SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: drain bolt, heating, brake rotor, lights, windshield wipers, oil type, service schedule

Page 891 of 1463

Diesel

Gasoline

(M161)

Gasoline

(M162) Diesel

GasolineApplication

Joint Type

Number of Spider

FrontFront

Rear

Front

Rear

Front (Full-Time)

Front (Part-Time)

Rear

Front

Rear

SECTION 3C

PROPELLER SHAFT

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 3C-1

General Specifications . . . . . . . . . . . . . . . . . . 3C-1

Component Locator . . . . . . . . . . . . . . . . . . . 3C-2

M/T & A/T (Part-time T/C) . . . . . . . . . . . . . . . . 3C-2

Maintenance and Repair . . . . . . . . . . . . . . . 3C-3

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 3C-3

Propeller Shaft . . . . . . . . . . . . . . . . . . . . . . . . 3C-3

SPECIFICATIONS

GENERAL SPECIFICATIONS

Description

Single or Single & Double Cardan

Single Cardan

Constant Velocity(CV) & Double Carden

Single Cardan

3

2

2

CV Joint : 1, Double Spiders : 1

2

Diesel

Gasoline

Shaft Dimensions

(L´O.D´I.D)

When Compressed

FullyFront

Rear

Front

Rear

Front

Rear-

-

-

M/T & MB A/T

BTRA A/T (2p-Type)

TONGIL

KSC

-576´f59.5´f63.5

973´

f63.5´f659.5

583.5´

f44.7´f50.8

973´

f63.5´f459.5

380.8´

f63.5´f59.5

591.5´

f63.5´f59.5

601.6´

f50.8´f44.7

579.6´

f50.8´f44.7

776.8´

f63.5´f59.5

Page 892 of 1463

3C-2 PROPELLER SHAFT

1 Flange Yoke

2 Cross and Bearing Assembly (with Snap Ring)

3 Cross and Bearing Assembly (with Snap Ring)

4 Slip Yoke Assembly

5 Grease Nipple

6 Dust Cap

7 Oil Seal

8 Split Washer

9 Slip Tube Shaft

10 Tube

Notice

Only the length of shaft is different and the components of front/rear shaft are the same.

(The deadener is inserted to the inside of tube of rear shaft, both ends)

COMPONENT LOCATOR

M/T & A/T (PART-TIME T/C)

1. Gasolin : E32

- Fromt Propeller Shaft

2. Diesel/Gasolin : E23,20

- Fromt Propeller Shaft

: A/T + Full - Time T/C

3. Gasolin

- Rear Propeller Shaft

Diesel

- Fromt & Rear Propeller Shaft

: M/T & A/T + FPart - Time T/C

11 Tube Yoke

12 Flange Yoke

13 Diesel : Cross and Bearing Assembly (with Snap Ring)

Gasoline : CV Joint (DOJ)

