SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: oil filter, door lock, open gas tank, technical specifications, oil, octane, fuel additives

Page 771 of 2053

1F3 -- 14 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

VACUUM UNIT REPLACEMENT

1 Bracket

2Bolt

3 Vacuum Unit

4 Vacuum Line

5 Seal Replace.............................

Page 772 of 2053

OM600 ENGINE CONTROLS 1F3 -- 15

D AEW OO M Y_2000

IDLE SPEED ADJUSTMENT

Service Data

EngineIdle Speed

OM661LA Engine750 -- 850 rpm

OM662LA Engine720 -- 820 rpm

Tools Required

667 589 00 21 00 TDC Pulse Generato

Commercial Tool

Digital Testere.g. Bosch, MOT 001.03g

Sun, DIT 9000

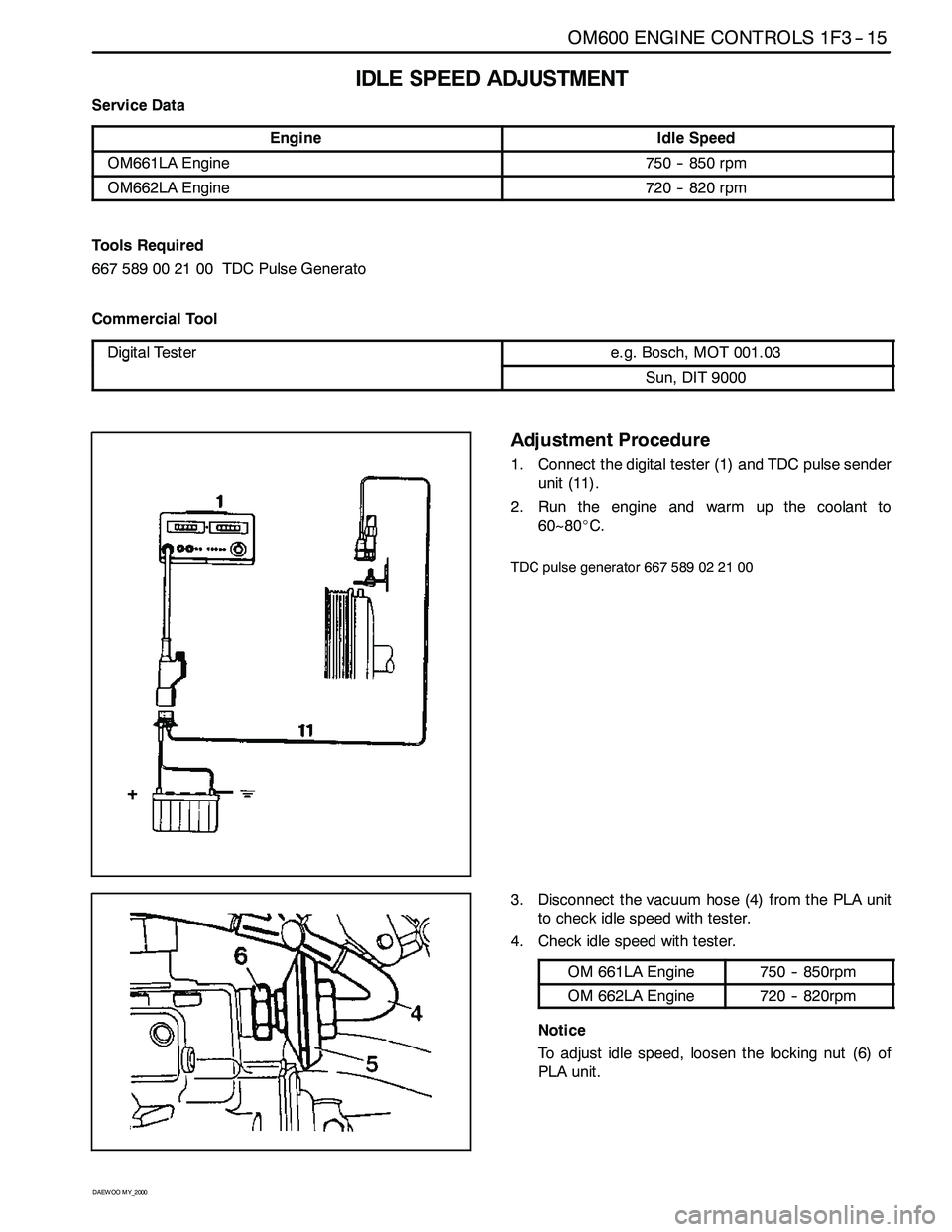

Adjustment Procedure

1. Connect the digital tester (1) and TDC pulse sender

unit (11).

2. Run the engine and warm up the coolant to

60~80_C.

TDC pulse generator 667 589 02 21 00

3. Disconnect the vacuum hose (4) from the PLA unit

to check idle speed with tester.

