section 2c SSANGYONG KORANDO 1997 Service Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 930 of 2053

SSAMGYONG MY2002

4A-10 HYDRAULIC BRAKES

KAA4A020

KAA4A030

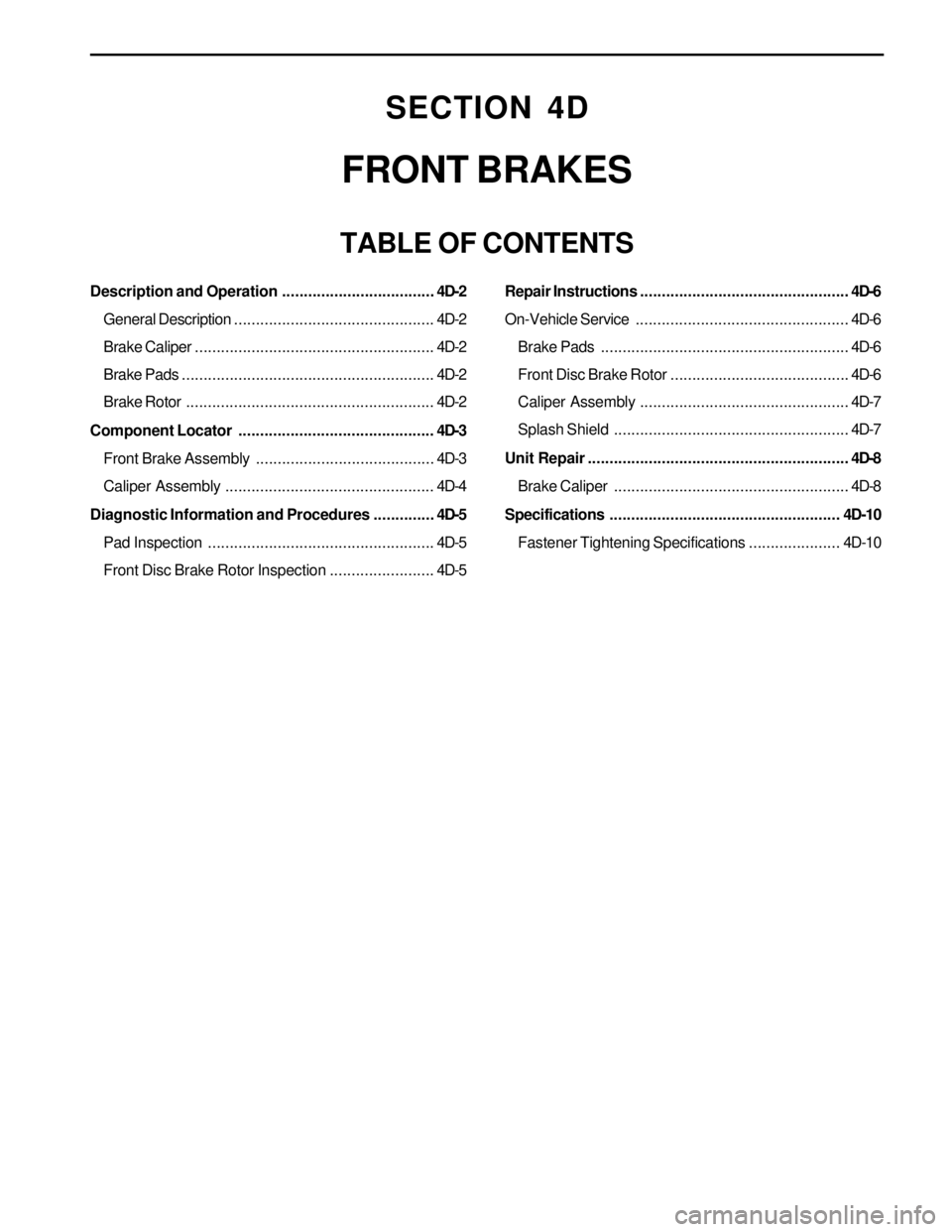

Notice: Keep brake fluid away from painted surfaces

because brake fluid will damage the paint finish.

2. Fill the master cylinder reservoir with brake fluid.

Keep the master cylinder reservoir at least one-

half full during the bleeding operation.

ON-VEHICLE SERVICE

MANUAL BLEEDING THE BRAKES

Removal and Installation Procedure

Important: Manual bleeding of the hydraulic modulator

is not possible. If air enters the antilock brake hydraulic

modulator, or if an unfilled modulator is installed, use

the scan tool to bleed air out of the brake system.