14 Diesel : Double Cardan

Gasoline : Stub Shaft

15 Tube

16 Cross and Bearing Assembly (with Snap Ring)

17 Center Couping Yoke

18 Boots Band

Page 893 of 1463

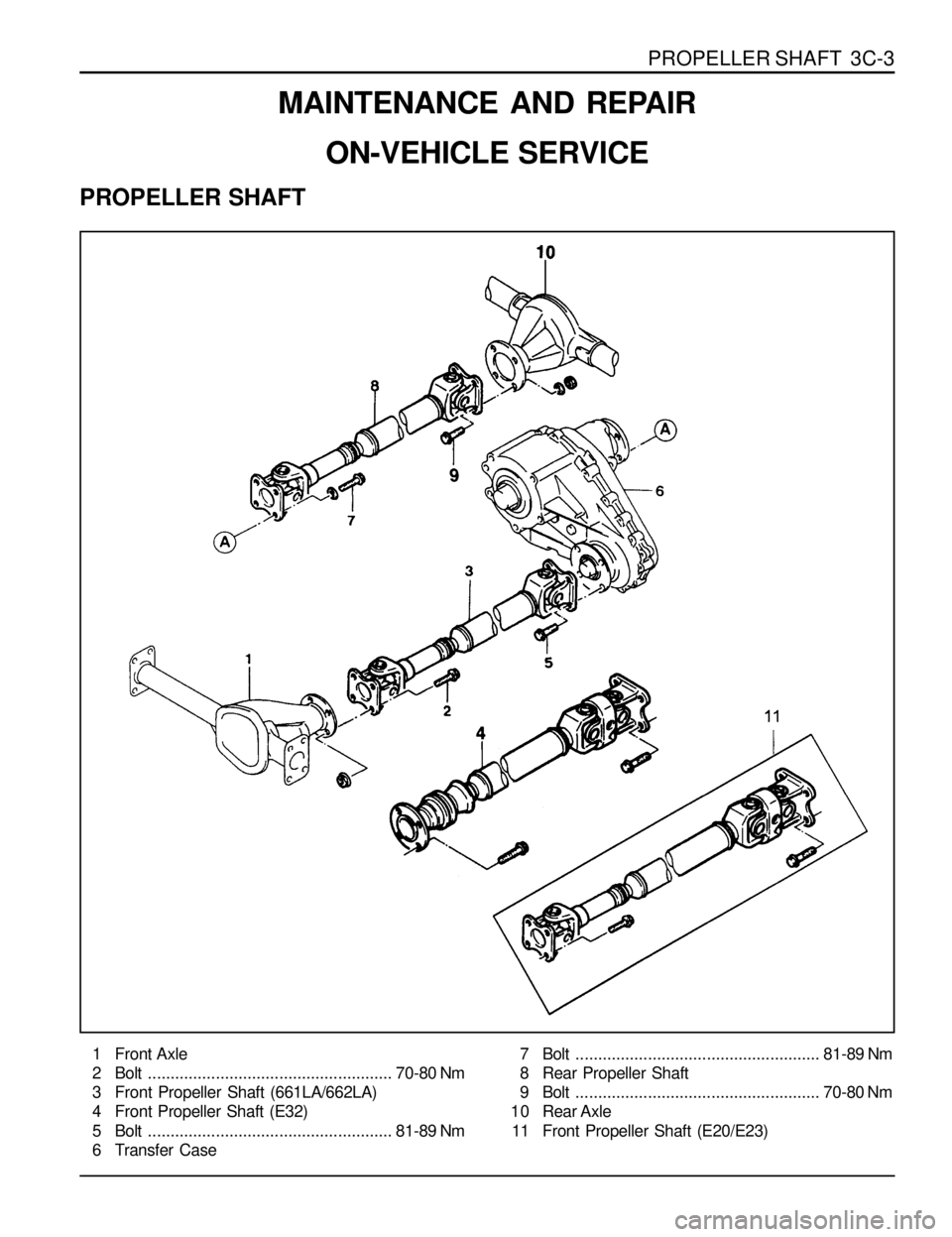

PROPELLER SHAFT 3C-3

1 Front Axle

2 Bolt......................................................70-80 Nm

3 Front Propeller Shaft (661LA/662LA)

4 Front Propeller Shaft (E32)

5 Bolt......................................................81-89 Nm

6 Transfer Case

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

PROPELLER SHAFT

