engine SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1453 of 2053

SSANGYONG MY2002

6A-2 POWER STEERING SYSTEM

DESCRIPTION AND OPERATION

GENERAL DESCRIPTION

The power steering system consists of three compo

nents: the power steering pump, the power steering

fluid reservoir and the power steering rack and pinion

gear.

The power steering pump is a vane-type pump providing

hydraulic pressure for the system and is powered by

the engine. It draws on the power steering fluid

reservoir, which in turn is connected to the power

steering gear.A pressure-relief valve inside the flow control valve

limits the pump pressure. The power steering rack and

pinion gear has a rotary control valve, which directs

hydraulic fluid coming from the power steering pump

to one side or the other side of the rack piston. The

integral rack piston is attached to the rack. The rack

piston converts hydraulic pressure to a linear force,

which moves the rack to the left or the right. The force

is then transmitted through the inner and the outer tie

rods to the steering knuckles, which turn the wheels.

Page 1455 of 2053

SSANGYONG MY2002

6A-4 POWER STEERING SYSTEM

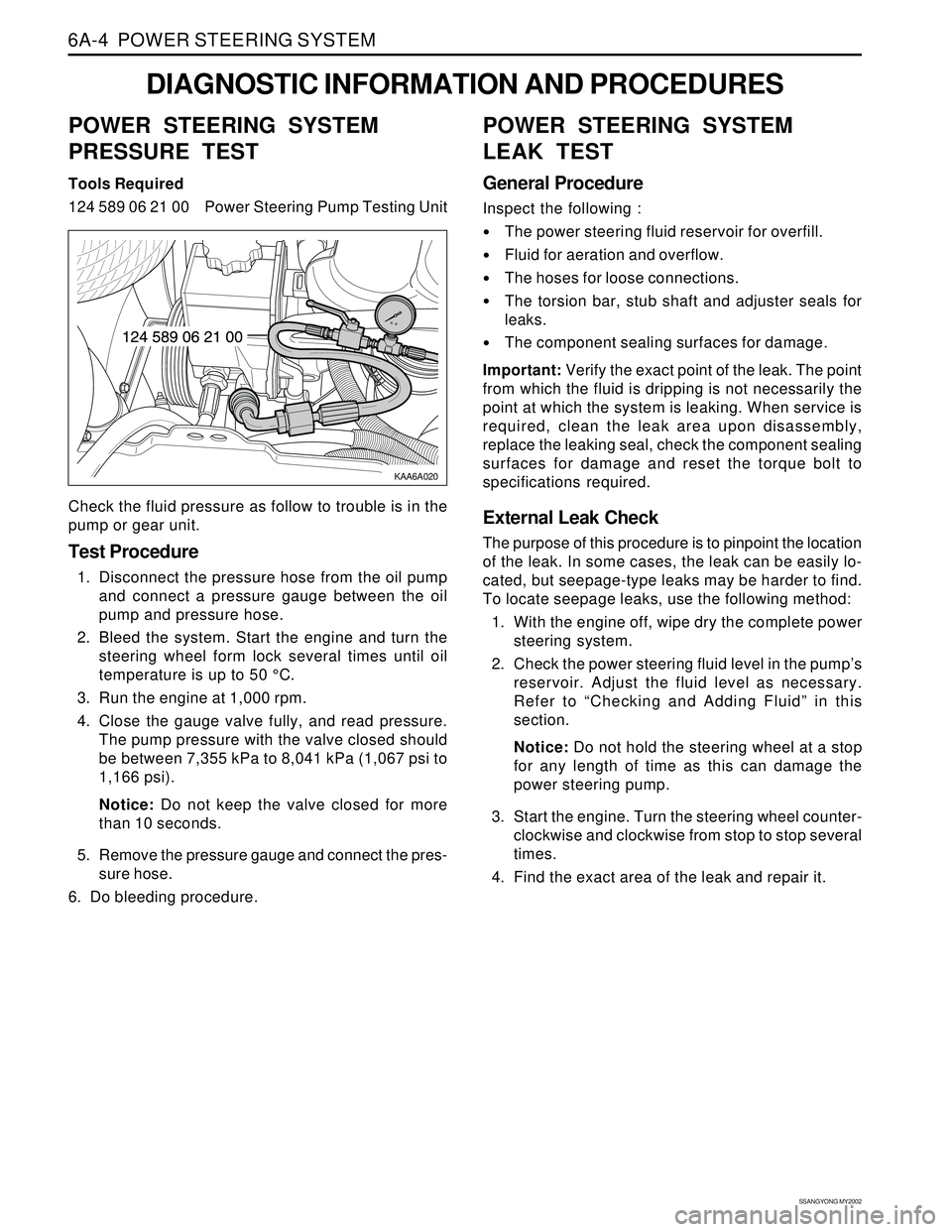

KAA6A020

DIAGNOSTIC INFORMATION AND PROCEDURES

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

124 589 06 21 00 Power Steering Pump Testing Unit

Check the fluid pressure as follow to trouble is in the

pump or gear unit.

Test Procedure

1. Disconnect the pressure hose from the oil pump

and connect a pressure gauge between the oil

pump and pressure hose.

2. Bleed the system. Start the engine and turn the

steering wheel form lock several times until oil

temperature is up to 50 °C.

3. Run the engine at 1,000 rpm.

4. Close the gauge valve fully, and read pressure.

The pump pressure with the valve closed should

be between 7,355 kPa to 8,041 kPa (1,067 psi to

1,166 psi).

Notice: Do not keep the valve closed for more

than 10 seconds.

5. Remove the pressure gauge and connect the pres-

sure hose.

6. Do bleeding procedure.

POWER STEERING SYSTEM

LEAK TEST

General Procedure

Inspect the following :

The power steering fluid reservoir for overfill.

Fluid for aeration and overflow.

The hoses for loose connections.

The torsion bar, stub shaft and adjuster seals for

leaks.

The component sealing surfaces for damage.

Important: Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the

point at which the system is leaking. When service is

required, clean the leak area upon disassembly,

replace the leaking seal, check the component sealing

