SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: wiring diagram, warning light, windshield wipers, auxiliary battery, ECO mode, ECU, diagnostic menu

Page 221 of 1463

1B2-32 M161 ENGINE MECHANICAL

3. Pointed rib.

4. Belt cord visible in the base of rib.

POLY V-BELT INSPECTION

lMake marks on the belt with chalk.

lRotate the engine and check the belt for damage.

Notice

If one of the following types of damages is found, replace

the belt.

1. Rubber lumps in the base of rib.

2. Dirt or grit ingrained.

Page 222 of 1463

M161 ENGINE MECHANICAL 1B2-33

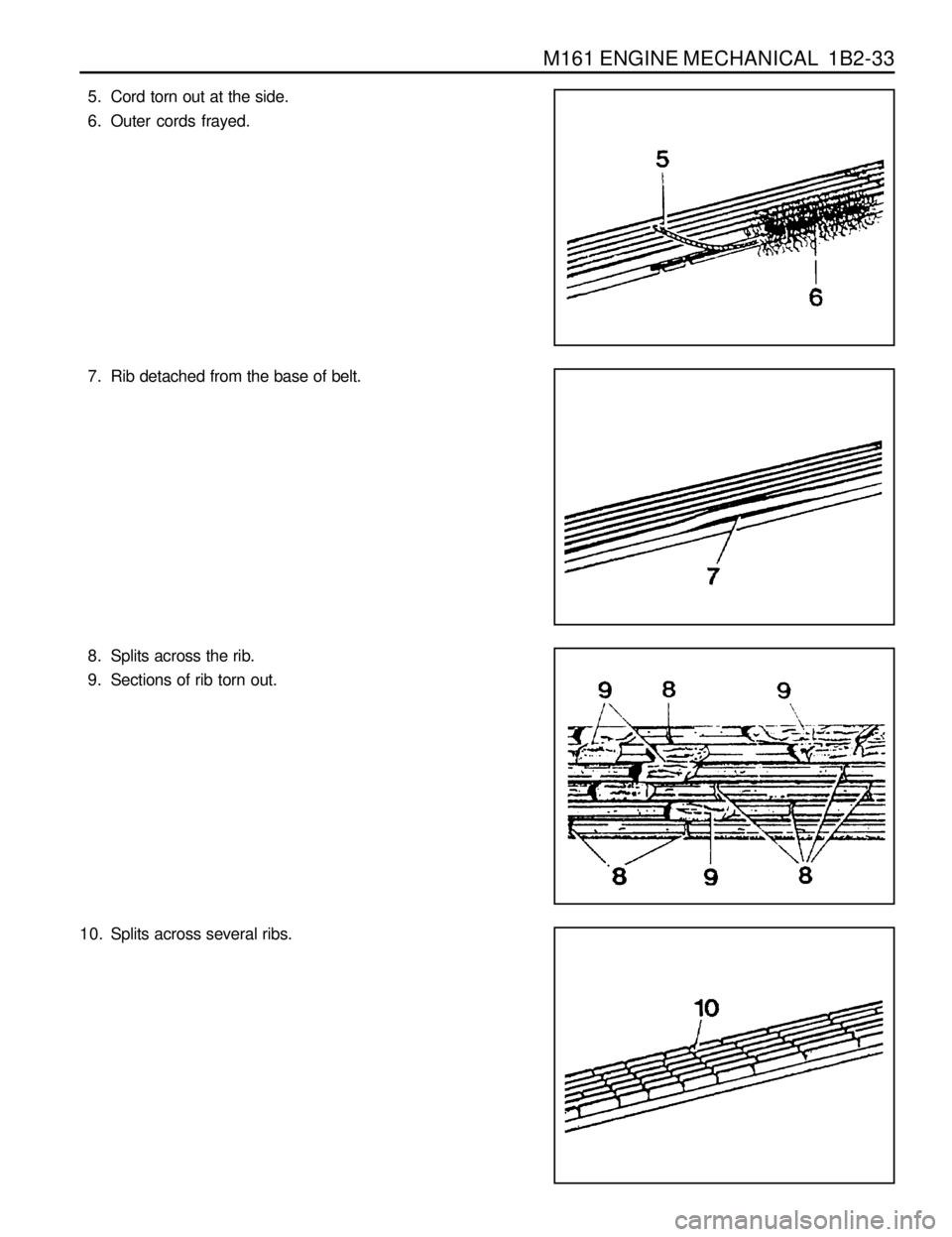

5. Cord torn out at the side.

6. Outer cords frayed.

7. Rib detached from the base of belt.

8. Splits across the rib.

9. Sections of rib torn out.

10. Splits across several ribs.

Page 223 of 1463

1B2-34 M161 ENGINE MECHANICAL

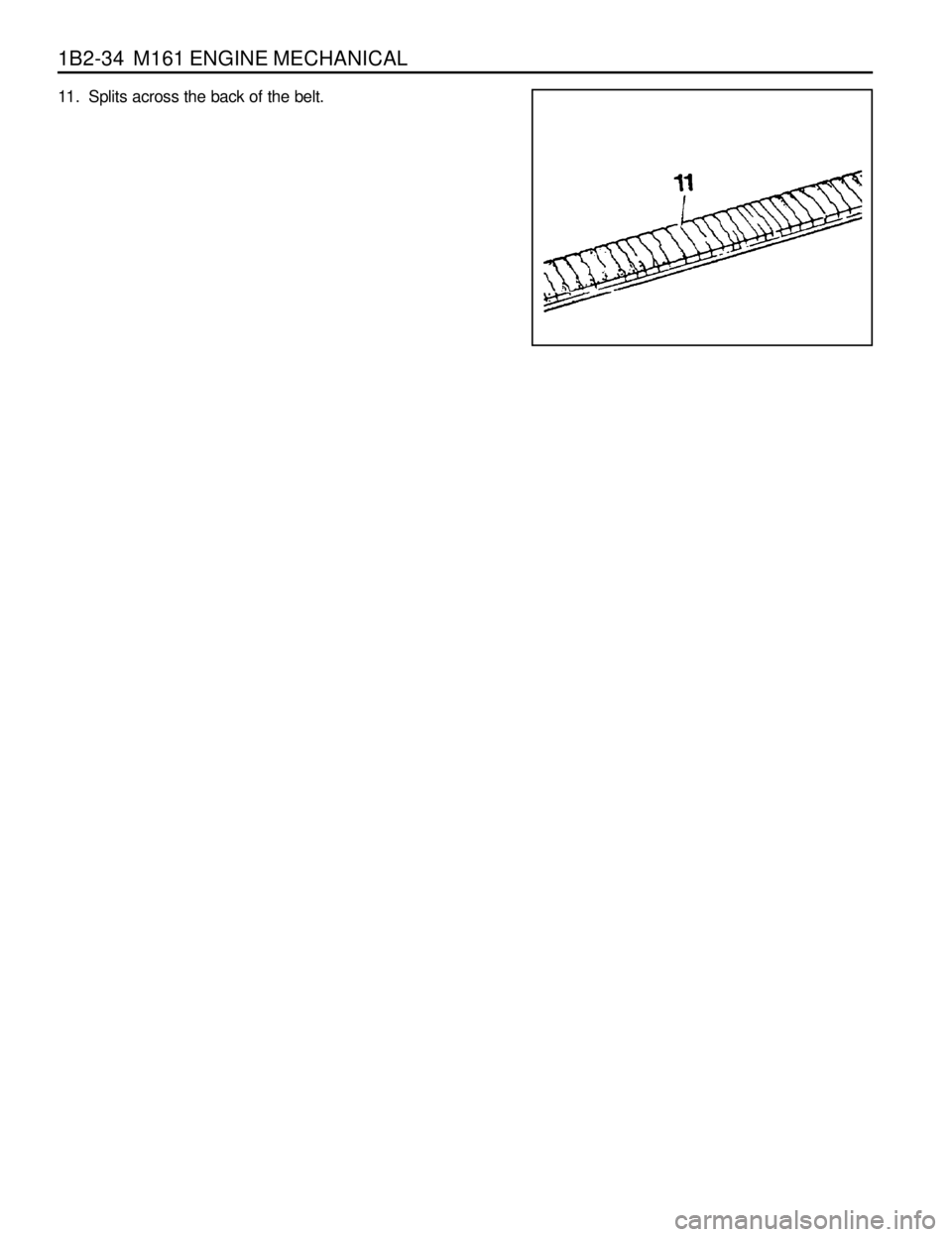

11. Splits across the back of the belt.

Page 224 of 1463

M161 ENGINE MECHANICAL 1B2-35

CYLINDER HEAD COVER

1 Ignition Coil Cover

2 Spark Plug Connector

3 Bolt (M6 X 45 : 4 pieces, M6 X 60 :

6 pieces)............................................. 10 ± 1 Nm4 Cylinder Head Cover

5 Gasket ................................................... Replace

Page 225 of 1463

1B2-36 M161 ENGINE MECHANICAL

Removal & Installation Procedure

1. Remove the intake air duct.

Installation Notice

2. Remove the ignition coil cover.

Installation Notice

3. Remove the spark plug connector and ignition cable.Notice

Release 3 screws from the ignition cover and remove the

cover for M161 Engine coil.