7 Bolt......................................................81-89 Nm

8 Rear Propeller Shaft

9 Bolt......................................................70-80 Nm

10 Rear Axle

11 Front Propeller Shaft (E20/E23)

Page 894 of 1463

3C-4 PROPELLER SHAFT

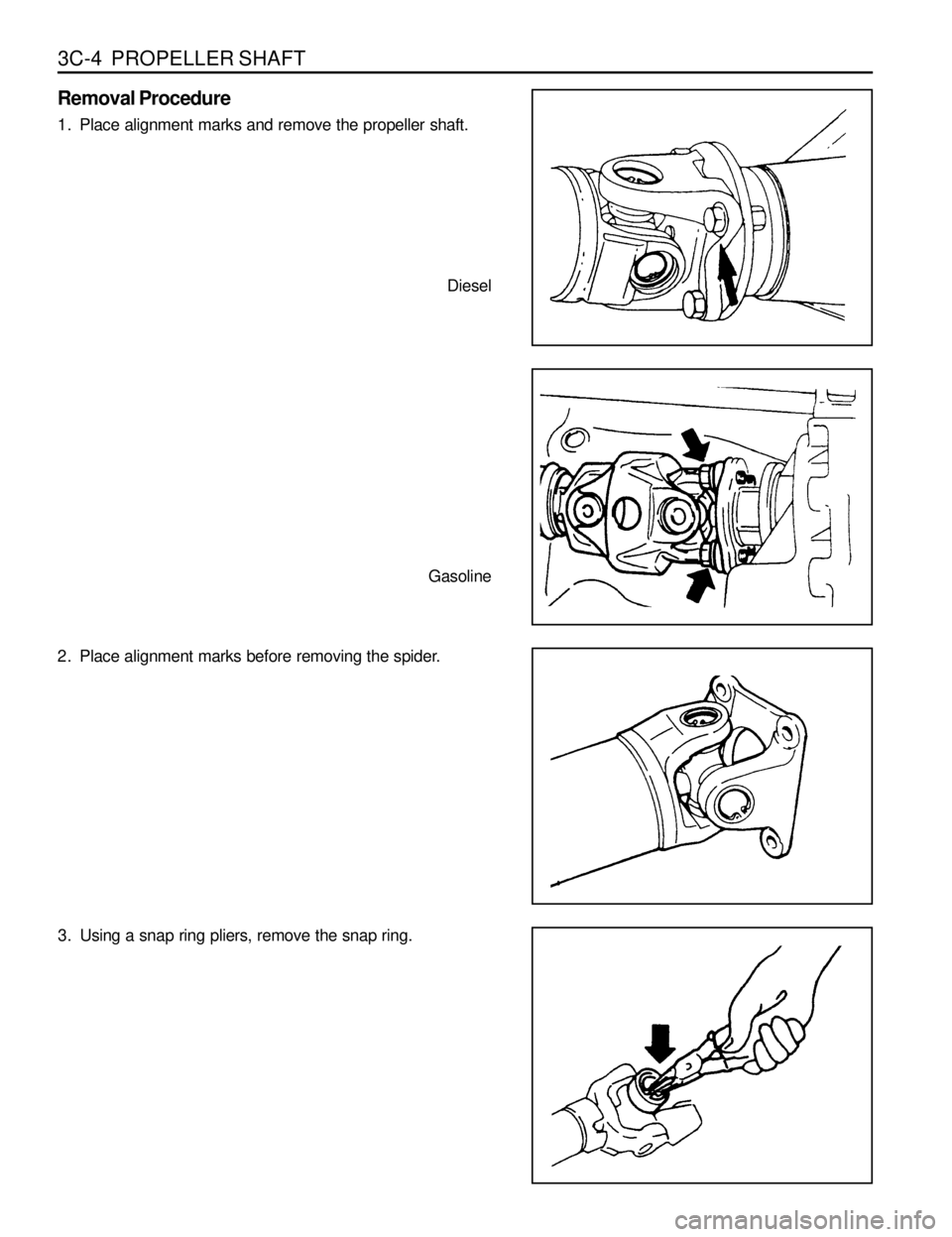

Removal Procedure

1. Place alignment marks and remove the propeller shaft.

2. Place alignment marks before removing the spider.

3. Using a snap ring pliers, remove the snap ring.

GasolineDiesel

Page 895 of 1463

