SSANGYONG MUSSO 1998 Workshop Repair Manual

Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1301 of 1463

SECTION 8A

SEAT BELTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 8A-1

Fastener Tightening Specifications . . . . . . . . . 8A-1

Component Locator . . . . . . . . . . . . . . . . . . . 8A-2

Front Seat Belt . . . . . . . . . . . . . . . . . . . . . . . . 8A-2

Rear Seat Belt . . . . . . . . . . . . . . . . . . . . . . . . 8A-3

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

General Description and System

Operation . . . . . . . . . . . . . . . . . . . . . . . . . 8A-4

Driver Seat Belt Warning . . . . . . . . . . . . . . . . 8A-4

Operation and Functional Checks . . . . . . . . . 8A-4

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Anchor BoltNlm

35 - 55

Page 1302 of 1463

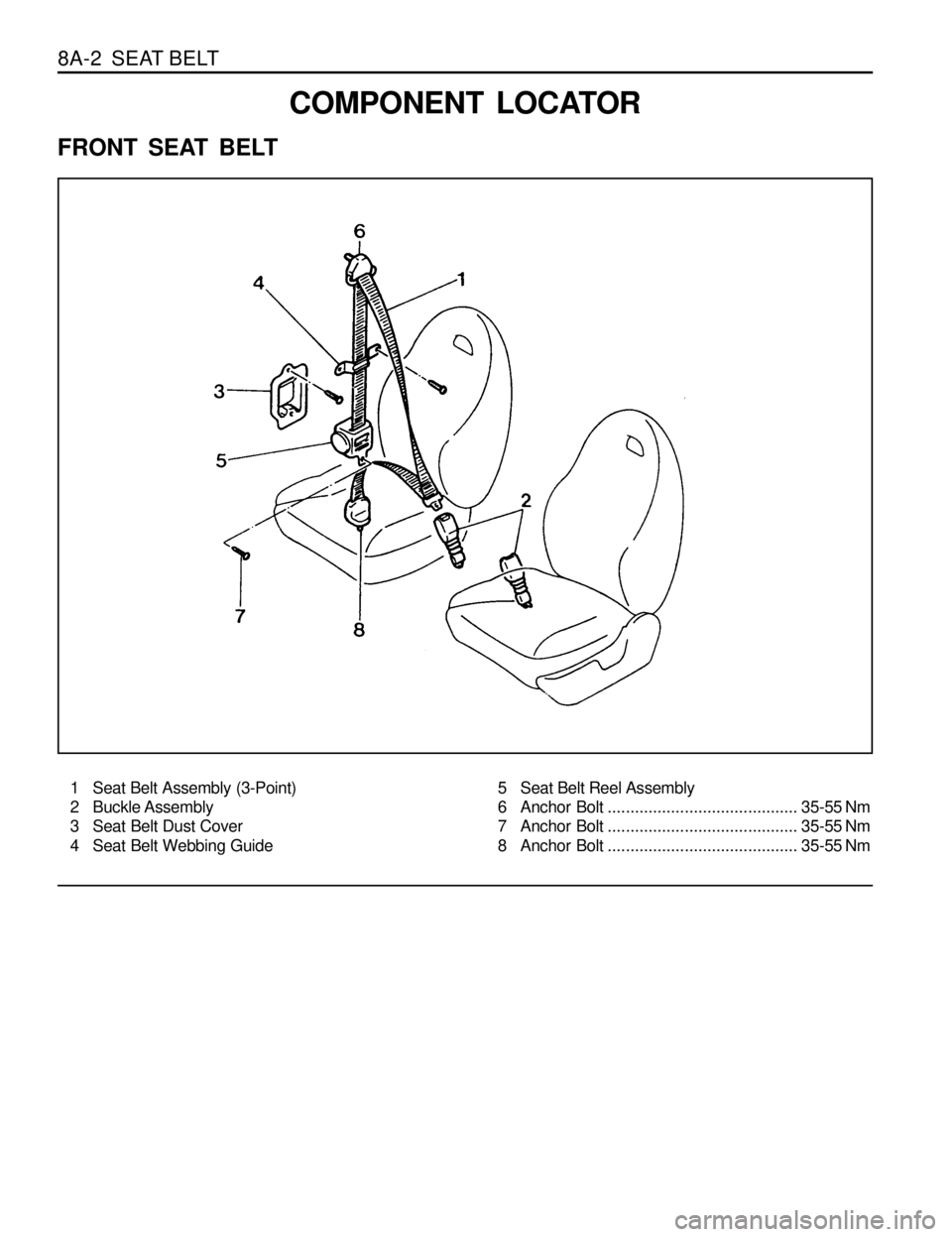

8A-2 SEAT BELT

COMPONENT LOCATOR

FRONT SEAT BELT

1 Seat Belt Assembly (3-Point)