Tightening Torque 9 - 11 Nm

Tightening Torque 9 - 10 Nm

Page 226 of 1463

M161 ENGINE MECHANICAL 1B2-37

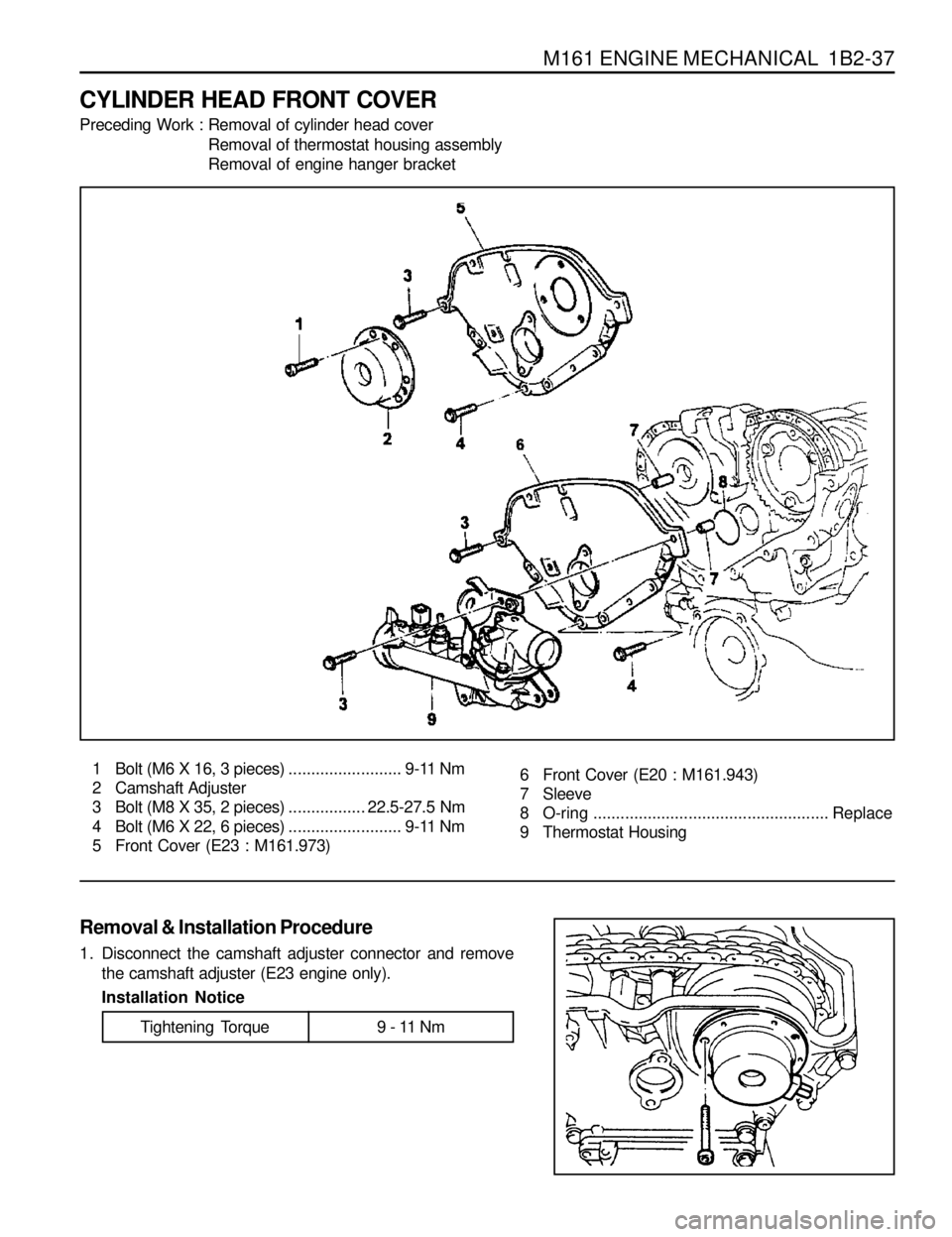

CYLINDER HEAD FRONT COVER

Preceding Work : Removal of cylinder head cover

Removal of thermostat housing assembly

Removal of engine hanger bracket

Removal & Installation Procedure

1. Disconnect the camshaft adjuster connector and remove

the camshaft adjuster (E23 engine only).

Installation Notice

Tightening Torque 9 - 11 Nm

1 Bolt (M6 X 16, 3 pieces)......................... 9-11 Nm

2 Camshaft Adjuster

3 Bolt (M8 X 35, 2 pieces).................22.5-27.5 Nm

4 Bolt (M6 X 22, 6 pieces)......................... 9-11 Nm

5 Front Cover (E23 : M161.973)6 Front Cover (E20 : M161.943)

7 Sleeve

8 O-ring .................................................... Replace

9 Thermostat Housing

Page 227 of 1463

1B2-38 M161 ENGINE MECHANICAL

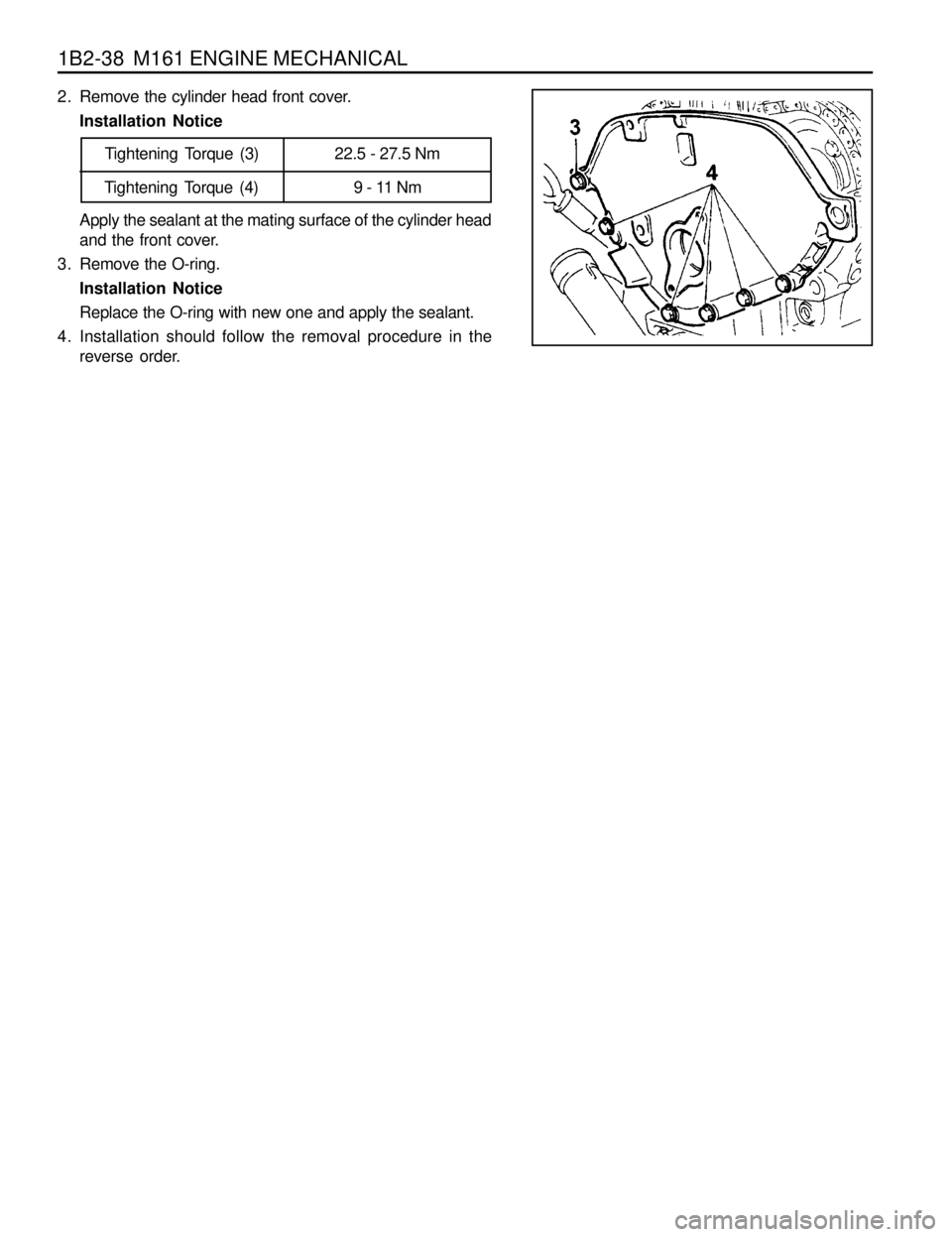

2. Remove the cylinder head front cover.

Installation Notice

Tightening Torque (3) 22.5 - 27.5 Nm

Tightening Torque (4) 9 - 11 Nm

Apply the sealant at the mating surface of the cylinder head

and the front cover.

3. Remove the O-ring.

Installation Notice

Replace the O-ring with new one and apply the sealant.

4. Installation should follow the removal procedure in the

reverse order.

Page 228 of 1463

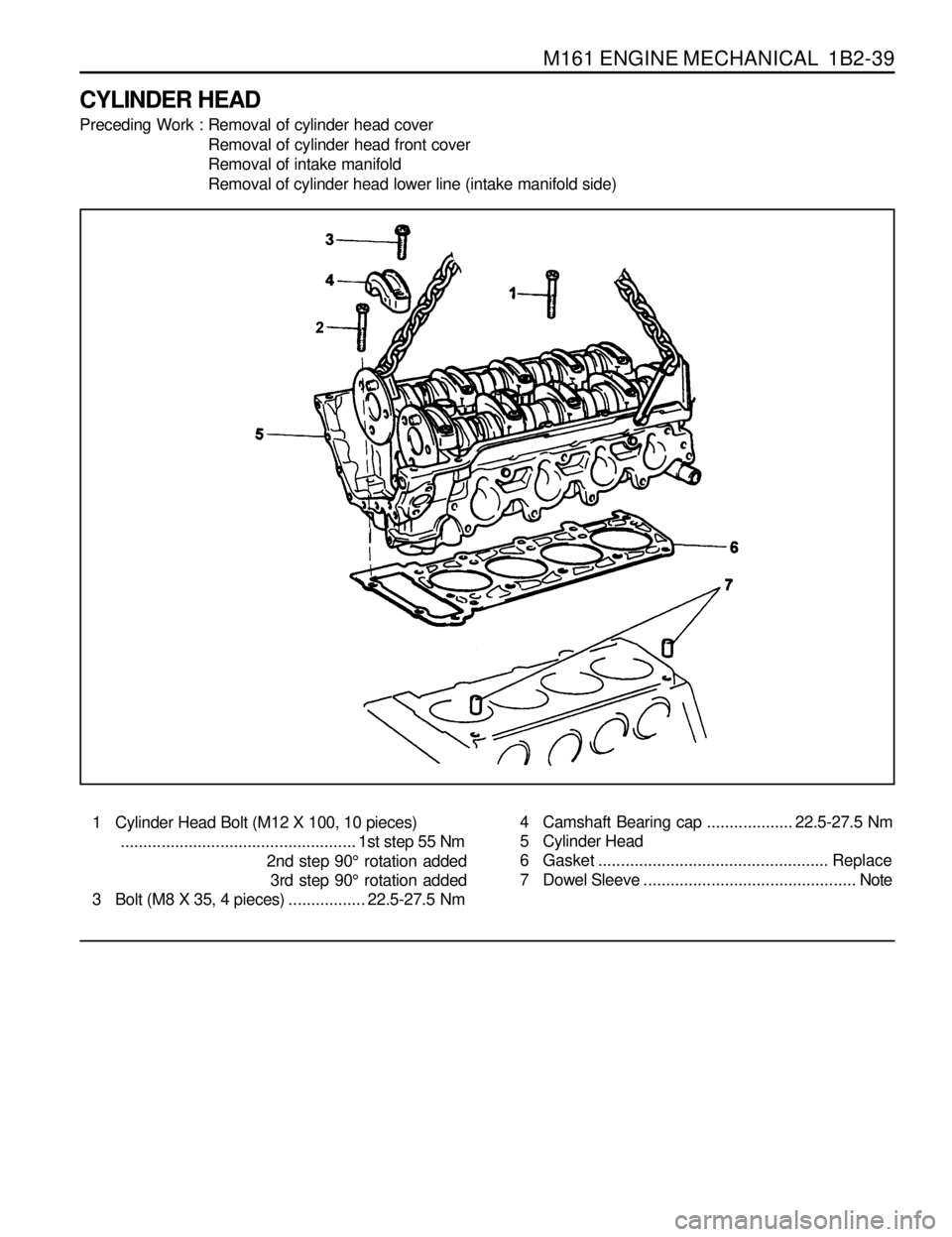

M161 ENGINE MECHANICAL 1B2-39

CYLINDER HEAD

Preceding Work : Removal of cylinder head cover

Removal of cylinder head front cover

Removal of intake manifold

Removal of cylinder head lower line (intake manifold side)

1 Cylinder Head Bolt (M12 X 100, 10 pieces)

....................................................1st step 55 Nm

2nd step 90° rotation added

3rd step 90° rotation added

3 Bolt (M8 X 35, 4 pieces).................22.5-27.5 Nm4 Camshaft Bearing cap...................22.5-27.5 Nm

5 Cylinder Head

6 Gasket ................................................... Replace

7 Dowel Sleeve...............................................Note

Page 229 of 1463

1B2-40 M161 ENGINE MECHANICAL

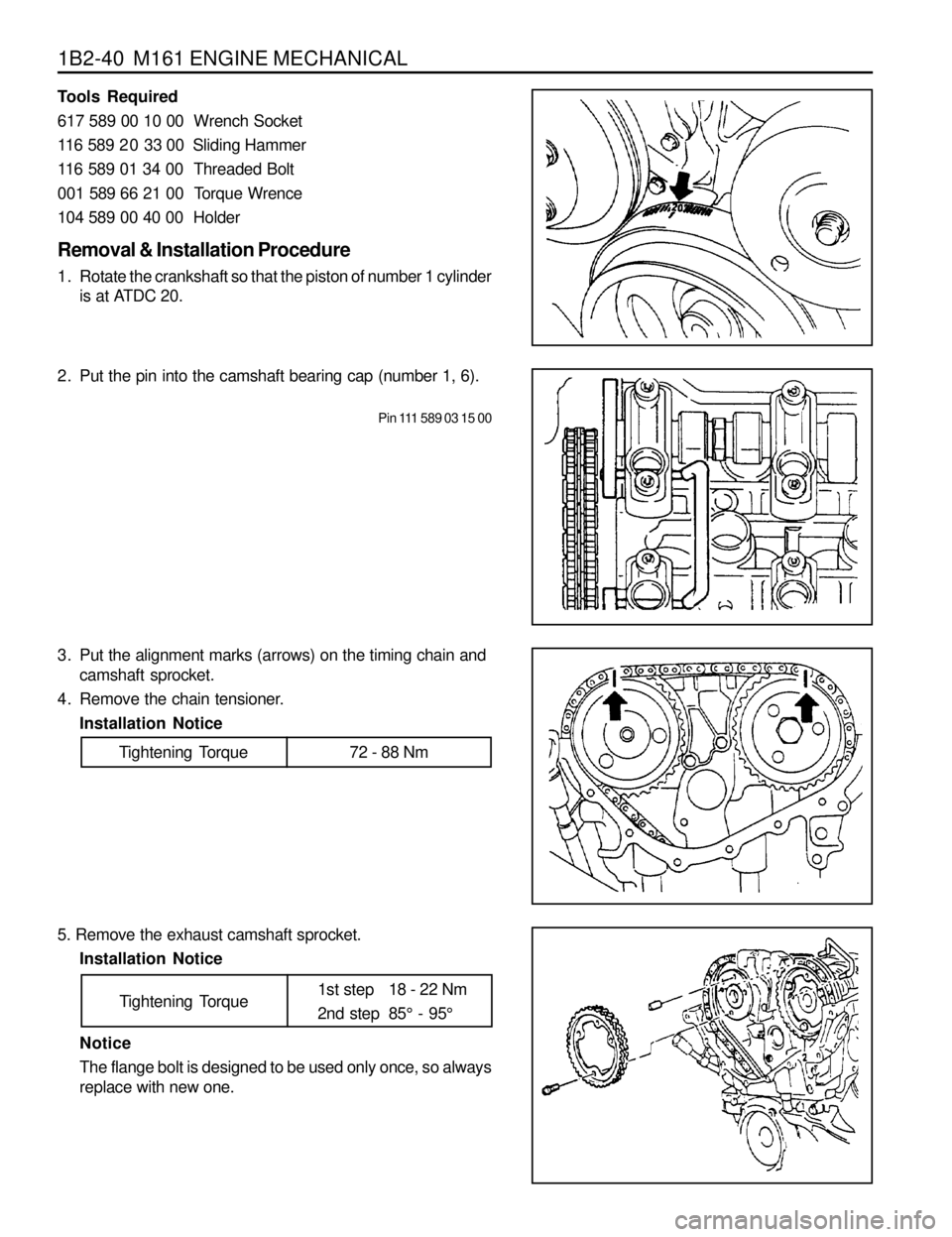

Tools Required

617 589 00 10 00 Wrench Socket

116 589 2 0 33 00 Sliding Hammer

116 589 01 34 00 Threaded Bolt

001 589 66 21 00 Torque Wrence

104 589 00 40 00 Holder

Removal & Installation Procedure

1. Rotate the crankshaft so that the piston of number 1 cylinder

is at ATDC 20.

2. Put the pin into the camshaft bearing cap (number 1, 6).

Pin 111 589 03 15 00

3. Put the alignment marks (arrows) on the timing chain and

camshaft sprocket.

4. Remove the chain tensioner.

Installation Notice

Tightening Torque 72 - 88 Nm

Tightening Torque1st step 18 - 22 Nm

2nd step 85° - 95°

5. Remove the exhaust camshaft sprocket.

Installation Notice

Notice

The flange bolt is designed to be used only once, so always

replace with new one.

Page 230 of 1463

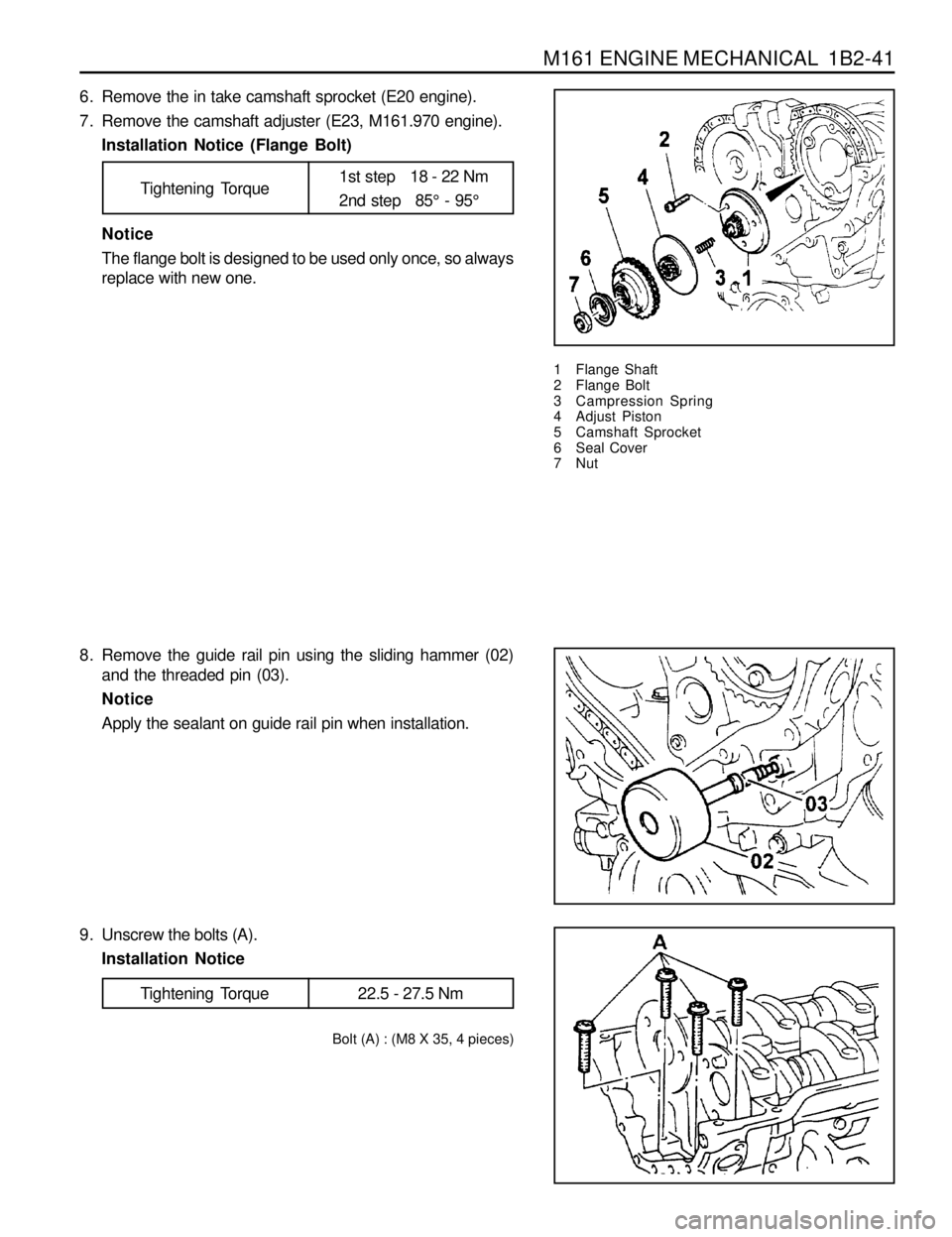

M161 ENGINE MECHANICAL 1B2-41

6. Remove the in take camshaft sprocket (E20 engine).

7. Remove the camshaft adjuster (E23, M161.970 engine).

Installation Notice (Flange Bolt)

1 Flange Shaft

2 Flange Bolt

3 Campression Spring

4 Adjust Piston

5 Camshaft Sprocket

6 Seal Cover

7 Nut

Tightening Torque1st step 18 - 22 Nm

2nd step 85° - 95°

Notice

The flange bolt is designed to be used only once, so always

replace with new one.

8. Remove the guide rail pin using the sliding hammer (02)

and the threaded pin (03).

Notice

Apply the sealant on guide rail pin when installation.

9. Unscrew the bolts (A).

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

Bolt (A) : (M8 X 35, 4 pieces)

Trending: warning, coolant capacity, filler, transmission, handbrake, fuel cap, torque