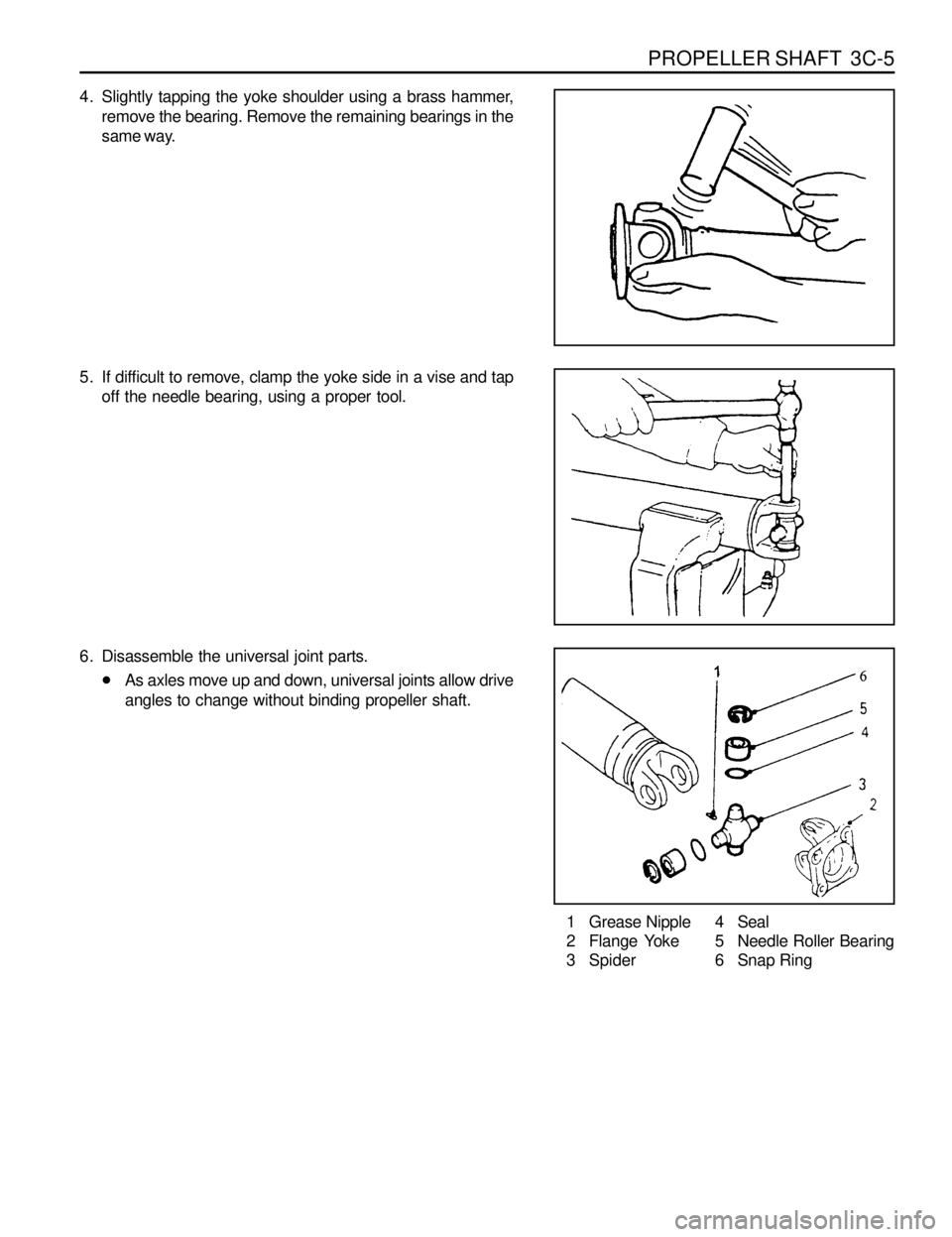

PROPELLER SHAFT 3C-5

5. If difficult to remove, clamp the yoke side in a vise and tap

off the needle bearing, using a proper tool.

6. Disassemble the universal joint parts.

lAs axles move up and down, universal joints allow drive

angles to change without binding propeller shaft.

1 Grease Nipple

2 Flange Yoke

3 Spider4 Seal

5 Needle Roller Bearing

6 Snap Ring

4. Slightly tapping the yoke shoulder using a brass hammer,

remove the bearing. Remove the remaining bearings in the

same way.

