SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: coolant level, rid height, oil type, keyless entry, fuel fill door release, recommended oil, ESP inoperative

Page 251 of 1463

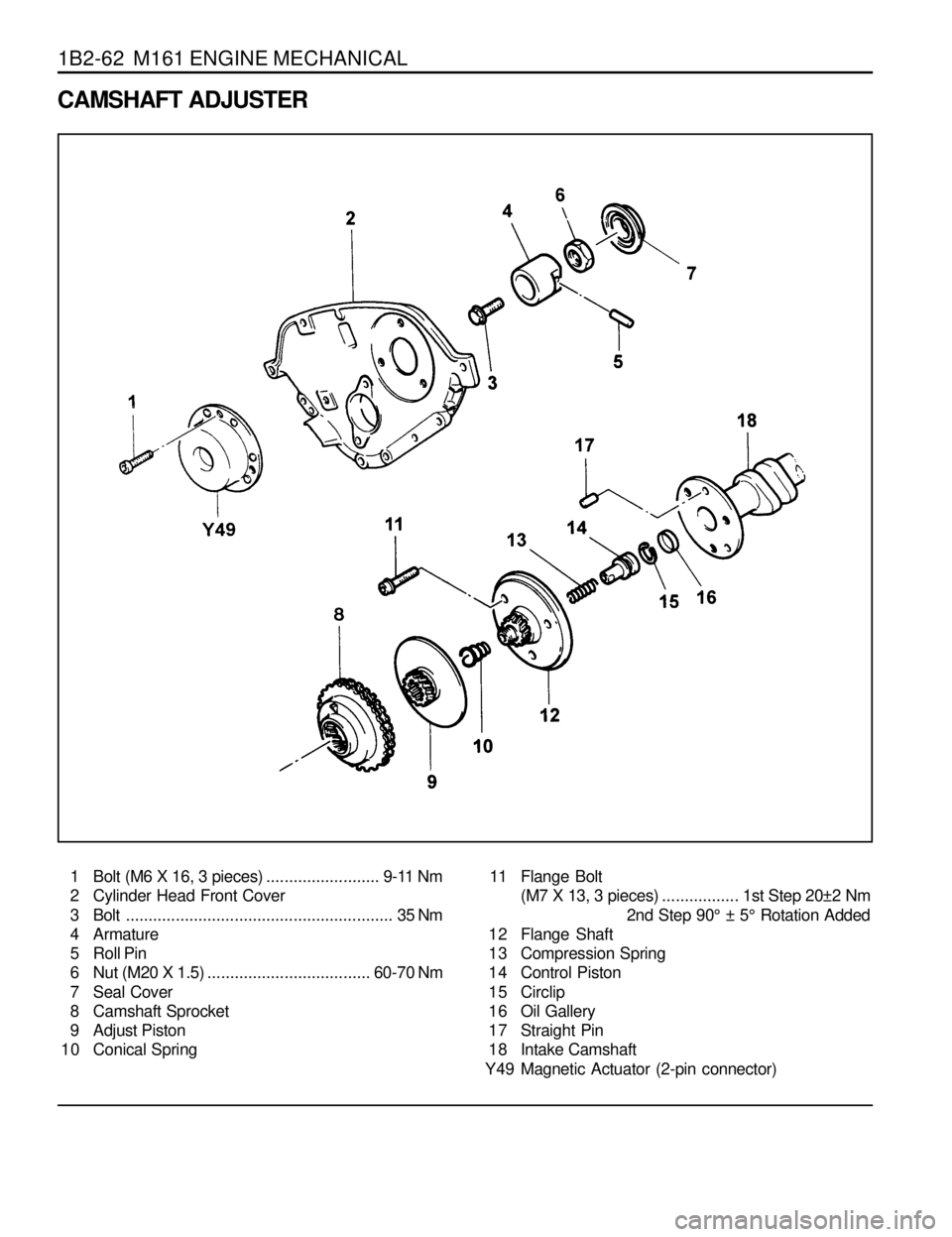

1B2-62 M161 ENGINE MECHANICAL

CAMSHAFT ADJUSTER

1 Bolt (M6 X 16, 3 pieces)......................... 9-11 Nm

2 Cylinder Head Front Cover

3 Bolt........................................................... 35 Nm

4 Armature

5 Roll Pin

6 Nut (M20 X 1.5)....................................60-70 Nm

7 Seal Cover

8 Camshaft Sprocket

9 Adjust Piston

10 Conical Spring11 Flange Bolt

(M7 X 13, 3 pieces).................1st Step 20±2 Nm

2nd Step 90° ± 5° Rotation Added

12 Flange Shaft

13 Compression Spring

14 Control Piston

15 Circlip

16 Oil Gallery

17 Straight Pin

18 Intake Camshaft

Y49 Magnetic Actuator (2-pin connector)

Page 252 of 1463

M161 ENGINE MECHANICAL 1B2-63

Removal & Installation Procedure

1. Turn the crankshaft and position the n0.1 cylinder piston at

ATDC 20°.

Notice

Turn the crankshaft in the direction of engine rotation.

2. Remove the cylinder head front cover.

3. Put the alignment marks (arrows) on the camshaft sprocket

and the timing chain.

4. Insert the insert pin into the no.1 and no.6 bearing cap hole

on camshaft to secure intake and exhaust camshaft.

5. Remove the chain tensioner.

