engine SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1298 of 2053

AUTOMATIC TRANSMISSION 5A-203

SSANGYONG MY2002

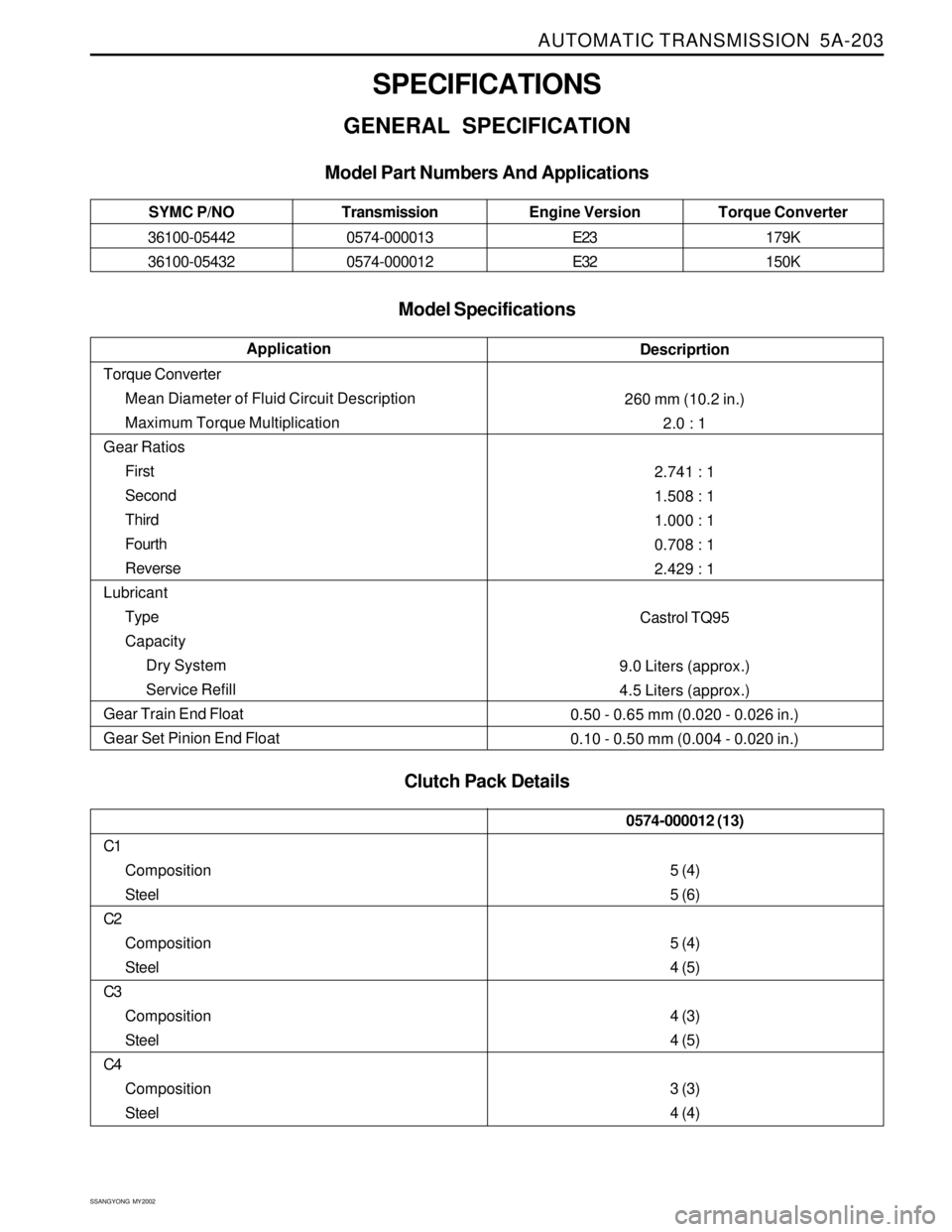

SPECIFICATIONS

GENERAL SPECIFICATION

Model Specifications

Clutch Pack Details Model Part Numbers And Applications

Descriprtion

260 mm (10.2 in.)