Page 896 of 1463

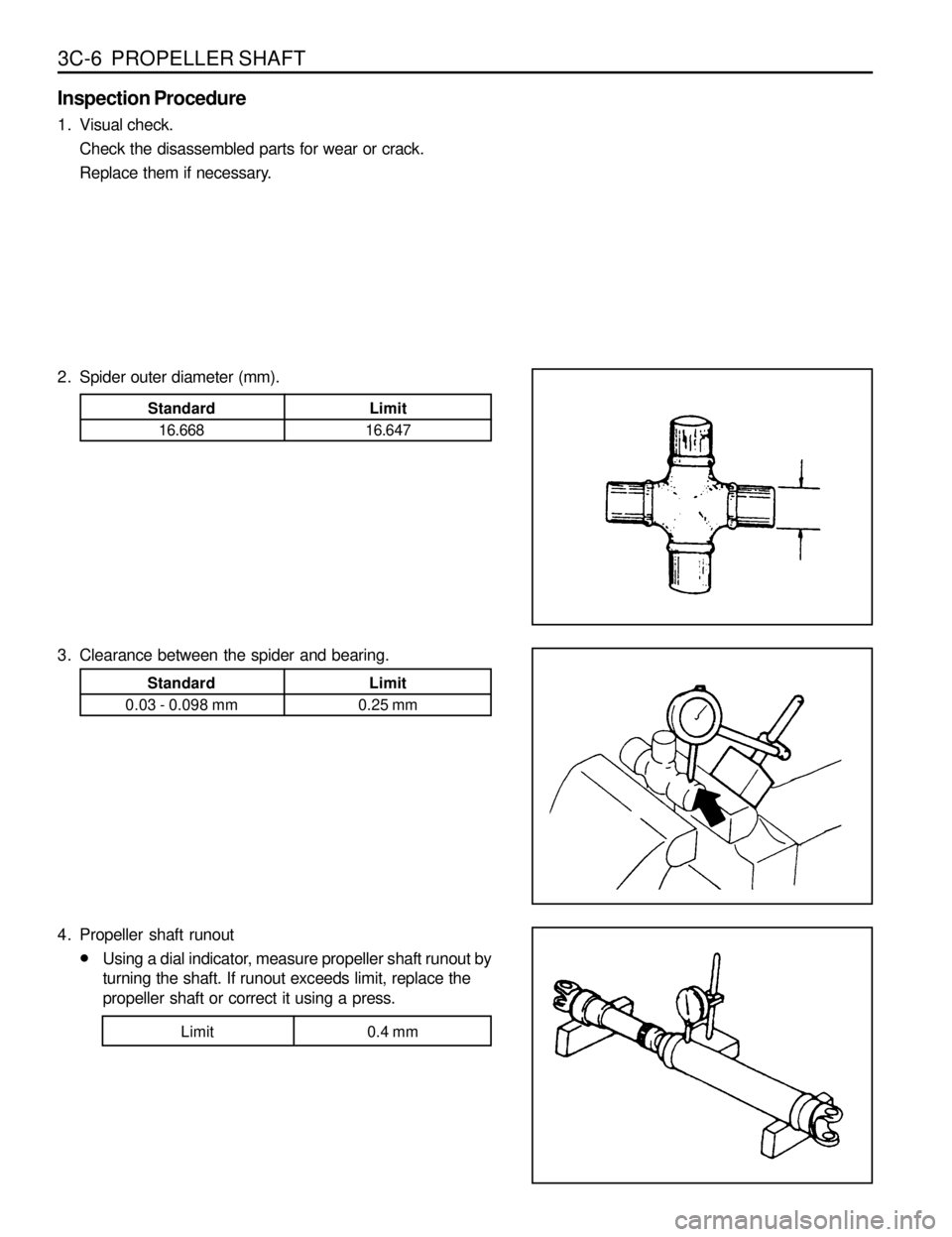

3C-6 PROPELLER SHAFT

3. Clearance between the spider and bearing.

4. Propeller shaft runout

lUsing a dial indicator, measure propeller shaft runout by

turning the shaft. If runout exceeds limit, replace the

propeller shaft or correct it using a press.

