automatic SSANGYONG KORANDO 2012 Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 842 of 1082

02-8

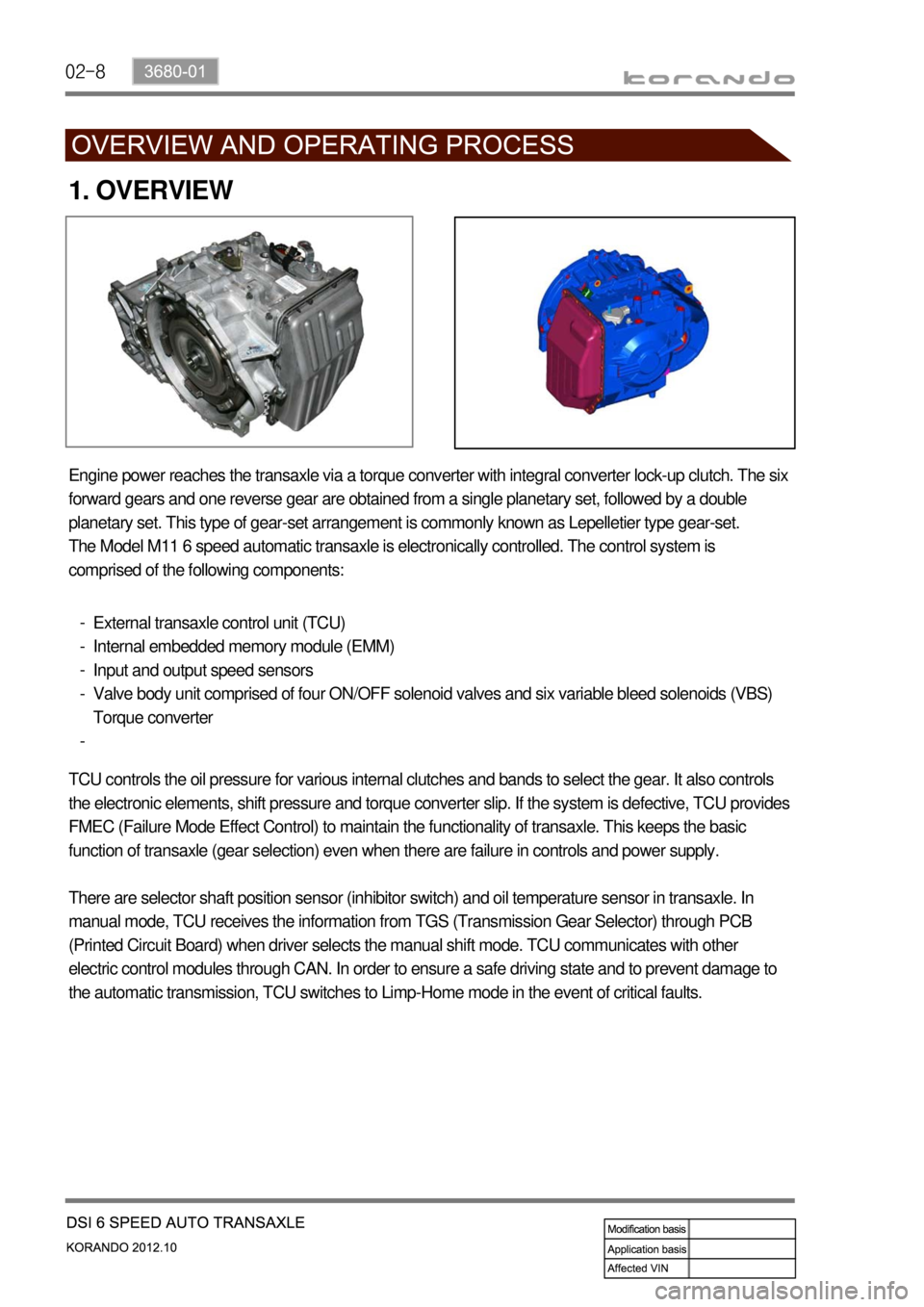

1. OVERVIEW

Engine power reaches the transaxle via a torque converter with integral converter lock-up clutch. The six

forward gears and one reverse gear are obtained from a single planetary set, followed by a double

planetary set. This type of gear-set arrangement is commonly known as Lepelletier type gear-set.

The Model M11 6 speed automatic transaxle is electronically controlled. The control system is

comprised of the following components:

External transaxle control unit (TCU)

Internal embedded memory module (EMM)

Input and output speed sensors

Valve body unit comprised of four ON/OFF solenoid valves and six variable bleed solenoids (VBS)

Torque converter -

-

-

-

-

TCU controls the oil pressure for various internal clutches and bands to select the gear. It also controls

the electronic elements, shift pressure and torque converter slip. If the system is defective, TCU provides

FMEC (Failure Mode Effect Control) to maintain the functionality of transaxle. This keeps the basic

function of transaxle (gear selection) even when there are failure in controls and power supply.