2.0 : 1

2.741 : 1

1.508 : 1

1.000 : 1

0.708 : 1

2.429 : 1

Castrol TQ95

9.0 Liters (approx.)

4.5 Liters (approx.)

0.50 - 0.65 mm (0.020 - 0.026 in.)

0.10 - 0.50 mm (0.004 - 0.020 in.)Application

Torque Converter

Mean Diameter of Fluid Circuit Description

Maximum Torque Multiplication

Gear Ratios

First

Second

Third

Fourth

Reverse

Lubricant

Type

Capacity

Dry System

Service Refill

Gear Train End Float

Gear Set Pinion End Float

Transmission

0574-000013

0574-000012Torque Converter

179K

150K Engine Version

E23

E32 SYMC P/NO

36100-05442

36100-05432

C1

Composition

Steel

C2

Composition

Steel

C3

Composition

Steel

C4

Composition

Steel

0574-000012 (13)

5 (4)

5 (6)

5 (4)

4 (5)

4 (3)

4 (5)

3 (3)

4 (4)

Page 1301 of 2053

5A-206 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

TCM WIRING DIAGRAM (GASOLINE ENGINE - 1

SCHEMATIC AND ROUTING DIAGRAMS

KAA5A010

Page 1302 of 2053

AUTOMATIC TRANSMISSION 5A-207

SSANGYONG MY2002

TCM WIRING DIAGRAM (GASOLINE ENGINE - 2 OF 2)

KAA5A020

Page 1303 of 2053

5A-208 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

TCM WIRING DIAGRAM (DIESEL ENGINE - 1 OF 2)

YAD5A230

Page 1304 of 2053

AUTOMATIC TRANSMISSION 5A-209

SSANGYONG MY2002

TCM WIRING DIAGRAM (DIESEL ENGINE - 2 OF 2)

YAD5A240

Page 1312 of 2053

SSANGYONG MY2002

5B-4 MANUAL TRANSMISSION

DIAGNOSTIC INFORMATION AND PROCEDURES

Control lever assembly broken or dam-

aged.

Damaged offset lever, shift fork, selector

place or selector arm.

Clutch not releasing.

Improper or low transmission oil.

Shift or shift rail binding.

Binding of sliding synchronizers or gears.

If reverse only, faulty backup switch.

Worn or damaged flywheel pilot bushing.

Engine idle speed too high.

Damaged or faulty clutch.

Pilot bearing between input shaft and

output shaft binding.

Damaged synchronizer.

Bell housing misaligned.

Damaged gear(s).

Worn or damaged flywheel pilot bushing.

Loosened transmission or flywheel

housing bolts, improper alignment.

Synchronizer damaged or excessively

worn.

Blocking ring damaged, worn index slots

or friction surfaces worn or damaged.

Excessive countershaft end play.

Worn or damaged fork due to loosened

shaft, rail or shifting fork.

Fork or offset lever loose on shaft or rail.

Worn or damaged forks, offset lever,

shaft or rail.Replace control lever and housing assem-

bly.

Remove extension, adapter or case

cover. Check or replace damaged parts.

Adjust or replace clutch.

Add or replace with specified oil.

Remove extension, adapter or case

cover. Check or replace damaged parts.

Remove extension, adapter or case

cover. Check synchronizers and gears

and replace damaged parts.

Check or replace backup switch.

Replace pilot bushing.

Adjust idle speed to specified speed.

Adjust or replace clutch.

Replace or check roller bearings.

Check or replace synchronizer parts.

Align bell housing and bore.

Check or replace gear(s).

Replace pilot bushing.

Tighten bolts to specified value. Realign

if necessary.

Check or replace synchronizer parts.

Check or replace blocking ring.

Check worn or damaged parts. Adjust

shim thickness using roller bearings if

necessary.

Check for wear or damaged. Replace

worn or damaged parts.

