torque SSANGYONG KORANDO 1997 Service Manual Online

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 303 of 2053

1B2 -- 10 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

11. Remove the hydraulic pipe of power steering.

Notice:Completely drain the oil.

12. Discharge the refrigerant from A/C system, and dis-

connect the discharge pipe and suction pipe from

the compressor.

13. Remove the fuel feed and return line.

Notice:Before removing the fuel lines, release the pres-

sure in the fuel system.

Installation Notice

Tightening Torque

21 -- 25 NSm (15 -- 18 lb-ft)

14. Disconnect the terminals from the generator.

Page 305 of 2053

1B2 -- 12 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

21. Separate the hose toward engine from canister

purge solenoid valve and canister. Refer toSection

1F2, Engine Control.

22. Remove the automatic transmission oil cooler line

retaining bolts from the automatic transmission side

and oil pan side.

23. Remove the automatic transmission oil cooler line

retaining bolts from engine side and oil pan side.

24. Separate the vacuum hose for brake booster.

25. Separate the other vacuum hoses.

26. By rotating the crankshaft from the front of engine,

remove the 6 torque converter mounting bolts from

the engine ring gear plate.

Installation Notice

Tightening Torque

42 NSm (31 lb-ft)

Page 306 of 2053

M161 ENGINE MECHANICAL 1B2 -- 13

D AEW OO M Y_2000

27. Remove the exhaust manifold and exhaust pipe.

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

28. Remove the transmission. Refer toSection 5A, Au -

tomatic Transmission.

29. Install a chain to the bracket of engine, by using a

hoist or crane.

30. Remove the engine mount nuts.

Installation Notice

Tightening Torque

70 NSm (52 lb-ft)

31. Carefully separate the engine assembly from the ve-

hicle.

32. Installation should follow the removal procedure in

the reverse order.

Page 311 of 2053

1B2 -- 18 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

GENERATOR

1 Bolt (M8 X 40, 3 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

2 Bolt (M8 X 70, 2 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............3 Bolt (M8 X 85, 1 piece)

22.5-- 27.5 NSm (16.6--20.3 lb-ft) .............

4 Generator Bracket

Removal & Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the drive belt.

3. Remove the generator.

4. Unscrew the generator carrier bolts and remove the

carrier.

Installation Notice

Tightening Torque

25 NSm (18 lb-ft)

Notice:Apply 3 Nm of torque when mounting the bolt

(1) ; apply 25 Nm of torque when mounting the bolts (2),

and (3) ; and then tighten the bolt (1) with 25 Nm of

torque.

5. Installation should follow the removal procedure in

the reverse order.

Page 312 of 2053

M161 ENGINE MECHANICAL 1B2 -- 19

D AEW OO M Y_2000

ENGINE MOUNT

Removal & Installation Procedure

1. Unscrew the upper engine mount nuts and remove

the engine.

Installation Notice

Tightening Torque

70 NSm (52 lb-ft)

2. Unscrew the lower nuts.

Installation Notice

Tightening Torque

38 NSm (28 lb-ft)

3. Remove the hydraulic engine mounting insulator.

4. Installation should follow the removal procedure in

the reverse order.

Page 314 of 2053

1B2 -- 22 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

TENSIONING DEVICE

Preceding Work: Removal of tensioning device shock absorber

1 Bolt (M8 x 75, 2 pieces) +

Washer 22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) ......

2 Bolt (M8 x 25, 1 pieces) +

Washer 22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) ......3 Tensioning Device

4 Stud bolt

5 Tensioning Arm

Removal & Installation Procedure

1. Turn the stud bolt to counterclockwise.

2. Insert the pin (111 589 01 15 00) into the hole in ten-

sioning arm.

3. Unscrew the bolts (1, 2) and remove the tensioning

device.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

4. Installation should follow the removal procedure in

the reverse order.

Page 316 of 2053

M161 ENGINE MECHANICAL 1B2 -- 23

D AEW OO M Y_2000

TENSIONING DEVICE SHOCK ABSORBER

1 End Cover

2 Bolt 40.5-- 49.5 NSm (29.9-- 36.5 lb-ft) .........

3 Tensioning Pulley

4 Bolt (M8 X 25) + Washer

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............5 Tensioning Device

6 Bolt (M8 X 35) + Washer

22.5-- 27.5 NSm (16.6--20.3 lb-ft) .............

7 Shock Absorber

Removal & Installation Procedure

1. Remove the end cover (1).

2. Remove the bolt (2) and remove the tensioning pulley

(3).

Installation Notice

Tightening Torque

40.5 -- 49.5 NSm

(29.9 -- 36.5 lb-ft)

