section 2c SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1230 of 2053

AUTOMATIC TRANSMISSION 5A-135

SSANGYONG MY2002

DTC P1742 Solenoid 2 Circuit Short

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S2 circuit in the transmission is

malfunctioning.

4. Check cable in the transmission for short to

ground.

6. Check resistance between S2 terminal A and B.

Standard value is 22 - 30 Ω.

9. Check connections of other connectors.If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

Solenoid Logic for Static Gear States

Gear

1st

2nd

3rd

4th

Reverse

Neutral

ParkS1

ON

OFF

OFF

ON

OFF

OFF

OFFS2

ON

ON

OFF

OFF

OFF

OFF

OFF

1Perform a Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1742?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 2 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the valve cover. Refer to the Transmission

in this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

Solenoid 2 (S2) on the valve body.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

Using a Digital Volt Meter (DVM), measure the

resistance between S2 terminal A and B.

Is the resistance within the specified value?

Replace the S2.

Is the action complete?

StepAction Value(s) Yes No

2

3

- Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 11 -

7

- Go to Step 11 -

20 - 30 ΩGo to

“Diagnostic

Aids”

Go to Step 7

- Go to Step 3Go to

“Diagnostic

Aids”

Page 1234 of 2053

AUTOMATIC TRANSMISSION 5A-139

SSANGYONG MY2002

DTC P1743 Solenoid 3 Circuit Short

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.3. Checks if the S3 circuit in the transmission is mal-

functioning.

4. Check cable in the transmission for short to

ground.

6. Check resistance between S3 terminal A and B.

Standard value is 22 - 30 Ω.

9. Check connections of other connectors.

- Go to Step 11 - 1Perform a Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1743?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 3 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the valve cover. Refer to the Transmission

in this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

Solenoid 3 (S3) on the valve body.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

Using a Digital Volt Meter (DVM), measure the resis-

tance between S3 terminal A and B.

Is the resistance within the specified value?

Replace the S3.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 3 to TCM terminal A10.

Does the test light illuminate?

Check for a poor connection at the 10-way transmission

connector and TCM connector and repair the malfunc-

tioning terminals as necessary.

Is a repair necessary?

StepAction Value(s) Yes No

2

3

- Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 11 -

7

8

9

- Go to Step 5 Go to Step 9

- Go to Step 11 Go to Step 10

- Go to Step 3Go to

“Diagnostic

Aids”

20 - 30 ΩGo to

“Diagnostic

Aids” Go to Step 7

- Go to Step 5 Go to Step 6

Page 1238 of 2053

AUTOMATIC TRANSMISSION 5A-143

SSANGYONG MY2002

DTC P1744 Solenoid 4 Circuit Short

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also check for chafed wires

that could short to bare metal or other wiring.

Inspect for broken wire inside the insulation.

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S4 circuit in the transmission is mal-

functioning.

4. Check cable in the transmission for short to

ground.

6. Check resistance between S4 terminal A and B.

Standard value is 22 - 30 Ω.

9. Check connections of other connectors.

- Go to Step 11 - 1Perform Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1744?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 4 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the valve cover. Refer to the Transmission

in this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

Solenoid 4 (S4) on the valve body.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

Using a Digital Volt Meter (DVM), measure the resis-

tance between S4 terminal A and B.

Is the resistance within the specified value?

Replace the S4.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 4 to TCM terminal A4.

Does the test light illuminate?

StepAction Value(s) Yes No

2

3

-

Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 11 -

7

8

- Go to Step 5 Go to Step 9

- Go to Step 3Go to

“Diagnostic

Aids”

20 - 30 ΩGo to

“Diagnostic

Aids” Go to Step 7

Page 1242 of 2053

AUTOMATIC TRANSMISSION 5A-147

SSANGYONG MY2002

DTC P1745 Solenoid 5 Circuit Short

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S5 circuit in the transmission is mal-

functioning.4. Check cable in the transmission for short to

ground.

6. Check resistance between S5 terminal A and B.

Standard value is 3.6 - 5.5 Ω.

