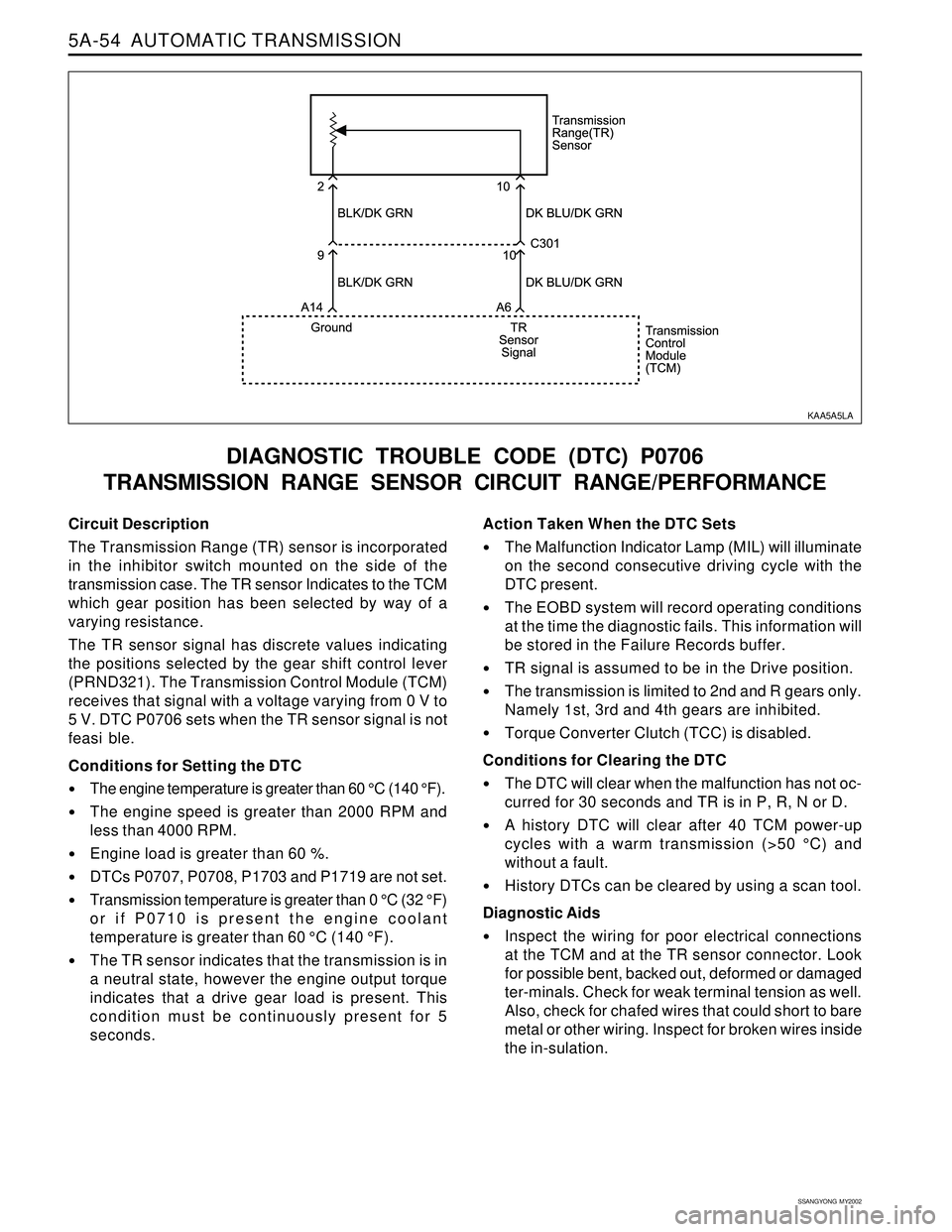

Circuit Description

The Transmission Range (TR) sensor is incorporated

in the inhibitor switch mounted on the side of the

transmission case. The TR sensor Indicates to the TCM

which gear position has been selected by way of a

varying resistance.

The TR sensor signal has discrete values indicating

the positions selected by the gear shift control lever

(PRND321). The Transmission Control Module (TCM)

receives that signal with a voltage varying from 0 V to

5 V. DTC P0706 sets when the TR sensor signal is not

feasi ble.

Conditions for Setting the DTC

•The engine temperature is greater than 60 °C (140 °F).

The engine speed is greater than 2000 RPM and

less than 4000 RPM.

Engine load is greater than 60 %.

DTCs P0707, P0708, P1703 and P1719 are not set.

Transmission temperature is greater than 0 °C (32 °F)

or if P0710 is present the engine coolant

temperature is greater than 60 °C (140 °F).

The TR sensor indicates that the transmission is in

a neutral state, however the engine output torque

indicates that a drive gear load is present. This

condition must be continuously present for 5

seconds.

DIAGNOSTIC TROUBLE CODE (DTC) P0706

TRANSMISSION RANGE SENSOR CIRCUIT RANGE/PERFORMANCE

Action Taken When the DTC Sets

The Malfunction Indicator Lamp (MIL) will illuminate

on the second consecutive driving cycle with the

DTC present.

The EOBD system will record operating conditions

at the time the diagnostic fails. This information will

be stored in the Failure Records buffer.

TR signal is assumed to be in the Drive position.

The transmission is limited to 2nd and R gears only.

Namely 1st, 3rd and 4th gears are inhibited.

Torque Converter Clutch (TCC) is disabled.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not oc-

curred for 30 seconds and TR is in P, R, N or D.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and at the TR sensor connector. Look

for possible bent, backed out, deformed or damaged

ter-minals. Check for weak terminal tension as well.

Also, check for chafed wires that could short to bare

metal or other wiring. Inspect for broken wires inside

the in-sulation.

KAA5A5LA

Page 1150 of 2053

AUTOMATIC TRANSMISSION 5A-55

SSANGYONG MY2002

Perform a Transmission Control Module (TCM)

Diagnostic System Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P0706?

1. Select Gear Lever Position on scan tool Data List.

2. Move the gear shift control lever through all of the

gear ranges (P, R, N, D, 3, 2, 1).

Does the scan tool display the correct gear lever

positions?

1. Inspect the TR sensor for damage to its rotating

part or its mountings.

2. Inspect the shaft driving the TR sensor for damage.

Is a repair necessary?

Replace the TR sensor or driving shaft as appropriate.

Is the acting complete?

Check for damage to the z-link within the transmission

and repair as necessary.

Is a repair necessary?

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

Check if any DTCs are set.

Are there any DTCs displayed or previously recorded

at Step 2 that have not been diagnosed?

DTC P0706 Transmission Range Sensor Circuit Range/Performance

1

StepAction Value(s) Yes No

2

3

4

5

6

- Go to Step 2Go to “TCM

Diagnostic

System Check”

- Go to Step 6 Go to Step 4

- Go to Step 5 Go to Step 6

- Go to Step 7 -

8 7

- Go to Step 8 Go to Step 2

- Go to Step 7 -

- Go to Step 3 Go to

“Diagnostic

Aids”

-Go to

applicable

DTC tableSystem OK,

Check

Complete