SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: parking brake, octane, oil, brakes, ignition switch, tccu, radio antenna

Page 151 of 2053

M162 ENGINE COOLING 1D1 -- 15

D AEW OO M Y_2000

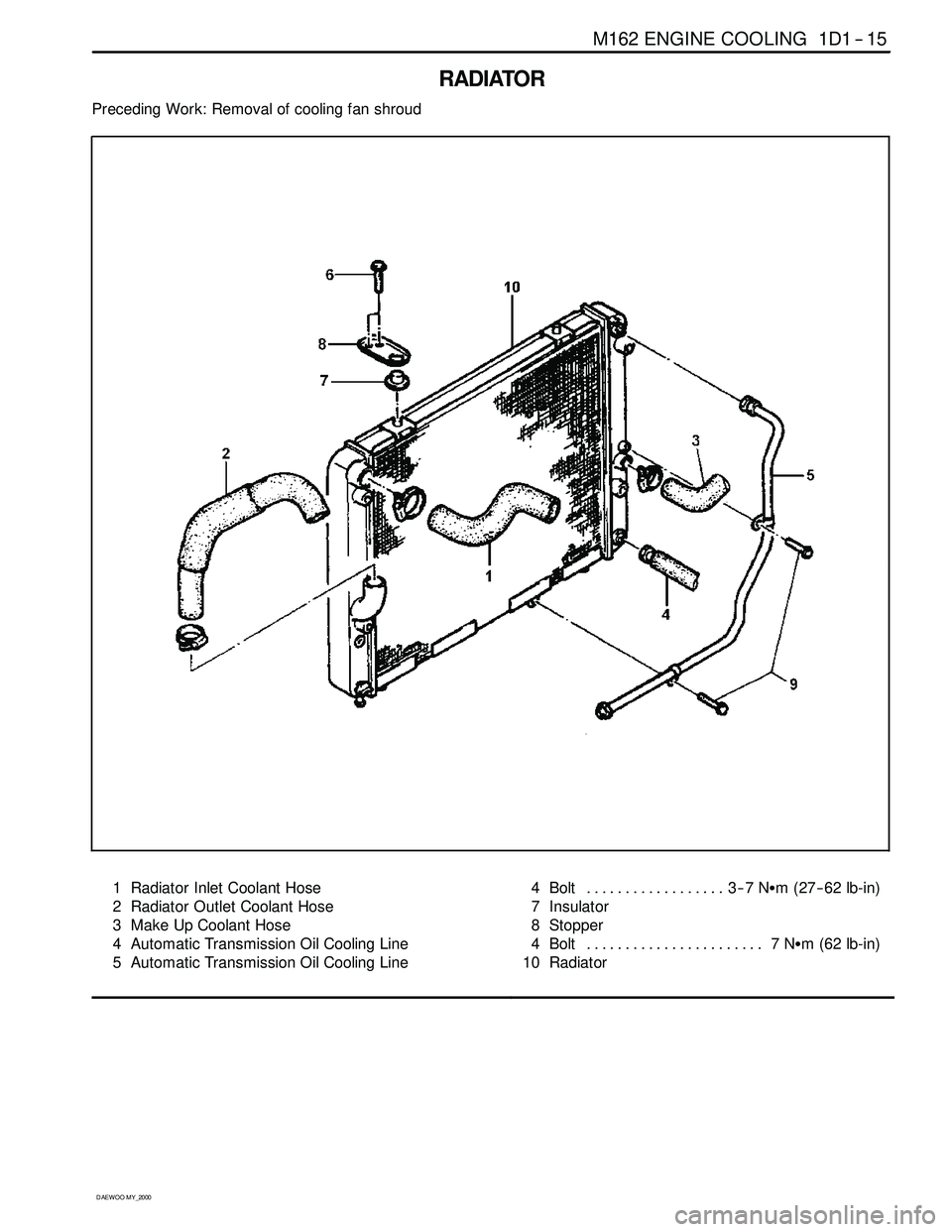

RADIATOR

Preceding Work: Removal of cooling fan shroud

1 Radiator Inlet Coolant Hose

2 Radiator Outlet Coolant Hose

3 Make Up Coolant Hose

4 Automatic Transmission Oil Cooling Line

5 Automatic Transmission Oil Cooling Line4Bolt 3--7NSm (27-- 62 lb-in) ..................

7 Insulator

8 Stopper

4Bolt 7NSm (62 lb-in) .......................

10 Radiator

Page 152 of 2053

1D1 -- 16 M162 ENGINE COOLING

D AEW OO M Y_2000

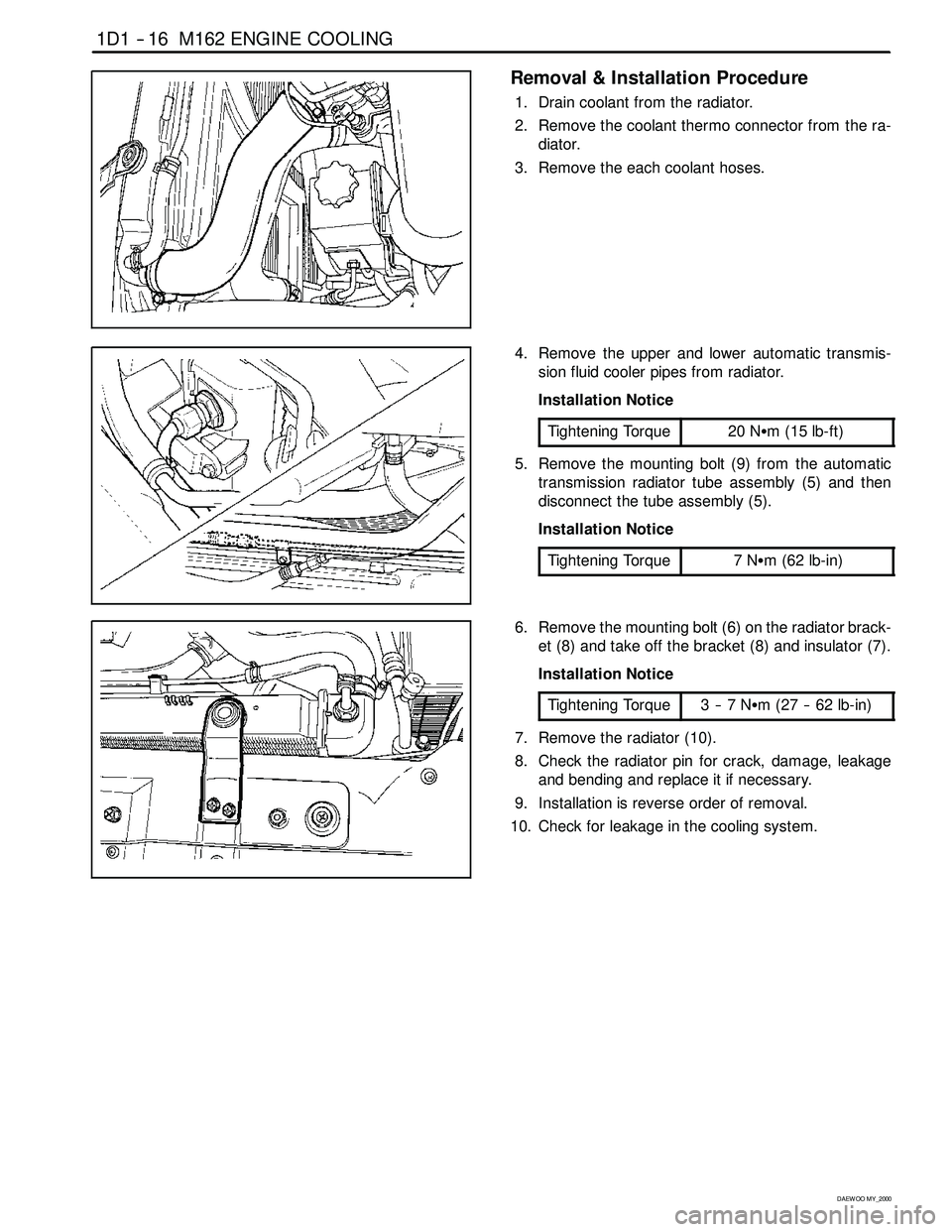

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the coolant thermo connector from the ra-

diator.

3. Remove the each coolant hoses.

4. Remove the upper and lower automatic transmis-

sion fluid cooler pipes from radiator.

Installation Notice

Tightening Torque

20 NSm (15 lb-ft)

5. Remove the mounting bolt (9) from the automatic

transmission radiator tube assembly (5) and then

disconnect the tube assembly (5).

Installation Notice

Tightening Torque

7NSm(62lb-in)

6. Remove the mounting bolt (6) on the radiator brack-

et (8) and take off the bracket (8) and insulator (7).

Installation Notice

Tightening Torque

3--7NSm (27 -- 62 lb-in)

7. Remove the radiator (10).

8. Check the radiator pin for crack, damage, leakage

and bending and replace it if necessary.

9. Installation is reverse order of removal.

10. Check for leakage in the cooling system.

Page 153 of 2053

D AEW OO M Y_2000

SECTION 1E1

M162 ENGINE ELECTRICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless other -

wise noted.

TABLE OF CONTENTS

Specifications 1E1 -- 2............................

Generator Specifications 1E1-- 2..................

Starting Motor Specifications 1E1-- 2...............

Battery Specifications 1E1-- 2.....................

Fastener Tightening Specifications 1E1 -- 2..........

Maintenance and Repair 1E1 -- 3...................

On-- Vehicle Service 1E1-- 3.........................Generator 1E1-- 3...............................

Starting Motor 1E1--4...........................

Battery 1E1--5.................................

Spark Plug 1E1 -- 6..............................

Ignition Cable 1E1-- 8............................

Unit Repair 1E1 -- 11..............................

Battery 1E1--11.................................

