SSANGYONG KORANDO 1997 Service Repair Manual

Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1251 of 2053

AUTOMATIC TRANSMISSION 5A-153

SSANGYONG MY2002

BLANK

Page 1252 of 2053

5A-154 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

DIAGNOSTIC TROUBLE CODE (DTC) P1747

SOLENOID 7 CIRCUIT SHORT

Circuit Description

The solenoid 7 is a normally open ON/OFF type sole-

noid that is used to control the application of the

Torque Converter Clutch (TCC).

The Solenoid 7 (S7) ON activates the TCC and is at-

tached to the pump body within the transmission. Volt-

age is supplied directly to the solenoid through the

Transmission Control Module (TCM).

The DTC P1747 sets when the solenoid 7, Torque

Converter Clutch Solenoid, circuit is shorted to ground.

The solenoid 7’s driver Integrated Chip (IC) status

indicates a faulty circuit.

Conditions for Setting the DTC

DTCs P1717 and P1718 are not set.

S7 is ON.

The solenoid 7’s driver Integrated Chip (IC) status

indicates a faulty circuit. This condition must be

continuously present for 60 milliseconds.

Action Taken When the DTC Sets

The solenoid 7 is always disabled (OFF) resulting

in the TCC being unlocked continuously.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred after ignition cycle.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

During the TCM’s testing, solenoid 7 is turned OFF/

ON by a very small (4 millisecond) pulses. This

pulse is too short for the solenoid to react so the

transmission operation is not affected.

The solenoid feedback voltage is measured before

the (4 millisecond) pulse and again during the

pulse. If the difference is outside the acceptable

limits the relevant fault is recorded.

Typical causes would be a short circuit to ground

in the wiring to or within the solenoid.

If several faults of solenoids are present, check

the wiring or connectors that are common to the

selected solenoids, especially the earth

connections.

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also check for chafed wires

that could short tobare metal or other wiring. Inspect

for broken wire inside the insulation.

KAC5A030YAD1E080

Page 1253 of 2053

AUTOMATIC TRANSMISSION 5A-155

SSANGYONG MY2002

DTC P1747 Solenoid 7 Circuit Short

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S7 circuit in the transmission is mal-

functioning.4. Check cable in the transmission for short to

ground.

7. Check resistance between S7 terminal A and B.

Standard value is 22 - 30 Ω.

10. Check connections of other connectors.

- Go to Step 15 Go to Step 7 1Perform a Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1747?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 7 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the pump assembly. Refer to the Pump in

this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

contact point attached onto the transmission case.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

With a test light connected to B+, probe the wiring

harness from contact point attached onto the trans-

mission case to S7.

Does the test light illuminate?

Using a Digital Volt Meter (DVM), measure the

resistance between S7 terminal A and B.

Is the resistance within the specified value?

Replace the S7.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 7 to TCM terminal A9.

Does the test light illuminate?

StepAction Value(s) Yes No

2

3

-

Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 12 -

7

8

9

- Go to Step 12 -

- Go to Step 5 Go to Step 10

- Go to Step 3Go to

“Diagnostic

Aids”

20 - 30 ΩGo to

“Diagnostic

Aids”

Go to Step 8

Page 1254 of 2053

5A-156 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

DTC P1747 Solenoid 7 Circuit Short (Cont’d)

Check for a poor connection at the 10-way transmission

connector and TCM connector and repair the malfunc-

tioning terminals as necessary.

Is a repair necessary?

1. Turn the ignition OFF.

2. Replace the TCM.

Is the action complete?

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

Check if any DTCs are set.

Are there any DTCs displayed or previously recorded

at Step 2 that have not been diagnosed?

