service SSANGYONG MUSSO 1998 Workshop Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 506 of 1463

Circulation Type

Radiation

Capability

SECTION 1D2

M161 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D2-1

General Specifications . . . . . . . . . . . . . . . . . 1D2-1

Fastener Tightening Specifications . . . . . . . . 1D2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1D2-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1D2-3

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D2-4

System Leakage Test . . . . . . . . . . . . . . . . . . 1D2-4

Maintenance and Repair . . . . . . . . . . . . . . 1D2-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1D2-5Coolant Drain and Fill Up . . . . . . . . . . . . . . . 1D2-5

Cooling Fan and Viscous Clutch . . . . . . . . . . 1D2-7

Coolant Pump . . . . . . . . . . . . . . . . . . . . . . . . 1D2-9

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D2-11

Thermostat Housing Assembly . . . . . . . . . . 1D2-12

Removal and Installation of Cooling

Fan Shroud . . . . . . . . . . . . . . . . . . . . . . . 1D2-14

Removal and Installation of Radiator . . . . . 1D2-15

SPECIFICATIONS

GENERAL SPECIFICATIONS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

Description

Water Cooling Forced Circulation

Down Flow

61,500 kcal/h

58,000 kcal/h

680 x 415 x 25 mm

680 x 415 x 28 mm

f 460, 9 Blades

ALUTEC-P78, Dragon Power Coolant A

50 : 50

10.5 L

3.4 L

1.4 bar Application

Cooling Type

Radiator

Dimension(Width´Height´Thickeness)

Cooling Fan

Anti-Freeze Agent

Mixing Ratio of Anti-Freeze Agen with Water (Anti-Freeze Agent : Water)

Coolant Capacity

Reservoir Capacity

Cap Operating Pressure (Reservoir Tank Pressure Cap)

Page 510 of 1463

M161 ENGINE COOLING 1D2-5

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

COOLANT DRAIN AND FILL UP

Draning & Filling up Procedure

1. Loosen the cap a little and release pressure and remove

the cap.

Notice

For the risk of scalding, the cap must not be opened unless

the coolant temperature is below 90oC.

2. Loosen the radiator lower drain cock and drain the coolant.

Notice

Collect coolant by using a proper container.

3. Drain the coolant from the crankcase by inserting a hose

(dia. 14mm) onto the drain bolt on the side of crankcase

(exhaust manifold) and by loosening the plug.

Notice

lJust loosen the drain plug to drain the coolant and do

not remove the plug completely.

lCollect coolant by using proper container.

Page 522 of 1463

SECTION 1D3

OM600 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D3-1

General Specifications . . . . . . . . . . . . . . . . . 1D3-1

Fastener Tightening Specifications . . . . . . . . 1D3-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-2

Cooling Circulation . . . . . . . . . . . . . . . . . . . . 1D3-2

Thermostat Operation . . . . . . . . . . . . . . . . . 1D3-3

Cooling System Leakage Test . . . . . . . . . . . 1D3-4

Maintenance and Repair . . . . . . . . . . . . . . 1D3-5On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1D3-5

Drain and Filling of Coolant . . . . . . . . . . . . . 1D3-5

Coolant Pump . . . . . . . . . . . . . . . . . . . . . . . . 1D3-6

Coolant Pump Housing . . . . . . . . . . . . . . . . . 1D3-8

Cooling Fan Clutch . . . . . . . . . . . . . . . . . . . 1D3-10

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-12

Cooling Sub-System . . . . . . . . . . . . . . . . . . 1D3-14

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-16

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Application

Coolant

Mixing Ratio (Water : anticorrosion)

CapacityDescription

ALUTEC P- 78

50 : 50

10.5L - 11L

9.5L - 10L

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Coolant Pump Bolt

Belt Pulley Bolt

Coolant Pump Housing Return Pipe Bolt

Thermostat Bolt

Cooling Fan Clutch Socket Bolt (Center)

Cooling Fan Clutch Socket Bolt (Side)

Radiator Bolt

Coolant Sub-tank BoltN

· ·· ·

·m

10

10

10

10

45

10

3 - 7

3 - 7

FASTENER TIGHTENING SPECIFICATIONS

662LA

661LA

Page 526 of 1463

OM600 ENGINE COOLING 1D3-5

DRAIN AND FILLING OF COOLANT

Preceding Work : Removal of skid plate

Drain / Filling

1. Loosen the pressure cap of reservoir by 1 notch and remove

pressure and then loosen the cap.