There are selector shaft position sensor (inhibitor switch) and oil temperature sensor in transaxle. In

manual mode, TCU receives the information from TGS (Transmission Gear Selector) through PCB

(Printed Circuit Board) when driver selects the manual shift mode. TCU communicates with other

electric control modules through CAN. In order to ensure a safe driving state and to prevent damage to

the automatic transmission, TCU switches to Limp-Home mode in the event of critical faults.

Page 844 of 1082

02-10

2) Transaxle Cooling

The transaxle cooling system ensures rapid warm-up and constant operating temperature resulting in

reduced fuel consumption and refined shift quality.

It also includes a cooler by-pass within the hydraulic system to allow sufficient lubrication to the transaxle

drivetrain in the event of a blockage in the transaxle cooler.

3) Shift Strategy

Gear Change ▶

Transaxle gear change is controlled by the

TCU. The TCU receives inputs from various

engine and vehicle sensors to select shift

schedules and to control the shift feel and

torque converter clutch (TCC) operation at each

gear change.

Coast down ▶

Coast down down shifts occur at 0% pedal

when the vehicle is coasting down to a stop.

Torque Demand ▶

Torque demand down shifts occur

(automatically) when the driver demand for

torque is greater than the engine can provide at

that gear ratio. If applied, the transaxle will

disengage the TCC to provide added

acceleration.