StepAction Value(s) Yes No

10

- Go to Step 12 Go to Step 11

13 11

- Go to Step 12 -

12

- Go to Step 13 Go to Step 2

-Go to

applicable

DTC tableSystem OK,

Check

Complete

Page 1255 of 2053

5A-160 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

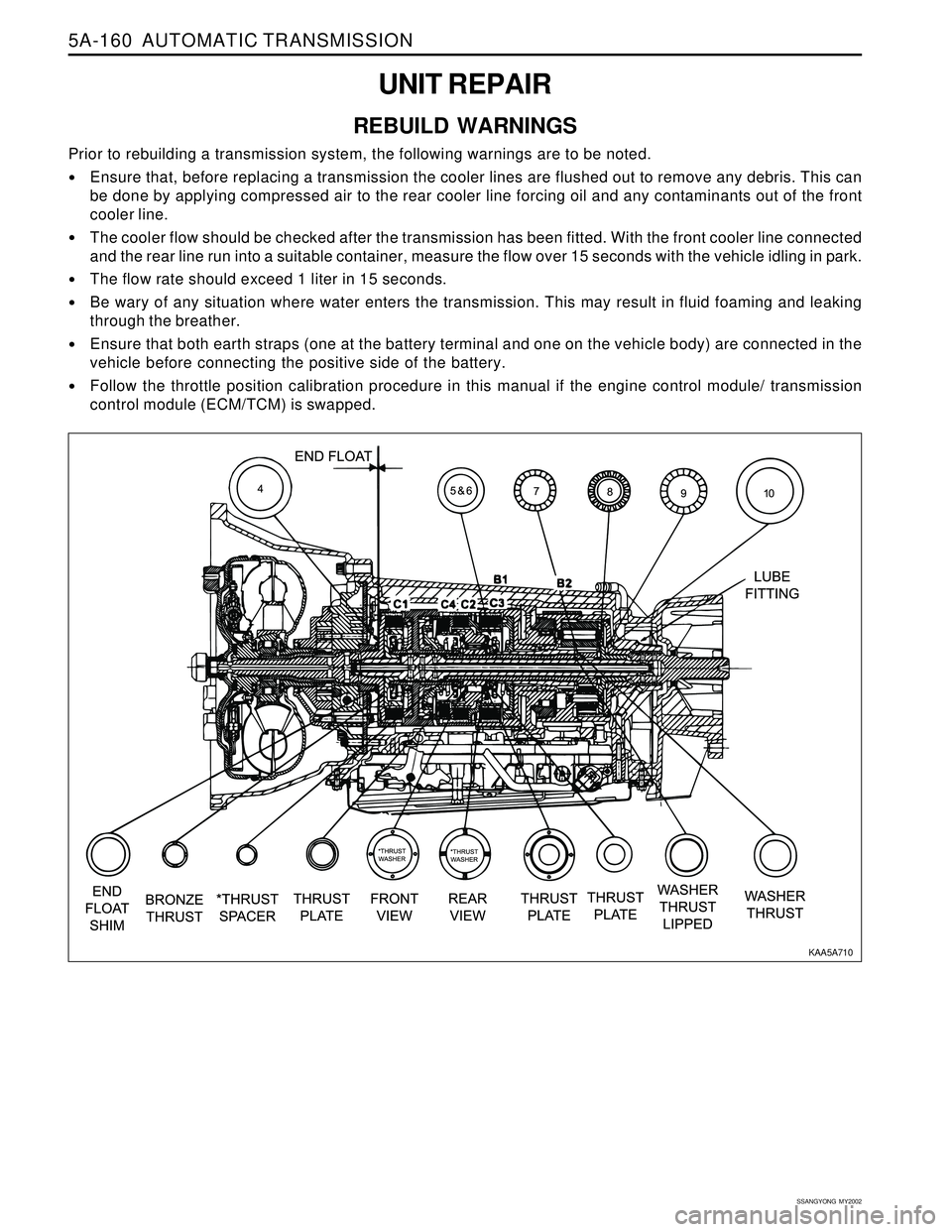

UNIT REPAIR

REBUILD WARNINGS

Prior to rebuilding a transmission system, the following warnings are to be noted.

Ensure that, before replacing a transmission the cooler lines are flushed out to remove any debris. This can

be done by applying compressed air to the rear cooler line forcing oil and any contaminants out of the front

cooler line.

The cooler flow should be checked after the transmission has been fitted. With the front cooler line connected

and the rear line run into a suitable container, measure the flow over 15 seconds with the vehicle idling in park.

The flow rate should exceed 1 liter in 15 seconds.

Be wary of any situation where water enters the transmission. This may result in fluid foaming and leaking

through the breather.

Ensure that both earth straps (one at the battery terminal and one on the vehicle body) are connected in the

vehicle before connecting the positive side of the battery.

Follow the throttle position calibration procedure in this manual if the engine control module/ transmission

control module (ECM/TCM) is swapped.

KAA5A710

Page 1256 of 2053

AUTOMATIC TRANSMISSION 5A-161

SSANGYONG MY2002

DISASSEMBLY PROCEDURE

Transmission

Tools Required

0555-336256Transmission Bench Cradle

0555-336257Pump Puller

Notice:

Remove the inhibitor switch before washing the

transmission in solvent or hot wash.

It is assumed that the transmission fluid has been

drained when the transmission was removed from

the vehicle and that the ‘special tools’ quoted are

available.

The transmission is dismantled in a modular fashion,

and the details of disassembly for each module are

given under the appropriate subject. Refer to Special

Tools Table in this chapter for details of all special

tools required when performing disassembly

procedures.

Technicians overhauling these transmissions will

also require a selection of good quality Torx bit

sockets, in particular numbers 30, 40 and 50, and

an 8 mm, 10 mm and 12 mm double hex socket.

