sensor SSANGYONG KORANDO 1997 Service Manual Online

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 459 of 2053

M161 ENGINE CONTROLS 1F2 -- 41

D AEW OO M Y_2000

Battery Voltage Correction Mode

When battery voltage is low, the ECM can compensate for a weak spark delivered by the ignition module by using the

following methods:

DIncreasing the fuel injector pulse width.

DIncreasing the idle speed rpm.

DIncreasing the ignition dwell time.

Fuel Cut- Off Mode

No fuel is delivered by the fuel injectors when the ignition is off. This prevents dieseling or engine run -- on. Also, the fuel

is not delivered if there are no reference pulses received from the CKP sensor. This prevents flooding.

Page 474 of 2053

1F2 -- 56 M161 ENGINE CONTROLS

D AEW OO M Y_2000

INDUCTION SYSTEM

THROTTLE VALVE ACTUATOR

YAA1F540

The throttle actuator is actuated by the Engine Control Module (ECM) according to the position of the accelerator pedal

position.

It has two potentiometers which signal the position of the throttle valve to the ECM to enable it to recognize the various

engine load states.

Ignition “Off”

In the de-- energized states the throttle valve position is determined to be spring capsule.

Ignition “On”

When the ignition S/W on the servo motor in the throttle actuator is operated by the ECM. The throttle valve adopts a

position in line with the coolant temperature.

Closed position

In the closed throttle position, the servo motor controls engine speed by operating the throttle valve further (greater

mixture) or closing it further (reduced mixture), depending on coolant temperature and engine load. When this is done,

the throttle valve can be closed further by the servo motor overcoming the force of the spring capsule (mechanical end

stop). If the actuator is de-- energized, the throttle valve is resting against the spring capsule.

Consequently, the throttle valve opening is a constant 10-- 12°approximately.

At no load, this produces an engine speed of about 1,800 rpm

Driving

When driving (part/full throttle), the servo motor controls the throttle valve in line with the various load states and ac-

cording to the input signals from the pedal value sensor according to the input signals from the pedal value sensor

according to the position of the accelerator pedal.

The function of the EA (electronic accelerator) in the ECM determines the opening angle of the throttle valve through

the throttle actuator. Further functions are;

DIdle speed control

DCruise control

DReducing engine torque for ASR/ABS operation

DElectronic accelerator emergency running

DStoring faults

DData transfer through CAN

Page 475 of 2053

M161 ENGINE CONTROLS 1F2 -- 57

D AEW OO M Y_2000

KAB1F240

Failure

CodeDescriptionTrouble AreaMaintenance Hint

104Throttle position sensor

1 low voltageTPS 1 short circuit to ground

or open

105Throttle position sensor

1 high voltageTPS 1 short circuit to power

108Throttle position sensor

2 low voltageTPS 2 short circuit to ground

or open

109Throttle position sensor

2 high voltageTPS 2 short circuit to powerDMonitoring the actual values through

scantool

116Throttle actuator

learning control failureWhen actuator adaption

fluctuation or not meet the

conditionscantool

DInspection the ECM pin 84, 85, 87,

112, 67, 68 about short circuit or open

with bad contact

119Throttle valve return

spring failureWhen return spring defective

of actuator

withbadcontact

DInspection the throttle valve actuator

DInspection the ECM

121Throttle actuator failureWhen supply voltage of the

actuator short circuit to power

InspectiontheECM

123

Different mass air flow

sensor signal with

throttle position sensorWhen shut down of output

driver

125Both throttle position

sensor failureWhen defective of both

potentiometers

Page 476 of 2053

1F2 -- 58 M161 ENGINE CONTROLS

D AEW OO M Y_2000

Failure

CodeDescriptionTrouble AreaMaintenance Hint

126

Throttle position sensor

1 not plausible with

Throttle position sensor

2

When difference between

TPS 1 and TPS 2DMonitoring the actual values through

scan tool

DIns

pection the ECMpin 84, 85, 87,

127High permanent throttle

signalWhen failure of wiring

harness or actuator

DInspectiontheECMpin84,85,87,

112, 67, 68 about short circuit or open

with bad contact

Itiththttlltt

185

Mass air flow sensor

and throttle position

sensor failureWhen difference between

MAF and TPS signal

DInspection the throttle valve actuator

DInspection the ECM

Circuit Description

The ECM supplies a 5 volt reference signal and a ground to the TP sensor. The TP sensor sends a voltage signal back