6. Unscrew the exhaust sprocket bolt and remove the exhaust

camshaft sprocket.

Installation Notice

Tightening Torque1st step 20 Nm

2nd step 90°

Notice

The flange bolt is designed to be used only once, so always

replace with new one.

Page 253 of 1463

1B2-64 M161 ENGINE MECHANICAL

7. Unscrew the bolt (3) from the armature (4) and remove

the roll pin, and remove the armature.

Installation Notice

Tightening Torque 35 Nm

8. Unscrew the nut (6) and remove the seal cover (7).

Installation Notice

Tightening Torque 60 - 70 Nm

Notice

Put the locking slot of nut toward armarture.

9. Take off the timing chain from intake camshaft sprocket.

10. Remove the cover (7), adjuster piston (9) and conical

spring (10) from intake camshaft sprocket.

11. Unscrew the bolt (11) and remove the flange shaft.

Installation Notice

Tightening Torque1st step 20 Nm

2nd step + 95°

Notice

The flange bolt is designed to be used only once, so always

replace with new one.

12. Installation should follow the removal procedure in the

reverse order.

13. Check and adjust the camshaft timing.

Page 254 of 1463

M161 ENGINE MECHANICAL 1B2-65

CAMSHAFT SPROCKET BOLT

Intake Flange Shaft Bolt

Notice

The sprocket bolts are designed to be used only once, so

always replace with new one.

Exhaust Camshaft Sprocket Bolt

Notice

The sprocket bolts are designed to be used only once, so

always replace with new one.

C. M7 x 13 Collar Bolt Torx-T30

e. 6.8 mm

16. Flange Shaft

18. Control Piston

22. Intake Camshaft

E. M7 x 13 Collar Bolt Torx-T30

e. 6.8 mm

13a.Camshaft Sprocket

22a.Exhaust Camshaft

Tightening Torque1st step 20 Nm

2nd step + 90°

Tightening Torque1st step 20 Nm

2nd step + 90°

Page 255 of 1463

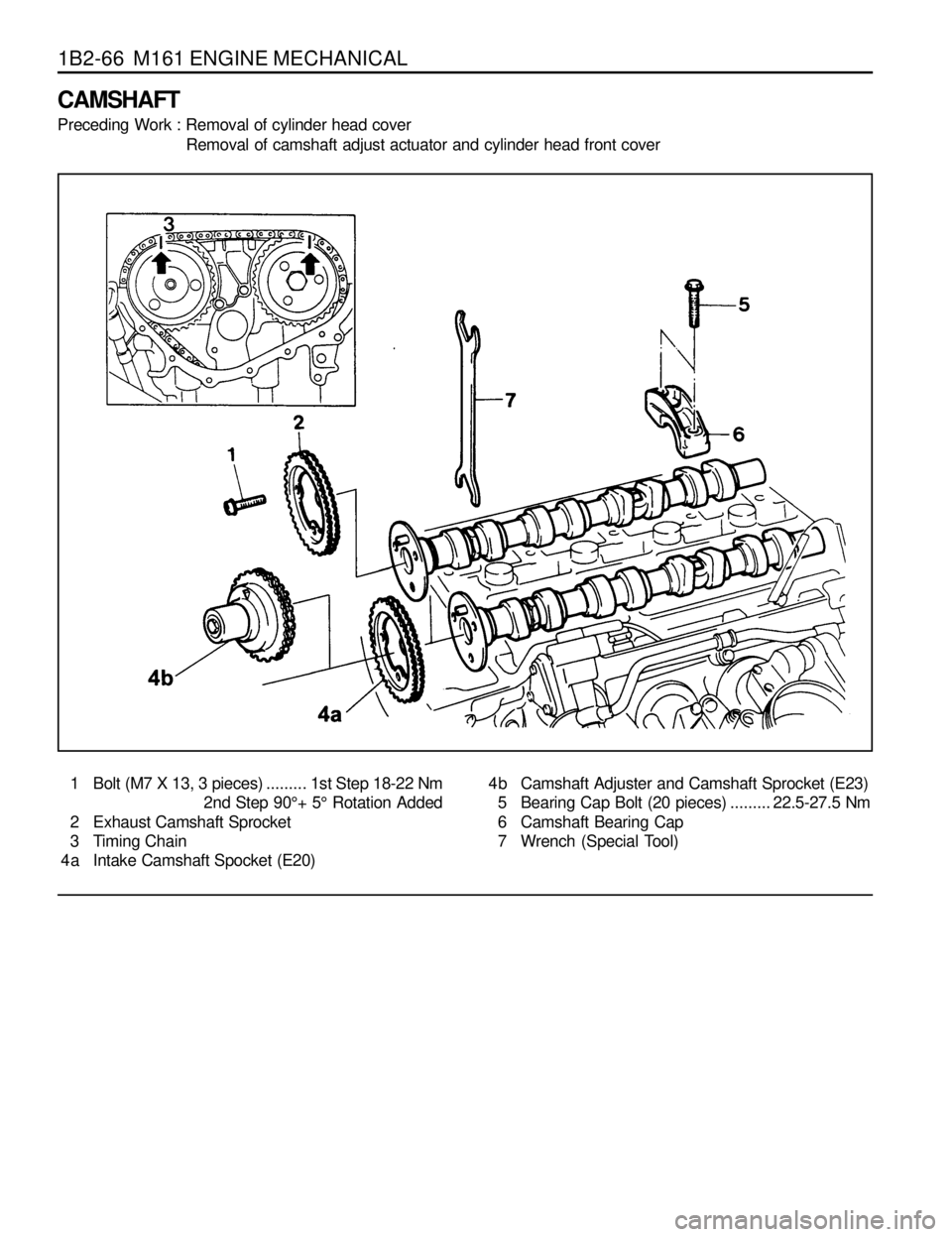

1B2-66 M161 ENGINE MECHANICAL

CAMSHAFT

Preceding Work : Removal of cylinder head cover

Removal of camshaft adjust actuator and cylinder head front cover

1 Bolt (M7 X 13, 3 pieces).........1st Step 18-22 Nm

2nd Step 90°+ 5° Rotation Added

2 Exhaust Camshaft Sprocket

3 Timing Chain

4a Intake Camshaft Spocket (E20)4b Camshaft Adjuster and Camshaft Sprocket (E23)

5 Bearing Cap Bolt (20 pieces).........22.5-27.5 Nm

6 Camshaft Bearing Cap

7 Wrench (Special Tool)

Page 256 of 1463

M161 ENGINE MECHANICAL 1B2-67

Tools Required

000 589 01 10 00 Box Wrench Insert

104 589 01 01 00Spanner

Removal & Installation Procedure

1. Turn the crankshaft and position the no.1 cylinder piston at

ATDC20°.

