service SSANGYONG MUSSO 1998 Workshop Manual Online

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 702 of 1463

M161 ENGINE CONTROLS 1F2-53

3. If there is no change in fuel pressure and maintain the

following pressure over 30 minutes, it is normal.

Internal Leakage Test

1. Connect the fuel pressure gauge to the fuel pressure test

connector.

2. Stop the engine for approx. 30 minutes and then check the

fuel pressure changes.

Fuel pressure

drops slowly

·Fuel leakage at the

injector

• Faulty fuel pressure

regulator's

diaphragm and O-

ring.

Fuel pressure

drops rapidly• Faulty check valve

in the fuel pump.

Possible Cause Pressure Change

Fuel Pressure(bar) 2.5

Discharging the pressure in fuel system

1. Remove the fuel pressure test connector.

Installation Notice

2. Remove the fuel pressure in fuel system by pressing the

service valve with a clean, pointy tool.

Notice

Place a cloth so that the fuel doesn't stain around.

Tightening Torque

22.5 - 27.5 Nm

Page 710 of 1463

M161 ENGINE CONTROLS 1F2-61

Notice

Replace the fuel pump relay if the measured value is over

9A. Notice

Check the fuel filter and fuel line when the fuel delivery is

not within specified value.

Measure the Current Consumption of Fuel Pump

1. Remove the fuel pump relay from fuse and relay box in

trunk, and turn the ignition switch to "ON" position.

2. Using a multi-tester, measure the current consumption by

connecting the terminal No.1 and No.3 of pump.

Measure the Fuel Delivery From the Fuel Pump

1. Disconnect the return pipe from fuel distributor and insert

the appropriate hose into it.

2 . Place the hose end into the beaker with the minimum capacity

of 1Liter.

3. Turn the ignition switch to "ON" position.

4. Connect the terminal No.33 and No.5 of ECU with a service

wire.

5. Measure the fuel delivery from the fuel pump.

1Liter/max.35sec. Specifed Value

5 - 9A Specifed Value

Page 727 of 1463

1F2-78 M161 ENGINE CONTROLS

Service Data

Resistance characteristic curve according to the coolant

temperature

Temperature(°C) Resistance(W) Voltage(V) Temperature(°C) Resistance(W) Voltage(V)

-40 48,550 4.8991 60 594 1.8632

-30 27,000 4.8214 70 434 1.5132

-20 15,670 4.7001 80 322 1.2179

-10 9,450 4.5215 90 243 0.9775

0 5,890 4.4273 100 185 0.7806

10 3,790 3.9562 110 143 0.6255

20 2,500 3.5714 120 111.6 0.5020

30 1,692 3.1426 130 88.0 0.4044

40 1,170 2.6959 140 71.2 0.3323

50 826 2.2618 - - -

Page 730 of 1463

SECTION 1F3

OM600 ENGINE CONTROLS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F3-1

Fastener Tightening Specifications . . . . . . . . 1F3-1

Maintenance and Repair . . . . . . . . . . . . . . 1F3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel Injection Pump Coding . . . . . . . . . . . . . 1F3-3

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-4

Vacuum Control System Test . . . . . . . . . . . . 1F3-5

Vacuum Pump(Sectional View) . . . . . . . . . . 1F3-10

Vacuum Pump Test . . . . . . . . . . . . . . . . . . . 1F3-11

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . 1F3-13

Vacuum Unit Replacement . . . . . . . . . . . . . 1F3-15Idle Speed Adjustment . . . . . . . . . . . . . . . . 1F3-16