Page 846 of 1082

02-12

1st Gear State ▶

The 1st gear state will display on the

instrument cluster. Unlike the normal 1st gear,

engine braking will be available in this manual

1st state. -

2nd Gear State ▶

The 2nd gear state will display on the

instrument cluster. 2-1 automatic kick-down

shifts are available. 2nd gear has engine

braking available. -

3rd Gear State ▶

The 3rd gear state will display on the

instrument cluster. 3-2 and 3-1 automatic

kick-down shifts are available. 3rd gear has

engine braking available. -

4th Gear State ▶

The 4th gear state will display on the

instrument cluster. 4-3 and 4-2 automatic

kick-down shifts are available. 4th gear has

engine braking available. -

5th Gear State ▶

The 5th gear state will display on the

instrument cluster. 5-4 and 5-3 automatic

kick-down shift is available. 5th gear has

engine braking available. -

6th Gear State ▶

The 6th gear state will display on the

instrument cluster. 6-5 and 6-4 automatic

kick-down shifts are available. 6th gear has

engine braking available. -

STD type

SVC type

Page 847 of 1082

02-133680-01

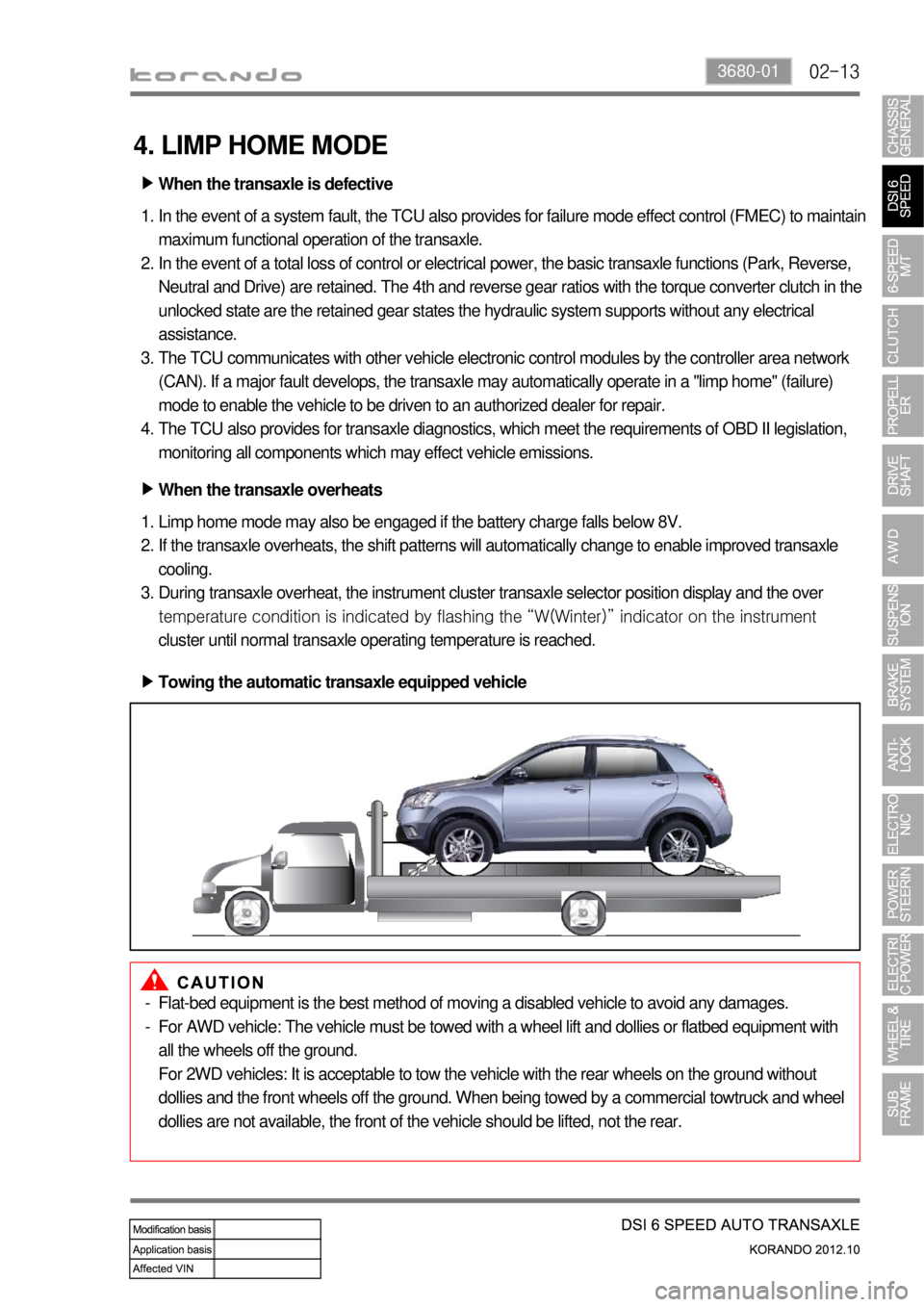

4. LIMP HOME MODE

When the transaxle is defective ▶

In the event of a system fault, the TCU also provides for failure mode effect control (FMEC) to maintain

maximum functional operation of the transaxle.

In the event of a total loss of control or electrical power, the basic transaxle functions (Park, Reverse,

Neutral and Drive) are retained. The 4th and reverse gear ratios with the torque converter clutch in the

unlocked state are the retained gear states the hydraulic system supports without any electrical

assistance.

The TCU communicates with other vehicle electronic control modules by the controller area network

(CAN). If a major fault develops, the transaxle may automatically operate in a "limp home" (failure)

mode to enable the vehicle to be driven to an authorized dealer for repair.

The TCU also provides for transaxle diagnostics, which meet the requirements of OBD II legislation,

monitoring all components which may effect vehicle emissions. 1.

2.

3.

4.

When the transaxle overheats ▶

Limp home mode may also be engaged if the battery charge falls below 8V.

If the transaxle overheats, the shift patterns will automatically change to enable improved transaxle

cooling.

During transaxle overheat, the instrument cluster transaxle selector position display and the over

<009b008c00940097008c00990088009b009c0099008c0047008a00960095008b0090009b00900096009500470090009a004700900095008b0090008a0088009b008c008b0047008900a00047008d00930088009a008f00900095008e0047009b008f008c00

4702c8007e004f007e00900095009b008c0099005002c90047>indicator on the instrument

cluster until normal transaxle operating temperature is reached. 1.

2.

3.

Towing the automatic transaxle equipped vehicle ▶

Flat-bed equipment is the best method of moving a disabled vehicle to avoid any damages.

For AWD vehicle: The vehicle must be towed with a wheel lift and dollies or flatbed equipment with

all the wheels off the ground.

For 2WD vehicles: It is acceptable to tow the vehicle with the rear wheels on the ground without

dollies and the front wheels off the ground. When being towed by a commercial towtruck and wheel

dollies are not available, the front of the vehicle should be lifted, not the rear. -

