SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: fuel type, power steering fluid, lights, fuse box diagram, jump start, height adjustment, sensor

Page 1291 of 1463

MANUAL & SEMIAUTO-HVAC 7B/C-17

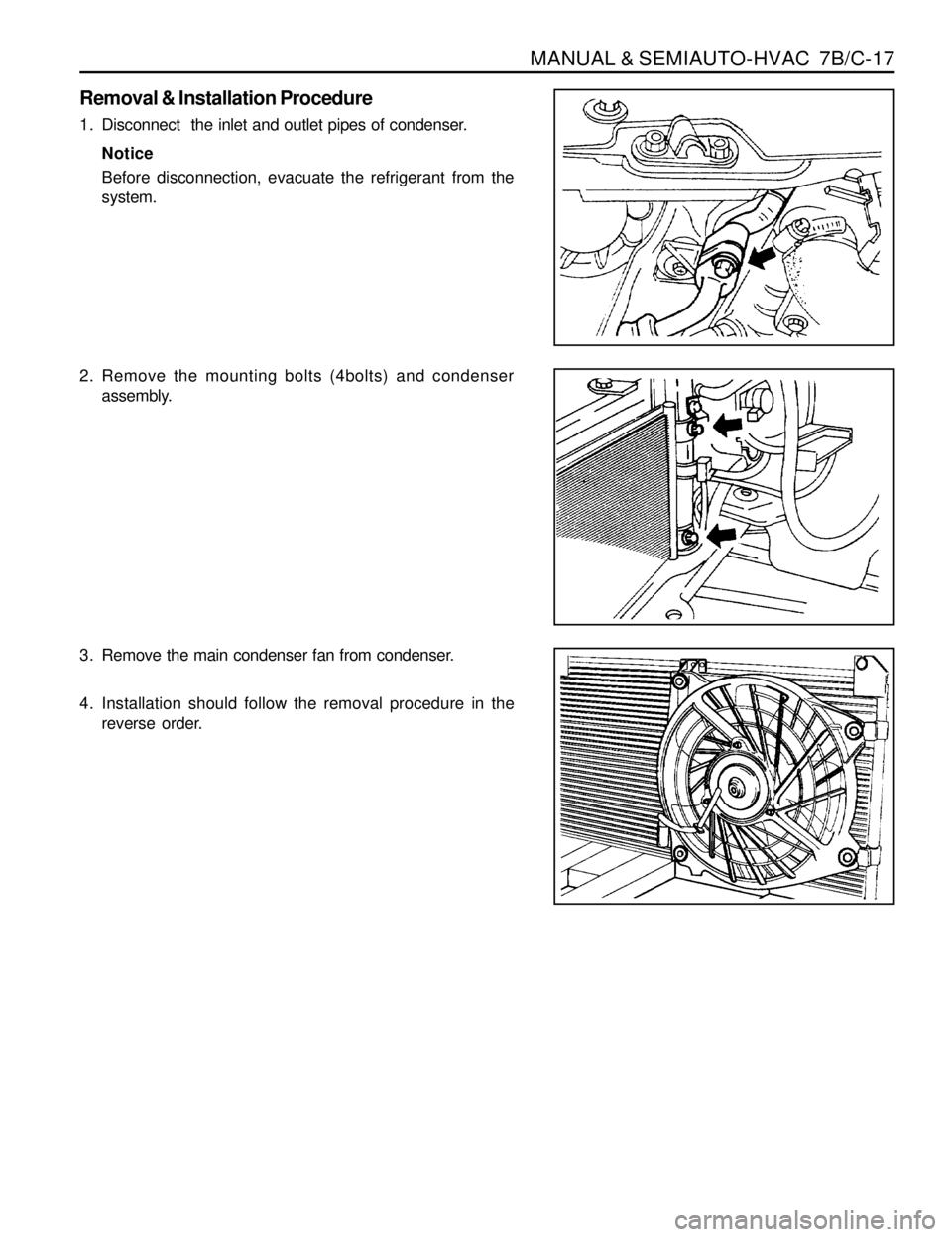

Removal & Installation Procedure

1. Disconnect the inlet and outlet pipes of condenser.

Notice

Before disconnection, evacuate the refrigerant from the

system.

2. Remove the mounting bolts (4bolts) and condenser

assembly.

3. Remove the main condenser fan from condenser.

4. Installation should follow the removal procedure in the

reverse order.