to the ECM relative to the throttle plate opening. The voltage signalwill vary from approximately 0.3 ~ 0.9 volts at

closed throttle, to over 4.0 ~ 4.6 volts at Wide Open Throttle (WOT).

The TP sensors serve for engine load control according to the drive pedal command. Load adjustments independent of

the drive pedal command can be implemented; such functions are, for instance, idle control, speed control, drive slip

control, load shock damping, and similar functions.

When the actuator current fails, the throttle valve is returned to emergency operating position by a spring. The throttle

valve position, thereby the actuator drive position checkback is provided by two potentiometers. The motor positions

the throttle valve against the return spring force. Motor and return spring are two separate energy sources. Each of

them is able to position the throttle valve in emergency position alone. Throttle valve position checkback and monitor-

ing is provided by two actual value potentiometers connected to the engine control electronics.

Throttle Actuator Inspection

1. Turn the ignition switch to “ON” position.

2. Measure the TPS 1 signal voltage at the ECM pin No. 87 and TPS 2 signal voltage at the ECM pin No. 85.

Pedal PositionSpecified Value

TPS1Closed0.3 ~ 0.9 vTPS1Opened4.0 ~ 4.6 v

TPS2Closed4.0 ~ 4.6 vTPS2Opened0.3 ~ 0.9 v

Throttle Actuator DC Motor Inspection

1. Turn the ignition switch to “ON” position.

2. Measure the signal voltage between the ECM pin No. 67 and No. 68.

Application

Specified Value

Ignition “ON”0.8 ~ 2.3 v

Engine StatusIdling1.0 ~ 2.5 v

(Coolant temperature is over 70°C)

Throttle Actuator DC Motor Resistance

1. Turn the ignition switch to “OFF” position.

2. Measure the resistance between the ECM pin No. 67 and No. 68.

Specified Value

<10Ω

Page 478 of 2053

1F2 -- 60 M161 ENGINE CONTROLS

D AEW OO M Y_2000

HOT FILM AIR MASS (HFM) SENSOR

YAA1F570

The Hot Film Air Mass (HFM) sensor with recognition of flow direction related to pulsating flow is designed for record-

ing load on Engine Control Module (ECM) by measuring the output voltage proportional to the reference voltage of the

ECM.

Mass Air Flow Sensor

Mass Air Flow (MAF) is a thermal flow meter whose sensor element with its temperature sensors and heating area is

exposed to the MAF to be measured. A heating area located in the center of a thin membrane is controlled to an over --

temperature by a heating resistor and a temperature sensor of this membrane. And the value of over -- temperature

depends on the temperature of the in-- flowing air.

Two temperature sensors on upstream and downstream of the heating area show the same temperature without in-

coming flow. With incoming flow, upstream part is cooled down but downstream temperature retains its temperature

more or less due to the air heated up in the heating area. This temperature difference in quantity and direction depends

on the direction of the incoming flow.

ECM modulates the flow of heating current to maintain the temperature differential between the heated film and the

intake air at a constant level. The amount of heating current required to maintain the temperature thus provides an

index for the MAF. This concept automatically compensates for variations in air density, as this is one of the factors that

determines the amount of warmth that the surrounding air absorbs from the heated element. MAF sensor is located

between the air filter and the throttle valve.