surfaces for damage and reset the torque bolt to

specifications required.

External Leak Check

The purpose of this procedure is to pinpoint the location

of the leak. In some cases, the leak can be easily lo-

cated, but seepage-type leaks may be harder to find.

To locate seepage leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary.

Refer to “Checking and Adding Fluid” in this

section.

Notice: Do not hold the steering wheel at a stop

for any length of time as this can damage the

power steering pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1456 of 2053

POWER STEERING SYSTEM 6A-5

SSANGYONG MY2002

BLEEDING THE POWER

STEERING SYSTEM

1. Disconnect the fuel line. Using a starter motor,

crank the engine and turn the steering wheel from

lock to start 5 or 6 times.

Notice: Do bleeding with engine cranking. If bleed

with idling, there can be a air contact with oil.

2. Connect the fuel feed line and start the engine at

idle speed.

3. Turn the steering wheel from lock to lock until there

is no more air in oil reservoir.

4. Connect the oil level is within specification.

5. By turning the steering wheel left to right, check

the oil level change.

Notice: If oil is not changes more than 5 mm, do

bleeding again. If oil level rises suddenly when

stopped engine, again.

MAINTENANCE

CHECKING AND ADDING FLUID

Notice: When adding fluid or making a complete fluid

change, always use DEXRON. - II power steering fluid.

Failure to use the proper fluid will cause hose and seal

damage and fluid leaks.

1. The power steering fluid level is indicated by marks

on a fluid level indicator on the fluid reservoir cap.

2. If the fluid is warmed up to 66 °C (150 °F), the fluid

level should be between the MAX and MIN marks.

Add fluid as needed.

3. If the fluid is cool, 21 °C (70 °F), the fluid level should

be at the MIN mark. Add fluid as needed.

Page 1458 of 2053

POWER STEERING SYSTEM 6A-7

SSANGYONG MY2002

KAA6A050

KAA6A060

4. Disconnect the return line pipe from the power

steering gear outlet.

Installation Notice

KAA6A070

5. Disconnect the pressure line pipe from the power

steering gear inlet.

Installation Notice

POWER STEERING PUMP HOSES

AND PIPES

Removal and Installation Procedure

1. Remove the battery. Refer to Section 1E, Engine

Electrical.

2. Siphon the power steering fluid from the fluid reser-

voir.

3. Disconnect the pressure line pipe from the outlet

connection on the power steering pump and return

hose from the inlet connection on the power

steering fluid reservoir.