Page 1292 of 1463

7B/C-18 MANUAL & SEMIAUTO-HVAC

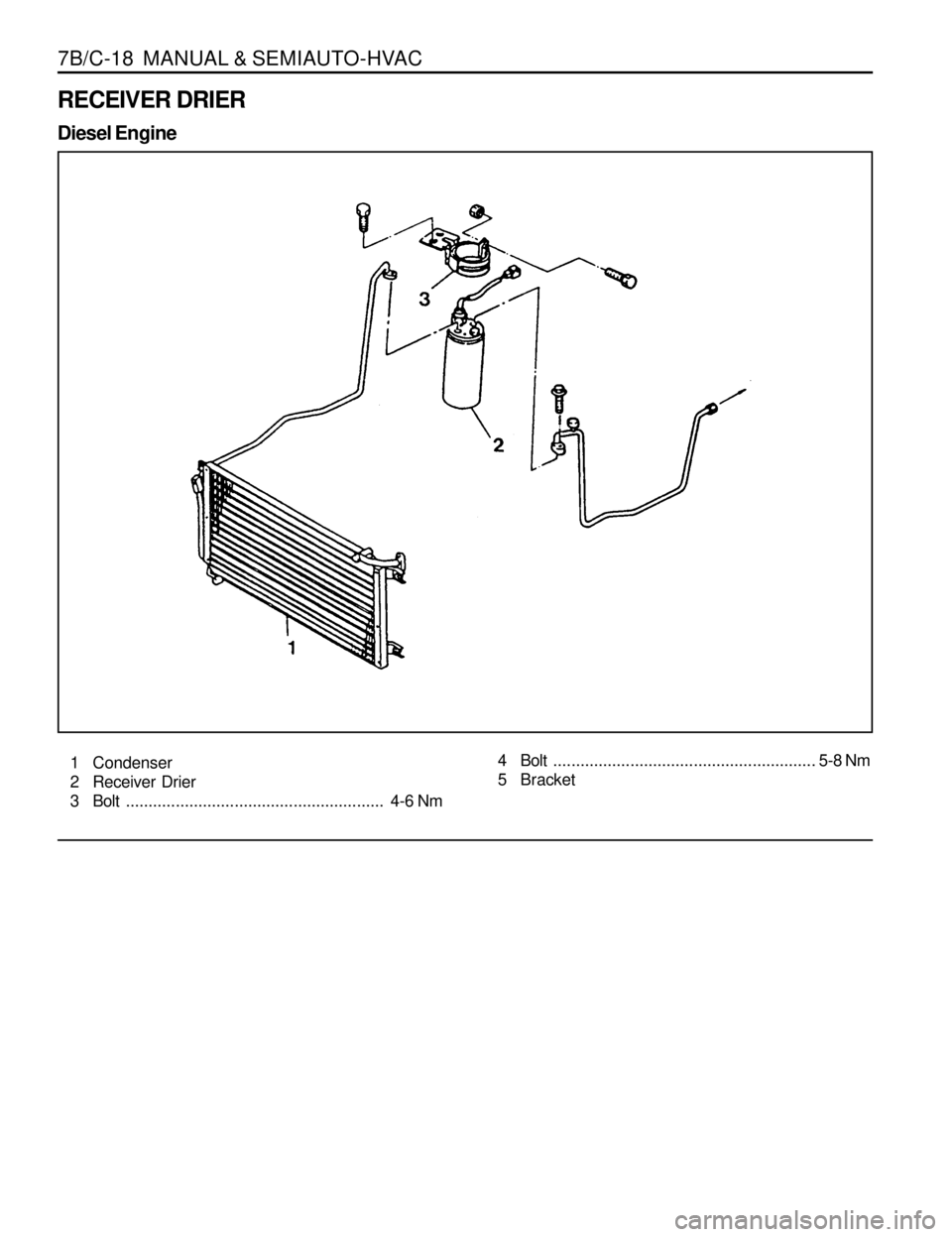

RECEIVER DRIER

Diesel Engine

1 Condenser

2 Receiver Drier

3 Bolt......................................................... 4-6 Nm4 Bolt..........................................................5-8 Nm