Under high fuel demands, the MAF sensor reads a high mass flow condition, such as Wide Open Throttle (WOT). The

ECM uses this information to enrich the mixture, thus increasing the fuel injector on-- time, to provide the correct

amount of fuel. When decelerating, the mass flow decreases. This mass flow change is sensed by the MAF sensor

and read by the ECM, which then decreases the fuel injector on-- time due to the low fuel demand conditions.

To facilitate the installation of the HFM in the intake passage, lubricating agents may be used. However, when lubri-

cants are used care must be taken to ensure that they do not enter the flow passage and cannot be sucked in with the

air flow.

Page 479 of 2053

M161 ENGINE CONTROLS 1F2 -- 61

D AEW OO M Y_2000

The following tables show the relationship between MAF and output voltage.

Mass Air Flow (kg/h)

Voltage (v)Mass Air Flow (kg/h)Voltage (v)

00.95 ~ 1.052503.51

101.283703.93

151.414804.23

301.716404.56

602.168004.82

1202.76

Intake Air Temperature

The Intake Air Temperature (IAT) sensor is a part of Hot Film Air Mass (HFM) sensor and is a thermistor, a resistor

which changes value based on the temperature of the air entering the engine. Low temperature produces a high resist-

ance, while high temperature causes a low resistance as the following table.

The ECM provides 5 volts to the IAT sensor through a resistor in the ECM and measures the change in voltage to

determine the IAT. The voltage will be high when the manifold air is cold and low when the air is hot. The ECM knows

the intake IAT by measuring the voltage.

The IAT sensor is also used to control spark timing when the manifold air is cold.

Te m p. (°C)

Rmin.(Ω)R nom. (Ω)R max. (Ω)

-- 4 0351403926043760

-- 2 0126601385015120

0511954995829

20229024202551

40109611661238

60565609654

80312340370

100184202222

120114127141

13091102114

Page 480 of 2053

1F2 -- 62 M161 ENGINE CONTROLS

D AEW OO M Y_2000

KAB1F250

Failure

CodeDescriptionTrouble AreaMaintenance Hint

03Intake air temperature

sensor low voltageIAT sensor short circuit to

ground or openDMonitoring the actual air temperature

throu

gh scan tool

04Intake air temperature

sensor high voltageIAT sensor short circuit to

power

throughscantool

DInspection the ECM pin 80, 79 about

short circuit or open with bad contact

05Intake air temperature

sensor plausibilityMalfunction in recognition of

IAT

When functional problem

p

DInspection the IAT sensor (integrated

in HFM sensor)

DInspection the ECM

09Mass air flow sensor

plausibilityMalfunction in recognition of

MAF

When air mass not plausibleDMonitoring the actual air mass flow

through scan tool

DIns

pection the ECMpin 81, 105 about

10Mass air flow sensor low

voltageMAF sensor short circuit to

ground or open

DInspectiontheECMpin81,105about

short circuit or open with bad contact

DInspection the MAF sensor (integrated

iHFM)

11Mass air flow sensor

high voltageMAF sensor short circuit to

powerin HFM sensor)

DInspection the ECM

Circuit Description

The heated element on the MAF is a platinum film resistor (heater). It is located on a ceramic plate together with the

other elements in the bridge circuit. The temperature sensitive resistor (flow sensor) also included in the bridge. The

separation of heater and flow sensor facilitates design of the control circuitry. Saw cuts are employed to ensure thermal

decoupling between the heating element and the intake air temperature (IAT) sensor. The complete control circuitry is

located on a single layer. The voltage at the heater provides the index for the mass air flow. The MAF’s electronic

circuitry then converts the voltage to a level suitable for processing in the ECM. This device does not need a burn off

process to maintain its measuring precision over an extended period. In recognition of the fact that most deposits

collect on the sensor element’s leading edge, the essential thermal transfer elements are located downstream on the

ceramic layer. The sensor element is also design to ensure that depositswill not influence the flow pattern around the

sensor.

