SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Page 460 of 1463

1B3-158 OM600 ENGINE MECHANICAL

CRANKSHAFT SPROCKET

Preceding Work : Removal of oil pan

Removal of timing case cover

1 12-Sided Stretch Bolt (M11) .. Check, 25Nm + 90°

2 Washer

3 Camshaft Sprocket

4 Timing Chain

5 Bearing Pin

6 Bearing Pin

7 Oil Pump

8 Oil Pump Sprocket

9 Oil Pump Chain

10 Washer11 Bolt............................................................25Nm

12 Crankshaft Sprocket

13 Crankshaft

15 Key

16 Guide Rail

17 Spring

18 Bushing

19 Tensioning Lever

Page 461 of 1463

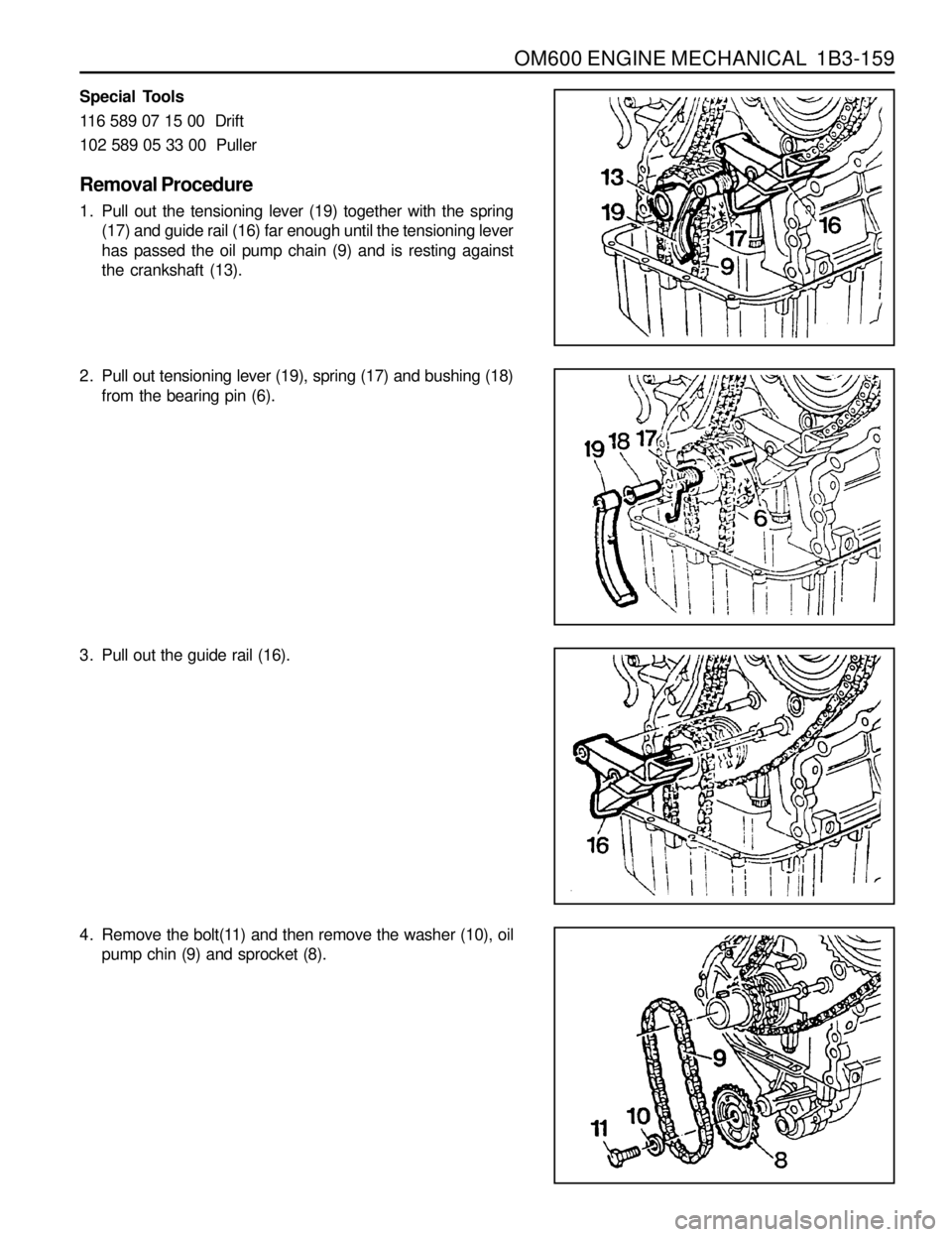

OM600 ENGINE MECHANICAL 1B3-159

Special Tools

116 589 07 15 00 Drift

102 589 05 33 00 Puller

Removal Procedure

1. Pull out the tensioning lever (19) together with the spring

(17) and guide rail (16) far enough until the tensioning lever

has passed the oil pump chain (9) and is resting against

the crankshaft (13).