-

Page 850 of 1082

02-16

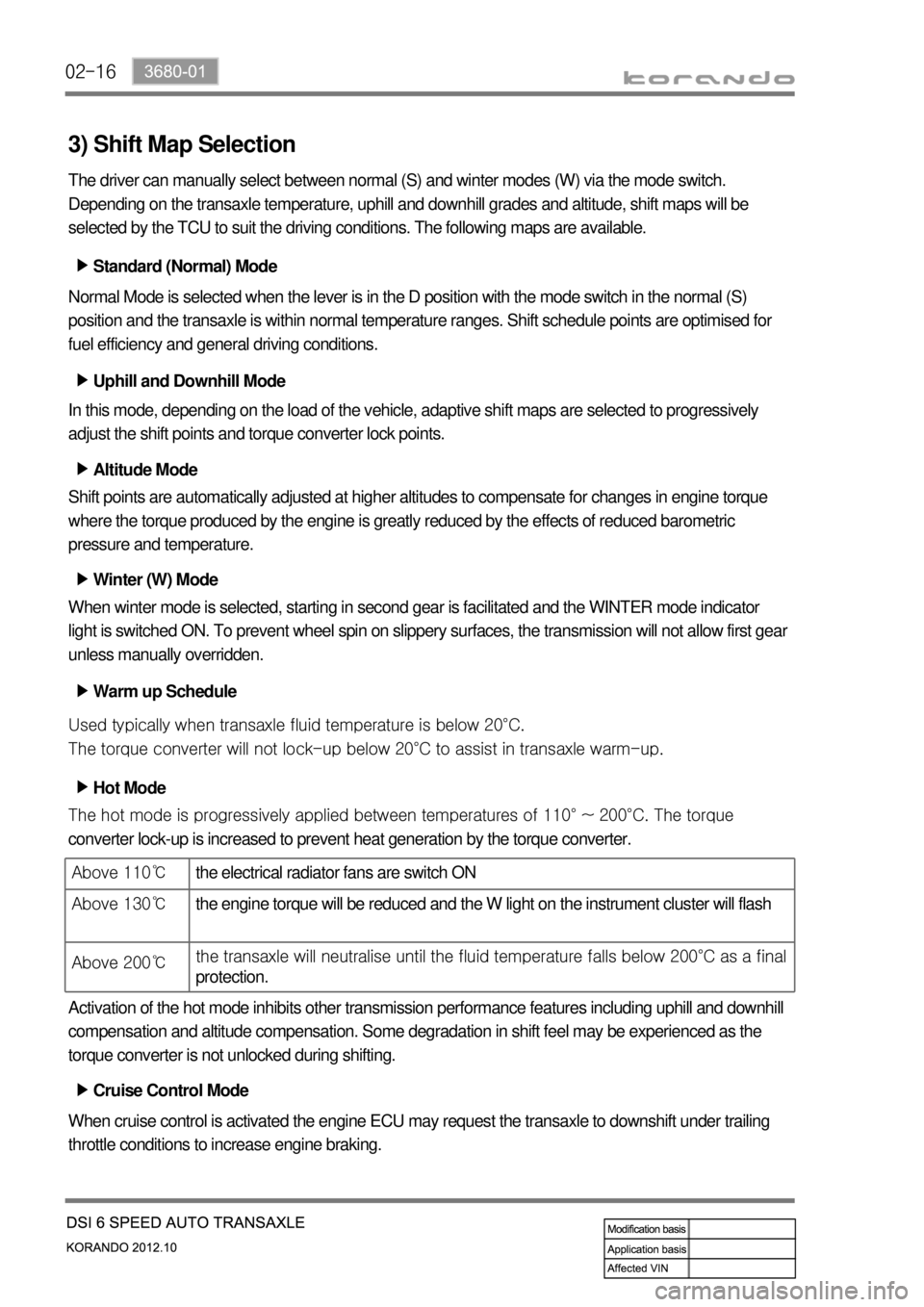

3) Shift Map Selection

The driver can manually select between normal (S) and winter modes (W) via the mode switch.

Depending on the transaxle temperature, uphill and downhill grades and altitude, shift maps will be

selected by the TCU to suit the driving conditions. The following maps are available.

Standard (Normal) Mode ▶

Normal Mode is selected when the lever is in the D position with the mode switch in the normal (S)

position and the transaxle is within normal temperature ranges. Shift schedule points are optimised for

fuel efficiency and general driving conditions.

Uphill and Downhill Mode ▶

In this mode, depending on the load of the vehicle, adaptive shift maps are selected to progressively

adjust the shift points and torque converter lock points.

Altitude Mode ▶

Shift points are automatically adjusted at higher altitudes to compensate for changes in engine torque

where the torque produced by the engine is greatly reduced by the effects of reduced barometric

pressure and temperature.

Winter (W) Mode ▶

When winter mode is selected, starting in second gear is facilitated and the WINTER mode indicator

light is switched ON. To prevent wheel spin on slippery surfaces, the transmission will not allow first gear

unless manually overridden.

Warm up Schedule ▶

<007c009a008c008b0047009b00a000970090008a00880093009300a00047009e008f008c00950047009b009900880095009a0088009f0093008c0047008d0093009c0090008b0047009b008c00940097008c00990088009b009c0099008c00470090009a00

470089008c00930096009e00470059005700b6006a0055>

The torque converter will not lock-up below 20°C to assist in transaxle warm-up.