5 Bracket

Page 1293 of 1463

MANUAL & SEMIAUTO-HVAC 7B/C-19

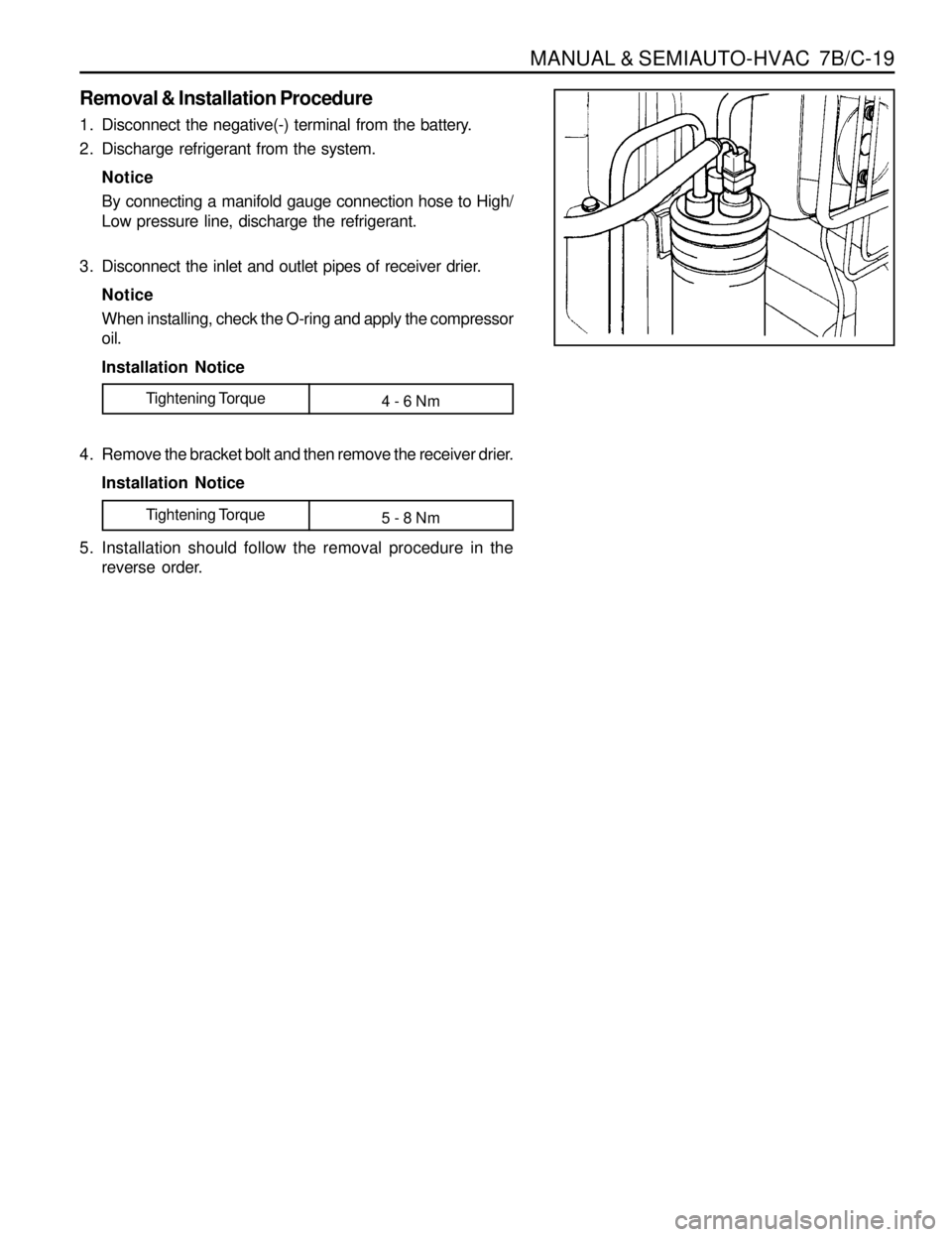

Removal & Installation Procedure

1. Disconnect the negative(-) terminal from the battery.

2. Discharge refrigerant from the system.

Notice

By connecting a manifold gauge connection hose to High/

Low pressure line, discharge the refrigerant.

3. Disconnect the inlet and outlet pipes of receiver drier.

Notice

When installing, check the O-ring and apply the compressor

oil.