Replacement modulators are shipped already filled

and bled. In normal on-vehicle service procedures

involving the modulator, such as the procedure to

replace the electronic brake control module, air will

not enter the modulator. In such cases, use the

bleeding procedure in this section.

1. Remove the booster reserve by applying the

brakes several times with the engine off, until all

the reserve is depleted.

Important: If no air is suspected to be in the

master cylinder, begin the bleeding procedure at

Step 12. If it is suspected that air is in the master

cylinder bore, then the master cylinder must be

bled, beginning with step 2.

REPAIR INSTRUCTIONS

Page 933 of 2053

HYDRAULIC BRAKES 4A-13

SSANGYONG MY2002

Tightening Torque 17 Nm (13 lb-ft)

FRONT BRAKE HOSE

Removal and Installation Procedure

1. Raise and suitably support the vehicle.

2. Disconnect the brake line from the brake hose sup

port bracket on the front frame on each side of the

vehicle and remove the retainer.

Installation Notice

KAA4A080

KAA4A090

KAA4A100

KAA4A110

3. Remove the brake hose from the brake hose

support bracket on the upper control arm.

4. Remove the front brake hose-to-front caliper

assembly bolt.

5. Remove the ring seals and the disc brake hose.

Installation Notice

Tightening Torque 30 Nm (22 lb-ft)

Bleed the brake system. Refer to “Manual

Bleeding the Brakes” in this section.

Check the brake system for leaks.

6. Installation should follow the removal procedure

in the reverse order.

REAR BRAKE HOSE

Removal and Installation Procedure

1. Raise and suitably support the vehicle.

2. Disconnect the brake line from the disc brake hose

at the rear axle bracket on each side of the vehicle.

Installation Notice

Tightening Torque 17 Nm (13 lb-ft)

Page 934 of 2053

SSAMGYONG MY2002

4A-14 HYDRAULIC BRAKES

KAA4A120

KAA4A130

KAA4A140

STOPLAMP SWITCH

Removal and Installation Procedure

1. Remove the stoplamp switch connector.

2. Remove the stoplamp switch.

3. Installation should follow the removal procedure

in the reverse order.

BRAKE PEDAL

Removal and Installation Procedure

1. Remove the stoplamp switch connector.

2. Remove the clevis pin and disconnect the brake

booster pushrod.

Installation Notice:

Install in the upper hole.

Install the snap pin fully in the hole of clevis

pin.

Apply the grease around the hold of clevis pin.

3. Remove the brake pedal mounting nut and remove

the brake pedal assembly.

Installation Notice

Tightening Torque 13 Nm (10 lb-ft)

4. Installation should follow the removal procedure

in the reverse order.

KAA4A070

3. Remove the rear bleeder valve from the caliper as

sembly.

Installation Notice

Tightening Torque 10 Nm (89 lb-ft)

Bleed the brake system. Refer to “Manual

Bleeding the Brakes” in this section.

Check the brake system for leaks.

4. Installation should follow the removal procedure in

the reverse order.

Page 937 of 2053

Description and Operation...................................4B-2

General Description.............................................4B-2

Component Locator.............................................4B-3

Repair Instructions................................................4B-4

On-Vehicle Service.................................................4B-4Brake Oil Level Switch .........................................4B-4

Brake Fluid Reservoir ...........................................4B-4

Master Cylinder...................................................4B-5

Specifications.......................................................4B-8

Fastener Tightening Specifications.......................4B-8

SECTION 4B

MASTER CYLINDER

TABLE OF CONTENTS

Page 938 of 2053

SSANGYONG MY2002

4B-2 MASTER CYLINDER

DESCRIPTION AND OPERATION

GENERAL DESCRIPTION

The master cylinder is designed for use in a parallel

split system. One front and one parallel to rear brakes

are served by the primary piston. The opposite front

and rear brakes are served by the secondary piston.

The master cylinder incorporates the functions of the

standard dual master cylinder, plus a low fluid level

indicator. The brake fluid level switch is attached under

the body of the plastic brake master cylinder reservoir.

Notice: Do not use lubricated shop air on the brake

parts, because oil will damage the rubber components.Important:•Replace all the components included in the repair

kits used to service the master cylinder.

Lubricate the rubber parts with clean brake fluid to

ease assembly.