2 Buckle Assembly

3 Seat Belt Dust Cover

4 Seat Belt Webbing Guide5 Seat Belt Reel Assembly

6 Anchor Bolt..........................................35-55 Nm

7 Anchor Bolt..........................................35-55 Nm

8 Anchor Bolt..........................................35-55 Nm

Page 1303 of 1463

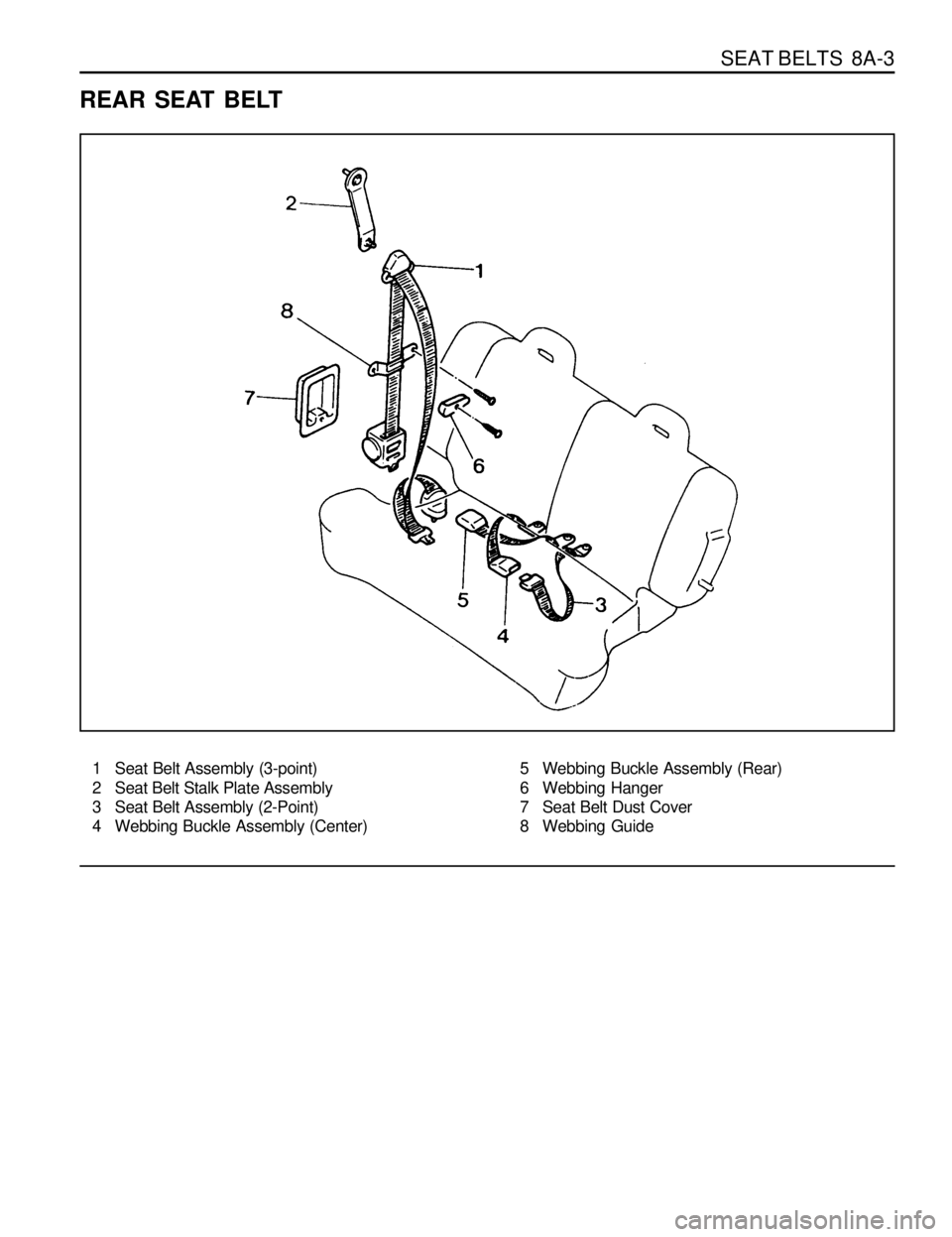

SEAT BELTS 8A-3

REAR SEAT BELT

1 Seat Belt Assembly (3-point)

2 Seat Belt Stalk Plate Assembly

3 Seat Belt Assembly (2-Point)

4 Webbing Buckle Assembly (Center)5 Webbing Buckle Assembly (Rear)

6 Webbing Hanger

7 Seat Belt Dust Cover

8 Webbing Guide

Page 1304 of 1463

8A-4 SEAT BELT

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DRIVER SEAT BELT WARNING

The driver's safety belt incorporates a safety belt reminder

light in the instment cluster remind the driver if the safety belt

is not fastened when the ignition is turnd ON.

OPERATION AND FUNCTIONAL

CHECKS

Caution:

lKeep sharp objects and potentially damaging objects

away from the seat belts.

lAvoid bending or damaging any portion of the buckle

or the latch plate.

lDo not bleach or dye the belt webbing. Use only mild

soap and water in order to clean the belts.

lWhen installing the seat belt anchor bolts and the

screws, start the bolts and screws by hand in order

to prevent crossthreading.

lDo not attempt any repairs on the retractor

mechsemblies with new assemblies.

lReplace any belts that are cut r damaged in any way.

1. Inspect all saet belt anchor bolts and the screw in order to

verify that they are secure.

2. Inspect the seat belt buckle. The buckle must lock and

unlock easily.

3. After inserting the latch into the buckle, tug sharply on the

belt. The buckle must remain locked.

4. Fully extend the shoulder belt portion to make sure that

there is no twisting or tears in the belt.

5. Let the shoulder belt retract fully. The belt should retract

easily.

Page 1305 of 1463

SECTION 8B

SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 8B-1

General Specifications . . . . . . . . . . . . . . . . . . 8B-1

Schematic and Routing Diagrams . . . . . . . . 8B-2

Air Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-2

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-3

Function Description . . . . . . . . . . . . . . . . . . 8B-4

Air Bag Module . . . . . . . . . . . . . . . . . . . . . . . . 8B-6

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-7

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-7

Self Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . 8B-10

Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . 8B-16

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

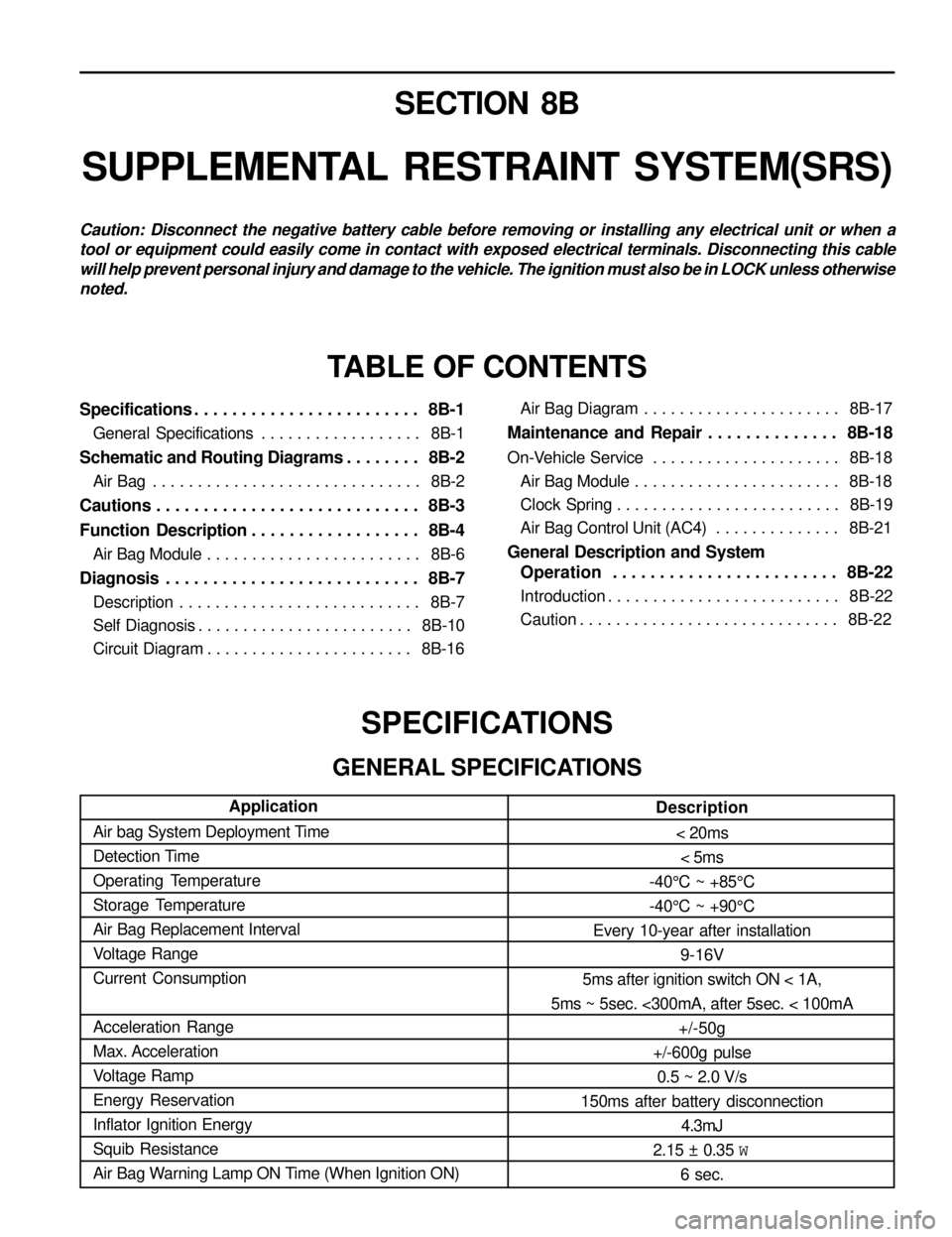

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Air bag System Deployment Time

Detection Time

Operating Temperature

Storage Temperature

Air Bag Replacement Interval

Voltage Range

Current Consumption

Acceleration Range

Max. Acceleration

Voltage Ramp

Energy Reservation

Inflator Ignition Energy

Squib Resistance

Air Bag Warning Lamp ON Time (When Ignition ON)Description

< 20ms

< 5ms

-40°C ~ +85°C

-40°C ~ +90°C

Every 10-year after installation

9-16V

5ms after ignition switch ON < 1A,

5ms ~ 5sec. <300mA, after 5sec. < 100mA

+/-50g

+/-600g pulse

0.5 ~ 2.0 V/s

150ms after battery disconnection

4.3mJ

2.15 ± 0.35 W

6 sec.