4. Check idle speed with tester.

OM 661LA Engine750 -- 850rpm

OM 662LA Engine720 -- 820rpm

Notice

To adjust idle speed, loosen the locking nut (6) of

PLA unit.

Page 773 of 2053

1F3 -- 16 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

5. Ensure not to damage the idle spring in the governor

and adjust idle speed by turning the PLA unit (5)

slowly.

ClockwiseRPM Decrease

CounterclockwiseRPM Increase

Notice

Do not rotate the PLA unit over 1/2 turn from the

position marking. If do, idle spring in the governor

will be severely damaged.

6. After adjustment, tighten the locking nut and place

the position marking with different color of paint.

Notice

If there are no changes in idle speed with PLA unit

adjustment, perform the service at a BOSCH Ser-

vice Center.

7. Connect the vacuum pump to the PLA vacuum unit

and build up vacuum approx. 500mbar. If engine

rpm increases by approx. 100rpm, It is normal.

Vacuum Pump 001 589 73 21 00

8. Connect the vacuum line (4).

9. Switch on all ancillaries and check the idle speed.

Page 774 of 2053

OM600 ENGINE CONTROLS 1F3 -- 17

D AEW OO M Y_2000

FUEL PUMP TEST

Notice

Before test, replace the fuel filter cartridge and fuel pre-

filter.

Fuel Feed Test

1. Disconnect the fuel return line (1) and seal up it with

plug.

2. Insert the plastic hose (5) and put the end into the

measuring beaker (6).

3. Disconnect the vacuum line (4) from vacuum unit

(engine stop) (5) and connect the vacuum pump (7)

to the vacuum unit.

4. To avoid the engine starting, build up vacuum

(approx. 500 mbar).

5. Operate the starter motor for exactly 30 seconds

and measure fuel volume in the beaker.

Min. volume150cm3for 30 seconds

Page 775 of 2053

1F3 -- 18 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

Fuel Pressure Test

Page 776 of 2053

OM600 ENGINE CONTROLS 1F3 -- 19

D AEW OO M Y_2000

Tools Required

617589042100 Tester

1. Disconnect the fuel line (2) from the fuel filter.

2. Remove the banjo bolt (4) from the fuel injection

pump and remove the seals (3) and fuel line (2).

3. Connect the tester (5).

4. Start the engine and read off the fuel pressure on

tester (5).

Notice

At Idle Speed> 0.3bar

At Full load> 0.5bar

If out of standard, replace the fuel feed pump.

Tester 617 589 04 21 00

5. Stop the engine.

6. Remove the tester.

7. Replace the seal and connect the fuel line (2).

Page 777 of 2053

1F3 -- 20 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

FUEL PUMP

1 Fuel Injection Pump

2 Pressure Line 13N∙m (10 lb-ft) ..............

3 Suction Line

4 Hose Clip Replace........................5 Gasket Replace..........................

6 Spring Lock Washer

7 Hexagon Nuts

8 Fuel Pump

Page 778 of 2053

OM600 ENGINE CONTROLS 1F3 -- 21

D AEW OO M Y_2000

INJECTION NOZZLE TEST

Preceding Work : Removal of fuel injection nozzle

1 Fuel Injection Nozzle New : 115-- 125 bar....

Used : min. 100bar

A Closed Spray = good

B Stringy Spray = poor2Tester

3Valve

Page 779 of 2053

1F3 -- 22 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

Tools Required

000589142700 Tester

Notice

When testing the injection nozzle, do not place your

hand into the spray of a nozzle. The spraywill penetrate

deep into the skin and destroy the tissue.

1. Connect the fuel injection nozzle to the tester (2).

Tester 000 589 14 27 00

2. Close the valve (3) and pump 5 times strongly.

3. Chatter test :

Slowly operate the hand lever at tester (approx. 1

stroke per second). The nozzlemust spray with a

gentle chattering.

4. Spray pattern test :

Operate the hand lever at tester rapidly (approx.

2~3 strokes per second).

DGood

The spray pattern shows closed and well atom-

ized.

DPoor

The spray pattern shows split, too wide and

stringy.

(Repair the fuel injection nozzle)

Page 780 of 2053

OM600 ENGINE CONTROLS 1F3 -- 23

D AEW OO M Y_2000

5. Opening pressure test :

Open the valve (3) and slowly operate the hand le-

ver at tester (approx. 1 stroke / second) and mea-

sure opening pressure.

New Nozzle115 -- 125bar

Used NozzleMin. 100bar

Difference Between NozzlesMax. 5bar

Notice

If out of standard, repair the injection nozzle.

6. Leak test

Slowly operate the hand lever at the tester until get a

pressure of approx. 90bar. Maintain this pressure

for more than 20 seconds and within this period no

drop of fuel should build up at the nozzle tip.

Trending: brakes, alternator, check engine, coolant capacity, coolant, warning lights, clutch