2. Put the alignment marks (arrows) on the camshaft sprocket

and the timing chain.

3. Remove the chain tensioner.

Installation Notice

Tightening Torque40 Nm

72 - 88 Nm

Screw Plug

Tensioner Assembly

4. Remove the exhoust camshaft sprocket.

Installation Notice

Tightening Torque1st step 35 - 45 Nm

2nd step 85° - 95°

Notice

The sprocket bolt is designed to be used only once, so

always replace with new one.

5. Take off the timing chain from intake camshaft sprocket,

and secute it not to fall down into the timing gear case.

6. Using the wrench (7), turn the camshaft until there is no

resistence in camshaft bearing area.

Page 257 of 1463

1B2-68 M161 ENGINE MECHANICAL

7. Remove the bearing cap, and remove the intake and the

exhaust camshaft.

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

Notice

Check the numbers on the bearing cap not to be miked

up.

8. Apply the engine oil on the valve tappet and camshaft

bearing.

9. Installation should follow the removal procedure in the

reverse order.

Notice

lBase circle of cam should cantact with the valve tappet.

lInstall the camshaft bearing caps according to the

numbers on the cylinder head cast and bearing cap.

10. Check the camshaft timing position.

Page 258 of 1463

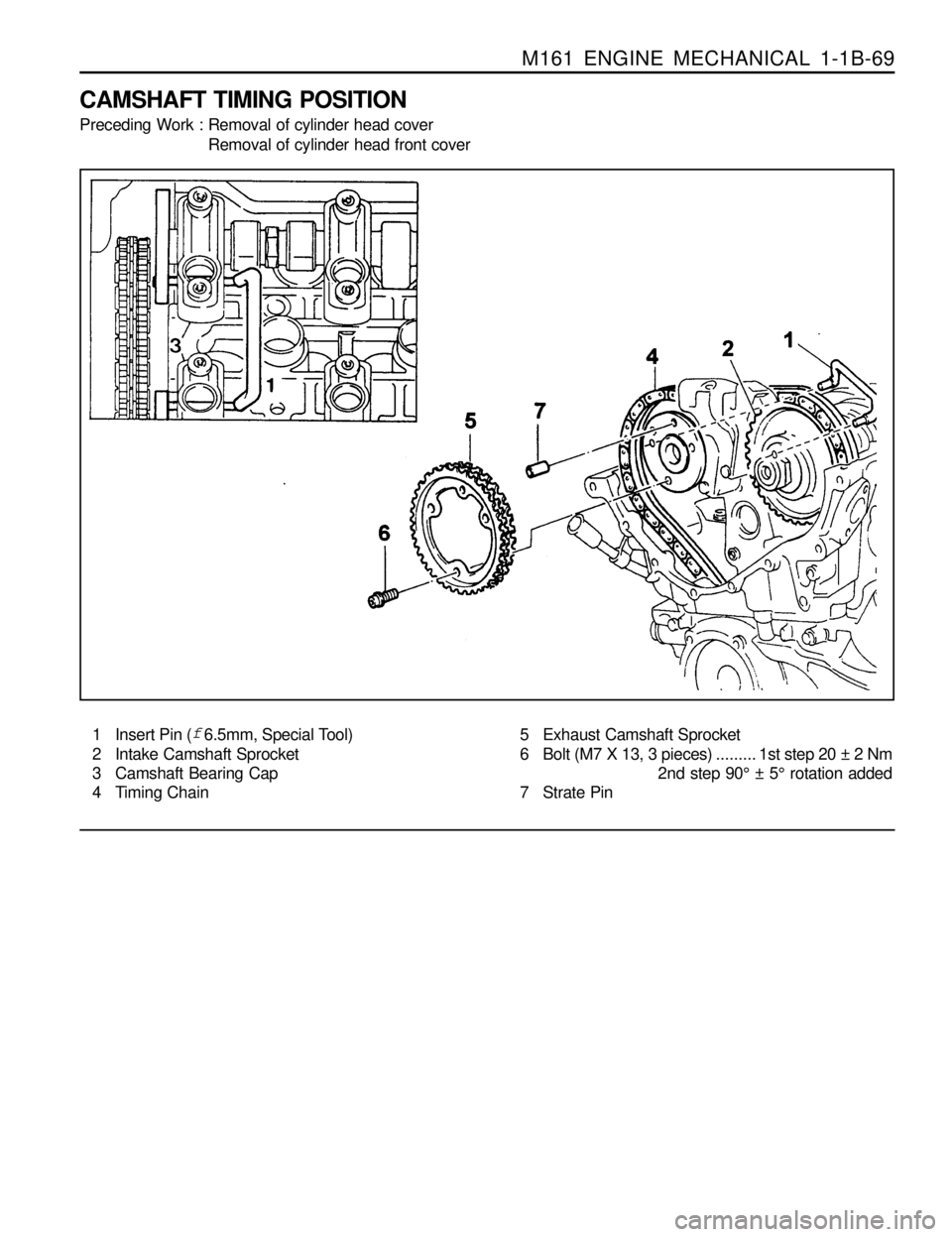

M161 ENGINE MECHANICAL 1-1B-69

CAMSHAFT TIMING POSITION

Preceding Work : Removal of cylinder head cover

Removal of cylinder head front cover

1 Insert Pin (f 6.5mm, Special Tool)

2 Intake Camshaft Sprocket

3 Camshaft Bearing Cap

4 Timing Chain5 Exhaust Camshaft Sprocket

6 Bolt (M7 X 13, 3 pieces).........1st step 20 ± 2 Nm

2nd step 90° ± 5° rotation added

7 Strate Pin

Page 259 of 1463

1B2-70 M161 ENGINE MECHANICAL