Installation Notice

4. Remove the bracket bolt and then remove the receiver drier.

Installation Notice

Tightening Torque

4 - 6 Nm

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque

5 - 8 Nm

Page 1294 of 1463

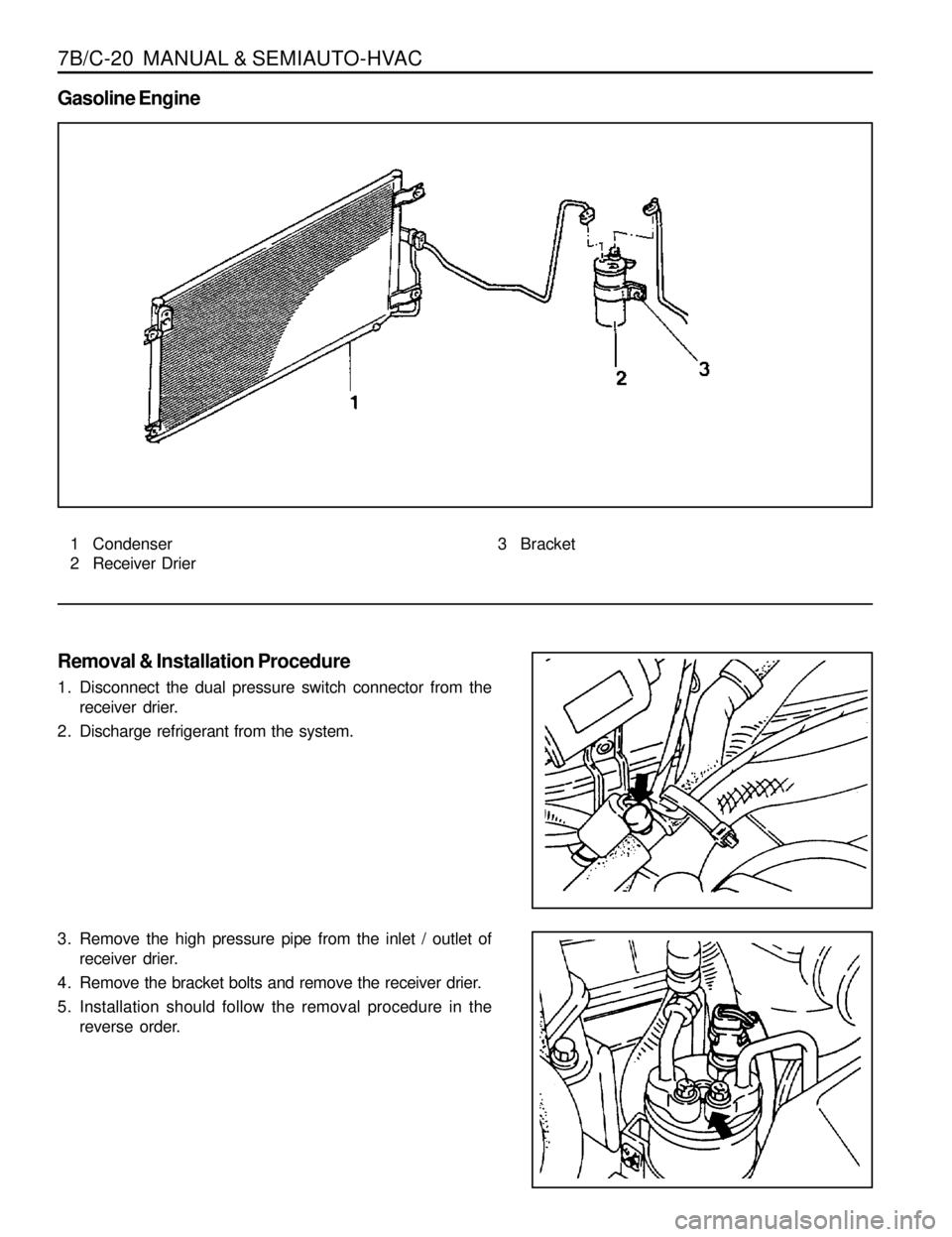

7B/C-20 MANUAL & SEMIAUTO-HVAC

1 Condenser

2 Receiver Drier3 Bracket

Removal & Installation Procedure

1. Disconnect the dual pressure switch connector from the

receiver drier.

2. Discharge refrigerant from the system.

3. Remove the high pressure pipe from the inlet / outlet of

receiver drier.

4. Remove the bracket bolts and remove the receiver drier.

5. Installation should follow the removal procedure in the

reverse order.