3. Unscrew the bolts (4,6) and remove the shock ab-

sorber (7).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Page 320 of 2053

M161 ENGINE MECHANICAL 1B2 -- 27

D AEW OO M Y_2000

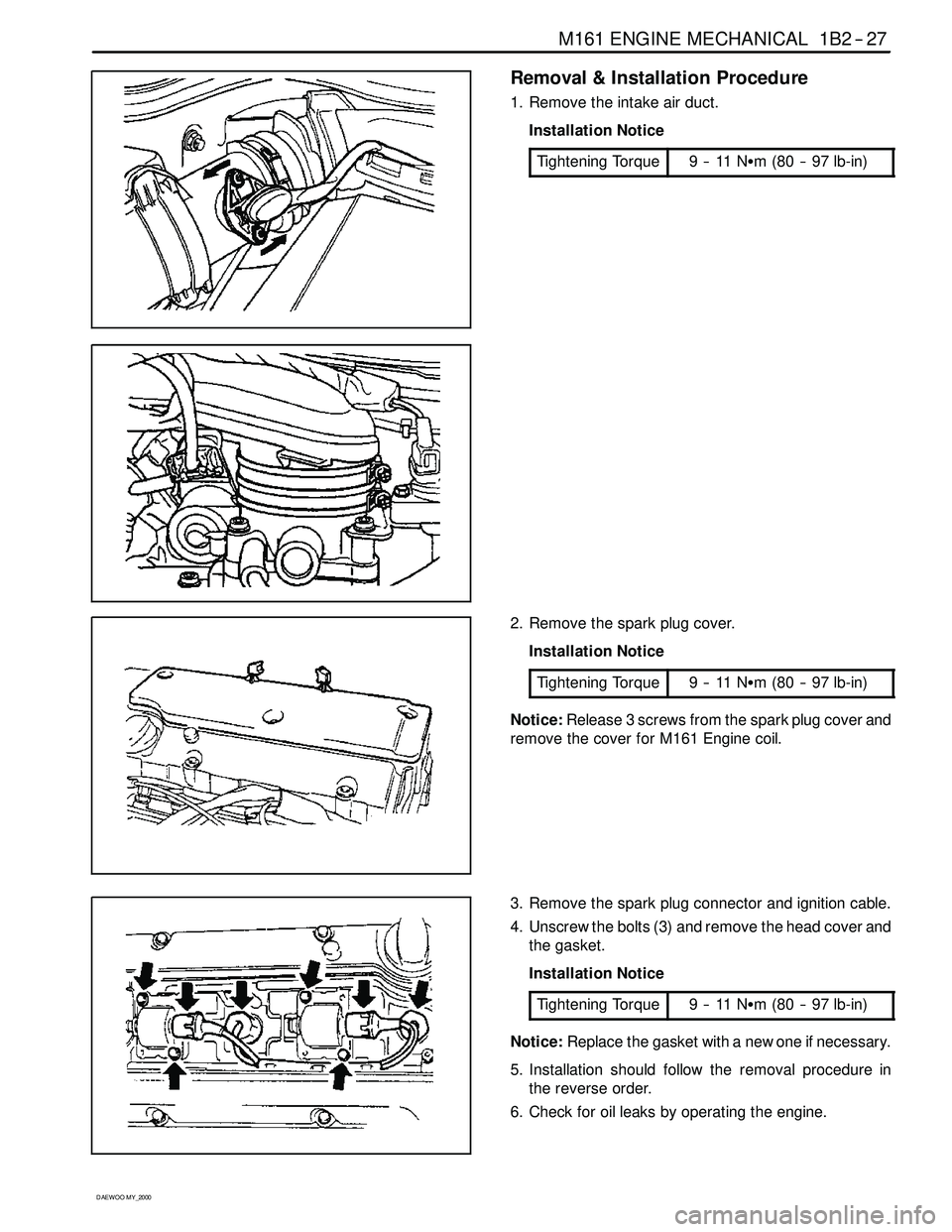

Removal & Installation Procedure

1. Remove the intake air duct.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

2. Remove the spark plug cover.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Notice:Release 3 screws from the spark plug cover and

remove the cover for M161 Engine coil.

3. Remove the spark plug connector and ignition cable.

4. Unscrew the bolts (3) and remove the head cover and

the gasket.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Notice:Replace the gasket with a new one if necessary.

5. Installation should follow the removal procedure in

the reverse order.

6. Check for oil leaks by operating the engine.

Page 322 of 2053

M161 ENGINE MECHANICAL 1B2 -- 29

D AEW OO M Y_2000

Removal & Installation Procedure

1. Disconnect the camshaft adjuster connector and re-

move the camshaft adjuster (E23 engine only).

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

2. Remove the cylinder head front cover.

Installation Notice

Tightening

Torque (3)

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Tightening

Torque (4)9--11NSm

(80 -- 97 lb-in)

Apply the sealant at the mating surface of the cylinder

head and the front cover.

3. Remove the O -- ring.

Installation Notice

Replace the O -- ring with new one and apply the seal-

ant.

4. Installation should follow the removal procedure in

the reverse order.

Page 324 of 2053

M161 ENGINE MECHANICAL 1B2 -- 31

D AEW OO M Y_2000

Tools Required

617589001000 AllenWrenchSocket

116 589 20 33 00 Sliding Hammer

116 589 01 34 00 Threaded Pin

111 589 03 15 00 Holding Pin

Removal & Installation Procedure

1. Rotate the crankshaft so that the piston of number 1

cylinder is at ATDC 20.

2. Put the holding pin 111 589 03 15 00 into the cam-

shaft bearing cap (number 1, 6).

3. Put the alignment marks (arrows) on the timing chain

and camshaft sprocket.

4. Remove the chain tensioner.

Installation Notice

Tightening Torque

72 -- 88 NSm (53 -- 65 lb-ft)

5. Remove the exhaust camshaft sprocket.

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The flange bolt is designed to be used only

once, so always replace with new one.