Replace extension, adapter or case

cover. Check or replace loose parts on

shaft or rail. Replace roll pin(s).

Remove extension, adapter or case

cover. Check for wear or damaged.

Replace damaged parts. Check Applicatio

Will not shift

(control lever moves)

Hard shift or control

lever will not move into

gear

Gears crash when

shifting

Transmission jumps

out

Transmission locked in

one gear

Action

Page 1313 of 2053

MANUAL TRANSMISSION 5B-5

SSANGYONG MY2002

Check worn or damaged synchronizer

parts and replace if necessary.

Check worn or damaged gears and

replace if necessary.

Add or drain and replace with proper oil.

Tighten as specified.

Realign correctly.

Check bearings, bearing rollers and parts

for wear or damage. Replace if neces-

sary.

Check for worn or damaged

gears(including speedometer gear).

Replace if necessary.

Clean all exposed surfaces, then check

for leaks.

Clean or replace vent or breather.

Check oil level.

Tighten as specified.

Clean leaking surfaces. Reapply sealant.

Replace oil seal.

Action

Worn or damaged synchronizer.

Worn or damaged gears.

Improper or low transmission oil.

Loose bolts or other attaching parts.

Improper flywheel housing to engine

crankshaft alignment.

Noisy transmission bearing.

Noisy gears.

Leakage from transmission.

Vent or breather clogged.

Too much oil.

Loose bolts at sealing faces.

Improperly applied sealant.

Worn or damaged oil seal.Check Applicatio

Transmission locked in

one gear

Transmission noise

Transmission leakage

Page 1328 of 2053

SSANGYONG MY2002

5B-20 MANUAL TRANSMISSION

7. Remove the front and rear propeller shafts from

the transfercase.

8. Support the transmission on an suitable jack.

Unscrew the center mounting nuts and each sides

mounting bolts and remove the cross member.

9. Remove the transmission mounting bolts.

Notice: For removing the transmission, there may

be any damage in the clutch housing inside CSC.

Thus remove the transmission with the clutch

housing.

10. Move the transmission jack backward careful and

disengage the transmission input shaft from the

engine.

Remove the transmission.

YAD5B320

YAD5B330

YAD5B340

YAD5B020

Page 1330 of 2053

SSANGYONG MY2002

5B-22 MANUAL TRANSMISSION

62 - 93 Nm

(45 - 69 lb-ft)

21 - 35 Nm

(15 - 26 lb-ft)

Check the housing face alignment.

- Place the dial indicator on the housing face.

- By rotating the crankshaft one revolution,

record the dial indicator reading.

Notice: If the reading is greater than 0.010 inch,

insert the shim between the engine and clutch

housing and adjust the alignment.

5. Check the following parts :

Pressure plate spring assembly

Disc

Flywheel

Input shaft pilot bearing

Notice: Replace the excessively worn parts.

6. Lubricate the clutch release bearing bore, fork

pivot head during assembly.

Installation Procedure

1. Install the transmission to the vehicle. At this time,

seat correctly the input shaft of the transmission

on the pilot bearing of the flywheel.

2. Tighten the transmission mounting bolts as the

specified torque on the vehicle.

Installation Notice

YAD5B390

YAD5B400

YAD5B410

YAD5B420

Tightening Torque77 - 87 Nm

(57 - 64 lb-ft)

3. Install the cross member and tighten as the

specified torque by supporting the suitable jack.

Installation Notice

Tightening

TorqueLeft/Right

Center

Page 1361 of 2053

SSAMGYONG MY2002

5C-6 CLUTCH

CLUTCH DISC

Preceding Work : Removal of the transmission

KAA5C040

1 Clutch Disc

2 Clutch Cover Assembly

3 Release Bearing

4 Clutch Housing5 Washer

6 Bolt........................................... 23 Nm (17 lb-ft)

7 Washer

8 Bolt........................................... 54 Nm (40 lb-ft)

Tools

602 589 00 40 00 Engine Lock

661 589 00 15 00 Centering Pin