2. Pull out tensioning lever (19), spring (17) and bushing (18)

from the bearing pin (6).

3. Pull out the guide rail (16).

4. Remove the bolt(11) and then remove the washer (10), oil

pump chin (9) and sprocket (8).

Page 463 of 1463

OM600 ENGINE MECHANICAL 1B3-161

Installation Procedure

1. Put the same alignment mark on the new crankshaft

sprocket as in the old sprocket.

Notice

Check the timing chain, camshaft sprocket, injection pump

timing sprocket, oil pump chain and oil pump sprocket for

wear and replace if necessary.

2. Install the new crankshaft sprocket (12) by using a drift (21).

Notice

Align the groove of sprocket and woodruff key (arrow)

exactly.

Drift 116 589 07 15 00

3. Fit the timing chain (4) on the crankshaft sprocket (12).

Notice

Align the alignment marks (arrow) on the chain and sprocket.

4. Install the camshaft sprocket (3).

Tightening Torque 25 Nm + 90°

Notice

Pay attention on the alignment marks and dowel pin (arrow).

Page 464 of 1463

1B3-162 OM600 ENGINE MECHANICAL

Notice

If the max. length ‘L’ of the stretch bolt exceeds 53.6mm,

replace it.

5. Fit the oil pump chain (9) on the crankshaft sprocket (12)

and insert the oil pump sprocket (8) into the oil pump chain

and then install it on the oil pump.

Notice

The curved side of the oil pump sprocket should face the

oil pump.

6. Insert the woodruff key (15).

7. Install the guide rail (16). Attach the spring (17) to guide rail

and to tensioning lever together onto the bearing pins (5,6).

Notice

Ensure that the spring is correctly located in the guide rail

(arrow).

Page 465 of 1463

OM600 ENGINE MECHANICAL 1B3-163

PISTON

Preceding Work : Removal of the cylinder head

Removal of the oil pump

1 Oil Ring

2 2nd Ring

3 Top Ring

4 Snap Ring.............................................. Replace

5 Piston Pin

6 Piston

7 Connecting Rod Bushing.......................... Check8 Connecting Rod

9 Connecting Rod Upper Bearing Shell

10 Connecting Rod Lower Bearing Shell

11 Connecting Rod Bearing Cap

12 Connecting Rod Bolt.........................35Nm + 90°

13 Crankcase

14 Cylinder Bore

Notice

There are two kinds of connecting rods (for machining) and they are different in weight approx. 15g. When replacing

the connecting rod, measure its weight and ensure that a engine has the same weight of connecting rods. If not, there

would be a unbalancing of engine.

Page 468 of 1463

1B3-166 OM600 ENGINE MECHANICAL

Installation Procedure

1. Fit the piston onto the connecting rod so that the arrow

(15) and the locking slot (16) are facing in direction of the

vehicle.

2. Coat the piston pin (15) with engine oil and insert it by hand.

Notice

Do not heat up the piston.

3. Install the new snap ring (4) into the grooves (arrow).

4. Check the piston rings (1, 2, 3) and replace them if

necessary.

5. Install and arrange the piston rings to be evenly 120° from

each ends gap.

Page 469 of 1463

OM600 ENGINE MECHANICAL 1B3-167

6. Coat the cylinder bore, connecting rod bearing journal,

connecting rod bearing shell and piston with oil.

7. Compress the piston rings with a tensioning strap (7).

Tensioning Strap 000 589 04 14 00

8. Insert the piston assembly into the cylinder with a wooden

stick (18).

Notice

The arrow on the piston crown must point toward the front

of vehicle.

9. Insert the connecting rod bearing shells (9, 10).

Notice

Be careful of the difference in upper and lower bearing

shells and not to be changed.

10. Position the connecting rod bearings caps.

Notice

Position so that the retaining lugs are on the same side of

the connecting rod bearing(arrow).

11. Measure stretch shaft diameter (C) of the connecting rod

bolts.

Limit ‘C’ 7.1mm

Page 470 of 1463

1B3-168 OM600 ENGINE MECHANICAL

12. Coat the bolts (12) with oil and then tighten the bolts.

Tightening Torque 40Nm + 90°

13. Rotate the crankshaft and check axial clearance between

the connecting rod and crankshaft.

14. Measure clearance between the piston crown and cylinder

StandardMax. 0.12mm

15. Position the piston at TDC and measure the distance

between the piston crown and the crankcase surface.

Notice

Measure at points marked.

Dial Gauge 001 589 00 53 21

Dial Gauge Holder 363 589 02 21 00

Standard Max. 0.965 mm

Page 471 of 1463

OM600 ENGINE MECHANICAL 1B3-169

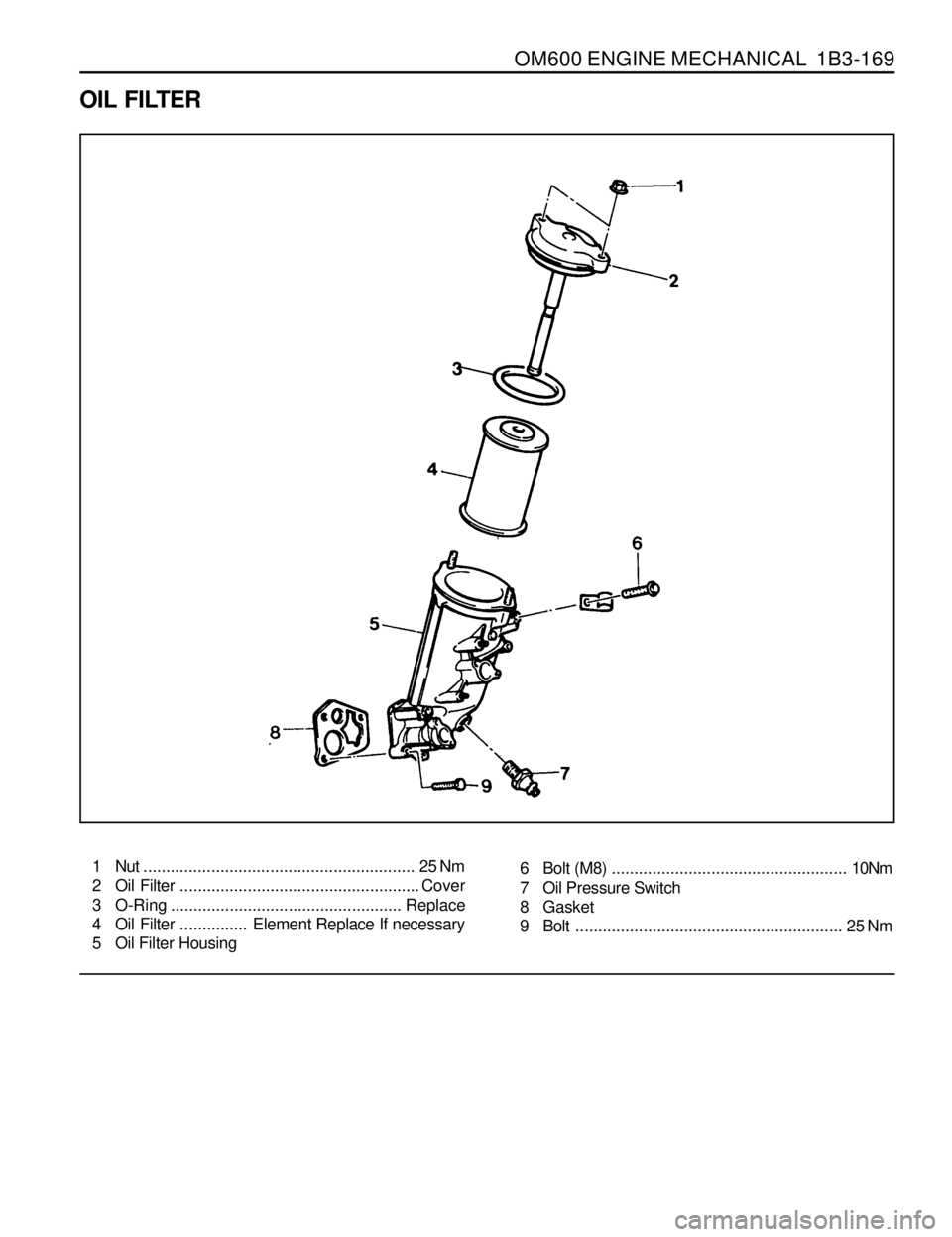

OIL FILTER

1 Nut ............................................................ 25 Nm

2 Oil Filter..................................................... Cover

3 O-Ring ................................................... Replace

4 Oil Filter...............Element Replace If necessary

5 Oil Filter Housing6 Bolt (M8)....................................................10Nm

7 Oil Pressure Switch

8 Gasket

9 Bolt........................................................... 25 Nm

Page 472 of 1463

1B3-170 OM600 ENGINE MECHANICAL

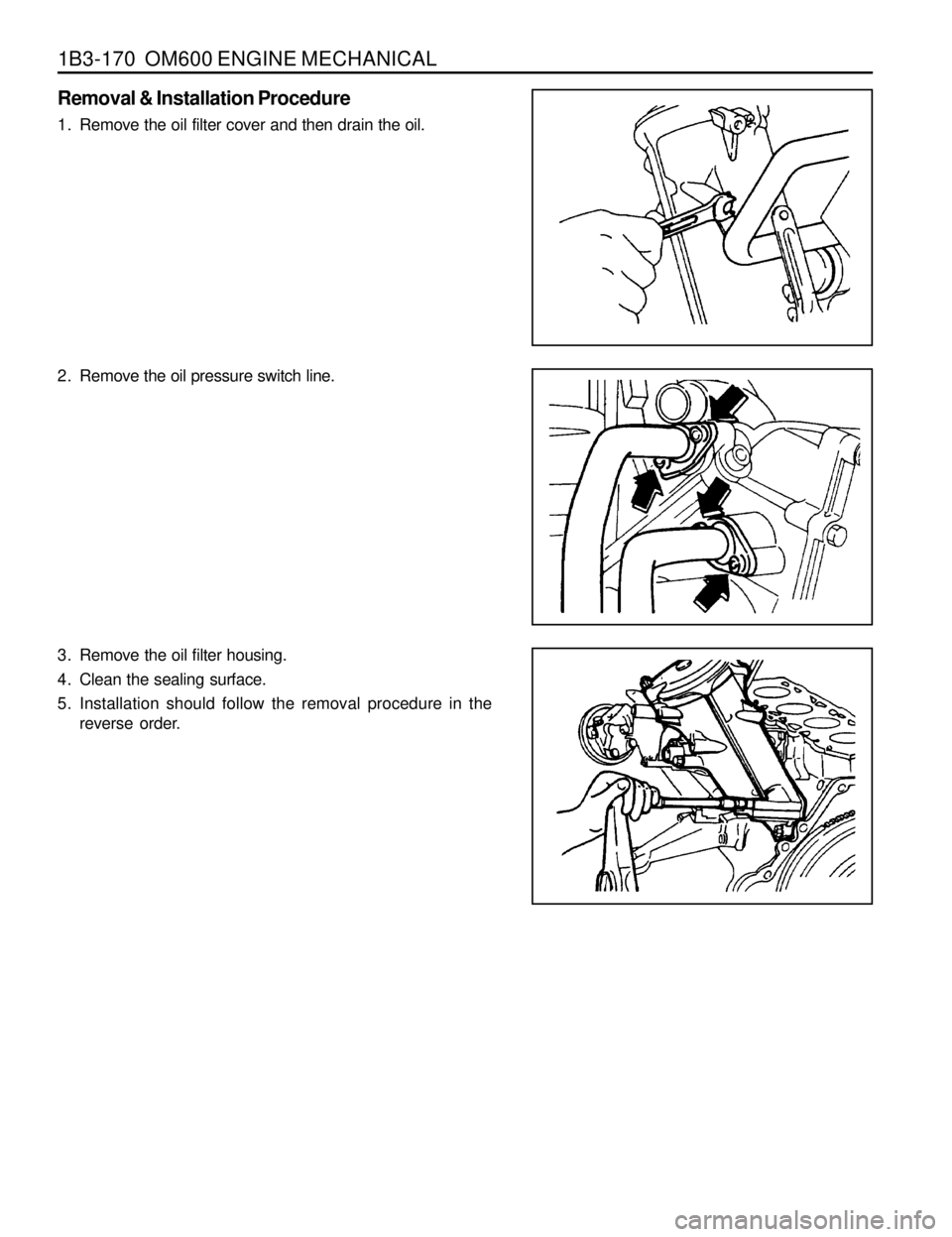

Removal & Installation Procedure

1. Remove the oil filter cover and then drain the oil.

2. Remove the oil pressure switch line.

3. Remove the oil filter housing.

4. Clean the sealing surface.

5. Installation should follow the removal procedure in the

reverse order.