Air Bag Diagram . . . . . . . . . . . . . . . . . . . . . . 8B-17

Maintenance and Repair . . . . . . . . . . . . . . 8B-18

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 8B-18

Air Bag Module . . . . . . . . . . . . . . . . . . . . . . . 8B-18

Clock Spring . . . . . . . . . . . . . . . . . . . . . . . . . 8B-19

Air Bag Control Unit (AC4) . . . . . . . . . . . . . . 8B-21

General Description and System

Operation . . . . . . . . . . . . . . . . . . . . . . . . 8B-22

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-22

Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-22

Page 1306 of 1463

8B-2 SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

SCHEMATIC AND ROUTING DIAGRAMS

AIR BAG

Page 1307 of 1463

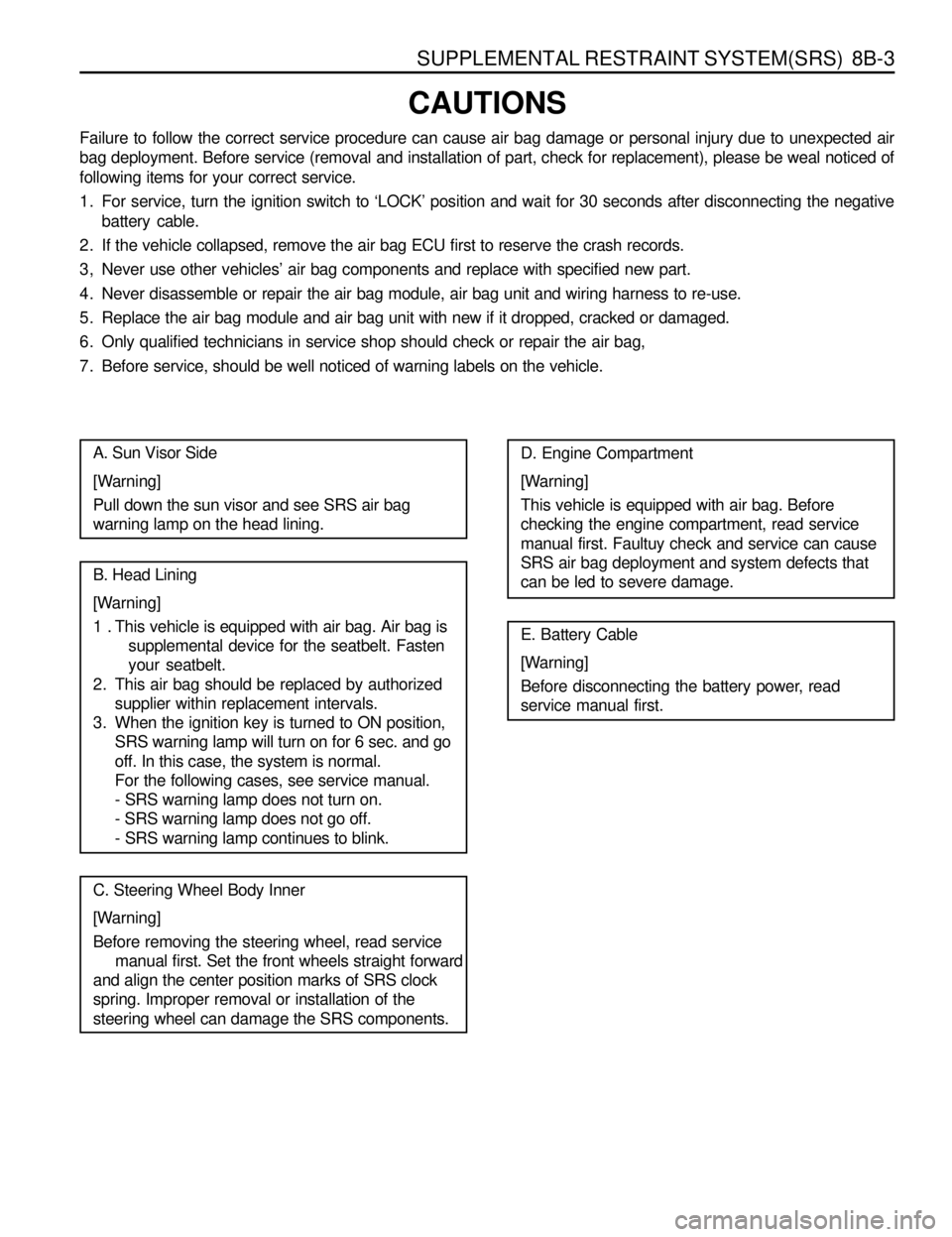

SUPPLEMENTAL RESTRAINT SYSTEM(SRS) 8B-3

CAUTIONS

Failure to follow the correct service procedure can cause air bag damage or personal injury due to unexpected air

bag deployment. Before service (removal and installation of part, check for replacement), please be weal noticed of

following items for your correct service.