The IAT sensor uses a thermistor to control the signal voltage to the ECM. The ECM supplies 5 volt reference and a

ground to the sensor. When the air is cold, the resistance is high; therefore the IAT signal voltagewill be high. If the

intake air is warm, resistance is low; therefore the IAT signal voltagewill be low.

Page 481 of 2053

M161 ENGINE CONTROLS 1F2 -- 63

D AEW OO M Y_2000

Mass Air Flow Sensor Input Voltage Inspection

1. Turn the ignition switch to “ON” position.

2. Measure the signal voltage between the ECM pin No. 103 and No. 104.

Application

Specified Value

Ignition “ON”0.9 ~ 1.1 v

Engine StatusIdling1.3 ~ 1.7 v

(Coolant temperature is over 70°C)

Notice:If the measured value is not within the specified value, the possible cause may be in cable or MAF sensor in

itself. Perform the 5 volt power supply inspection procedures.

Mass Air Flow Sensor 5 volt Power Supply Inspection

1. Turn the ignition switch to “OFF” position.

2. Disconnect the HFM sensor connector.

3. Turn the ignition switch to “ON” position.

4. Measure the voltage between the ECM pin No. 108 and MAF sensor connecter terminal No. 3.

Specified Value

4.7~5.2v

Notice:If the measured value is not within the specified value, the possible cause may be in cable or ECM coupling.

5. Measure the voltage between the ECM pin No. 105 and MAF sensor connecter terminal No. 4.

Specified Value

4.7~5.2v

Notice:If the measured value is not within the specified value, the possible cause may be in cable or ECM coupling.

Mass Air Flow Sensor 12 volt Power Supply Inspection

1. Turn the ignition switch to “OFF” position.

2. Disconnect the HFM sensor connector.

3. Turn the ignition switch to “ON” position.

4. Measure the voltage between the ECM pin No. 105 and MAF sensor connecter terminal No. 2.

Specified Value

11 ~ 14 v

Notice:If the measured value is not within the specified value, the possible cause may be in cable or Over Voltage

Protection Relay (OVPR).

