SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Page 405 of 1463

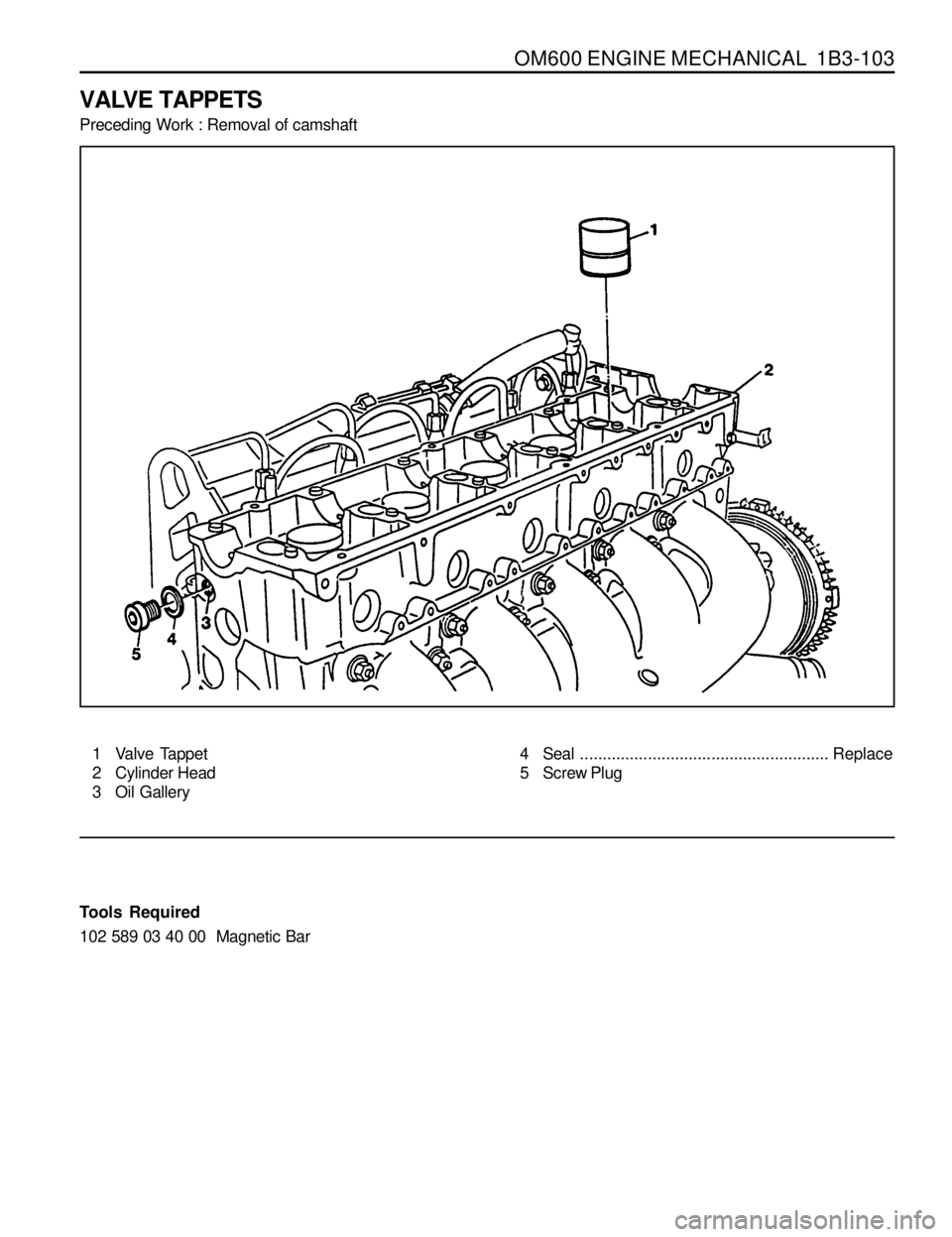

OM600 ENGINE MECHANICAL 1B3-103

VALVE TAPPETS

Preceding Work : Removal of camshaft

1 Valve Tappet

2 Cylinder Head

3 Oil Gallery4 Seal....................................................... Replace

5 Screw Plug

Tools Required

102 589 03 40 00 Magnetic Bar

Page 406 of 1463

1B3-104 OM600 ENGINE MECHANICAL

Replacement Procedure

1. Pull out the valve tappet (1).

Magnetic Bar 102 589 03 40 00

2. Remove the plug (5) and blow compressed air into the oil

gallery (3). At this time, check that the outlet bores(arrow)

at the seat of the valve tappet are clear.

3. Replace the seal (4) and tighten the plug (5).

4. Insert the new valve tappet.

Notice

Coat the valve tappet with oil.

Page 413 of 1463

OM600 ENGINE MECHANICAL 1B3-111

6. Remove the spring retainer(3) and spring (4).

7. Check the valve spring and replace if necessary.

8. Insert valve spring (4) with the color coding (arrow) facing

down and insert valve spring Retainer(3).

9. By press the spring retainer(3) with press lever (90), install

the valve cotters with magnetic finger (10).

Press Lever 667 589 00 31 00

Magnetic Finger 116 589 06 63 00

10. Remove the supporting bar.

11. Remove the holding wheel (7) from the timing chain (5).

Holding Wheel 603 589 01 40 00

13. Coat the valve tappet with oil and install it.

Magnetic Bar 102 589 03 40 00

Page 432 of 1463

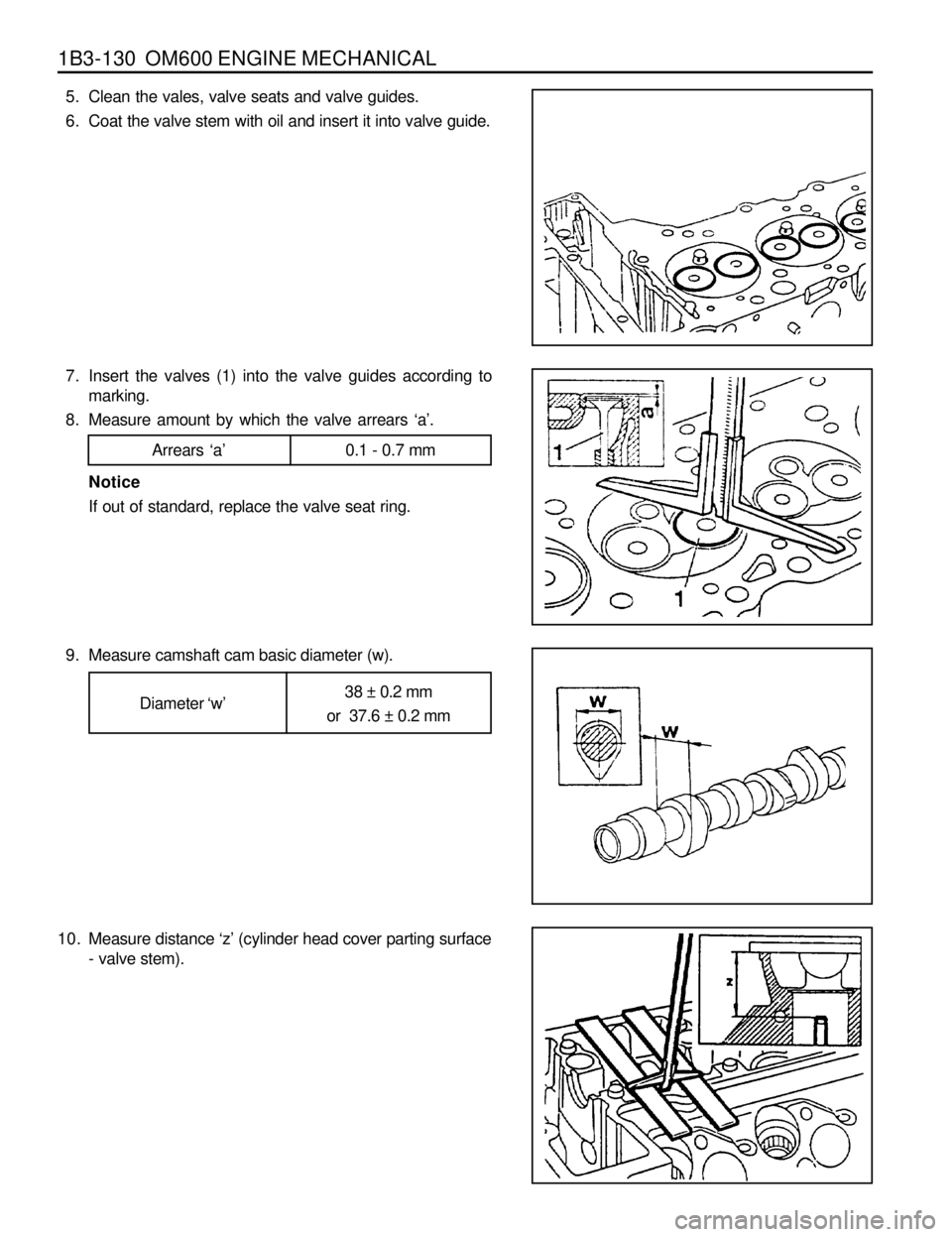

1B3-130 OM600 ENGINE MECHANICAL

10. Measure distance ‘z’ (cylinder head cover parting surface

- valve stem). 5. Clean the vales, valve seats and valve guides.

6. Coat the valve stem with oil and insert it into valve guide.

7. Insert the valves (1) into the valve guides according to

marking.

8. Measure amount by which the valve arrears ‘a’.

Arrears ‘a’ 0.1 - 0.7 mm

Notice

If out of standard, replace the valve seat ring.