Notice

Do not remove radiator cap when coolant is above 90°C.

2. Open the drain plug and drain the coolant.

Notice

Collect the coolant by using the proper bottle.

3. Remove the drain plug(1) and seal(2) of cylinder block and

drain the coolant.

4. Replace the seal to new one and tighten the drain plug

Installation Notice

Tightening Torque 30 Nm

5. Tighten the drain plug of the lower radiator.

6. Fill the coolant through coolant reservoir-tank.

Notice

lA proportion of 50% by volume of water / anticorrosion

must be ensured

7. After engine is running at idle speed, check the level of

coolant. If necessary, add enough specified coolant.

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Page 539 of 1463

SECTION 1E1

M162 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E1-1

Alternator Specifications . . . . . . . . . . . . . . . . 1E1-1

Starting Motor Specifications . . . . . . . . . . . . 1E1-2

Battery Specifications . . . . . . . . . . . . . . . . . . 1E1-2

Fastener Tightening Specifications . . . . . . . . 1E1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1E1-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1E1-3

Maintenance and Repair . . . . . . . . . . . . . . 1E1-4

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1E1-4

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E1-4

Starting Motor . . . . . . . . . . . . . . . . . . . . . . . . 1E1-5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E1-6

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . 1E1-7

Ignition Cable . . . . . . . . . . . . . . . . . . . . . . . . 1E1-9

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . 1E1-12

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E1-12

SPECIFICATIONS

ALTERNATOR SPECIFICATIONS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

Application

Output Voltage

Current

Resistance Between Rotor Core and Slip RingDescription

12 - 14 V

115 A

¥ W

Page 542 of 1463

1E1-4 M162 ENGINE ELECTRICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ALTERNATOR

