SSANGYONG KORANDO 1997 Service Repair Manual

Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1271 of 2053

5A-176 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Planet Carrier Assembly and Centre Support

1. Check the carrier and planet assembly for any

damage or irregularity and ensure that all pinions

rotate freely and that the pinion end float is within

0.10 mm - 0.50 mm.

2. Install the One Way Clutch (OWC) retainer (1) to

the planet carrier with the inner edge pointing down-

wards. Inspect the OWC race and the sprag

assemblies for wear or damage. Replace if

necessary.

3. Install the outer (3) race in the drum. Press the

race to the bottom of the drum and install the

retaining circlip (2). Ensure the circlip is firmly

seated in its groove.

4. Install the OWC (1) into the outer race with the lip

edge uppermost. Lubricate the sprags with auto-

matic transmission fluid.

5. Check that the plugs are fitted to the centre

support, then assemble the centre support into

the OWC, ensuring that the support will rotate in

an anti-clock-wise direction only.

6. Lubricate the No. 9 needle bearing and washer

with petroleum jelly and fit them to the rear face

of the planet carrier.

7. In s t a l l th e

KAA5A0A0

KAA5A760

KAA5A750

KAA5A560

Tightening Torque20 - 27 Nm

(15 - 20 lb-ft)

Page 1272 of 2053

AUTOMATIC TRANSMISSION 5A-177

SSANGYONG MY2002

Adaptor Housing Assembly

1. Install a new seal to the adaptor housing.

2. Position a new gasket onto the adaptor housing.

Notice: Do not use petroleum jelly to hold the gasket

in position.

3. Apply additional Loctite 202 or equivalent as required

to the adapter housing bolts. Install the adaptor

housing and torque the bolts to specification.

Installation Notice

Front Servo Assembly

1. Lubricate the cover ‘O’ ring with automatic

transmission fluid and fit to the cover.

2. Lubricatethepiston‘O’ rings with automatic trans-

mission fluid and fit to the piston.

3. Assemble the piston, push rod, spring, belleville

washer, seat and retaining ring.

4. Fit the piston push rod assembly into the front

servo cover.

5. Install the front servo block and spring into the

case.

6. Install the front servo assembly into the case.

KAA5A0C0

KAA5A520 KAA5A0B0

Tightening Torque30 - 35 Nm

(22 - 26 lb-ft)

7. Compress the servo cover and fit the servo cover

retaining circlip, aligning the gap with the pan rail,

and ensuring that it is completely seated in its

groove.

Notice: Ensure that the front servo snap ring is

installed correctly. Orient the circlip with the gap at

the bottom, near the pan rail.

KAA5A0D0

Page 1273 of 2053

5A-178 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

4. Install the front band into the transmission case,

ensuring that it is properly seated in place.

Notice: If fitting a new band, soak the band in

automatic transmission fluid for a minimum of 5

minutes prior to assembly.

5. Position the reaction strut in its retaining clip and

engage it with the band and anchor strut.

6. Position the apply strut in its retaining clip and

engage it with the band and the servo piston rod.

C2/C4 Clutch Assembly

Tools Required

0555-336259Clutch Spring Compressor

0555-336260Clutch Pack Clearance Kit

Notice:

Check pistons for cracks.

Do not mix the clutch piston return springs.

Ensure that the snap rings are fitted correctly.

1. Check the feed orifices in the cylinder bore are clear

of obstructions.

2. Check the C2 piston bleed orifices are clear of

obstructions.

3. Lubricate the ‘O’ rings with Automatic Transmission

Fluid (ATF)

4. Fit the small ‘O’ ring onto the inner groove, and

the large ‘O’ ring onto the outer groove of the

piston.

Notice: ‘O’ rings must not be twisted in the grooves.

KAA5A0E0

KAA5A550

KAA5A0F0

Front Band Assembly

1. Install the reaction anchor strut to the case.

2. Check the band for all cracks or damage along its

lining and metal backing.

3. Position the strut retainers on the band.

Page 1274 of 2053

AUTOMATIC TRANSMISSION 5A-179

SSANGYONG MY2002

5. Check the C4 piston bleed orifices are clear of

obstructions.

6. Lubricate the ‘O’ rings with ATF.

7. Fit the small ‘O’ rings onto the inner groove and

the large ‘O’ rings onto the outer groove of the

piston.

8. Position the clutch cylinder with the C2/C4 cavity

facing upwards.