9. Measure camshaft cam basic diameter (w).

Diameter ‘w’38 ± 0.2 mm

or 37.6 ± 0.2 mm

Page 441 of 1463

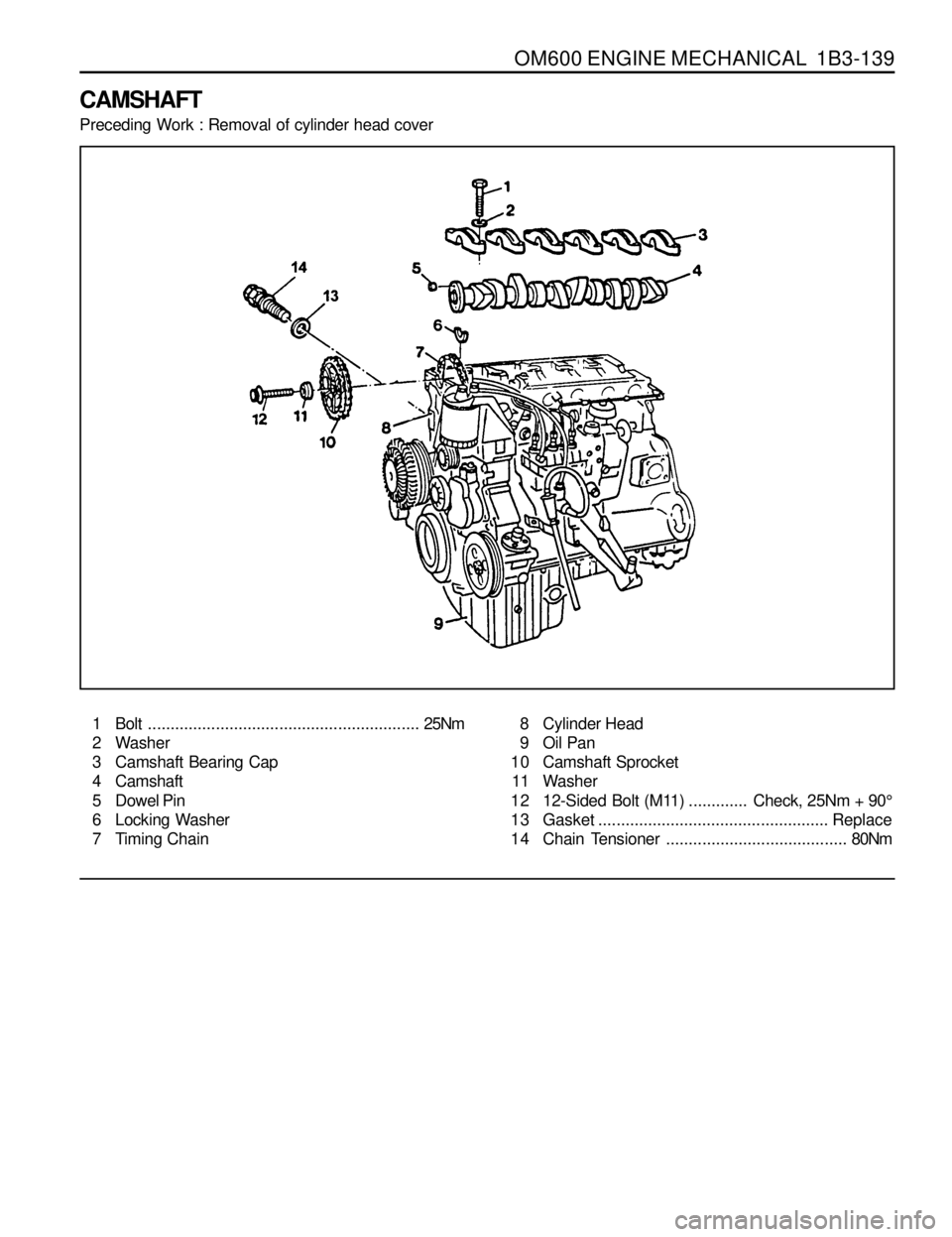

OM600 ENGINE MECHANICAL 1B3-139

CAMSHAFT

Preceding Work : Removal of cylinder head cover

1 Bolt............................................................25Nm

2 Washer

3 Camshaft Bearing Cap

4 Camshaft

5 Dowel Pin

6 Locking Washer

7 Timing Chain8 Cylinder Head

9 Oil Pan

10 Camshaft Sprocket

11 Washer

12 12-Sided Bolt (M11).............Check, 25Nm + 90°

13 Gasket ................................................... Replace

14 Chain Tensioner........................................80Nm

Page 444 of 1463

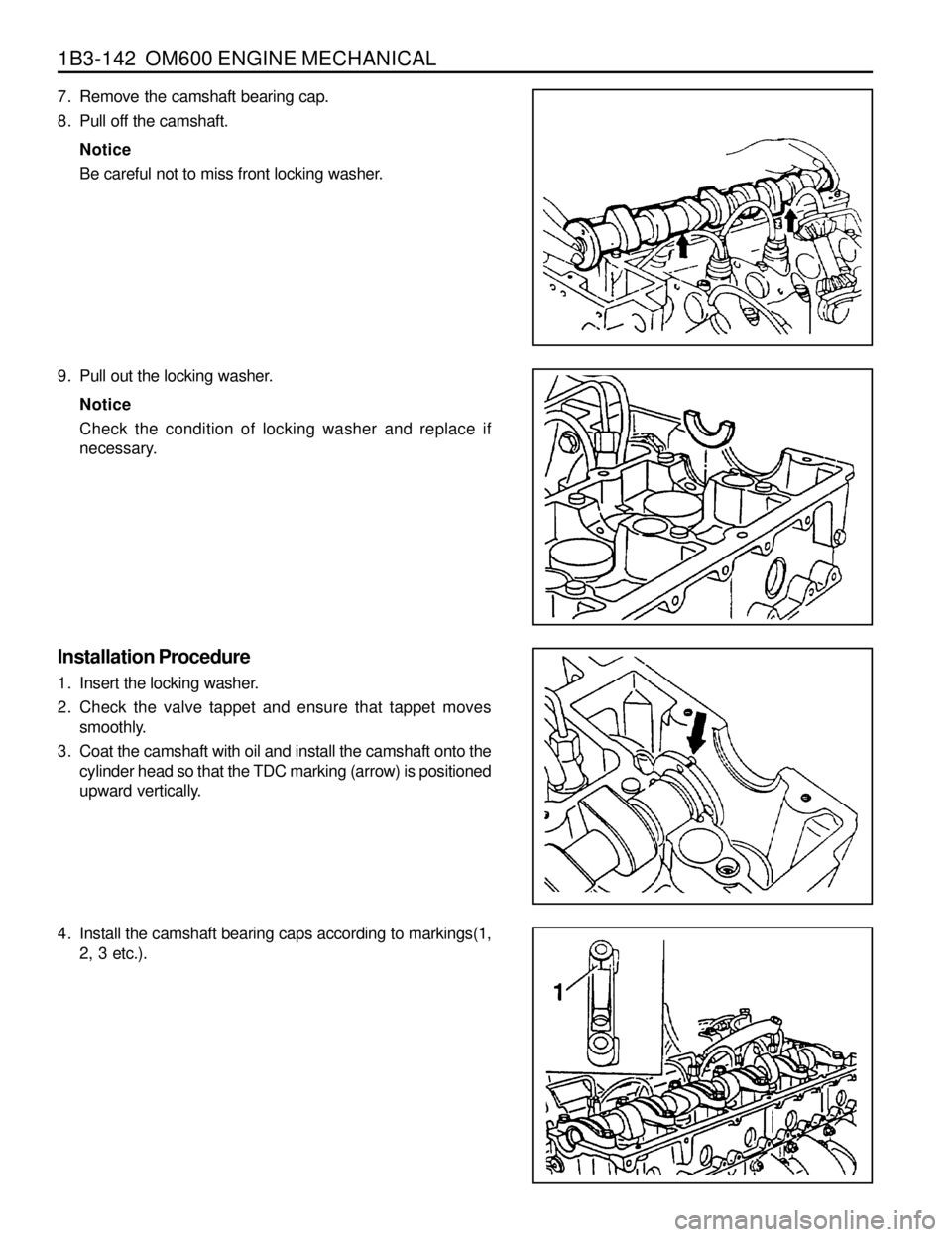