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F3-18

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-21

Injection Nozzle Test . . . . . . . . . . . . . . . . . . 1F3-22

Injection Nozzles . . . . . . . . . . . . . . . . . . . . . 1F3-25

Injection Nozzle Repair . . . . . . . . . . . . . . . . 1F3-27

Removal and Installation of

Injection Timing Device . . . . . . . . . . . . . . 1F3-30

Injection Timing Device . . . . . . . . . . . . . . . . 1F3-35

Start of Delivery Test

(Position Sensor, RIV Method) . . . . . . . . . 1F3-37

Fuel Injection Pump . . . . . . . . . . . . . . . . . . 1F3-46

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Fuel Tank Mounting Nut

Fuel Pump Pressure Line

Fuel Injection Nozzle

Fuel Injection Pipe

Nozzle Tensioning Nut

Screw Plug

Left-Hand Thread BoltN·m

28 - 47

13

35 - 40

18

80

30

46

Page 731 of 1463

1F3-2 OM600 ENGINE CONTROLS

FUEL SYSTEM

1 Fuel Injection Pump

2 Fuel Feed Pump

3 Overflow Valve

4 Injection Nozzle

5 Pre-filter6 Fuel Return Hose

7 Injection Line

8 Fuel Tank

9 Fuel Filter

10 Choke Orifice

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Page 745 of 1463

1F3-16 OM600 ENGINE CONTROLS

Idle Speed

750 - 850 rpm

720 - 820 rpm Engine

OM661LA Engine

OM662LA Engine

Tools Required

667 589 00 21 00 TDC Pulse Generato

Commercial Tool

IDLE SPEED ADJUSTMENT

Service Data

e.g. Bosch, MOT 001.03

Sun, DIT 9000 Digital Tester

Adjustment Procedure

1. Connect the digital tester (1) and TDC pulse sender unit

(11).

2. Run the engine and warm up the coolant to 60~80°C.

TDC pulse generator 667 589 02 21 00

3. Disconnect the vacuum hose (4) from the PLA unit to check

idle speed with tester.

4. Check idle speed with tester.

Notice

To adjust idle speed, loosen the locking nut (6) of PLA unit.

OM 661LA Engine750 - 850rpm

OM 662LA Engine

720 - 820rpm

Page 746 of 1463

OM600 ENGINE CONTROLS 1F3-17

6. After adjustment, tighten the locking nut and place the

position marking with different color of paint.

Notice

If there are no changes in idle speed with PLA unit

adjustment, perform the service at a BOSCH Service Center.

7. Connect the vacuum pump to the PLA vacuum unit and

build up vacuum approx. 500mbar. If engine rpm increases

by approx. 100rpm, It is normal.