10. Check connections of other connectors.

- Go to Step 12 - 1Perform Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1745?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side.

4. Turn the mode knob of STET to 5 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the valve cover. Refer to the Transmission

in this section.

2. With a test light connected to B+ probe the wiring

harnesses from 10-way transmission connector to

Solenoid 5 (S5) on the valve body.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

Using a Digital Volt Meter (DVM), measure the resis-

tance between S5 terminal A and B.

Is the resistance within the specified value?

Replace the S5.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 5 to TCM terminal.

Does the test light illuminate?

Probe the wiring harness from 10-way transmission

connector terminal 8 to TCM terminal A1.

Does the test light illuminate?

Check for a poor connection at the 10-way transmission

connector and TCM connector and repair the malfunc-

tioning terminals as necessary.

Is a repair necessary?

StepAction Value(s) Yes No

2

3

-

Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 12 -

7

8

9

- Go to Step 5 Go to Step 9

10

- Go to Step 5 Go to Step 10

- Go to Step 12 Go to Step 11

- Go to Step 3Go to

“Diagnostic

Aids”

3.6 - 5.5 ΩGo to

“Diagnostic

Aids” Go to Step 7

Page 1247 of 2053

AUTOMATIC TRANSMISSION 5A-159

SSANGYONG MY2002

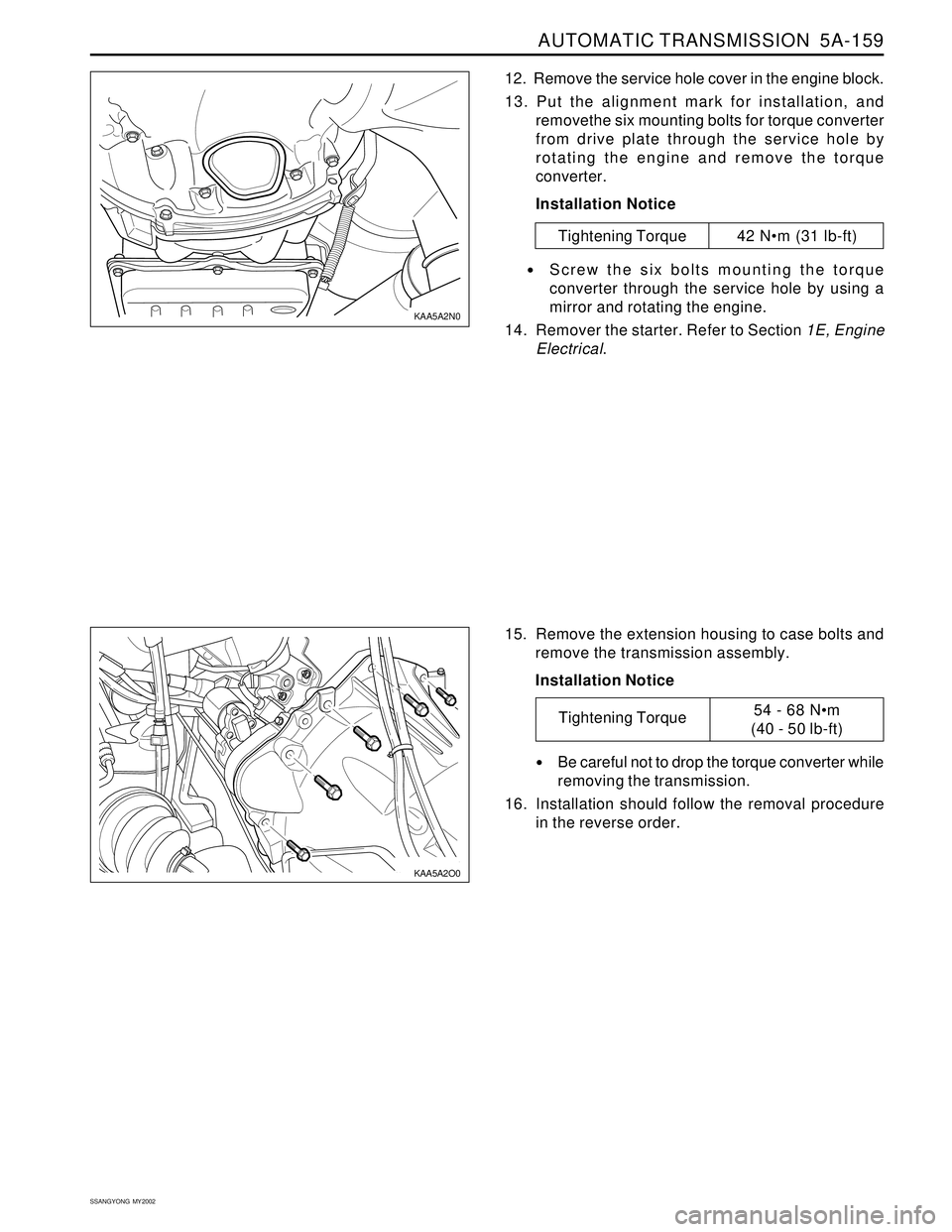

12. Remove the service hole cover in the engine block.

13. Put the alignment mark for installation, and

removethe six mounting bolts for torque converter

from drive plate through the service hole by

rotating the engine and remove the torque

converter.

Installation Notice

Screw the six bolts mounting the torque

converter through the service hole by using a

mirror and rotating the engine.

14. Remover the starter. Refer to Section 1E, Engine

Electrical.