Hot Mode ▶

<007b008f008c0047008f0096009b004700940096008b008c00470090009a0047009700990096008e0099008c009a009a0090009d008c009300a0004700880097009700930090008c008b00470089008c009b009e008c008c00950047009b008c0094009700

8c00990088009b009c0099008c009a00470096008d00470058>10° ~ 200°C. The torque

converter lock-up is increased to prevent heat generation by the torque converter.

Activation of the hot mode inhibits other transmission performance features including uphill and downhill

compensation and altitude compensation. Some degradation in shift feel may be experienced as the

torque converter is not unlocked during shifting.

Cruise Control Mode ▶

When cruise control is activated the engine ECU may request the transaxle to downshift under trailing

throttle conditions to increase engine braking.

Above 110℃the electrical radiator fans are switch ON

Above 130℃the engine torque will be reduced and the W light on the instrument cluster will flash

Above 200℃the transaxle will neutralise until the fluid tem

perature falls below 200°C as a final

protection.

Page 863 of 1082

03-33660-01

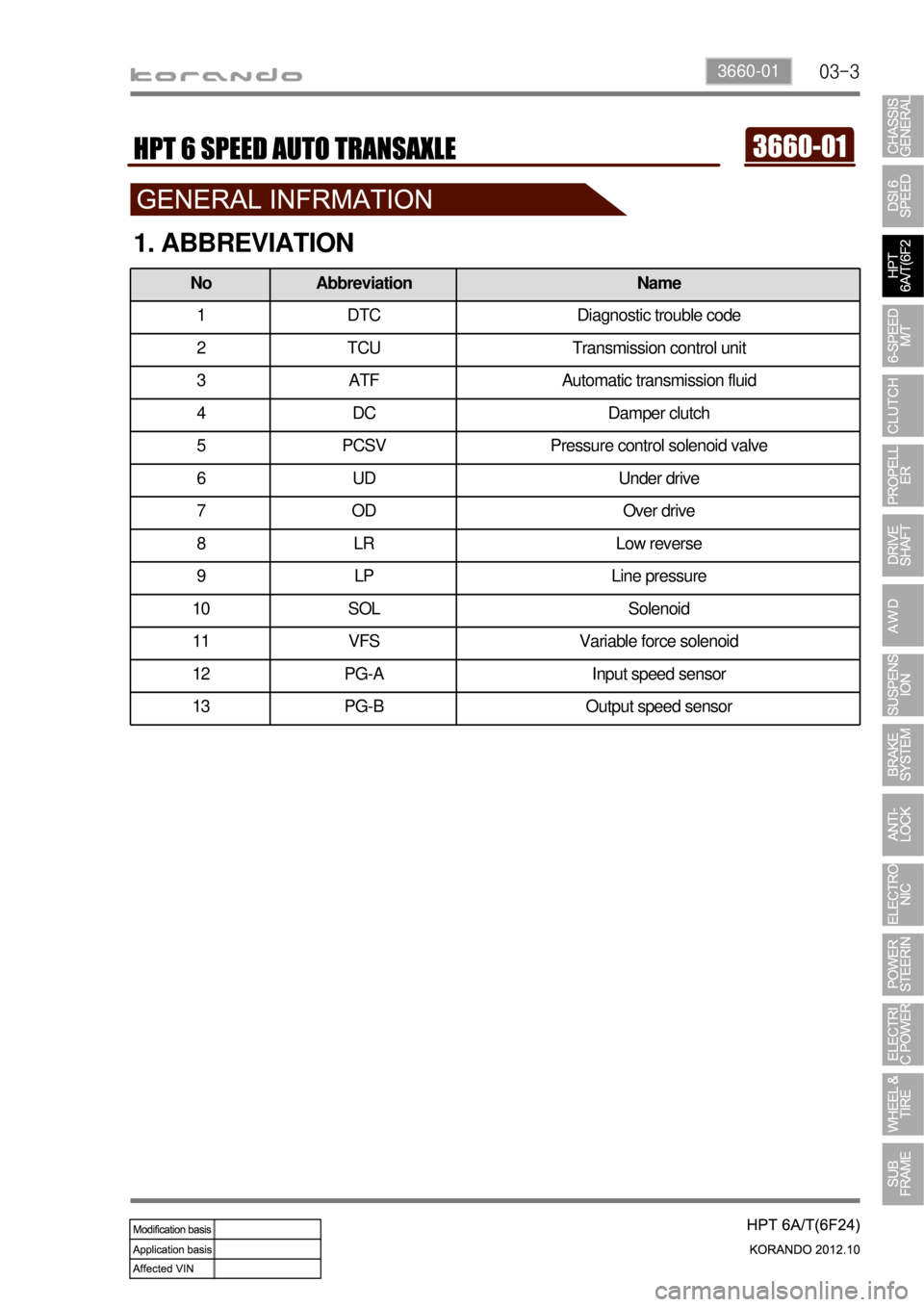

1. ABBREVIATION

No Abbreviation Name

1 DTC Diagnostic trouble code

2 TCU Transmission control unit

3 ATF Automatic transmission fluid

4 DC Damper clutch

5 PCSV Pressure control solenoid valve

6 UD Under drive

7OD Over drive

8 LR Low reverse

9 LP Line pressure

10 SOL Solenoid

11 VFS Variable force solenoid

12 PG-A Input speed sensor

13 PG-B Output speed sensor

Page 864 of 1082

03-4

2. GENERAL INFORMATION

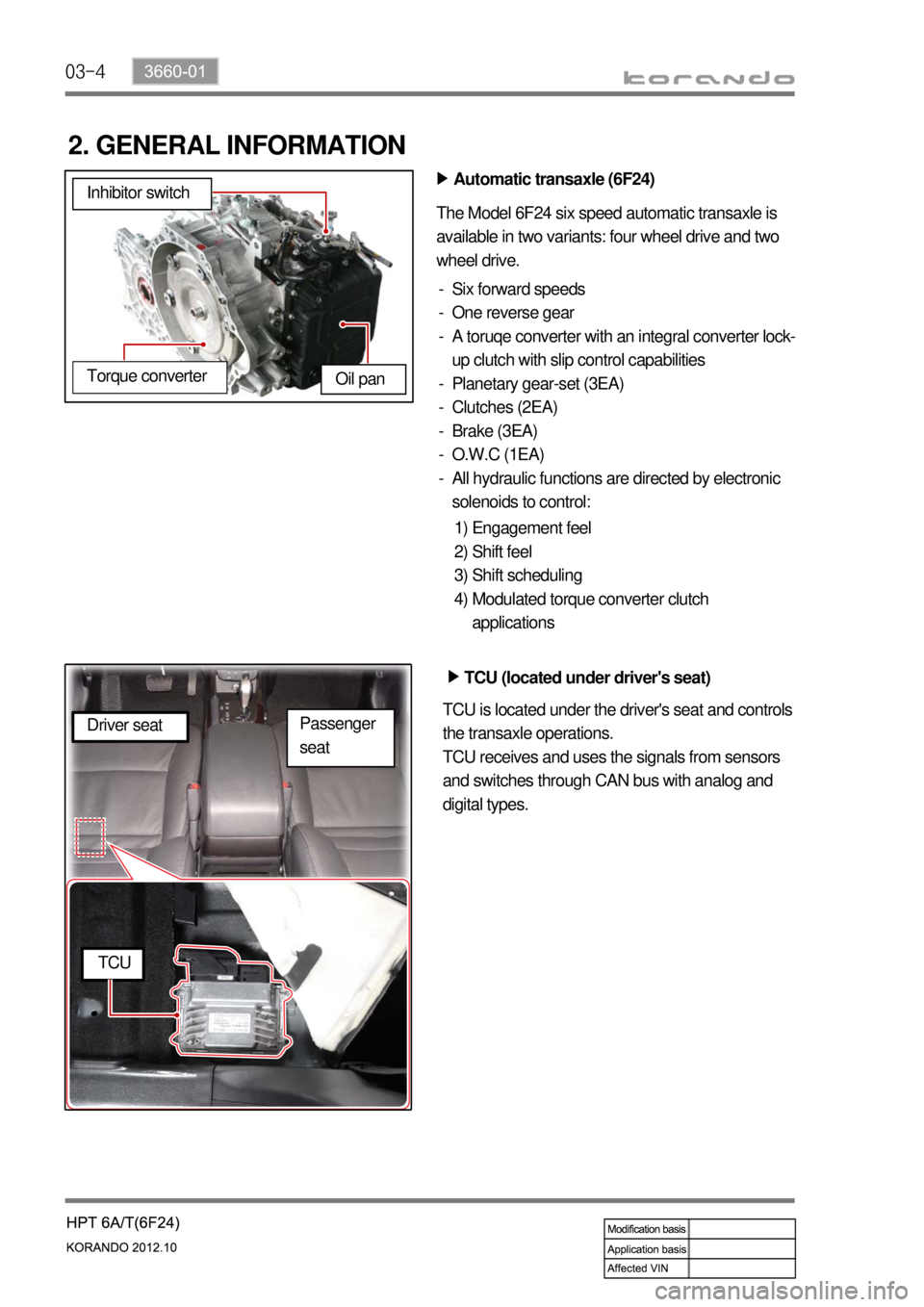

Automatic transaxle (6F24) ▶

The Model 6F24 six speed automatic transaxle is

available in two variants: four wheel drive and two

wheel drive.