If any hydraulic component is removed or discon-

nected, it may be necessary to bleed all or part of

the brake system. Refer to Section 4F, Antilock

Brake System and Traction Control System.

The torque values specified are for dry, unlubricated

fasteners.

Perform all service operations on a clean bench,

free from all traces of mineral oil.

Page 941 of 2053

MASTER CYLINDER 4B-5

SSANGYONG MY2002

KAA4B060

4. Remove and discard the brake fluid reservoir seals

from the master cylinder body.

Installation Notice:

Lubricate the new brake fluid reservoir seals with

clean brake fluid.

After the installation, bleed the brake system.

Refer to Section 4F, Antilock Brake System and

Traction Control System.

5. Installation should follow the removal procedure

in the reverse order.

YAD4A340

YAD4A350

YAD4A360

3. Remove the master cylinder.

Retain the master cylinder in the vice and

remove the retainer ring from the master cylinder

using the snap ring plier. 2. Loosen the mounting nut of the master cylinder

and remove the master cylinder from the power

booster.

MASTER CYLINDER

Removal Procedure

1. Disconnect the brake lines from the master

cylinder.

Notice: The brake fluid may damage paintwork, if

spillage onto paintwork, wash with cold water

immediately.

Page 944 of 2053

Description and Operation....................................4C-2

General Description..............................................4C-2

Component Locator..............................................4C-3

Diagnostic Information and Procedures...............4C-4

Power Booster Functional Check..........................4C-4

Repair Instructions................................................4C-5On-Vehicle Service.................................................4C-5

Power Booster Assembly.....................................4C-5

Vacuum Hose......................................................4C-6

Specifications.......................................................4C-7

General Specification ...........................................4C-7

Fastener Tightening Specifications.......................4C-7

SECTION 4C

POWER BOOSTER

TABLE OF CONTENTS

Page 945 of 2053

SSANGYONG MY2002

4C-2 POWER BOOSTER

DESCRIPTION AND OPERATION

GENERAL DESCRIPTION

The power booster is a double-diaphragm, vacuum-sus

pended unit. In normal operating mode, with the service

brakes in the release position, a vacuum-suspended

booster operates with a vacuum on both sides of its

diaphragm. When the brakes are applied, air at

atmospheric pressure is admitted to one side of the

diaphragm to provide the power assist.When the brakes are released, atmospheric air is shut

off from that side of the diaphragm. The air is then

drawn from the booster through the vacuum check

valve by the vacuum source.

Important: If any hydraulic component is removed or

disconnected, it may be necessary to bleed all or part

of the brake system. Refer to Section 4F, Antilock

Brake System and Traction Control System.

Page 948 of 2053

POWER BOOSTER 4C-5

SSANGYONG MY2002

REPAIR INSTRUCTIONS

KAA4C030

KAA4A040

KAA4C050

ON-VEHICLE SERVICE

POWER BOOSTER ASSEMBLY

Removal and Installation Procedure

1. Remove the master cylinder. Refer to Section 4B,

Master Cylinder.

2. Remove the vacuum hose from the booster.

3. Remove the clevis pin and disconnect the pedal

and brake booster push rod.

Installation Notice:

•Apply the grease around the hole of clevis pin.

4. Remove the power booster mounting nuts and re-

move the booster from the dash panel.

Installation Notice

Tightening Torque 17 Nm (13 lb-ft)

Install the new gasket.

5. Installation should follow the removal procedure

in the reverse order.

Page 951 of 2053

Description and Operation...................................4D-2

General Description..............................................4D-2

Brake Caliper.......................................................4D-2

Brake Pads..........................................................4D-2

Brake Rotor.........................................................4D-2

Component Locator.............................................4D-3

Front Brake Assembly.........................................4D-3

Caliper Assembly................................................4D-4

Diagnostic Information and Procedures..............4D-5

Pad Inspection....................................................4D-5

Front Disc Brake Rotor Inspection........................4D-5Repair Instructions................................................4D-6

On-Vehicle Service.................................................4D-6

Brake Pads.........................................................4D-6

Front Disc Brake Rotor .........................................4D-6

Caliper Assembly................................................4D-7

Splash Shield......................................................4D-7

Unit Repair............................................................4D-8

Brake Caliper......................................................4D-8

Specifications.....................................................4D-10

Fastener Tightening Specifications.....................4D-10

SECTION 4D

FRONT BRAKES

TABLE OF CONTENTS