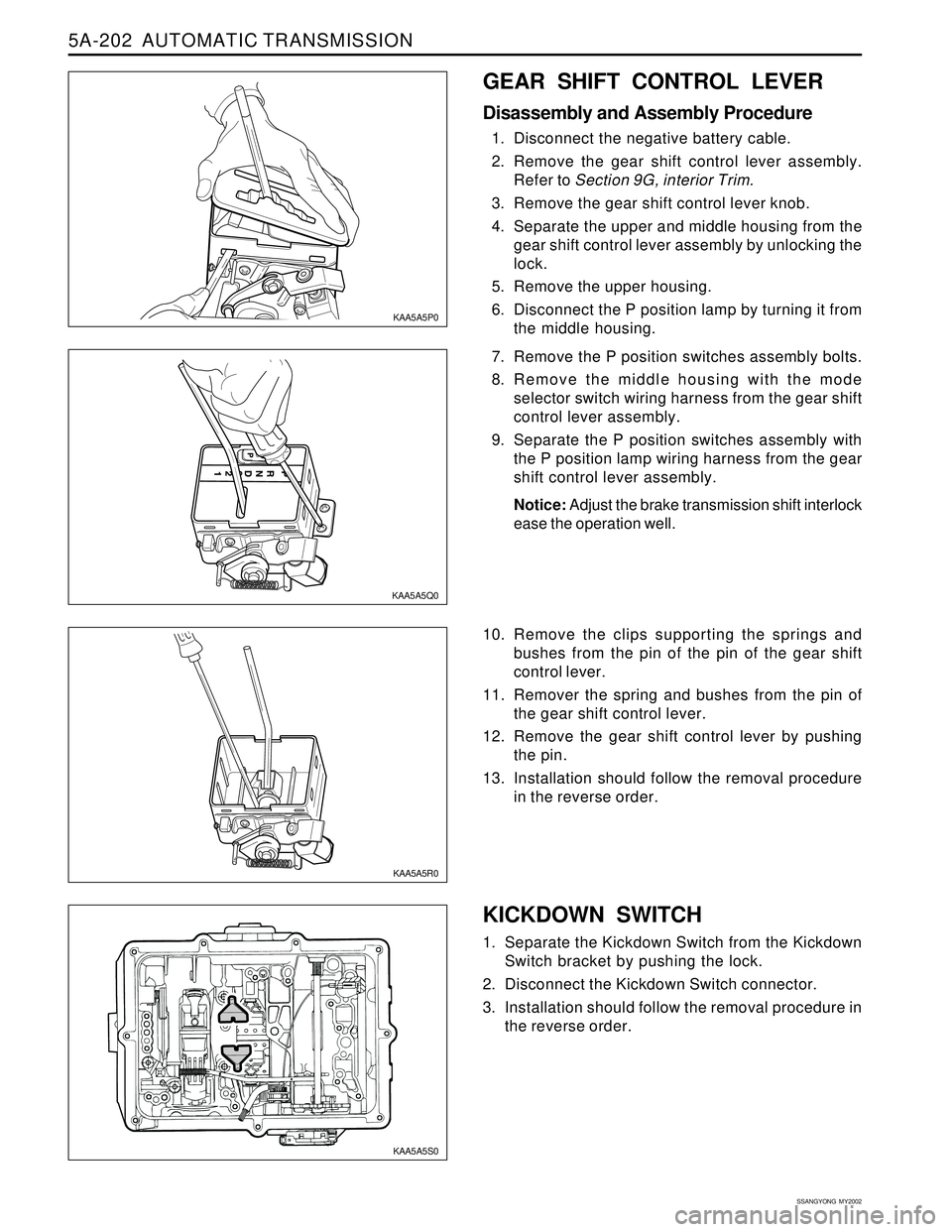

15. Remove the extension housing to case bolts and

remove the transmission assembly.

Installation Notice

Be careful not to drop the torque converter while

removing the transmission.

16. Installation should follow the removal procedure

in the reverse order.

KAA5A2N0

KAA5A2O0

Tightening Torque54 - 68 Nm

(40 - 50 lb-ft)

Tightening Torque 42 Nm (31 lb-ft)

Page 1249 of 2053

AUTOMATIC TRANSMISSION 5A-151

SSANGYONG MY2002

DTC P1746 Solenoid 6 Circuit Short

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S6 circuit in the transmission is mal-

functioning.4. Check cable in the transmission for short to

ground.

6. Check resistance between S6 terminal A and B.

Standard value is 22 - 30 Ω.

9. Check connections of other connectors.

- Go to Step 11 - 1Perform a Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1746?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 6 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the valve cover. Refer to the Transmission

in this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

Solenoid 6 (S6) on the valve body.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

Using a Digital Volt Meter (DVM), measure the

resistance between S6 terminal A and B.

Is the resistance within the specified value?

Replace the S6.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 6 to TCM terminal A12.

Does the test light illuminate?

Check for a poor connection at the 10-way transmission

connector and TCM connector and repair the malfunc-

tioning terminals as necessary.

Is a repair necessary?

StepAction Value(s) Yes No

2

3

-

Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 11 -

7

8

9

- Go to Step 5 Go to Step 9

- Go to Step 11 Go to Step 10

- Go to Step 3Go to

“Diagnostic

Aids”

20 - 30 ΩGo to

“Diagnostic

Aids” Go to Step 7

Page 1253 of 2053

AUTOMATIC TRANSMISSION 5A-155

SSANGYONG MY2002

DTC P1747 Solenoid 7 Circuit Short

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S7 circuit in the transmission is mal-

functioning.4. Check cable in the transmission for short to

ground.

7. Check resistance between S7 terminal A and B.

Standard value is 22 - 30 Ω.

10. Check connections of other connectors.

- Go to Step 15 Go to Step 7 1Perform a Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1747?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 7 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the pump assembly. Refer to the Pump in

this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

contact point attached onto the transmission case.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

With a test light connected to B+, probe the wiring

harness from contact point attached onto the trans-

mission case to S7.

Does the test light illuminate?

Using a Digital Volt Meter (DVM), measure the

resistance between S7 terminal A and B.

Is the resistance within the specified value?

Replace the S7.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 7 to TCM terminal A9.

Does the test light illuminate?