Page 482 of 2053

1F2 -- 64 M161 ENGINE CONTROLS

D AEW OO M Y_2000

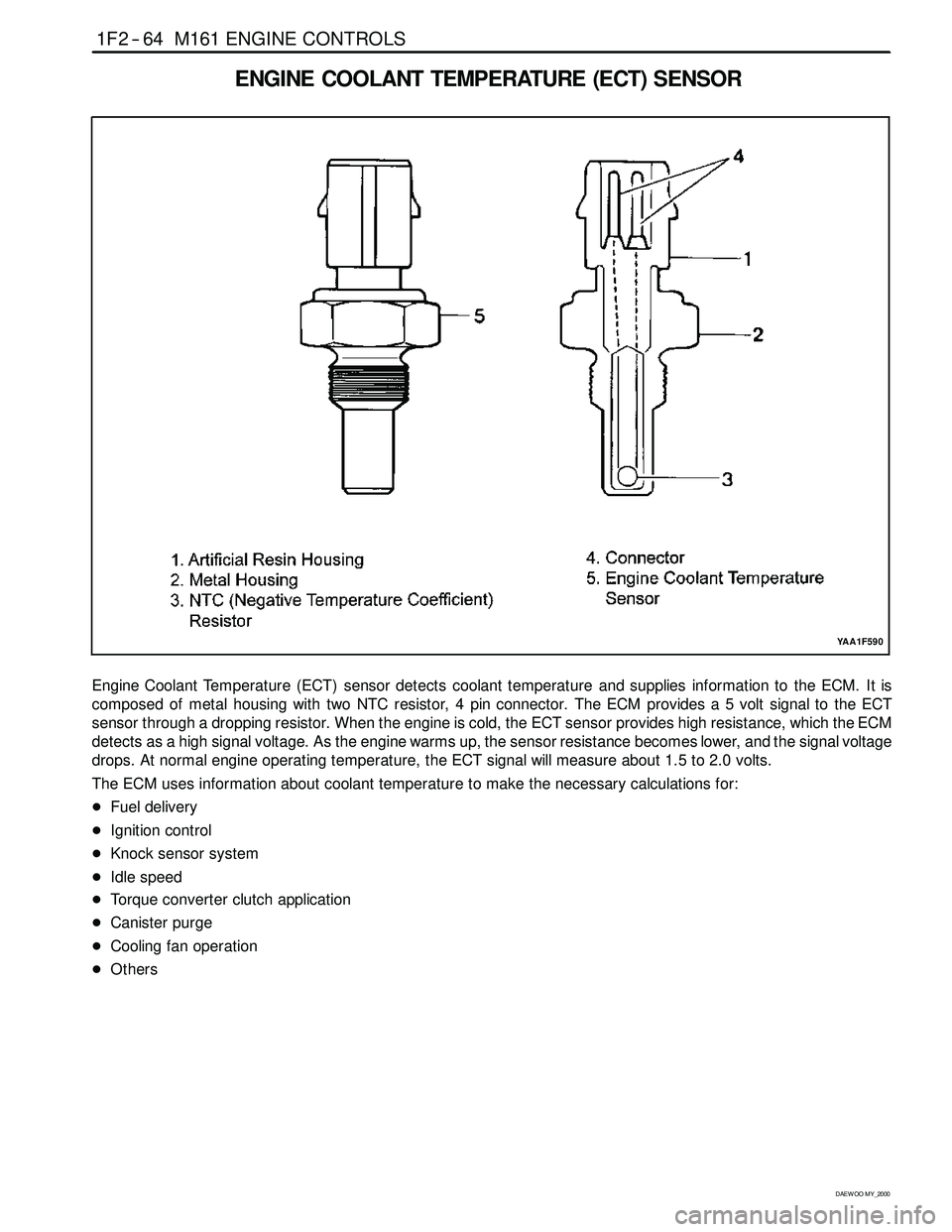

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

YAA1F590

Engine Coolant Temperature (ECT) sensor detects coolant temperature and supplies information to the ECM. It is

composed of metal housing with two NTC resistor, 4 pin connector. The ECM provides a 5 volt signal to the ECT

sensor through a dropping resistor. When the engine is cold, the ECT sensor provides high resistance, which the ECM

detects as a high signal voltage. As the engine warms up, the sensor resistance becomes lower, and the signal voltage

drops. At normal engine operating temperature, the ECT signalwill measure about 1.5 to 2.0 volts.

The ECM uses information about coolant temperature to make the necessary calculations for:

DFuel delivery

DIgnition control

DKnock sensor system

DIdle speed

DTorque converter clutch application

DCanister purge

DCooling fan operation

DOthers

Page 484 of 2053

1F2 -- 66 M161 ENGINE CONTROLS

D AEW OO M Y_2000

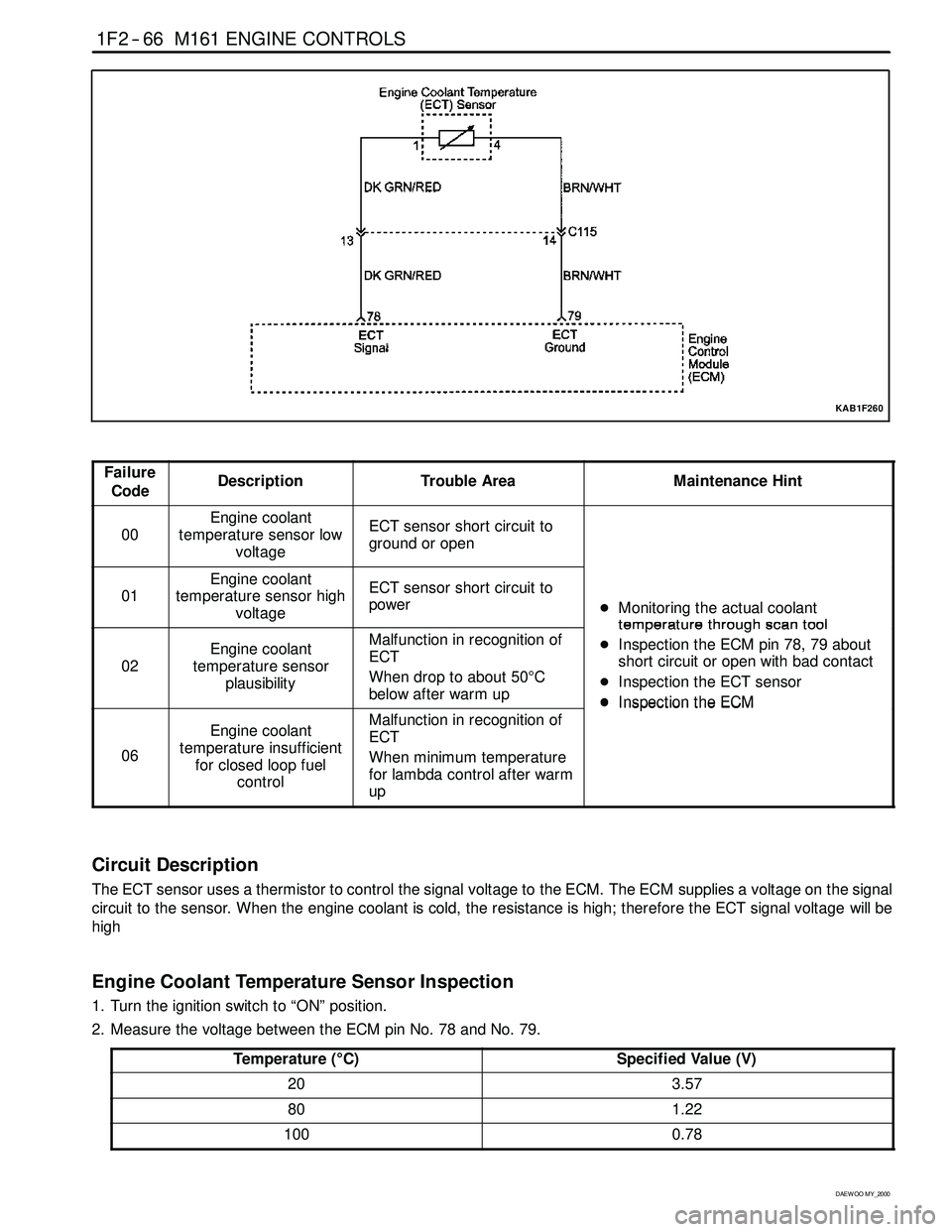

KAB1F260

Failure

CodeDescriptionTrouble AreaMaintenance Hint

00

Engine coolant

temperature sensor low

voltageECT sensor short circuit to

ground or open

01

Engine coolant

temperature sensor high

voltageECT sensor short circuit to

power

DMonitoring the actual coolant

temperaturethroughscantool

02

Engine coolant

temperature sensor

plausibilityMalfunction in recognition of

ECT

When drop to about 50°C

below after warm uptemperaturethroughscantool

DInspection the ECM pin 78, 79 about

short circuit or open with bad contact

DInspection the ECT sensor

DIns

pection the ECM

06

Engine coolant

temperature insufficient

for closed loop fuel

controlMalfunction in recognition of

ECT

When minimum temperature

for lambda control after warm

up

DInspectiontheECM

Circuit Description

The ECT sensor uses a thermistor to control the signal voltage to the ECM. The ECM supplies a voltage on the signal

circuit to the sensor. When the engine coolant is cold, the resistance is high; therefore the ECT signal voltagewill be

high

Engine Coolant Temperature Sensor Inspection

1. Turn the ignition switch to “ON” position.

2. Measure the voltage between the ECM pin No. 78 and No. 79.

Temperature (°C)

Specified Value (V)

203.57

801.22

1000.78