Six forward speeds

One reverse gear

A toruqe converter with an integral converter lock-

up clutch with slip control capabilities

Planetary gear-set (3EA)

Clutches (2EA)

Brake (3EA)

O.W.C (1EA)

All hydraulic functions are directed by electronic

solenoids to control: -

-

-

-

-

-

-

-

Engagement feel

Shift feel

Shift scheduling

Modulated torque converter clutch

applications 1)

2)

3)

4) Inhibitor switch

Oil pan

Torque converter

TCU (located under driver's seat) ▶

TCU is located under the driver's seat and controls

the transaxle operations.

TCU receives and uses the signals from sensors

and switches through CAN bus with analog and

digital types. Driver seat

TCU

Passenger

seat

Page 865 of 1082

03-53660-01

The shiftable gear can be adjusted by pressing the

"UP (D+)" or "DOWN(D-)" switch when the gear

selector lever is in “M” position.

Shift lock release button

If the selector lever cannot be moved from

“P” or “N” position, try to move the lever

while pushing down this button with finger. For

safety, turn off the engine and depress the

brake pedal before the attempt.

Shift up Shift down Tip switches on steering wheel ▶

Meter cluster ▶

This indicator shows the current position of

the gear.

Gear selector lever ▶

Lever positions

P : Park

R : reverse

N : Neutral

D : DriveTip switch (manual shift switch)

The shiftable gear can be adjusted by

moving this switch to forward and rearward

when the gear selector lever is in “M”

position.