Vacuum Pump 001 589 73 21 00

8. Connect the vacuum line (4).

9. Switch on all ancillaries and check the idle speed.

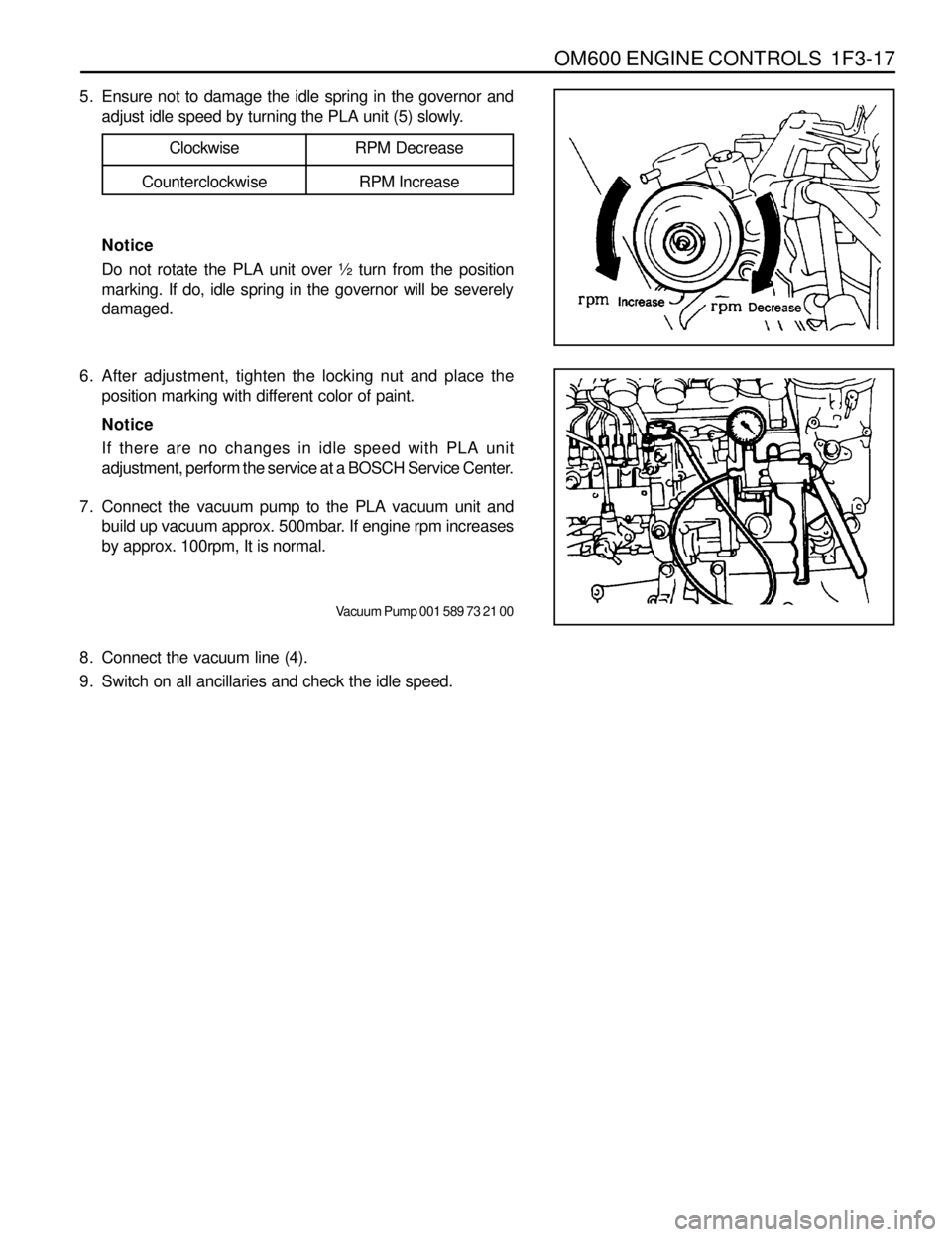

5. Ensure not to damage the idle spring in the governor and

adjust idle speed by turning the PLA unit (5) slowly.

