SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: stop start, cabi, run flat, steering wheel, wheel bolt torque, Break, fuel

Page 131 of 2053

M162 ENGINE MECHANICAL 1B1 -- 105

D AEW OO M Y_2000

Replacement Procedure

1. Remove the intake and exhaust manifolds.

2. Pull back the core plug until the end of one side

comes out using the screw driver.

3. Pull out the plug carefully using a pliers.

4. Clean the sealing surface and apply Loctite 241.

5. Press in new plug using a drift.

Notice:Wait for about 45minutes before filling the cool-

ant so that the Loctite 240 hardens.

6. Warm up the engine and check the coolant for leaks.

Page 132 of 2053

1B1 -- 106 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

CYLINDER BORE

Group Code Letter and Cylinder Bore Size

Group Code Letter of CylinderPiston Type to be UsedCylinder Bore Size (mm)

AAorXφ89.900 --φ89.906

XA, X or Bφ89.906 --φ89.912

BXorBφ89.912 --φ89.918

X+5X+5φ89.950 --φ89.968

X+10X+10φ90.000 --φ90.018

Repair Size

Ty peGroup Code Letter 1)Cylinder Bore Size (mm)

Standard Sizeφ89.9Aφ89.900 --φ89.906φ

Xφ89.906 --φ89.912

Bφ89.912 --φ89.918

1st Repair Size

(StddSi025)

Aφ90.150 --φ90.156p

(Standard Size + 0.25)Xφ89.156 --φ90.162

Bφ90.162 --φ90.168

2nd Repair Size

(StddSi05)

Aφ90.400 --φ90.406p

(Standard Size + 0.5)Xφ90.406 --φ90.412

Bφ90.412 --φ90.418

1) The group code letters are carved on the surface of the piston crown and in the mating surface of the crankcase.

Page 133 of 2053

M162 ENGINE MECHANICAL 1B1 -- 107

D AEW OO M Y_2000

ServiceDataStandard

Wear Limit in Longitudinal and Transverse Direction0.1 mm

Permissible Deviation of Cylinder Out -- of -- roundWhen new0.007 mmy

Wear limit0.05 mm

Permissible Deviation of Rectangular Cylinder Height (Except Chamfered Area)0.05 mm

Basic Peak -- to-- valley Height After Final Honing and Brushing0.003 -- 0.006 mm

Chamfer Angle60°

Honing Angle50°±10°

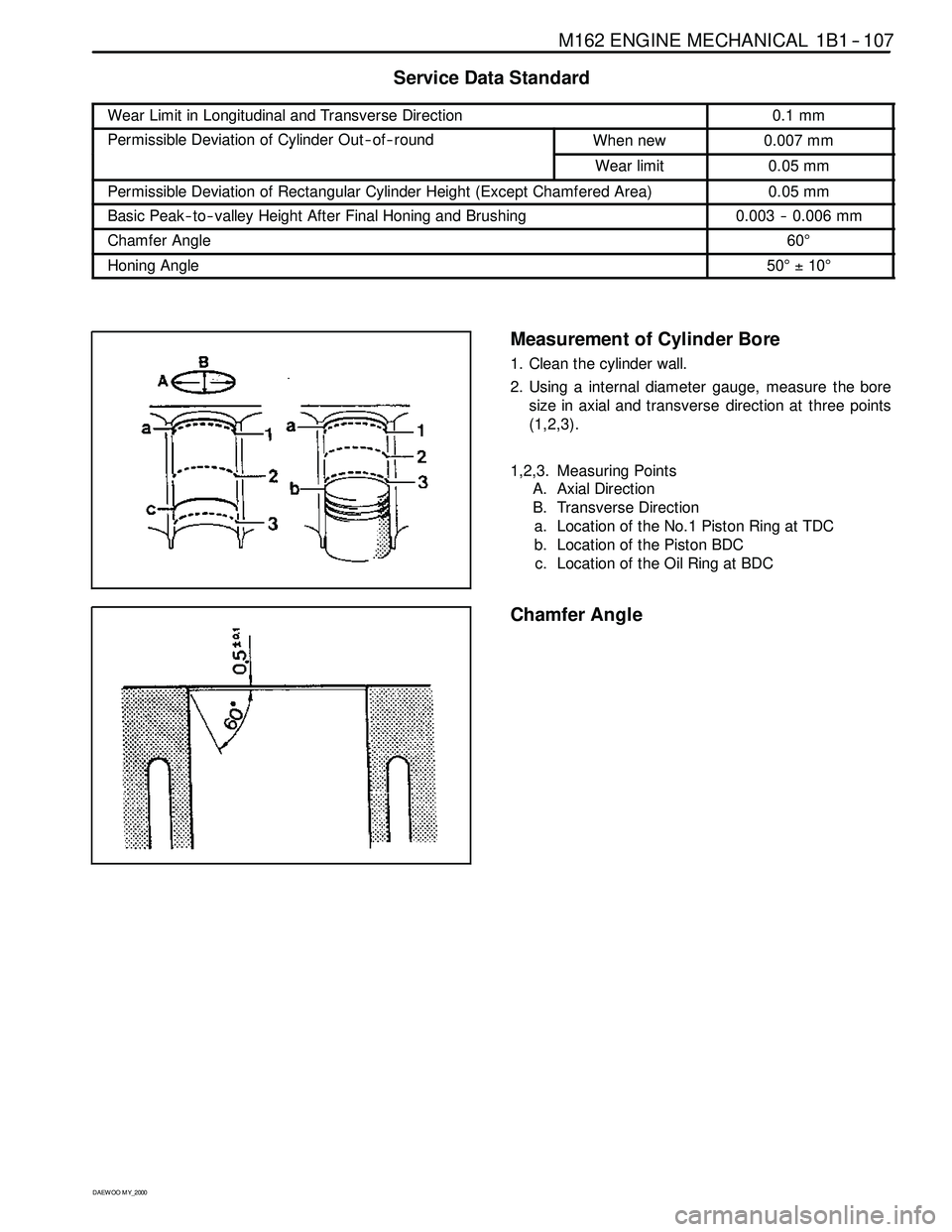

Measurement of Cylinder Bore

1. Clean the cylinder wall.

2. Using a internal diameter gauge, measure the bore

size in axial and transverse direction at three points

(1,2,3).

1,2,3. Measuring Points

A. Axial Direction

B. Transverse Direction

a. Location of the No.1 Piston Ring at TDC

b. Location of the Piston BDC

c. Location of the Oil Ring at BDC

Chamfer Angle

Page 134 of 2053

1B1 -- 108 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

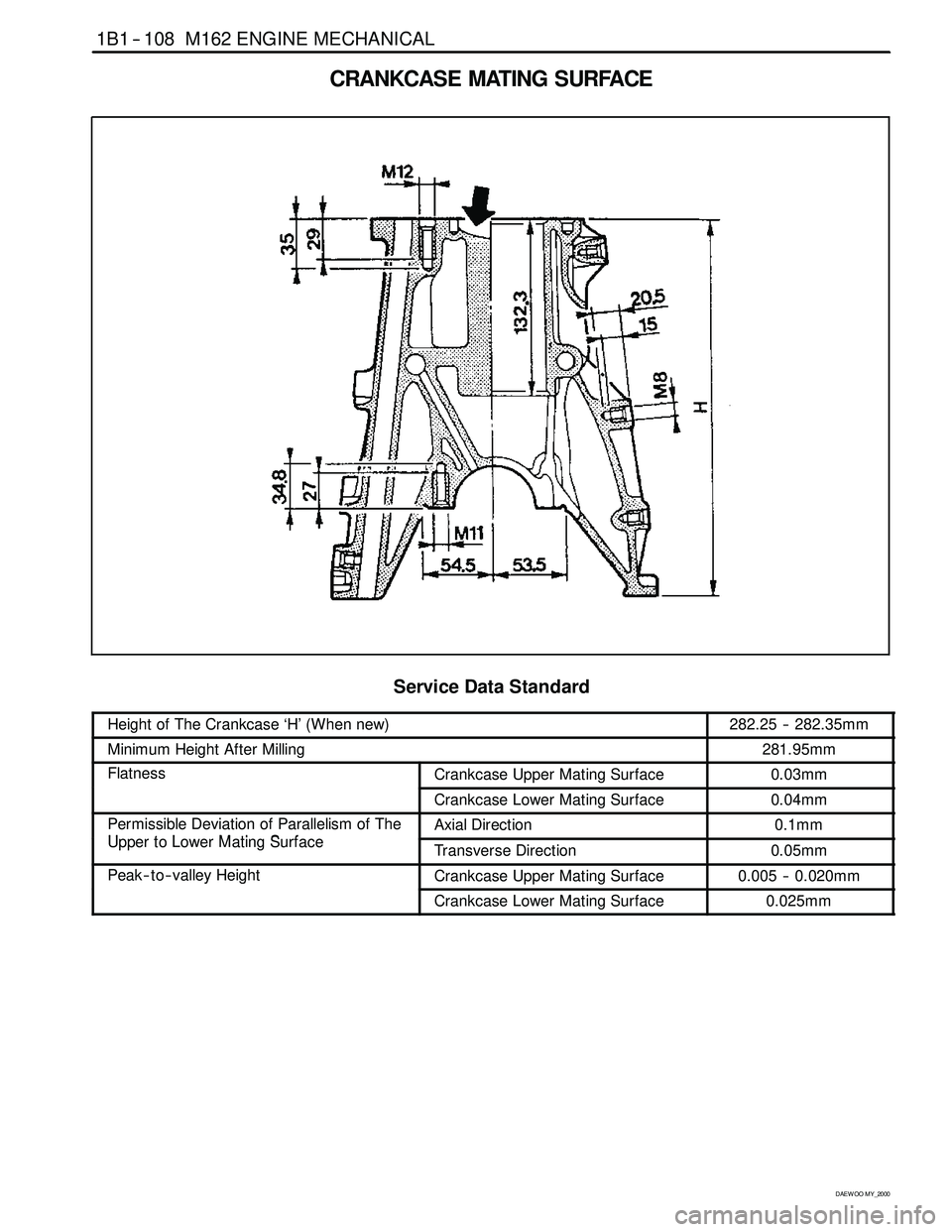

CRANKCASE MATING SURFACE

ServiceDataStandard

Height of The Crankcase ‘H’ (When new)282.25 -- 282.35mm

Minimum Height After Milling281.95mm

FlatnessCrankcase Upper Mating Surface0.03mm

Crankcase Lower Mating Surface0.04mm

Permissible Deviation of Parallelism of The

UtLMtiSf

Axial Direction0.1mm

Upper to Lower Mating SurfaceTransverse Direction0.05mm

Peak -- to-- valley HeightCrankcase Upper Mating Surface0.005 -- 0.020mmyg

Crankcase Lower Mating Surface0.025mm

Page 135 of 2053

M162 ENGINE MECHANICAL 1B1 -- 109

D AEW OO M Y_2000

Chamfering Procedure

1. Chamfer angle : 60°

2. Polish the lower chamfered area evenly with a grinder

after finishing the chamfering with a suitable tool

(e.g., hand milling cutter).

Page 136 of 2053

1B1 -- 110 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

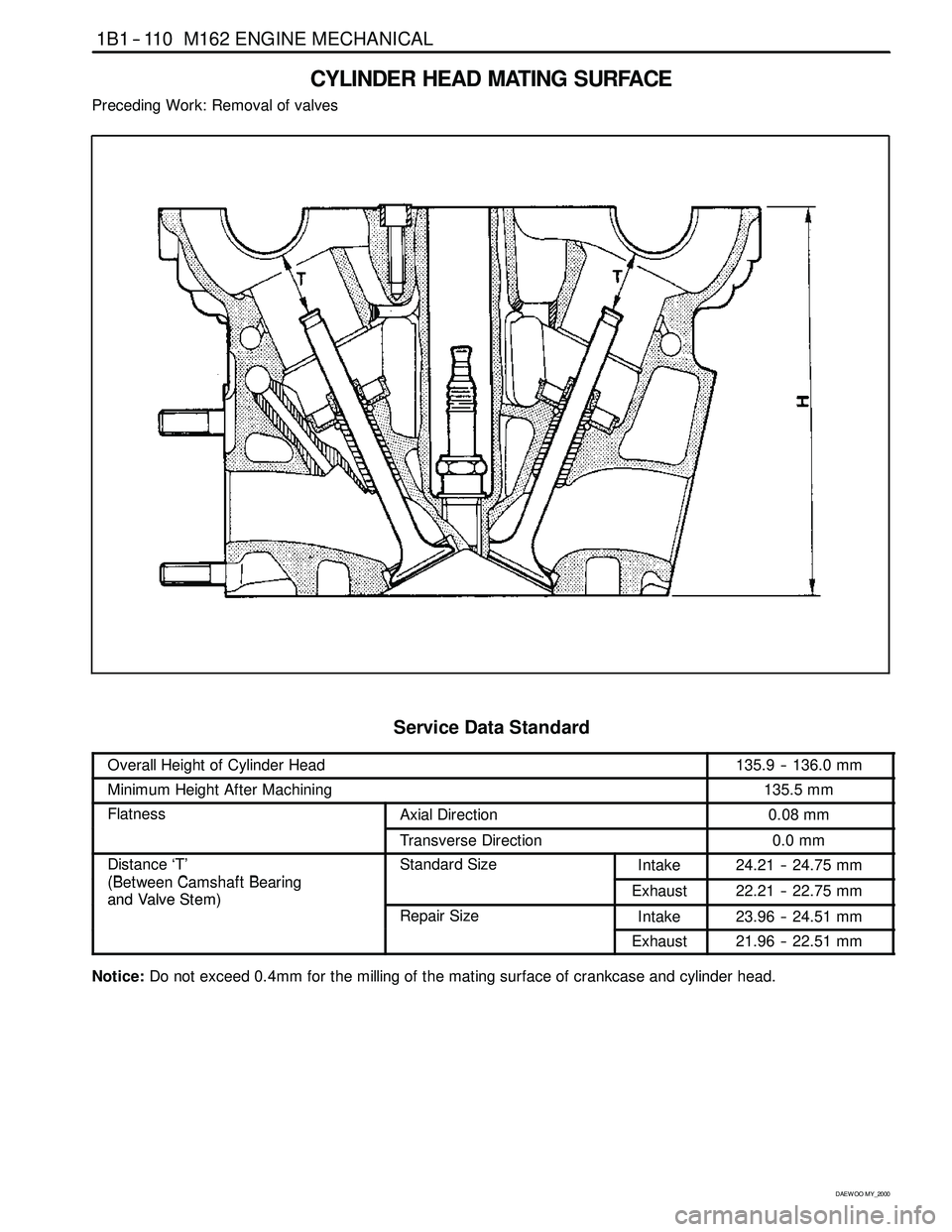

CYLINDER HEAD MATING SURFACE

Preceding Work: Removal of valves

ServiceDataStandard

Overall Height of Cylinder Head135.9 -- 136.0 mm

Minimum Height After Machining135.5 mm

FlatnessAxial Direction0.08 mm

Transverse Direction0.0 mm

Distance ‘T’

(BtChftBi

Standard SizeIntake24.21 -- 24.75 mm

(Between Camshaft Bearing

andValveStem)Exhaust22.21 -- 22.75 mmandValveStem)

Repair SizeIntake23.96 -- 24.51 mmp

Exhaust21.96 -- 22.51 mm

Notice:Do not exceed 0.4mm for the milling of the mating surface of crankcase and cylinder head.

Page 137 of 2053

D AEW OO M Y_2000

SECTION 1D1

M162 ENGINE COOLING

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless other -

wise noted.

TABLE OF CONTENTS

Specifications 1D1 -- 2............................

General Specifications 1D1-- 2....................

Fastener Tightening Specifications 1D1 -- 2..........

Special Tools 1D1 -- 3.............................

Special Tools Table 1D1-- 3.......................

Diagnosis 1D1 -- 4.................................

System Leakage Test 1D1-- 4.....................

Maintenance and Repair 1D1 -- 5...................

On-- Vehicle Service 1D1-- 5.........................Coolant Drain and Fill Up 1D1 -- 5..................

Coolant Connection Fitting 1D1 -- 7.................

Wat er Pum p 1D1 -- 8.............................

Thermostat 1D1 -- 10.............................

Oil Cooler Pipe Line 1D1 -- 11.....................

Cooling Fan and Viscous Clutch 1D1 -- 12...........

Cooling Fan Shroud 1D1 -- 14.....................

Radiator 1D1-- 15................................

Page 138 of 2053

1D1 -- 2 M162 ENGINE COOLING

D AEW OO M Y_2000

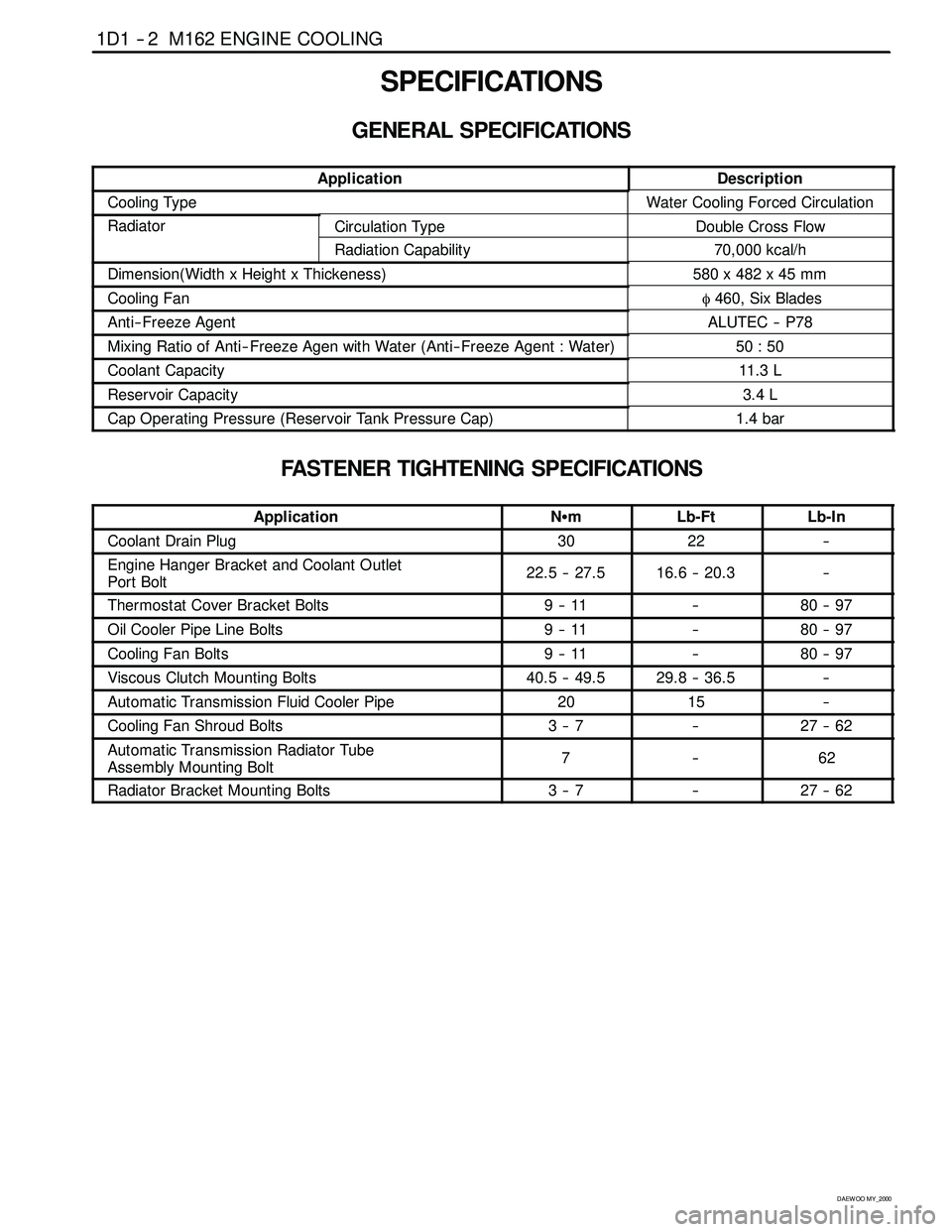

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationDescription

Cooling TypeWater Cooling Forced Circulation

RadiatorCirculation TypeDouble Cross Flow

Radiation Capability70,000 kcal/h

Dimension(Width x Height x Thickeness)580 x 482 x 45 mm

Cooling Fanφ460, Six Blades

Anti-- Freeze AgentALUTEC -- P78

Mixing Ratio of Anti-- Freeze Agen with Water (Anti-- Freeze Agent : Water)50 : 50

Coolant Capacity11. 3 L