Installation Notice

Tightening Torque 44 Nm (33 lb-ft)

Tightening Torque 17 Nm (13 lb-ft)

Tightening Torque 17 Nm (13 lb-ft)

Page 1465 of 2053

SSANGYONG MY2002

6B-4 POWER STEERING PUMP

KAA6B010

REPAIR INSTRUCTIONS

ON-VEHICLE SERVICE

SERPENTINE ACCESSORY DRIVE

BELT

Removal and Installation Procedure

1. Remove the electric cooling fan. Refer to Section

1D, Engine Cooling.

2. Use a wrench to turn the tensioner bolt clockwise,

compressing the tensioner, and releasing the

tension on the serpentine accessory drive bolt.

KAA6B020

3. Remove the serpentine accessory drive belt.

Page 1466 of 2053

POWER STEERING PUMP 6B-5

SSANGYONG MY2002

KAA6B050

5. Remove the power steering pump assembly

mounting bolts.

Installation Notice

KAA6B040

3. Siphon the power steering fluid from the fluid reser-

voir.

4. Disconnect the pressure line pipe from the outlet

connectionon the power steering pump and return

hose from the inlet connection on the power

steering fluid reservoir.

Installation Notice

Tightening Torque 44 Nm (33 lb-ft)

KAA6B010

POWER STEERING PUMP

ASSEMBLY

Removal and Installation Procedure

1. Remove the battery. Refer to Section 1E, Engine

Electrical.

2. Use a wrench to turn the tensioner bolt clockwise,

compressing the tensioner, and releasing the

tension on the serpentine accessory drive belt.

Loosen the serpentine accessory drive belt.

Tightening Torque 25 Nm (17 lb-ft)

6. Remove the power steering pump assembly.

Page 1473 of 2053

POWER STEERING GEAR 6C-5

SSANGYONG MY2002

Check the power steering pump for insufficient pres-

sure.

Check the power steering pump flow control valve for

sticking and improper operation.

Check the power steering pump serpentine belt for

slippage.

Check for air contamination in the power steering

system.ChecksActionReplace the power steering pump.

Replace the power steering pump.

Tighten the power steering serpentine belt.

Bleed the power steering system

Steering Surges or Jerks When Turning with Engine Running

Check for air contamination in the power steering

system.

Check the power steering pump serpentine belt for

looseness.ChecksActionBleed the power steering system.

Tighten the power steering serpentine belt.

Steering Vibrates During Low Speed or Static Steering

Excessive Wheel Kickback or Loose Steering

Check for air contamination in the power steering

system.

Check the wheel bearings for wear or damage.

Check the steering gear mounting for improper instal-

lation.

Check the intermediate shaft joints for improper

Installation.

Check the outer tie rods and the ball joints for

looseness.ChecksActionBleed the power steering system.

Replace the wheel bearings.

Tighten the steering gear mounting bracket nuts and

bolts.

Adjust the intermediate shaft between the steering

gear and the steering column. Replace the intermedi-

ate shaft.

Tighten the tie rods and the ball joints. Replace the tie

rods and the ball joints.

Hard Steering or Lack of Assist (Especially During Parking)

Check the intermediate shaft joints for improper

installation.

Check the power steering pump flow control valve for

sticking and improper installation.

Check the power steering pump for insufficient pressure.

Check the power steering pump for internal leaks.

Check for a loose or a worn intermediate shaft.

Check the power steering pump serpentine belt tension.ChecksActionAdjust the intermediate shaft between the steering gear

and the steering column. Replace the coupling flange.

Replace the power steering pump.

Replace the power steering pump.

Replace the power steering pump.

Tighten the intermediate shaft. Replace the intermedi-

ate shaft, as needed.

Tighten the power steering serpentine belt.

Page 1474 of 2053

SSANGYONG MY2002

6C-6 POWER STEERING GEAR

POWER STEERING RACK AND

PINION GEAR BENCH TESTING

Removal and Installation Procedure

Notice: Pressure checks or pressure and flow checks

may also be conducted using this setup.

1. Disconnect and remove the power steering gear.

Refer to “Rack and Pinion Assembly” in this

section.

2. Place the power steering gear on a bench next to

the vehicle.