Preceding Work : Removal of the drivebelt

Removal & Installation Procedure

1. Disconnect the negative battery terminal.

2. Unscrew the nut and disconnect the terminal (1).

Installation Notice

1 Terminal (B+)

2 Terminal (D+)

3 Combination Bolt

4 Alternator

3. Unscrew the nut and disconnect the terminal (2).

Installation Notice

Tightening Torque 14 - 18 Nm

4. Unscrew the combination bolt (3).

Installation Notice

Tightening Torque 4 - 5 Nm

5. Remove the alternator.

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 42 - 50 Nm

Page 551 of 1463

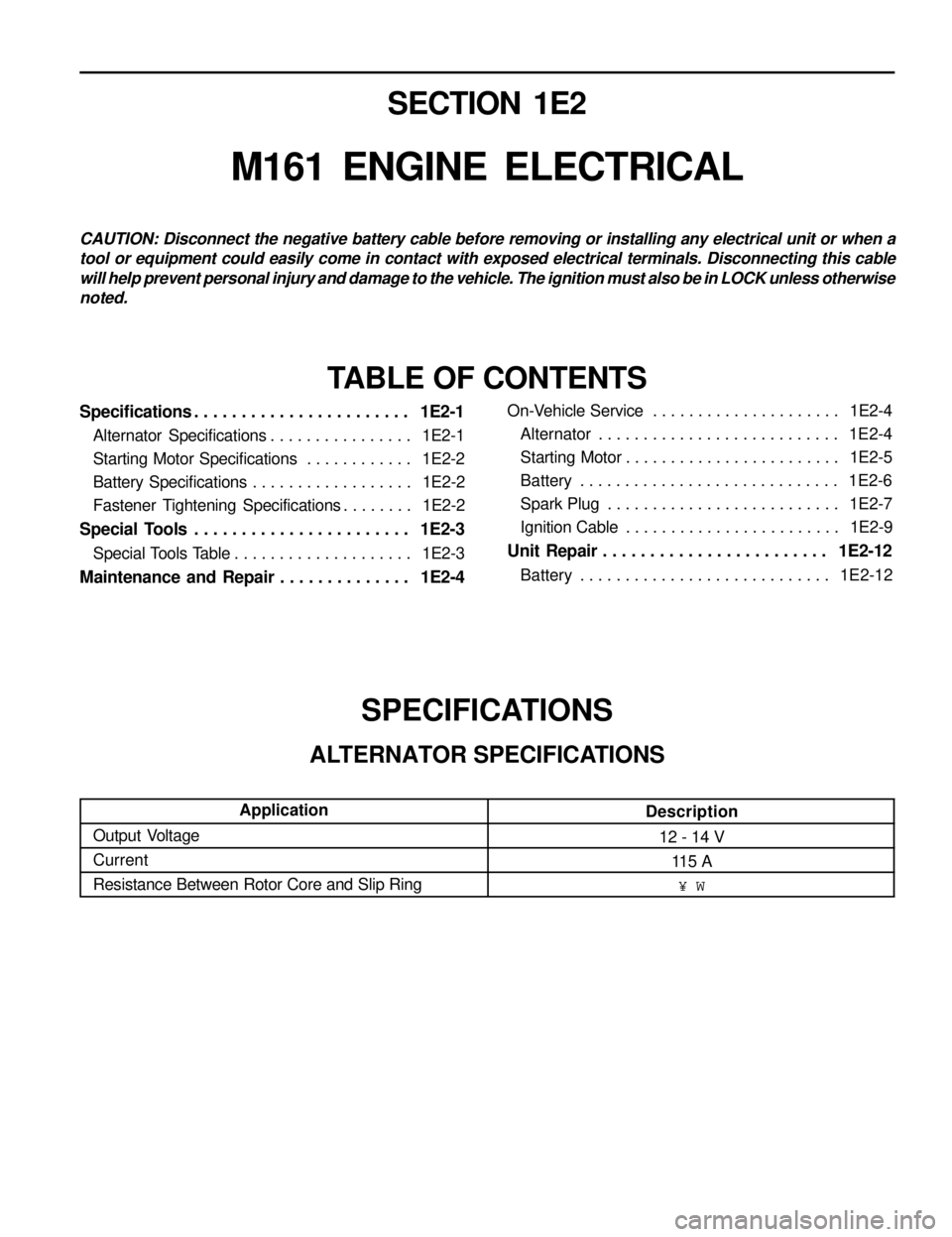

SECTION 1E2

M161 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E2-1

Alternator Specifications . . . . . . . . . . . . . . . . 1E2-1

Starting Motor Specifications . . . . . . . . . . . . 1E2-2

Battery Specifications . . . . . . . . . . . . . . . . . . 1E2-2

Fastener Tightening Specifications . . . . . . . . 1E2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1E2-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1E2-3

Maintenance and Repair . . . . . . . . . . . . . . 1E2-4

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1E2-4

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-4

Starting Motor . . . . . . . . . . . . . . . . . . . . . . . . 1E2-5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-6

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-7

Ignition Cable . . . . . . . . . . . . . . . . . . . . . . . . 1E2-9

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . 1E2-12

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-12

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

SPECIFICATIONS

ALTERNATOR SPECIFICATIONS

Application

Output Voltage

Current

Resistance Between Rotor Core and Slip RingDescription

12 - 14 V

115 A

¥ W

Page 554 of 1463

1E2-4 M161 ENGINE ELECTRICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ALTERNATOR

Preceding Work : Removal of the drivebelt

Removal & Installation Procedure

1. Disconnect the negative battery terminal.

2. Unscrew the nut and disconnect the terminal (1).

Installation Notice

1 Terminal (B+)

2 Terminal (D+)

3 Combination Bolt

4 Alternator

3. Unscrew the nut and disconnect the terminal (2).

Installation Notice

Tightening Torque 14 - 18 Nm

4. Unscrew the combination bolt (3).

Installation Notice

Tightening Torque 4 - 5 Nm

5. Remove the alternator.

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 42 - 50 Nm

Page 563 of 1463

SECTION 1E3

OM600 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E3-1

General Specifications . . . . . . . . . . . . . . . . . 1E3-1

Maintenance and Repair . . . . . . . . . . . . . . 1E3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1E3-2

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Application

Alternator

Starter

Glow PlugDescription

12V - 75A

12V - 2.2kW

11.5V

SPECIFICATIONS

GENERAL SPECIFICATIONS

Glow Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-2

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-6

Starter Motor . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-8

Page 564 of 1463

1E3-2 OM600 ENGINE ELECTRICAL

Preheating System

General information

The preheating system consists of control, coolant temperature

sensor and glow plugs.

lControl relay - preheating time.

lCoolant temperature sensor.

lGlow plug.

GLOW PLUG

1 Wiring Harness

2 Nut .............................................................. 4 Nm3 Wire Terminal

4 Glow Plug

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE