torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 369 of 2053

1B2 -- 76 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

17. Rivet the link pin.

Check the condition and it again if necessary.

18. Install the chain tensioner.

Installation Notice

Ti

ghteningScrew Plug40 NSm

(30 lb-ft)

Tightening

TorqueTensioner

Assembly72 -- 88 NSm

(53 -- 65 lb-ft)

19. Check the camshaft timing position.

Page 372 of 2053

M161 ENGINE MECHANICAL 1B2 -- 79

D AEW OO M Y_2000

Tools Required

111 589 03 15 00 Holding Pin

Removal & Installation Procedure

1. Position the number 1 cylinder to ATDC20°guide rail.

2. Install the holding pin 111 589 03 15 00 into the no.1

and no.6 bearing cap hole.

3. Remove the chain tensioner.

Installation Notice

Ti

ghteningScrew Plug40 NSm

(30 lb-ft)

Tightening

TorqueTensioner

Assembly72 -- 88 NSm

(53 -- 65 lb-ft)

4. Unscrew the bolt (1) and remove the guide rail.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

5. Installation should follow the removal procedure in

the reverse order.

Page 375 of 2053

1B2 -- 82 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

Tools Required

615 589 01 33 00 Crankshaft Sprocket Puller

Removal & Installation Procedure

1. Put the assembly mark at the crankshaft sprocket (4)

and the timing chain (10) with the paint (arrow).

Installation Notice

Align the assembly marks on crankshaft sprocket and

timing chain. Also, align the assembly marks on cam-

shaft sprocket and timing chain when installing.

2. Unscrew the bolt (6) and remove the oil pump sprock-

et (7) from the oil pump.

Installation Notice

Tightening Torque

29 -- 35 NSm (21 -- 26 lb-ft)

3. Remove the oil pump roller chain (9).

4. Remove the oil pump chain tensioner (1), oil pump

chain bushing (3), and the oil pump chain spring (2).

5. Remove the crankshaft sprocket (4) using crankshaft

sprocketpuller615589013300.

Notice:

DMake sure not to lose the crankshaft pulley key (5)

when removing.

DInstall the crankshaft sprocket (4) after warming it up.

6. Installation should follow the removal procedure in

the reverse order.

Page 378 of 2053

M161 ENGINE MECHANICAL 1B2 -- 85

D AEW OO M Y_2000

1. Check the piston ring gap and apply the engine oil to

the piston pin and the connecting rod bushing.

2. Connect the piston and the connecting rod by press-

ing in the piston pin (6) and install the snap ring to the

groove.

3. Clean the cylinder bore, connecting rod bearing jour-

nal, connecting rod bearing shell and the piston and

coat them with engine oil.

4. Install the piston ring.

5. Install the piston so that the arrow on the piston head

faces to the forward of the vehicle.

6. After aligning the connecting rod and the bearing cap

mark (// or a number), tighten the bolts.

Installation Notice

TighteningTorque1st step: 40 NSm (30 lb-ft)TighteningTorque2nd step: 90°

Apply the engine oil to the bearing cap upper and low-

er bearing shells.

7. Check if the crankshaft rotates without any trouble by

rotating it.

Page 380 of 2053

M161 ENGINE MECHANICAL 1B2 -- 87

D AEW OO M Y_2000

Inspection

1. Measure the basic bore of the connecting rod bear-

ing.

Notice:If the basic bore exceeds the value of

51.614mm, replace the bearing or check the connecting

rod.

2. Check connecting rod bolts.

Length When New (L)

51.7 -- 52 mm

Max. Length (L)52.9 mm

TighteningTo rque

1st step: 40 NSm

(30 lb-ft)

TighteningTorque

2nd step: 90°

Notice:If the length exceeds max. length, replace it.

3. Check the assembly mark (indication//or number:ar-

row) of the connecting rods and the bearing cap when

installing.

Notice

DMake sure it doesn’t exceed over 4g with other con-

necting rods when replacing the connecting rods.

DCheck if the connecting rod and the bearing cap are

accurately seated on the groove when replacing the

bearing.

Page 383 of 2053

1B2 -- 90 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

OIL PAN

1Bolt

2Bolt

3Bolt

4Bolt5Bolt

6OilPan

7 Gasket

Removal & Installation Procedure

1. Remove the drain plug and drain the oil completely.

2. Unscrew the bolts and remove the oil pan and gasket.

Notice:Arrange the bolts according to each size.

3. Clean the inside of oil pan and sealing surface, then

apply the sealant.

4. Replace the gasket with new one.

5. Install the oil pan with gasket, and tighten each bolt in

specified torque.

6. Check for oil leaks while running the engine.

Page 385 of 2053

M161 ENGINE MECHANICAL 1B2 -- 97

D AEW OO M Y_2000

OIL PRESSURE RELIEF VALVE

Preceding Work: Removal of oil pan

1 Screw Plug 50 NSm (37 lb-ft) ................

2 Compression Spring3 Guide Pin

4Piston

Removal & Installation Procedure

1. Remove the screw plug (1).

Installation Notice

Tightening Torque

50 NSm (37 lb-ft)

2. Remove the spring (2), guide pin (3) and the piston

(4).

3. Installation should follow the removal procedure in

the reverse order.

Notice:Don’t use the seal for the screw plug.