1. For service, turn the ignition switch to ‘LOCK’ position and wait for 30 seconds after disconnecting the negative

battery cable.

2. If the vehicle collapsed, remove the air bag ECU first to reserve the crash records.

3, Never use other vehicles’ air bag components and replace with specified new part.

4. Never disassemble or repair the air bag module, air bag unit and wiring harness to re-use.

5. Replace the air bag module and air bag unit with new if it dropped, cracked or damaged.

6. Only qualified technicians in service shop should check or repair the air bag,

7. Before service, should be well noticed of warning labels on the vehicle.

A. Sun Visor Side

[Warning]

Pull down the sun visor and see SRS air bag

warning lamp on the head lining.

B. Head Lining

[Warning]

1 . This vehicle is equipped with air bag. Air bag is

supplemental device for the seatbelt. Fasten

your seatbelt.

2. This air bag should be replaced by authorized

supplier within replacement intervals.

3. When the ignition key is turned to ON position,

SRS warning lamp will turn on for 6 sec. and go

off. In this case, the system is normal.

For the following cases, see service manual.

- SRS warning lamp does not turn on.

- SRS warning lamp does not go off.

- SRS warning lamp continues to blink.

C. Steering Wheel Body Inner

[Warning]

Before removing the steering wheel, read service

manual first. Set the front wheels straight forward

and align the center position marks of SRS clock

spring. Improper removal or installation of the

steering wheel can damage the SRS components.D. Engine Compartment

[Warning]

This vehicle is equipped with air bag. Before

checking the engine compartment, read service

manual first. Faultuy check and service can cause

SRS air bag deployment and system defects that

can be led to severe damage.

E. Battery Cable

[Warning]

Before disconnecting the battery power, read

service manual first.

Page 1308 of 1463

8B-4 SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

FUNCTION DESCRIPTION

Air Bag Control Unit (AC4)

Air bag control unit (AC4) is installed on the center portion of

the front floor tunnel.

It is a central control unit that control all functions and determines

whether deploy the air bag or not with the collision signal from

the built-in accelerometer sensor and has function of diagnosing

system defects.

Internal air bag control unit is consisted as follows;

lMicroprocessor

lASICs (Upper side ASIC & lower side ASIC)