Gasoline Engine

Page 1295 of 1463

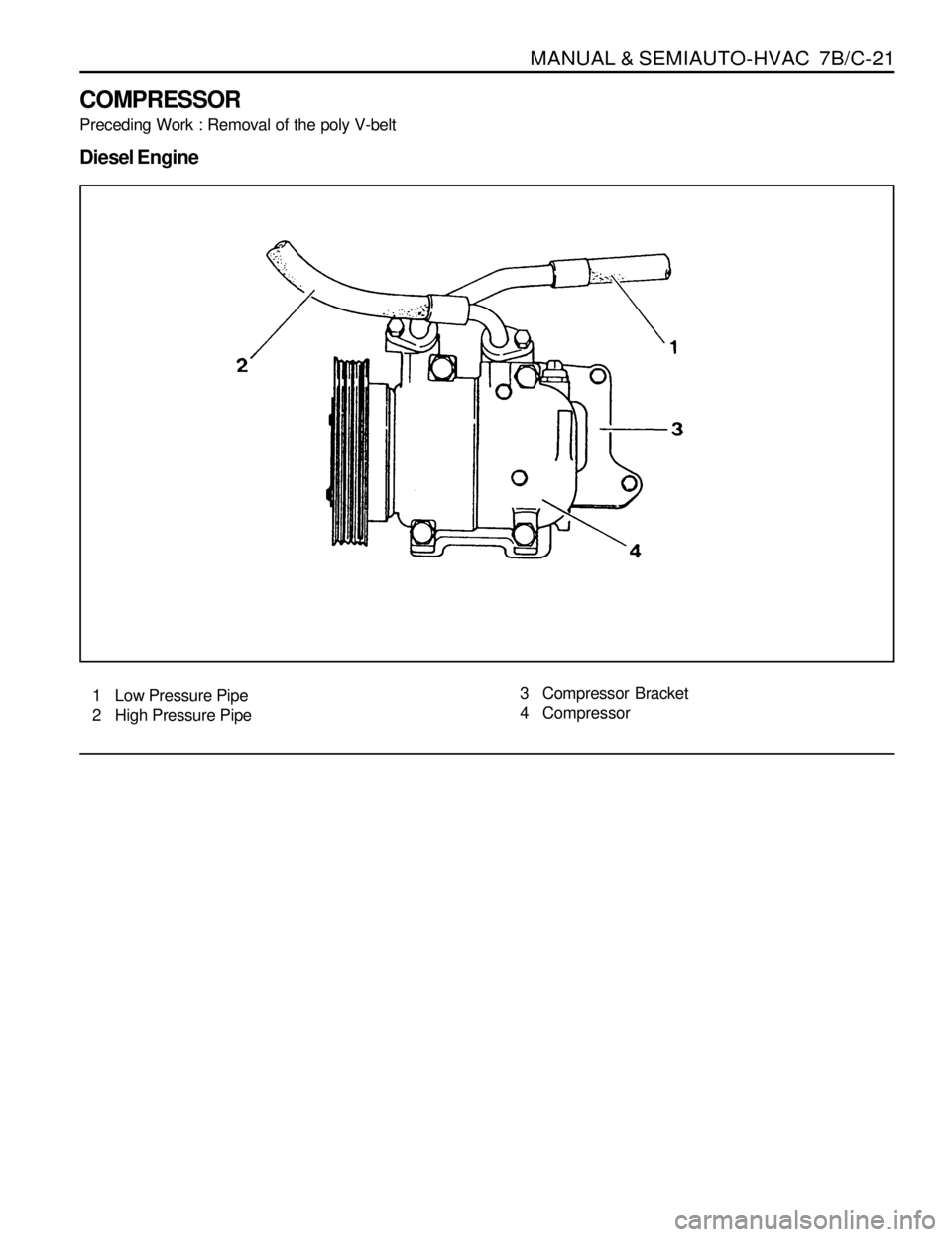

MANUAL & SEMIAUTO-HVAC 7B/C-21

COMPRESSOR

Preceding Work : Removal of the poly V-belt

Diesel Engine

1 Low Pressure Pipe

2 High Pressure Pipe3 Compressor Bracket

4 Compressor

Page 1296 of 1463

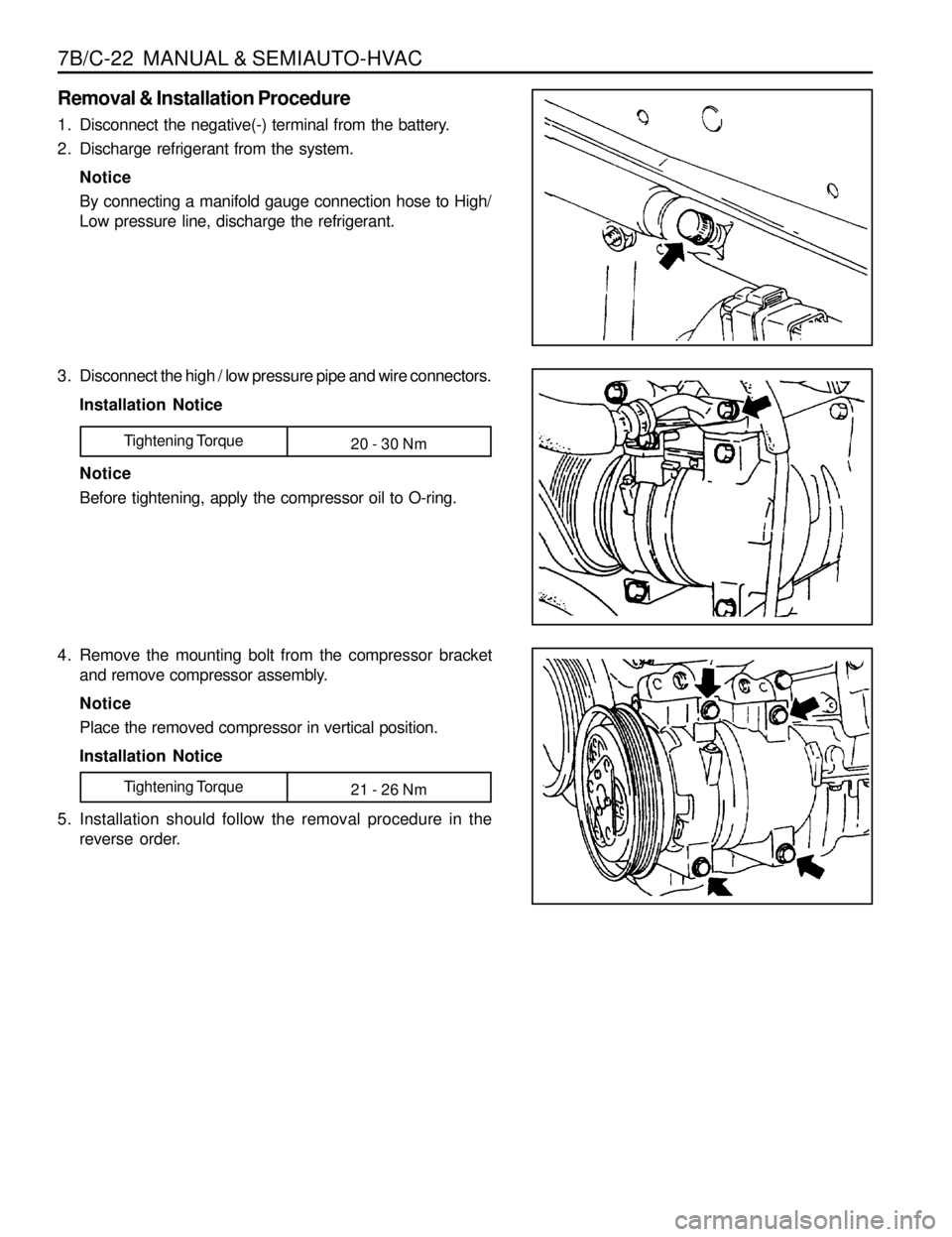

7B/C-22 MANUAL & SEMIAUTO-HVAC

Removal & Installation Procedure

1. Disconnect the negative(-) terminal from the battery.

2. Discharge refrigerant from the system.

Notice

By connecting a manifold gauge connection hose to High/

Low pressure line, discharge the refrigerant.

3. Disconnect the high / low pressure pipe and wire connectors.

Installation Notice

Notice

Before tightening, apply the compressor oil to O-ring.

Tightening Torque

20 - 30 Nm

4. Remove the mounting bolt from the compressor bracket

and remove compressor assembly.

Notice

Place the removed compressor in vertical position.