9. Fit the C4 piston into the C2 piston with the bleed

orifices in alignment.

10. Install the C2/C4 piston assembly into the

cylinder, with the piston bleed orifices aligned with

the holes on the outside of the cylinder, until the

outer diameter of the C2 piston enters the inner

diameter of the cylinder.

KAA5A0G0

11. Assemble the piston return spring to the piston,

and fit the spring retainer over the spring.

12. Using 0555-336259 clutch spring compressor,

compress the spring sufficiently to enable the

installation of the retaining circlip ensuring that

the circlip is firmly seated in its groove, then

remove the tool.

Notice: The wire diameter of this spring is 4.3 mm.

13. Check the C1 piston check valves are not

damaged and are free to move, and that the

cylinder feed orifices are clear of obstructions.

14. Lubricate the ‘O’ rings with ATF and fit them to

their respective grooves.

Notice: ‘O’ rings must not be twisted in the

grooves.

KAA5A690

Page 1275 of 2053

5A-180 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

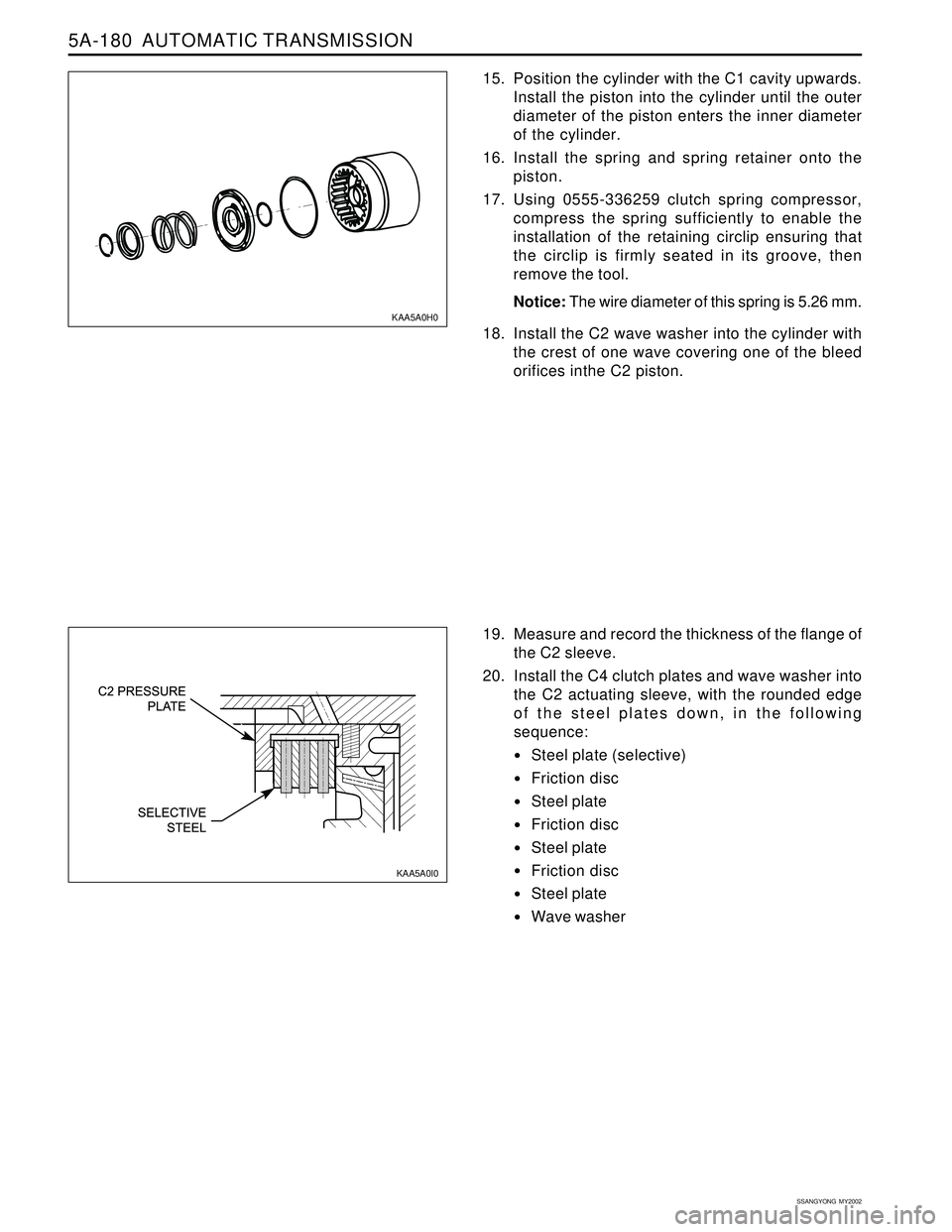

15. Position the cylinder with the C1 cavity upwards.

Install the piston into the cylinder until the outer

diameter of the piston enters the inner diameter

of the cylinder.