1. Remove the converter and the converter housing.

2. Mount the transmission on the transmission bench

cradle 0555-336256.

3. Remove the oil pan and the oil pan seal.

4. Remove each end of the filter retaining clip from

the valve body and remove the filter.

5. Disconnect the wires from each solenoid and ground

and lay the wiring to one side.

6. Remove the valve body securing screws and

remove the valve body from the case.

KAA5A500

KAA5A510

Page 1257 of 2053

5A-162 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

7. Remove the front servo cover circlip.

8. Remove the front servo cover, piston and spring.

Notice: The plastic servo block is retained by the

piston return spring only.

9. Remove the adaptor housing bolts and adaptor

housing.

10. Remove the pump to case bolts using a multi-

hex 8 mm spanner.

11. Using the pump puller 0555-336257, remove the

pump and pump cover.

12. Remove the input shaft, forward clutch cylinder,

and the overdrive shaft as an assembly,

withdrawing them through the front of the case.

13. Remove the C3 clutch cylinder and sun gears.

14. Remove the front band struts. Remove the front

band.

KAA5A520

KAA5A530

KAA5A550 KAA5A540

Page 1258 of 2053

AUTOMATIC TRANSMISSION 5A-163

SSANGYONG MY2002

15. Remove the two centre support retaining bolts

using a T50 Torx bit.

16. Remove the centre support retaining circlip.

Notice: Do not hammer the output shaft to remove

the centre support as this will cause permanent

damage to the thrust bearing surfaces.

17. Remove the centre support, 1 - 2 one way clutch,

and planetary gear set as an assembly.

18. Remove the parking rod cam plate using a T40

Torx bit.

19. Remove the rear band struts and remove the band.

Notice: Vise the both end of rear band using the

plier and lean forward about 15 degrees

20. Remove the output shaft assembly.

Transmission Case

Tools Required

0555-336258Cross Shaft Pin Remover/Installer

(Detent Lever)

0555-336261Cross Shaft Seal Remover

0555-336265Cross Shaft Pin Remover/Installer

(Inhibitor Switch)

1. Remove the pin from the side of cross shaft

inhibitor switch using cross shaft pin remover/

installer (inhibitor switch) 0555-336265.

2. Remove the inhibitor switch bolts and inhibitor

switch from the case.

3. Remove the cross shaft seals with cross shaft seal

remover 0555-336261.

4. Remove the circlip from the cross shaft. Pull the

shaft to release the drive pin from the selector

quadrant.

KAA5A560

KAA5A570

KAA5A580

KAA5A590

Page 1259 of 2053

5A-164 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

5. Using cross shaft pin remover/installer (detent le-

ver) 0555-336258, press the pin from the cross

shaft and withdraw the shaft from the case.

6. Remove the cross shaft pin and spring.

7. Remove the manual valve lever and the park rod.

8. Depress the tangs and withdraw the 10 pin

connector into the case. Remove the wiring loom

assembly.

9. Detach the No. 7 solenoid wire from the front of

the case.

10. Remove the parking pawl pivot pin and the pawl

and spring from the case.

11. Remove the shaft and the rear servo lever.

12. Remove the rear servo cover and piston assembly.

13. Remove the B1R circlip, valve and spring.

14. Remove both band adjustment shims.

15. Inspect the output shaft bushing in the case and

replace if necessary.

16. Inspect cooler line fittings and replace as

necessary.

17. Inspect the case for damage.

KAA5A600

KAA5A610

KAA5A620

KAA5A630

Page 1260 of 2053

AUTOMATIC TRANSMISSION 5A-165

SSANGYONG MY2002

18. To remove the park rod lever: Remove the circlip

from the inner end of the pivot shaft and tap the

outer end of the shaft until it moves free from the

case, then using a wide shallow tapered drift as a

wedge, drive the pin out from the inside of the

case and remove the lever and spring.

Notice: Do not remove the park rod lever unless

absolutely necessary.

Forward Clutch Cylinder

Tools Required

0555-336259Clutch Spring Compressor

1. Place the assembly in a horizontal position.

2. Remove the No. 4 needle bearing (2) and adjust-

ment shims (1) from the input shaft.

3. Remove the circlip from the front of the clutch cylin-

der and remove the input shaft.

4. Remove the overdrive shaft and the C1 clutch hub

assembly from the clutch cylinder.

5. Remove the C1 clutch plates from the cylinder.

6. Remove the circlip retaining the C3 clutch hub in

the rear of the clutch cylinder and remove the hub.

7. Remove the C2/C4 clutch hub assembly and

remove the No. 5 needle bearing from the C4 hub.

8. Removethe C2 clutch plates.

KAA5A640

KAA5A650

KAA5A660

KAA5A670