Installation Notice

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque

21 - 26 Nm

Page 1297 of 1463

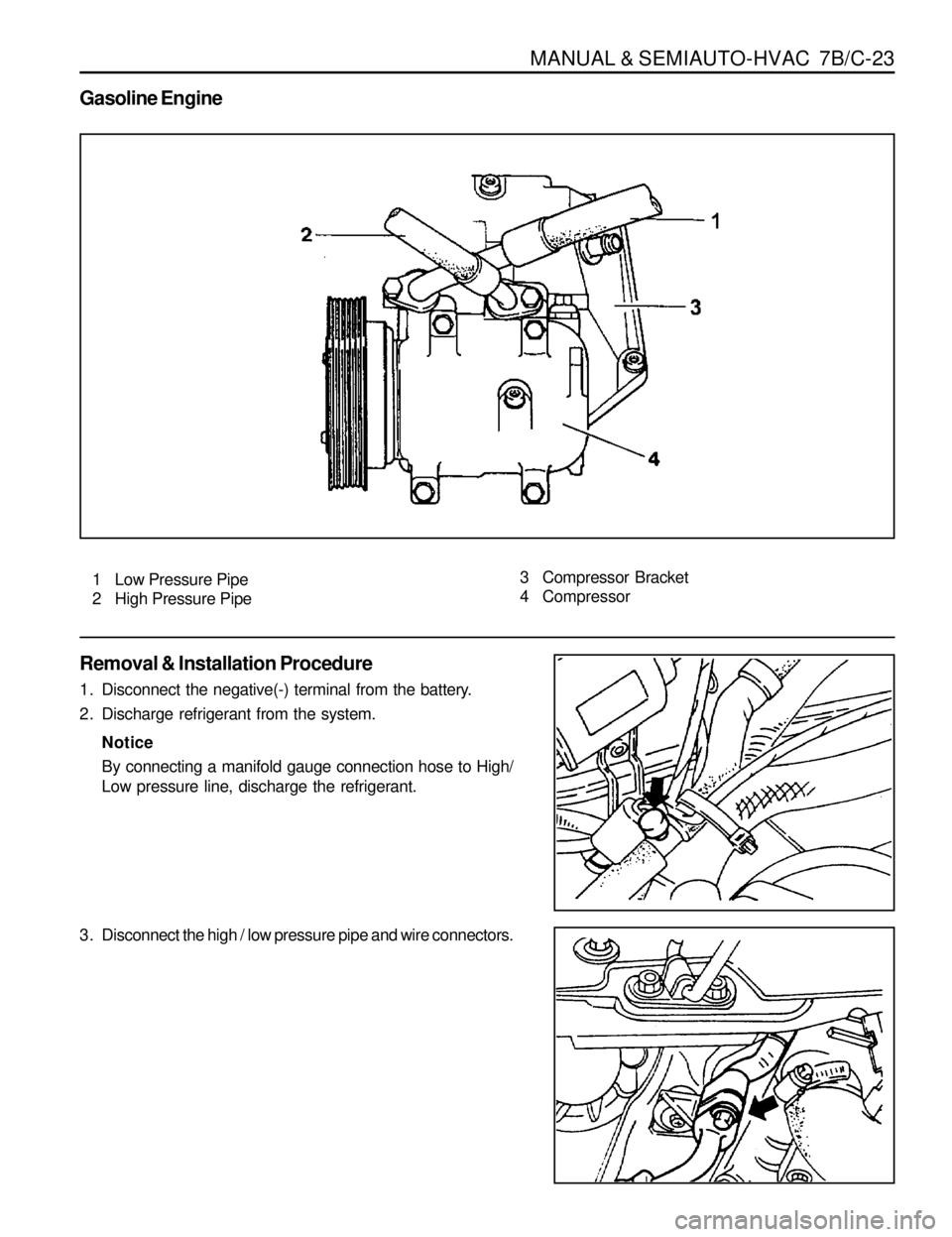

MANUAL & SEMIAUTO-HVAC 7B/C-23

Gasoline Engine

1 Low Pressure Pipe

2 High Pressure Pipe3 Compressor Bracket

4 Compressor

Removal & Installation Procedure

1. Disconnect the negative(-) terminal from the battery.

2. Discharge refrigerant from the system.

Notice

By connecting a manifold gauge connection hose to High/

Low pressure line, discharge the refrigerant.

3. Disconnect the high / low pressure pipe and wire connectors.

Page 1298 of 1463

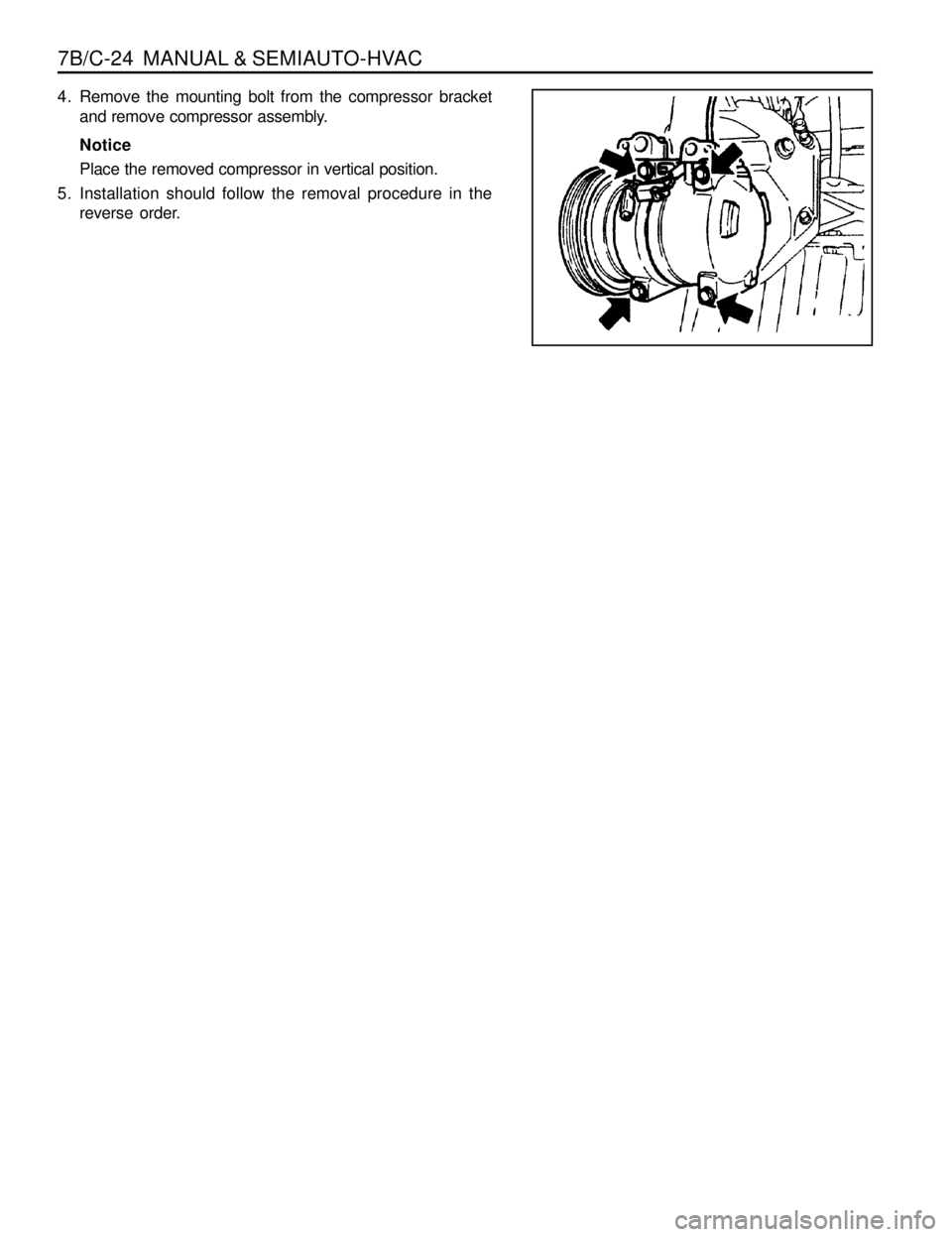

7B/C-24 MANUAL & SEMIAUTO-HVAC

4. Remove the mounting bolt from the compressor bracket

and remove compressor assembly.