16. Install the spring and spring retainer onto the

piston.

17. Using 0555-336259 clutch spring compressor,

compress the spring sufficiently to enable the

installation of the retaining circlip ensuring that

the circlip is firmly seated in its groove, then

remove the tool.

Notice: The wire diameter of this spring is 5.26 mm.

18. Install the C2 wave washer into the cylinder with

the crest of one wave covering one of the bleed

orifices inthe C2 piston.

19. Measure and record the thickness of the flange of

the C2 sleeve.

20. Install the C4 clutch plates and wave washer into

the C2 actuating sleeve, with the rounded edge

of the steel plates down, in the following

sequence:

Steel plate (selective)

Friction disc

Steel plate

Friction disc

Steel plate

Friction disc

Steel plate

Wave washer

KAA5A0H0

KAA5A0I0

Page 1276 of 2053

AUTOMATIC TRANSMISSION 5A-181

SSANGYONG MY2002

21. Holding the cylinder horizontal, install the sleeve

and clutch plate assembly into the cylinder, with

the crest of one wave of the washer in line with

one of the holes in the outside of the cylinder,

until the sleeve contacts the C2 wave washer.

22. Check the C4 clutch pack clearance using 0555-

336260 clutch pack clearance kit.

Notice: With the C2 wave spring compressed, and

the clutch Pack supporting a 2 kg weight, the

dimension from the underside of the C2 pressure plate

to the selective steel is to be between 1.4 - 1.8 mm. If

the clutch is to be gauged from the top of the pressure

plate, then the dimension is to be the actual thickness

of the pressure plate plus 1.4 - 1.8 mm.

23. Use selective plates to achieve the correct

specification. If new friction plates are being fitted,

remove the clutch pack and soak the friction plates

in ATF for a minimum of 5 minutes prior to reassembly.

Notice: The clutch pack clearance must be taken

before the elements are soaked in ATF.

KAA5A0K0KAA5A0J0

24. Reassemble the sleeve and clutch pack into the

cylinder. Observe the alignment of the wave

washer to the hole in the cylinder.

25. Install the C2 clutch plates in the cylinder in the

following sequence:

Friction disc

Steel plate

Friction disc

Steel plate

Steel plate (0574-000013, `014, `015, `016,

`019, `022), or Friction disc (0574-000012 & `017)

Steel plate (selective)

Friction disc

Steel plate (selective)

Friction disc

KAA5A0L0

Page 1277 of 2053

5A-182 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

26. Check the clutch pack clearance using only the

weight from 0555-336260 clutch pack clearance

kit.

Notice: With the clutch pack supporting a 2

kgweight, the dimension from the C3 clutch hub

locating step to the friction plate is to be between

0.80 - 1.05 mm.

27. Use selective plates to achieve the correct

specifica-tion. If new friction plates are being

fitted, remove the clutch pack and soak the friction

plates in ATF for a minimum of 5 minutes prior to

reassembly.

Notice: The clutch pack clearance must be taken

before the elements are soaked in ATF.

28. Lubricate and fit the 3-4 OWC and end caps to

the C2 hub.

32. Apply petroleum jelly to the No. 5 needle bearing

and fit it to the C4 hub.

33. Remove the C2 clutch plates from the clutch cylin-

der.

34. Fit the thrust plate over the cylinder inner hub.

35. Engage the C2/C4 clutch hub assembly in the C4

clutch plates.

36. Install the C2 clutch plates.

37. Install the C3 hub and secure it with the circlip,

ensuring that the circlip is firmly seated in its

groove. 29. Align the tangs and fit the nylon thrust washer

onto the C4 hub.

30. Align and fit the C4 hub to the C2 clutch and the

OWC assembly.

31. Check the rotation of the C2 hub. While holding

the C4 hub, the C2 hub should rotate in the

clockwise direction and lockup in the anti-

clockwise direction when viewed from the C2 hub.