StepAction Value(s) Yes No

2

3

-

Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 12 -

7

8

9

- Go to Step 12 -

- Go to Step 5 Go to Step 10

- Go to Step 3Go to

“Diagnostic

Aids”

20 - 30 ΩGo to

“Diagnostic

Aids”

Go to Step 8

Page 1286 of 2053

AUTOMATIC TRANSMISSION 5A-191

SSANGYONG MY2002

24. Install the pump and cover assembly over the

input shaft being careful not to damage the sealing

rings. Apply additional Loctite 202 or equivalent

as required to the pump cover to case bolts.

Install and tighten bolts to specification.

Installation Notice

KAA5A1M0

Tightening Torque24 - 34 Nm

(18 - 25 lb-ft)

25. Check that the transmission end float is 0.50 -

0.65 mm. If the unshimmed end float clearance is

greater than specification, shims are to be placed

between the No. 4 bearing and the input shaft

bearing surface. If the end float clearance is less

than 0.5 mm then the transmission has been

assembled incorrectly or the parts are out of

specification.

26. Perform the following steps to check the end float :

a. Attach a dial indicator to the front of the trans-

mission case with the stylus resting on the end

of the input shaft.

b. Apply a force of approximately 250 N or 25 kg

to the input shaft.

c. Zero the dial indicator.

d. Place a small lever behind the forward clutch

cylinder and lever the cylinder forward.

e. The measurement recorded on the dial indicator

is the transmission end float or clearance be-

tween the No. 4 bearing and the converter sup-

port tube.

27. On completion of this procedure, adjust the front

and rear bands to specifications. Refer to “Front

and Rear Band Adjustment” in this section.

KAA5A1N0

Page 1297 of 2053

5A-202 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

KICKDOWN SWITCH

1. Separate the Kickdown Switch from the Kickdown

Switch bracket by pushing the lock.

2. Disconnect the Kickdown Switch connector.

3. Installation should follow the removal procedure in

the reverse order.

KAA5A5S0

GEAR SHIFT CONTROL LEVER

Disassembly and Assembly Procedure

1. Disconnect the negative battery cable.

2. Remove the gear shift control lever assembly.

Refer to Section 9G, interior Trim.

3. Remove the gear shift control lever knob.

4. Separate the upper and middle housing from the

gear shift control lever assembly by unlocking the

lock.

5. Remove the upper housing.

6. Disconnect the P position lamp by turning it from

the middle housing.

7. Remove the P position switches assembly bolts.

8. Remove the middle housing with the mode

selector switch wiring harness from the gear shift

control lever assembly.

9. Separate the P position switches assembly with

the P position lamp wiring harness from the gear

shift control lever assembly.

Notice: Adjust the brake transmission shift interlock

ease the operation well.

10. Remove the clips supporting the springs and

bushes from the pin of the pin of the gear shift

control lever.

11. Remover the spring and bushes from the pin of

the gear shift control lever.

12. Remove the gear shift control lever by pushing

the pin.

13. Installation should follow the removal procedure

in the reverse order.

KAA5A5P0

KAA5A5Q0

KAA5A5R0

Page 1309 of 2053

SECTION 5B

MANUAL TRANSMISSION

TABLE OF CONTENTS

General Description and Operation.....................5B-2

Shift Lever...........................................................5B-2

Transmission Assembly.......................................5B-2

Specifications......................................................5B-3

Diagnostic Information and Procedures..............5B-4

Diagnosis Table...................................................5B-6

Component Locator............................................5B-7

Cross-Sectional View ...........................................5B-7

Power Flow..........................................................5B-8

Seni-Remote Kit Disassembly and Assembly.......5B-9

Transmission Assembly.....................................5B-10

Transmission Assembly Disassembled View......5B-11Maintenance and Repair................................... 5B-14

On-Vehicle Service...............................................5B-14

Semi-Remote Kit................................................5B-14

Transmission.....................................................5B-19

Unit Repair.......................................................... 5B-24

Major Unit..........................................................5B-24

Main Shaft.........................................................5B-34

Input Shaft........................................................5B-38

Counter Shaft....................................................5B-40

Extension Housing.............................................5B-40

Shift Cover........................................................5B-41

Inspection of Components.................................5B-45