1B3-142 OM600 ENGINE MECHANICAL

4. Install the camshaft bearing caps according to markings(1,

2, 3 etc.).

7. Remove the camshaft bearing cap.

8. Pull off the camshaft.

Notice

Be careful not to miss front locking washer.

9. Pull out the locking washer.

Notice

Check the condition of locking washer and replace if

necessary.

Installation Procedure

1. Insert the locking washer.

2. Check the valve tappet and ensure that tappet moves

smoothly.

3. Coat the camshaft with oil and install the camshaft onto the

cylinder head so that the TDC marking (arrow) is positioned

upward vertically.

Page 446 of 1463

1B3-144 OM600 ENGINE MECHANICAL

10. Check the TDC marking of OT on the crankshaft.8. Install the chain tensioner.

Tightening Torque 80 Nm

Notice

Replace the seal.

Before installation, by pumping in the oil approx. 10 times,

fill the oil.

9. Remove the engine lock.

Notice

If max. length ‘L’ of the 12-sided bolt exceeds 53.6mm,

replace it.

Page 448 of 1463

1B3-146 OM600 ENGINE MECHANICAL

Notice

Always install the chain tensioner to be filled with oil.

Place the chain tensioner in engine oil up to over the collar on the hexagon head with the thrust pin facing up.

Slowly push down the thrust pin as far as the stop 7~10 times with the aid of a press or a column drill

Faulty chain tensioners should be replaced completely.