Notice

Place the removed compressor in vertical position.

5. Installation should follow the removal procedure in the

reverse order.

Page 1299 of 1463

MANUAL & SEMIAUTO-HVAC 7B/C-25

HEATER AND AIR CONDITIONER CONTROL BOX

1 Blower Switch

2 Recirculation Switch

3 Mode Switch4 A/C Switch

5 Temperature Control Lever

6 In-vehicle Sensor

MANUAL

SATC

Page 1300 of 1463

7B/C-26 MANUAL & SEMIAUTO-HVAC

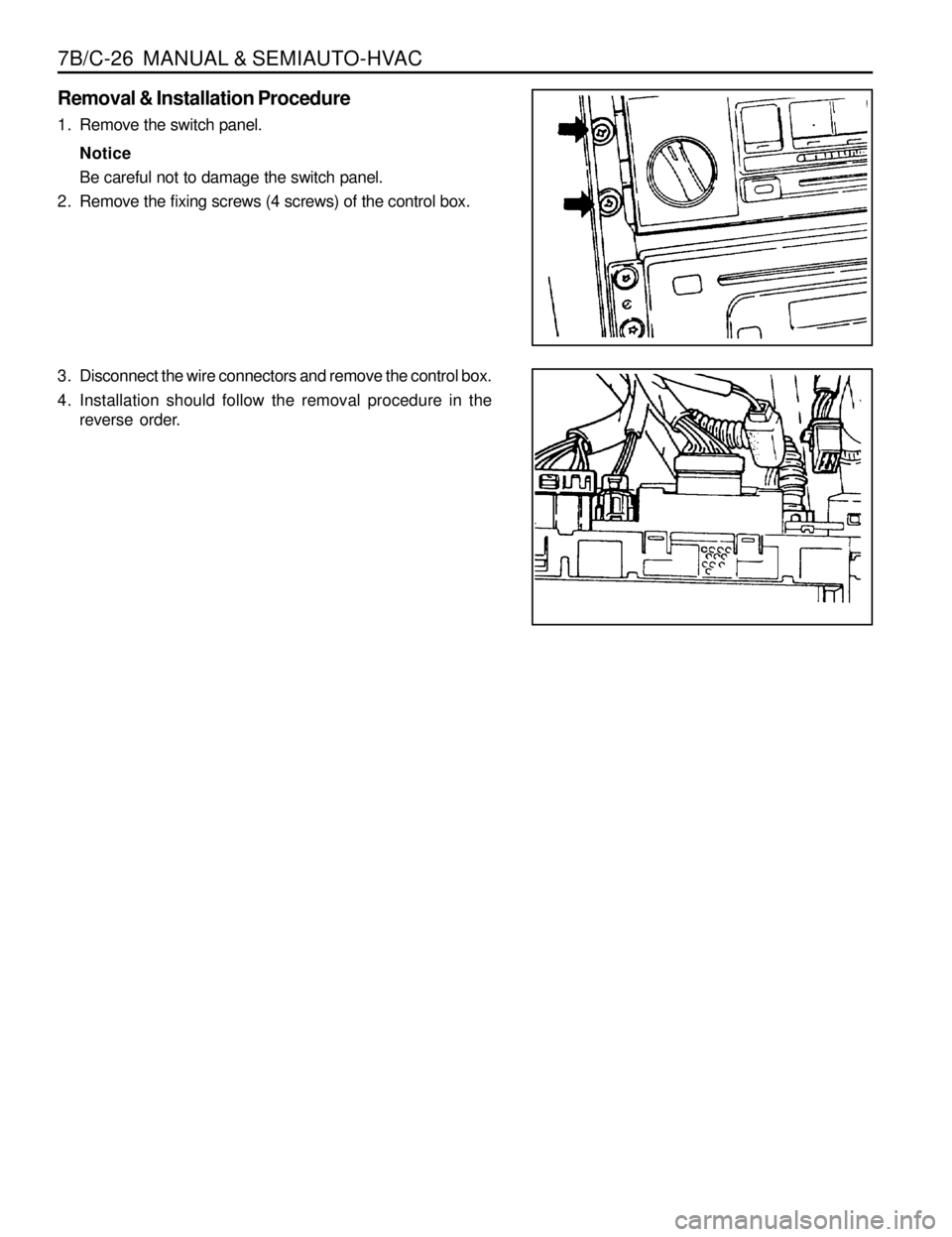

Removal & Installation Procedure

1. Remove the switch panel.

Notice

Be careful not to damage the switch panel.

2. Remove the fixing screws (4 screws) of the control box.

3. Disconnect the wire connectors and remove the control box.

4. Installation should follow the removal procedure in the

reverse order.

Trending: compression ratio, traction control, cruise control, seat memory, brake light, brake pads replacement, open hood