Standard

0.03 - 0.098 mmLimit

0.25 mm

Inspection Procedure

1. Visual check.

Check the disassembled parts for wear or crack.

Replace them if necessary.

2. Spider outer diameter (mm).

Standard

16.668Limit

16.647

Limit 0.4 mm

Page 897 of 1463

PROPELLER SHAFT 3C-7

Installation Procedure

Clean the disassembled parts and replace them if damaged.

1. Align the alignment marks of the yoke and assemble the

spider, bearing and snap ring.

2. Apply grease to the inner of the bearing cap of the needle

roller bearing and assemble the needle roller.

Grease EP #2

6. Possible cause of vibration.

lDrift away of balance weights.

lExcessive runout of the propeller shaft.

lUsing normal bolts.

lExcessive wear of the universal joint.

lSticks in sleeve joint.

lDrive angle changes in universal joints or cross causes

vibration and can be detected around 60~100 km/h. 5. Universal joint starting torque.

Starting Torque 3 - 8 kglcm

Page 898 of 1463

3C-8 PROPELLER SHAFT

3. Install the bearing cap to the yoke and insert the spider.

Install the opposite side cap by tapping with a plastic

hammer. Adjust clearance of the spider pin to be within 0.1

mm and install the snap ring.

4. Align the alignment marks and install the front and rear

propeller shaft. Tighten the nuts to the specified torque.

GasolineDiesel

Page 899 of 1463

SECTION 3D

REAR DRIVE AXLE

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 3D-1

General Specifications . . . . . . . . . . . . . . . . . . 3D-1

Fastener Tightening Specifications . . . . . . . . . 3D-2

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-3

Noise (During Straight Driving) . . . . . . . . . . . . 3D-3

Oil Leakage . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-3

Noise (During Turning) . . . . . . . . . . . . . . . . . . 3D-3

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-3

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-4Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-4

Component Locator . . . . . . . . . . . . . . . . . . . 3D-5

Maintenance and Repair . . . . . . . . . . . . . . . 3D-6

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 3D-6

Axle Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-6

Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-9

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . 3D-11

Axle Housing . . . . . . . . . . . . . . . . . . . . . . . . . 3D-11

LSD (Limited Slip Diffrential) . . . . . . . . . . . . . 3D-16

SPECIFICATIONS

GENERAL SPECIFICATIONS

Axle Shaft Type

Axle Housing Type

Differential

Reduction Ratio

Type

Gear

M/T

M/T

A/T (MB)

M/T

A/T (BTRA)

M/T

A/T (BTRA)

Description

Semi - floating

Salibury (Build-up)