Notice

Do not rotate the PLA unit over ½ turn from the position

marking. If do, idle spring in the governor will be severely

damaged.Clockwise

Counterclockwise

RPM Decrease

RPM Increase

Page 766 of 1463

OM600 ENGINE CONTROLS 1F3-37

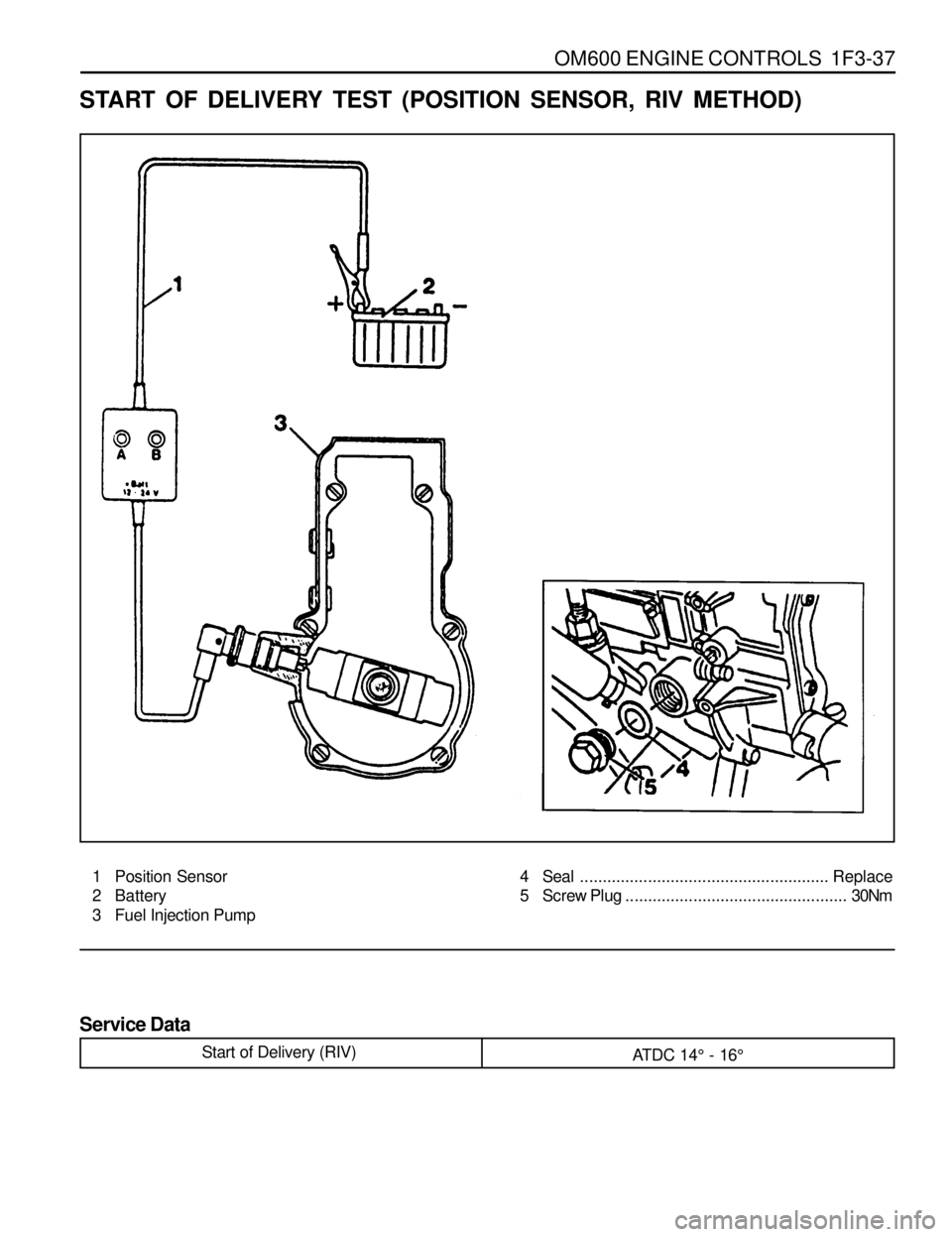

START OF DELIVERY TEST (POSITION SENSOR, RIV METHOD)

1 Position Sensor

2 Battery

3 Fuel Injection Pump4 Seal....................................................... Replace

5 Screw Plug.................................................30Nm

Service Data

Start of Delivery (RIV)

ATDC 14° - 16°

Page 769 of 1463

1F3-40 OM600 ENGINE CONTROLS

Start of Delivery (RIV)

Idle Speed (Connection Diagram for Testers With Adapter)