Page 154 of 2053

1E 1 -- 2 M162 ENGINE ELECTRICAL

D AEW OO M Y_2000

SPECIFICATIONS

GENERATOR SPECIFICATIONS

ApplicationDescription

Current11 5 A

Output Voltage12 -- 14 v

Resistance Between Rotor Core and Slip Ring‚ąě‚Ą¶

STARTER SPECIFICATIONS

ApplicationDescription

Output Power1.8 kw

Voltage12 v

BATTERY SPECIFICATIONS

ApplicationDescription

Capacity90 AH

Max. Tolerance Between Cells‚Č•0.04

Specific Gravity‚Č•1.24

FASTER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Generator Terminal B+Nut14 -- 1810 -- 13--

Generator Terminal D+Nut4--5--35 -- 44

Generator Mounting Bolt2518--

Battery Cable Nut on Starting Motor12 -- 159--11--

Electric Wire Nut on Starting Motor6--7--53 -- 62

Starting Motor Mounting Bolt35 -- 4826 -- 35--

Battery Mounting Bracket Nut12 -- 189--13--

Battery Negative Cable12 -- 189--13--

Battery Positive Cable12 -- 189--13--

Spark Plug Cover Bolt9--11--80 -- 97

Ignition Cable Bolt9--11--80 -- 97

Spark plug20 -- 3015 -- 22--

Page 155 of 2053

M162 ENGINE ELECTRICAL 1E 1 -- 3

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

GENERATOR

Preceding Work : Removal of the drivebelt

Removal & Installation Procedure

1. Disconnect the negative battery terminal.

2. Unscrew the nut and disconnect the terminal (1).

Installation Notice

Tightening Torque

14 -- 18 NSm (10 -- 13 lb-ft)

3. Unscrew the nut and disconnect the terminal (2).

Installation Notice

Tightening Torque

4--5NSm (35 -- 44 lb-in)

1 Terminal (B+)

2 Terminal (D+)

4. Unscrew the generator mounting bolt (3).

Installation Notice

Tightening Torque

25 NSm (18 lb-ft)

5. Remove the generator.

6. Installation should follow the removal procedure in

the reverse order.

3 Generator Mounting Bolt

4 Generator

Page 156 of 2053

1E 1 -- 4 M162 ENGINE ELECTRICAL

D AEW OO M Y_2000

STARTING MOTOR

Removal & Installation Procedure

1. Disconnect the ground cable.

2. Unscrew the nut and disconnect the battery cable(1).

Installation Notice

Tightening Torque

12 -- 15 NSm (9 -- 11 lb-ft)

3. Unscrew the nut and disconnect the engine electric

wire (2).

Installation Notice

Tightening Torque

6--7NSm (53 -- 62 lb-in)

1 Battery Cable

2 Engine Electric Wire

4. Unscrew the mounting bolts (3) of starting motor.

Installation Notice

Tightening Torque

35 -- 48 NSm (26 -- 35 lb-ft)

5. Remove the starting motor.

6. Installation should follow the removal procedure in

the reverse order.

3 Fixing Bolt

4StartingMotor

Page 157 of 2053

M162 ENGINE ELECTRICAL 1E 1 -- 5

D AEW OO M Y_2000

BATTERY

1 Cable Terminal ( -- )

2 Cable Terminal Cap ( -- )

3 Cable Terminal Cap (+)

4Nut

5 Fuseblink Box

6 Terminal (+)7 Battery holddown Bracket

8 Battery Clamp Bolt

9 Battery

10 Sub Tray

11 Battery Tray

Removal & Installation Procedure

Notice

DDisconnect the battery negative cable first.

DInsert the clamp bolt (8) into the battery tray hole (11)

from inside when installing.

Page 158 of 2053

1E 1 -- 6 M162 ENGINE ELECTRICAL

D AEW OO M Y_2000

SPARK PLUG

Preceding Work: Removal of intake air duct

1 Spark Plug Cover

2 Bolt (M6 X 60, 7 pieces)

9--11 NSm (80-- 97 lb-in) .....................

3 Spark PlugT1/1 Ignition Coil : Cylinder 2 and 5

T1/2 Ignition Coil : Cylinder 3 and 4

T1/3 Ignition Coil : Cylinder 1 and 6

Page 159 of 2053

M162 ENGINE ELECTRICAL 1E 1 -- 7

D AEW OO M Y_2000

Replacement Procedure

1. Remove the seven bolts (2) and remove the spark

plug cover.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

2. Remove the two bolts (M6 X 25) from each ignition

cable and remove the ignition cable.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

3. Remove the spark plug.

Installation Notice

Tightening Torque

20 -- 30 NSm (15 -- 22 lb-ft)

Page 160 of 2053

1E 1 -- 8 M162 ENGINE ELECTRICAL

D AEW OO M Y_2000

IGNITION CABLE

Preceding Work: Removal of intake air duct

1 Control Cable Connection

2 Ignition Cable

3 Spark Plug Connector

4 Coupling Plug5a, 5b Secondary Voltage Connection

EIronCore

L1 Secondary Ignition Coil

L2 Primary Ignition Coil

Trending: tailgate, overheating, boot, oil filter, manual transmission, section 2c, air bleeding