Reservoir Capacity3.4 L

Cap Operating Pressure (Reservoir Tank Pressure Cap)1.4 bar

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Coolant Drain Plug3022--

Engine Hanger Bracket and Coolant Outlet

Port Bolt22.5 -- 27.516.6 -- 20.3--

Thermostat Cover Bracket Bolts9--11--80 -- 97

Oil Cooler Pipe Line Bolts9--11--80 -- 97

Cooling Fan Bolts9--11--80 -- 97

Viscous Clutch Mounting Bolts40.5 -- 49.529.8 -- 36.5--

Automatic Transmission Fluid Cooler Pipe2015--

Cooling Fan Shroud Bolts3--7--27 -- 62

Automatic Transmission Radiator Tube

Assembly Mounting Bolt7--62

Radiator Bracket Mounting Bolts3--7--27 -- 62

Page 139 of 2053

M162 ENGINE COOLING 1D1 -- 3

D AEW OO M Y_2000

SPECIAL TOOLS AND EQUIPMENT

SPECIAL TOOLS TABLE

124 589 15 21 00

Tester603 589 00 40 00

Fan Clutch Holder

Page 140 of 2053

1D1 -- 4 M162 ENGINE COOLING

D AEW OO M Y_2000

DIAGNOSIS

SYSTEM LEAKAGE TEST

Tools Required

124 589 15 21 00 Tester

Test Procedure

1. Loosen the cap a little and release pressure and re-

move the cap.

Notice:For the risk of scalding, cap must not be opened

unless the coolant temperature is below 90°C.

2. Fill coolant up to upper edge (arrow) of reservoir.

3. Connect the special tool to the reservoir filler cap and

apply 1.4 bar of pressure.

Tester 124 589 15 21 00

4. If the pressure on the tester drops, check leakage at

the all coolant hoses and pipes and each connec-

tions. Replace or retighten if necessary.

Trending: STARTER RELAY, display, fog light bulb, coolant level, transmission fluid, catalytic converter, fuel filter