Page 387 of 2053

M161 ENGINE MECHANICAL 1B2 -- 99

D AEW OO M Y_2000

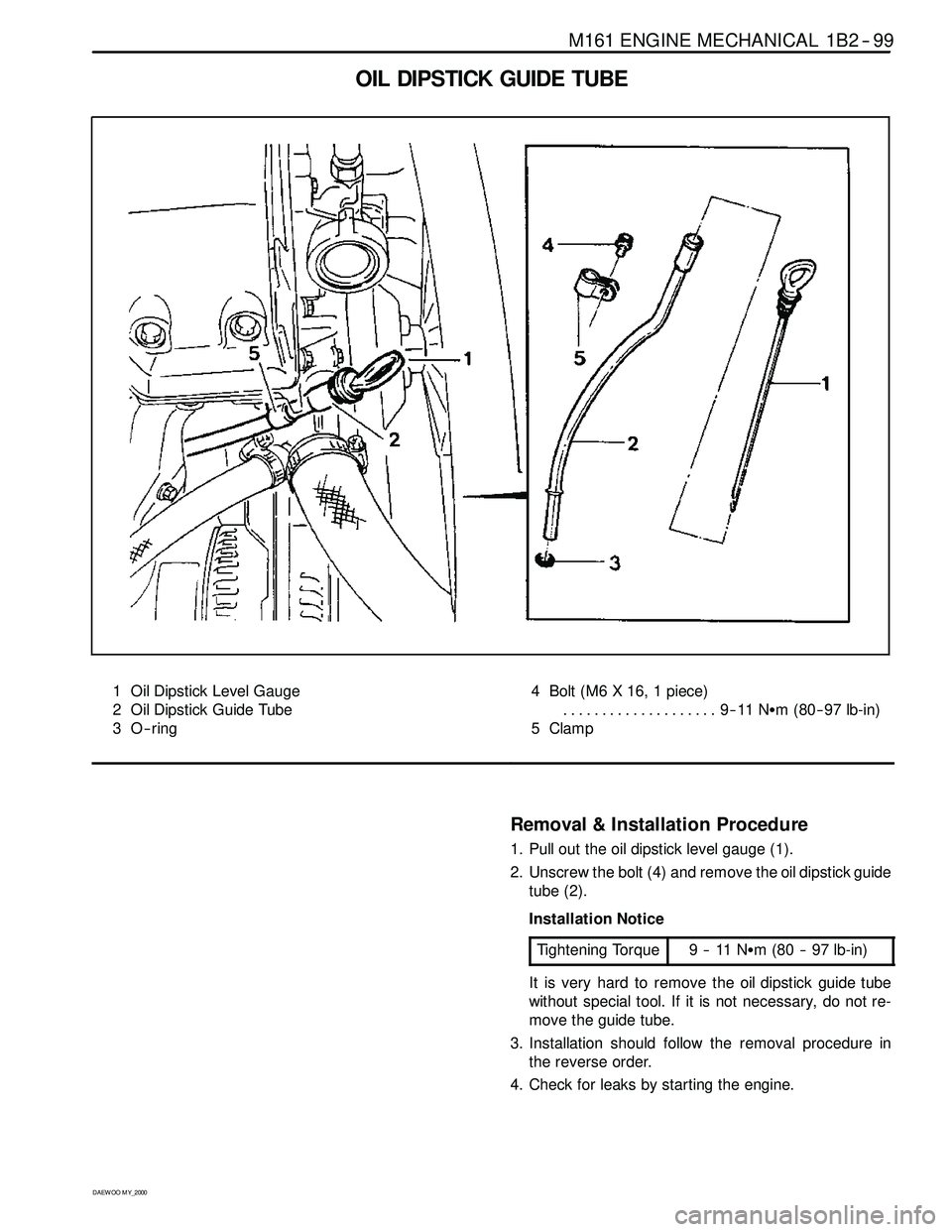

OIL DIPSTICK GUIDE TUBE

1 Oil Dipstick Level Gauge

2 Oil Dipstick Guide Tube

3O--ring4 Bolt (M6 X 16, 1 piece)

9--11 NSm (80-- 97 lb-in) ....................

5 Clamp

Removal & Installation Procedure

1. Pull out the oil dipstick level gauge (1).

2. Unscrew the bolt (4) and remove the oil dipstick guide

tube (2).

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

It is very hard to remove the oil dipstick guide tube

without special tool. If it is not necessary, do not re-

move the guide tube.

3. Installation should follow the removal procedure in

the reverse order.

4. Check for leaks by starting the engine.

Page 401 of 2053

1D2 -- 6 M161 ENGINE COOLING

D AEW OO M Y_2000

4. After complete draining of the coolant, remove the

hose connector to drain plug and reinstall the drain

plug.

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

5. Tighten the radiator lower drain cock.

6. Remove the de-- aeration hose clamp in the water

pump and remove the de-- aeration hose.

7. Fill up the coolant through the coolant reservoir

tank.

Notice

DMatchtheanti--freezeandthewaterratioto50:50.

DSupplement the coolant until the coolant overflows to

the deaeration hose.

8. Insert the de--aeration hose and completely tighten

the clamp.

9. Check the coolant level in the coolant reservoir tank.

10. Warm up(until thermostat is opened) the engine and

recheck the coolant level in the reservoir tank and fill

up the coolant if necessary.

Page 403 of 2053

1D2 -- 8 M161 ENGINE COOLING

D AEW OO M Y_2000

Tools Required

111 589 02 01 00 Open End Wrench

111 589 00 40 00 Open End Wrench

Removal & Installation Procedure

1. Install the holder (special tool : 111 589 00 40 00) to

the bolt at the pulley as shown in the right figure to

hold the pulley.

2. Remove the viscous clutch using an open end

wrench(specialtool:111589020100).

Installation Notice

Tightening Torque

40.5 -- 49.5 NSm

(29.8 -- 36.5 lb-ft)

Notice:The union nut is left threaded screw.

3. Remove the 3 bolts (1) from the viscous clutch and

remove the cooling fan and the viscous clutch.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Notice:You may change the procedure (2) and (3) if ne-

cessary.

4. Installation should follow the removal procedure in

the reverse order.