1 Fuel Injection Pump

2 Rl Sensor

3 Digital Tester4 TDC Pulse Sender Unit

5 Battery

6 Rl Pulse Generator

Service Data

ATDC 14° - 16°

OM661LA : 720 - 820 rpm, OM662LA : 750 - 850 rpm

Page 773 of 1463

1F3-44 OM600 ENGINE CONTROLS

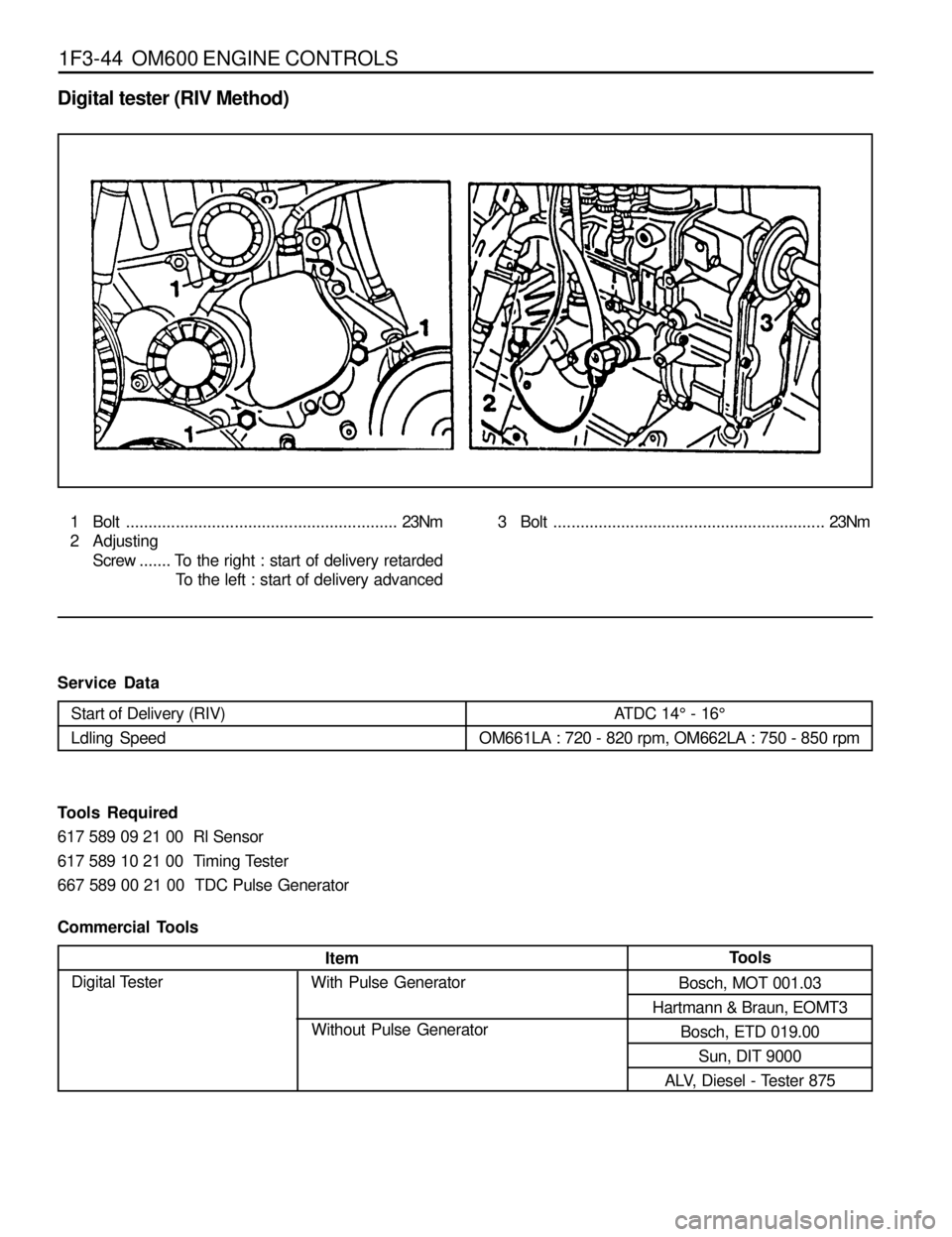

Tools Required

617 589 09 21 00 Rl Sensor

617 589 10 21 00 Timing Tester

667 589 00 21 00 TDC Pulse Generator

Commercial Tools

Item

Digital Tester

With Pulse Generator

Without Pulse GeneratorTools

Bosch, MOT 001.03

Hartmann & Braun, EOMT3

Bosch, ETD 019.00

Sun, DIT 9000

ALV, Diesel - Tester 875

Digital tester (RIV Method)

1 Bolt............................................................23Nm

2 Adjusting

Screw....... To the right : start of delivery retarded

To the left : start of delivery advanced3 Bolt............................................................23Nm

Service Data

Start of Delivery (RIV)

Ldling Speed

ATDC 14° - 16°

OM661LA : 720 - 820 rpm, OM662LA : 750 - 850 rpm