3 Screw Plug

4 Aluminum Gasket

5 Ball

6 Ball Guide

7 Compression Spring

8 Compression Spring

9 Housing

10 Thrust Pin11 Valve Disc

12 O-Ring

13 Snap Ring

14 Compression Spring

15 Filler

A Feed Bore from Cylinder Head

B To Oil Pan

Page 458 of 1463

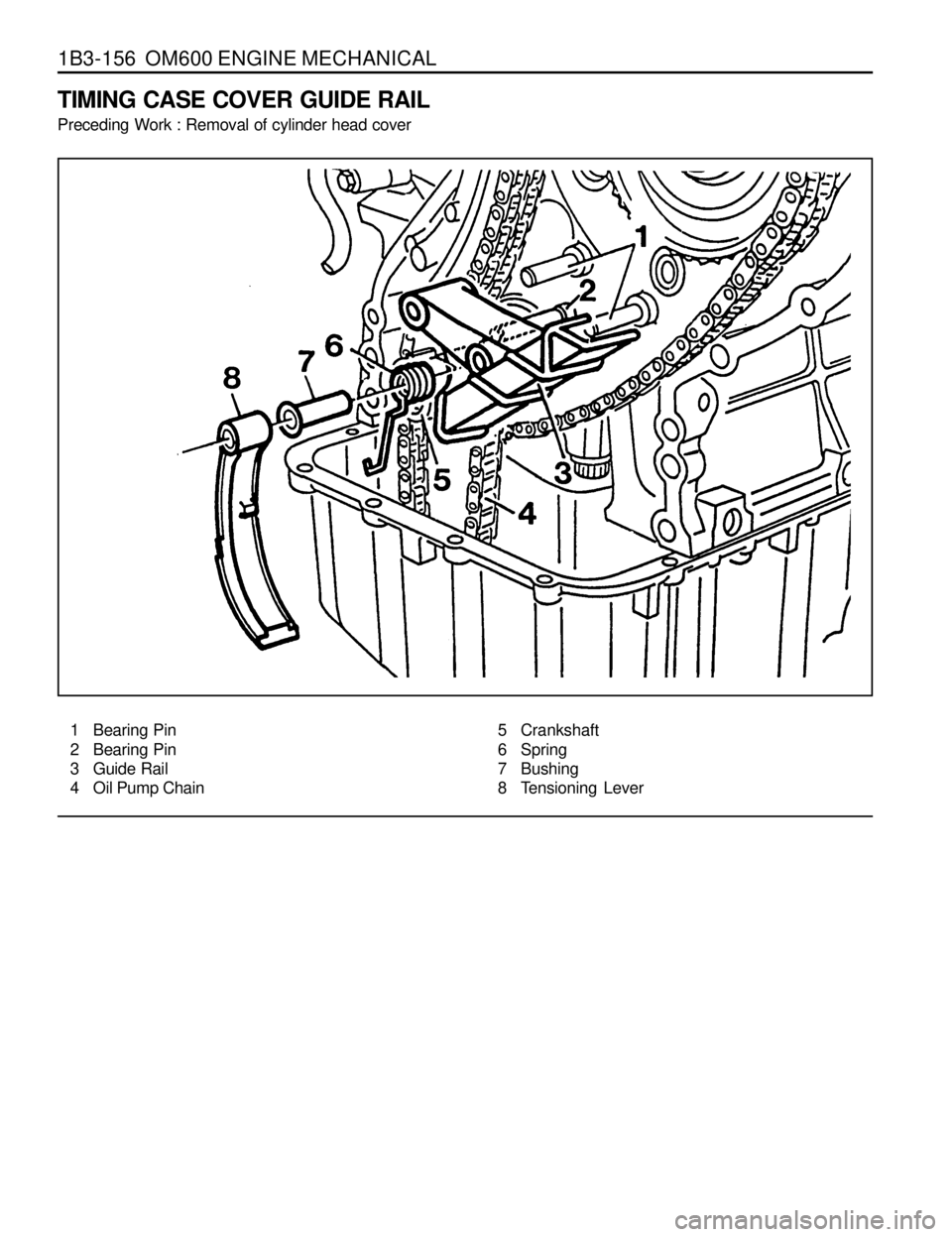

1B3-156 OM600 ENGINE MECHANICAL

TIMING CASE COVER GUIDE RAIL

Preceding Work : Removal of cylinder head cover

1 Bearing Pin

2 Bearing Pin

3 Guide Rail

4 Oil Pump Chain5 Crankshaft

6 Spring

7 Bushing

8 Tensioning Lever

Page 459 of 1463

OM600 ENGINE MECHANICAL 1B3-157

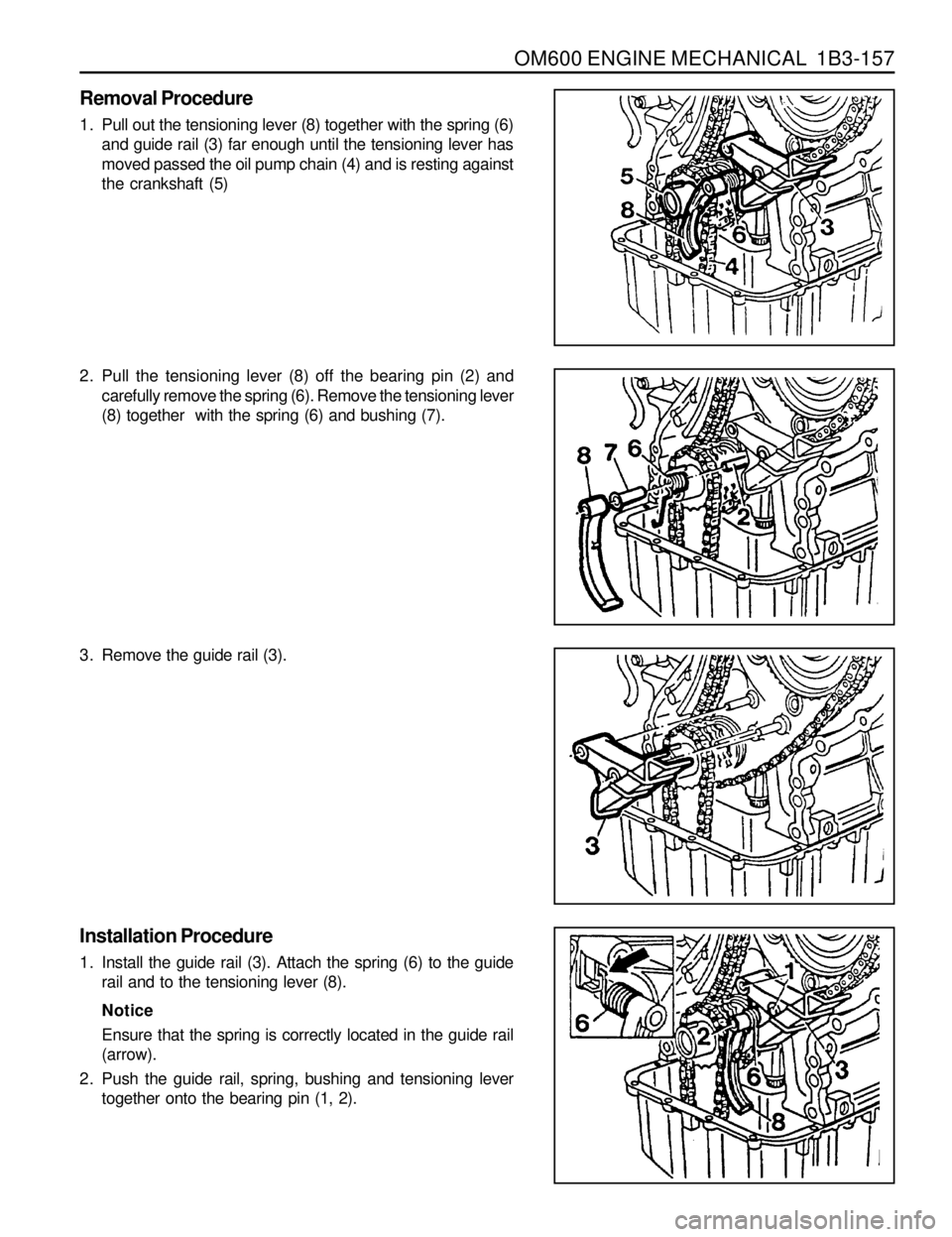

Removal Procedure

1. Pull out the tensioning lever (8) together with the spring (6)

and guide rail (3) far enough until the tensioning lever has

moved passed the oil pump chain (4) and is resting against

the crankshaft (5)

2. Pull the tensioning lever (8) off the bearing pin (2) and

carefully remove the spring (6). Remove the tensioning lever

(8) together with the spring (6) and bushing (7).

3. Remove the guide rail (3).

Installation Procedure

1. Install the guide rail (3). Attach the spring (6) to the guide

rail and to the tensioning lever (8).

Notice

Ensure that the spring is correctly located in the guide rail

(arrow).

2. Push the guide rail, spring, bushing and tensioning lever

together onto the bearing pin (1, 2).