Selection of Manual/Automatic Shift Function

D: Automatic shift according to the driving condition

M: Manual shift

Page 866 of 1082

03-6

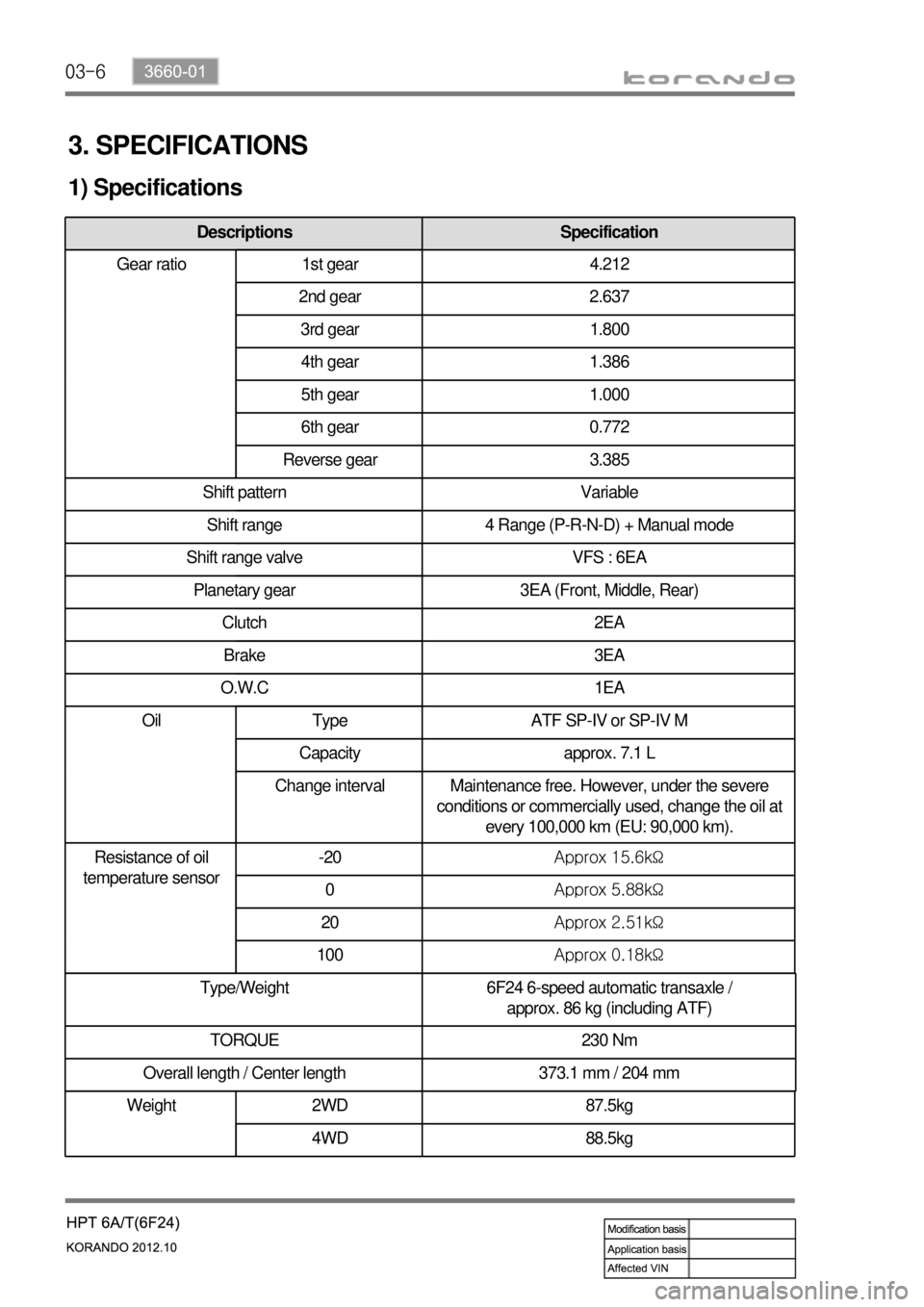

3. SPECIFICATIONS

1) Specifications

Type/Weight 6F24 6-speed automatic transaxle /

approx. 86 kg (including ATF)

TORQUE 230 Nm

Overall length / Center length 373.1 mm / 204 mm

Descriptions Specification

Gear ratio 1st gear 4.212

2nd gear 2.637

3rd gear 1.800

4th gear 1.386

5th gear 1.000

6th gear 0.772

Reverse gear 3.385

Shift pattern Variable

Shift range 4 Range (P-R-N-D) + Manual mode

Shift range valve VFS : 6EA

Planetary gear 3EA (Front, Middle, Rear)

Clutch 2EA

Brake 3EA

O.W.C 1EA

Oil Type ATF SP-IV or SP-IV M

Capacity approx. 7.1 L

Change interval Maintenance free. However, under the severe

conditions or commercially used, change the oil at

every 100,000 km (EU: 90,000 km).

Resistance of oil

temperature sensor-20Approx 15.6kΩ

0Approx 5.88kΩ

20Approx 2.51kΩ

100Approx 0.18kΩ

Weight 2WD 87.5kg

4WD 88.5kg

Page 868 of 1082

03-8

Automatic transaxle Bolt (engine) 17 mm X 4

14 mm X 1 85.0 ~ 100.0Nm

Bolt (start motor) 14 mm X 2 48.0 ~ 58.8Nm

Bolt (oil pan) 14 mm X 4 56.0 ~ 62.0Nm

Bolt (torque converter) 17 mm X 6 45.0 ~ 52.0Nm

Eye bolt 22 mm X 1 3.0 ~ 5.0Nm

Drain plug 24 mm X 1 34.0 ~ 44.0Nm

Nut (range select lever) 14 mm X 1 17.6 ~ 24.5Nm

Bolt (inhibitor switch) 10 mm X 2 9.8 ~ 11.7Nm

Bolt (oil pan) 10 mm X 19 12.0 ~ 14.0Nm

Bolt (solenoid harness) 10 mm X 6 9.8 ~ 11.7Nm

Bolt (oil temperature sensor) 10 mm X 1 9.8 ~ 11.7Nm

Bolt (input & output sensor) 10 mm X 2 9.8 ~ 11.7Nm

Bolt (detent spring) 12 mm X 1 12.0 ~ 16.0Nm

Bolt (valve body) 10 mm X 8 9.8 ~ 11.7Nm

Bolt (V/B solenoid bracket) H5 mm X 9 9.8 ~ 11.7Nm

Bolt (torque converter housing) 12 mm X 20 28.0 ~ 35.0Nm

Bolt (oil guide A) 10 mm X 3 9.8 ~ 11.7Nm

Bolt (oil guide B) 10 mm X 1 5.0 ~ 7.0Nm

Bolt (oil filter) H5 mm X 2 9.8 ~ 11.7Nm

5. TIGHTENING TORQUE

DescriptionsSize x

NumbersTightening torque

(Nm)

TGS lever Nut 12 mm X 4 17.6 ~ 21.6Nm

Nut (manual control lever) 13 mm X 1 14.0 ~ 20.0Nm

Nut (floor) 12 mm X 1 17.6 ~ 21.6Nm

Nut (dash panel) 12 mm X 2 17.6 ~ 21.6Nm

A/T bracket Bolt (left bracket) 17 mm X 3 88.2 ~ 107.8Nm

Bolt (right bracket) 17 mm X 4 88.2 ~ 107.8Nm

Bolt (upper bracket) 17 mm X 4 88.2 ~ 107.8Nm

TGS lever

TGS cable