Tools Required

104 589 01 01 00 Spanner

111 589 03 15 00 Insert Pin

Inspection Procedure

1. Position the NO.1 cylinder piston to ATDC 20° by turning

the crankshaft

Notice

When the ATDC 20° mark on vibration damper is aligned

with timing gear case cover, the intake and exhaust cam of

cylinder will make the slope to the center and will face up.

In this way, the insert hole in NO.1 and NO.4 camshaft

bearing cap will match in line with the flange hole for

camshaft sprocket.

2. Check the timing as below procedure;

- Check if the insert pin (111 589 03 15 00) can be inserted

into the NO.1 and NO.4 bearing cap hole.

- At this condition, check if the ATDC 20° mark on vibration

damper aligns with the marker on the timing gear case.

Page 260 of 1463

M161 ENGINE MECHANICAL 1B2-71

Adjustment Procedure

1. Position the NO.1 cylinder to ATDC 20° .

2. Remove the chain tensioner.

3. Remove the exhaust camshaft sprocket.

4. Adjust the timing position with inserting the insert pin

(

f6.5mm, 111 589 03 15 00) into the NO.1 and NO.4

camshaft bearing cap hole and flange hole while rotating

the camshaft by using wrench (104 589 01 01 00).

5. Install the chain to the intake camshaft sprocket.

6. Install the chain to the exhaust camshaft sprocket and

tighten the bolt.

Installation Notice

Tightening Torque1st step 20 Nm

2nd step + 90°

The sprocket bolt is designed to be used only once, so

replace with new one.

7. Install the chain tensioner.

Installation Notice

Screw plug

Tensioner assembly40 Nm

80 ± 8 Nm Tightening

Torque

8. Check the camshaft timing.

Trending: radiator cap, adding oil, key battery, coolant reservoir, ride height, ground clearance, technical data