Conventional Type

Hypoid Gear

4.55

4.55

3.73

4.55

5.38

4.27

4.89Application

661NA

662NA

661LA

662LA

Page 900 of 1463

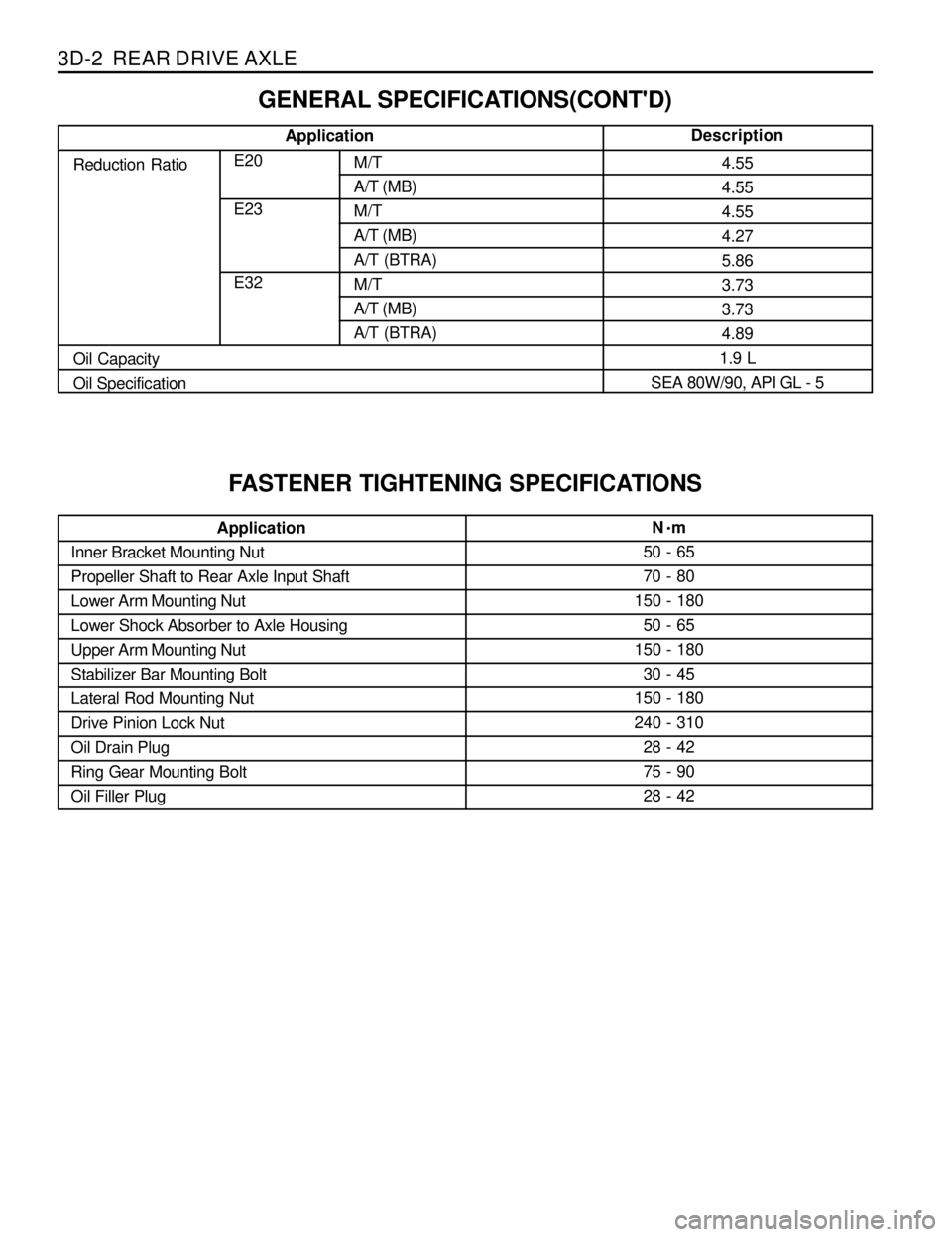

3D-2 REAR DRIVE AXLE

FASTENER TIGHTENING SPECIFICATIONS

Application

Inner Bracket Mounting Nut

Propeller Shaft to Rear Axle Input Shaft

Lower Arm Mounting Nut

Lower Shock Absorber to Axle Housing

Upper Arm Mounting Nut

Stabilizer Bar Mounting Bolt

Lateral Rod Mounting Nut

Drive Pinion Lock Nut

Oil Drain Plug

Ring Gear Mounting Bolt

Oil Filler PlugN

· ·· ·

·m

50 - 65

70 - 80

150 - 180

50 - 65

150 - 180

30 - 45

150 - 180

240 - 310

28 - 42

75 - 90

28 - 42

4.55

4.55

4.55

4.27

5.86

3.73

3.73

4.89

1.9 L

SEA 80W/90, API GL - 5 M/T

A/T (MB)

M/T

A/T (MB)

A/T (BTRA)

M/T

A/T (MB)

A/T (BTRA)

Oil Capacity

Oil Specification

ApplicationDescription

GENERAL SPECIFICATIONS(CONT'D)

E20

E23

E32 Reduction Ratio

Trending: open hood, set clock, technical data, brake rotor, lug pattern, window, wheel torque