lAccelerometer sensor

lArming sensor

lSystem energy backup condenser

lSquib energy backup condenser

Page 1309 of 1463

SUPPLEMENTAL RESTRAINT SYSTEM(SRS) 8B-5

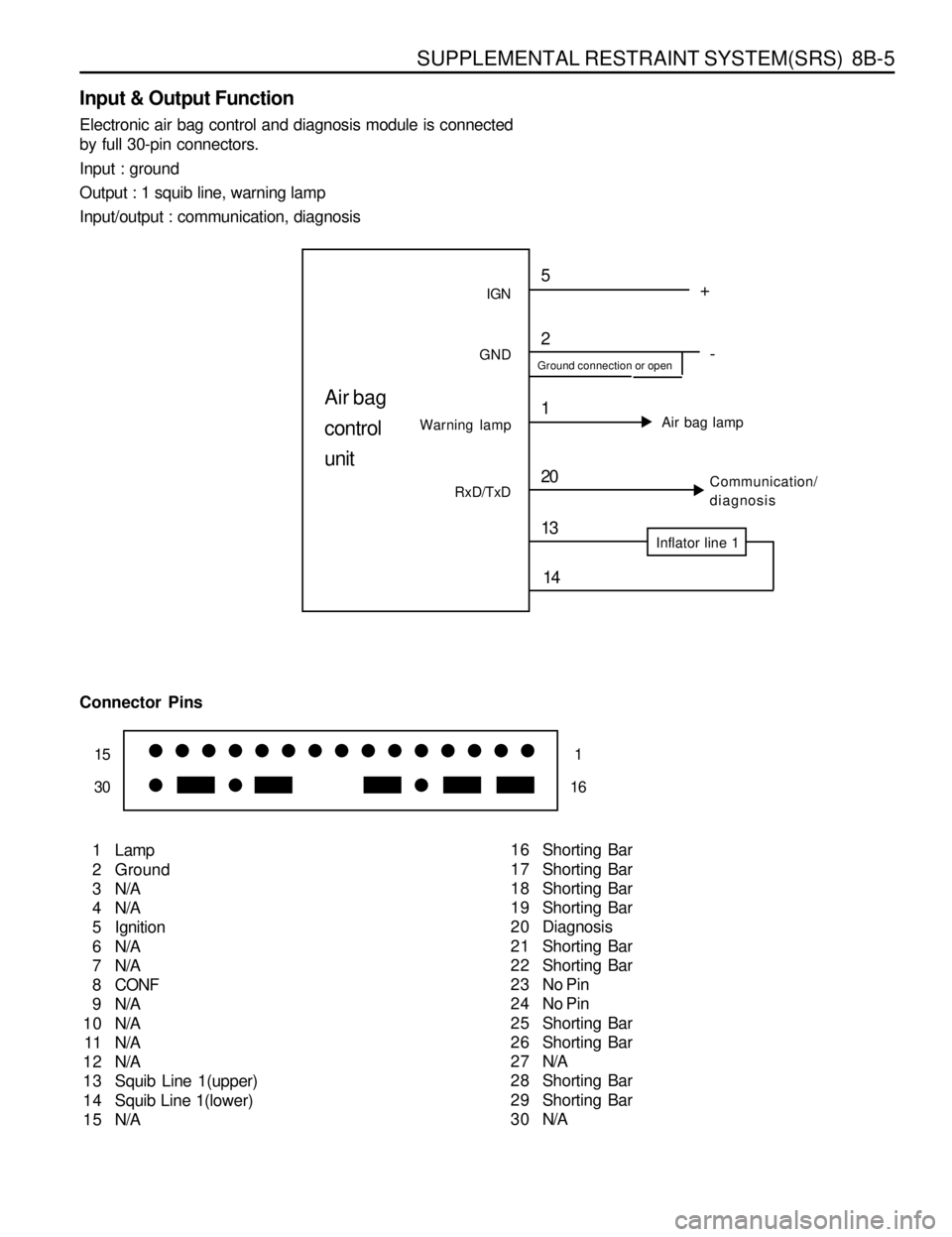

Input & Output Function

Electronic air bag control and diagnosis module is connected

by full 30-pin connectors.

Input : ground

Output : 1 squib line, warning lamp

Input/output : communication, diagnosis

16 Shorting Bar

17 Shorting Bar

18 Shorting Bar

19 Shorting Bar

20 Diagnosis

21 Shorting Bar

22 Shorting Bar

23 No Pin

24 No Pin

25 Shorting Bar

26 Shorting Bar

2 7 N/A

28 Shorting Bar

29 Shorting Bar

3 0 N/A 1 Lamp

2 Ground

3 N/A

4 N/A

5 Ignition

6 N/A

7 N/A

8 CONF

9 N/A

1 0 N/A

11 N/A

1 2 N/A

13 Squib Line 1(upper)

14 Squib Line 1(lower)

1 5 N/A

IGN

GND

Warning lamp

RxD/TxD

Inflator line 1

+

- 5

2

1

20

13

14

Air bag lamp

Communication/

diagnosis

Air bag

control

unit

Ground connection or open

Connector Pins

15

301

16

Page 1310 of 1463

8B-6 SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

AIR BAG MODULE

Air bag module is installed in the pad of steering wheel center and inflator is consisted of igniter, explosives, gas

generating material and bag. When crashed, the air bag control unit sends current to the air bag module through

squib line and this current ignites as ignition energy (6mJ) momentarily igniting explosives and bag will be inflated

by nitrogen gas protecting driver at the same and then deflates.

1 Air bag Module

2 Module Housing

3 Bag

4 Module Bracket

5 Retainer Ring

6 Inflator

7 Horn Switch

8 Backing Plate