KAA5A0M0

KAA5A0N0

KAA5A0O0

Page 1278 of 2053

AUTOMATIC TRANSMISSION 5A-183

SSANGYONG MY2002

C3 Clutch and Reverse Sun Gear Assembly

Tools Required

0555-336259Clutch Spring Compressor

0555-336260Clutch Pack Clearance Kit

1. Check the orifices in the cylinder are clear of ob-

structions.

2. Check the C3 cylinder bush outside diameter and

the centre support inside diameter are in good

condition and not damaged. Coat the sealing rings

with automatic transmission fluid and fit into the

C3 cylinder grooves.

3. Check the reverse sun gear splines, grooves and

thrust face for condition. Coat the ‘O’ ring with

automatic transmission fluid and fit it to the groove

of the reverse sun gear.

4. Lubricate the C3 washer with petroleum jelly and

fit to the inner face of the reverse sun gear.

5. Install the reverse sun gear in the C3 cylinder,

ensuring that the ‘O’ ring compression is

adequate but not excessive.

Notice: ‘O’ rings must not be twisted in the

grooves.

KAA5A0P0

6. Coat the C3 piston ‘O’ rings with automatic trans-

mission fluid and fit the small ‘O’ ring onto the

inner ring and the large ‘O’ ring onto the outer

ring of the C3 piston.

7. Check that the bleed orifices of the piston are

clean and clear of obstructions.

8. Install the C3 piston in the cylinder until the

outside diameter of the piston enters the inside

diameter of the cylinder.

Notice: Take care not to cut the ‘O’ ring.

9. Assemble the spring and spring retainer on the

piston. Using 0555-336259 clutch spring

compressor compress the spring sufficiently to

enable the installation of the retaining circlip,

ensuring that the circlip is firmly seated in the

groove, and remove the tool.

10. Fit the C3 wave plate to the C3 piston face,

ensuring that one crest of the wave plate of the

C3 piston face is aligned over one of the piston

orifices.

KAA5A0Q0

KAA5A730

Page 1279 of 2053

5A-184 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

11. Assemble the clutch plates and discs into the

cylinder in the following sequence :

Steel plate

Friction disc

Steel plate

Steel plate (0574-000013, `014, `015, `016, `019,

`022), or Friction disc (0574-000012, `017)

Steel plate (selective)

Friction disc

Steel plate (selective)

Friction disc

12. Align and fit the pressure plate with the

counterbore facing away from the clutch plates.

13. Install the circlip.

14. Check the C3 clutch clearance using 0555-336260

clutch pack clearance kit in the following manner

(weight only).

a. Place the weight on the pressure plate and

measure the distance from the end of the

cylinder to the top of the pressure plate.

b. Record this figure.

c. Remove the weight.

d. Lift the pressure plate up against the circlip

and measure the distance from the end of the

cylinder to the top of the pressure plate.

e. Record this figure.

f. Subtract the second reading from the first read-

ing to obtain the clutch pack clearance.KAA5A0R0

KAA5A0S0

Page 1280 of 2053

AUTOMATIC TRANSMISSION 5A-185

SSANGYONG MY2002

Notice: With the clutch pack supporting a weight

of 2kg, the clearance between the snap ring and

the top of the pressure plate is to be between 1.07

- 1.45 mm.

15. If new friction plates are being fitted, remove the

clutch pack and soak the friction elements in auto-

matic transmission fluid for a minimum of five min-

utes prior to reassembly.

Notice: The clutch pack clearance must be taken

before the elements are soaked in automatic

transmission fluid.

Forward Sun Gear and C3 Clutch Pack

Assembly

1. Fit the No. 7 needle bearing assembly over the

for-ward sun gear, ensuring that the thrust washer

is between the bearing and the sun gear.

2. Lubricate the lipped thrust plate with petroleum

jelly and fit the thrust plate onto the reverse sun

gear.

KAA5A0U0 KAA5AOTA

3. Align and fit the C3 clutch assembly over the for-

ward sun gear.

4. Lubricate the No. 6 needle bearing with petroleum

jelly and fit it to the thrust plate. Ensure the lugs

on the outside diameter of the bearing fit in the

thrust plate counterbore.

5. Align and fit the plastic thrust washer to the thrust

plate with petroleum jelly.

6. Install the assembly over the forward sun gear

shaft against the No. 6 needle bearing.

7. Place the assembly to one side.

KAA5A0W0KAA5A0V0