3. Disconnect the pressure line at the point where the

hose connects to the pipe. Extend this line to reach

the power steering gear on the bench.

4. Disconnect the return line from the power steering

fluid reservoir. Extend this line to reach the power

steering gear on the bench.

5. Connect the power steering pipes to the power

steering gear.

6. Start the engine and allow it to idle for 10 seconds.

7. Check the power steering fluid level. Refer to

Section 6A, Power Steering System.

8. Start the engine and turn the rack and pinion stub

shaft a full turn in each direction. Hold the shaft

against each stop for 5 seconds.

9. Inspect for possible leak points. Refer to Section

6A, Power Steering System.

Installation Procedure

1. Stop the engine.

2. Disconnect the power steering pipes from the power

steering gear.

KAA6C020

3. Remove the extensions and reconnect the pressure

and return lines.

4. Install and connect the power steering gear. Refer

to “Rack and Pinion Assembly” in this section.

5. Start the engine and allow it to idle for 10 seconds.

6. Check the power steering fluid level. Refer to

Section 6A, Power Steering System.

STRAIGHT-AHEAD CHECK

After all the necessary operations on the steering gear

are completed (removing and installing, disassembling

and assembling), check the exact straight-ahead posi-

tion of the steering in each case.

With the vehicle on the floor, place the steering wheel

in the straight-ahead position. Mark the centerline of

both tires on the floor. Turn the steering wheel all the

way to the right and mark the new centerline of both

tires on the floor.

Page 1490 of 2053

SSANGYONG MY2002

6E-4 POWER STEERING AND COLUMN

DIAGNOSTIC INFORMATION AND PROCEDURES

STEERING WHEEL FREEPLAY

INSPECTION

KAA6E020

Inspection Procedure

1. Start the engine and set the wheels in straight

ahead position.

2. Slightly move the steering wheel to the left and

right and measure steering wheel free play when

the front wheel is start to move.

Notice: If exceeds specification, the steering

column shaft connections and steering linkage

clearance. Replace or repair if necessary.

StandardMax. 30 mm

STEERING EFFORT INSPECTION

KAA6E030

Inspection Procedure

1. Place a vehicle on the paved flat ground with front

wheels in a straight ahead position.

2. Start the engine and run it at 1,000 rpm.

3. Using a scale, measure the steering effort in both

directions.

Notice : The difference in steering effort of left

and right should be within 0.6 kg.

StandardMax. 3.0 kg

Page 1502 of 2053

SECTION 7A

HEATING AND VENTILATION SYSTEM

CAUTION: The cooling system is pressurized when hot. Injury can result from removing the coolant reservoir

cap before the engine is sufficiently cool.

TABLE OF CONTENTS

Description and Operation ................................7A-2

Heating and Ventilation System .........................7A-2

Components Locator ..........................................7A-3

Heater System ...................................................7A-3

Diagnostic Information and Procedures ..........7A-4

Heater System ...................................................7A-4

Blower Electrical ................................................7A-8

Mode Controls Do Not Work .............................7A-10

Air Source Selection Not Controlled ..................7A-12

Temperature Controls Do Not Work ..................7A-13

Too Much Heat .................................................7A-14

Blower Noise ....................................................7A-16

Repair Instructions ............................................7A-18

On-Vehicle Service..............................................7A-18

Temperature Control Cable Adjustment ............7A-18

Controller Assembly and Temperature

Control Cable .................................................7A-18

Control Assembly Knob Lighting ......................7A-19Air Intake Door Actuator ...................................7A-19

Mode Control Door Actuator .............................7A-20

Heater/Air Distributor Case Assembly ..............7A-20

Blower Motor ....................................................7A-21

Blower Resistor ................................................7A-22

Blower Unit .......................................................7A-22

Heater Inlet Hose ..............................................7A-23

Heater Outlet Hose ...........................................7A-23

Heater Core......................................................7A-24

Rear Heater Duct ..............................................7A-24

Air Filter ............................................................7A-24

Specifications .................................................... 7A-25

Heater Temperature Specification .....................7A-25

Heater Unit .......................................................7A-25

Fastener Tightening Specification .....................7A-25

Schematic and Routing Diagrams ................... 7A-26

Non - A/C Wiring Diagram ................................7A-26

Airflow Through Vents .......................................7A-28