SSANGYONG MUSSO 2003 Service Manual

Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 121 of 1574

M162 ENGINE MECHANICAL 1B1-85

PISTON Preceding Work : Removal of engineRemoval of cylinder head Removal of oil pan Removal of oil pumpRemoval of baffle plate

1 Connecting Rod Bearing Cap

2 Connecting Rod

3 Connecting Rod Bolt (M9 x 52, 12 pieces).................................................... 1st step 40 Nm

2nd step 90 ° + 5 ° 4 Piston

5 Snap Ring

6 Piston Pin

Page 122 of 1574

1B1-86 M162 ENGINE MECHANICAL

Tools Required

001 589 72 21 00 Torqued Wrench

000 589 04 14 00 Clamping Strap Removal Procedure

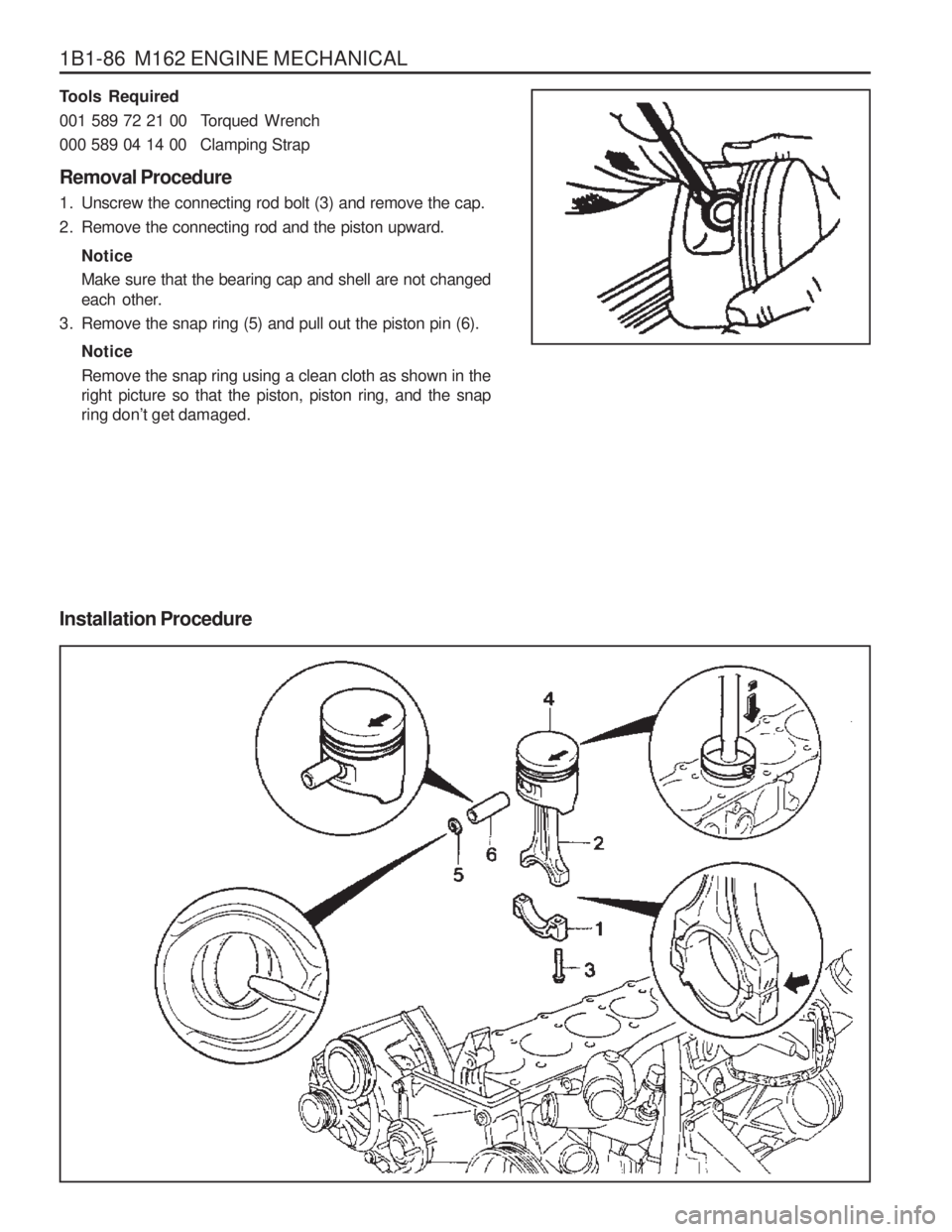

1. Unscrew the connecting rod bolt (3) and remove the cap.

2. Remove the connecting rod and the piston upward.Notice Make sure that the bearing cap and shell are not changed

each other.

3. Remove the snap ring (5) and pull out the piston pin (6).

Notice Remove the snap ring using a clean cloth as shown in the right picture so that the piston, piston ring, and the snapring don ’t get damaged.

Installation Procedure

Page 123 of 1574

M162 ENGINE MECHANICAL 1B1-87

1. Check the piston ring gap and apply the engine oil to thepiston pin and the connecting rod bushing.

2. Connect the piston and the connecting rod by pressing in the piston pin (6) and install the snap ring to the groove.

3. Clean the cylinder bore, connecting rod bearing journal, connecting rod bearing shell and the piston and coat them with engine oil.

4. Install the piston ring using the tensioning strap(000 589 04 14 00).

5. Install the piston so that the arrow on the piston head faces to the forward of the vehicle.

6. After aligning the connecting rod and the bearing cap mark (// or a number), tighten the bolts.

Installation Notice

Tightening Torque 1st step 35 - 45 Nm

2nd step 90

° + 5 °

Apply the engine oil to the bearing cap upper and lower bearing shells.

7. Check if the crankshaft rotates without any trouble by rotating it.

Page 124 of 1574

1B1-88 M162 ENGINE MECHANICAL

CONNECTING ROD Preceding Work : Removal of piston

1 Connecting Rod Bushing

2 Oil Gallery

3 Balance Weight

4 Connecting Rod Bolt(M9 x 52, 12 m pieces) .. 1st step 40+5 Nm 2nd step 90°+10 °

5 Fit Sleeve

6 Upper Connecting Rod Bearing

7 Lower Connecting Rod Bearing

8 BearingShell Lug

9 Marking [Indication(//) or Numbers]

Service Data Standard

Distance (L) from The Connecting Rod Bearing Bore Center to The Bushing Bore Center Width of The Connecting Rod (B) at Bearing BoreWidth of The Connecting Rod (b) at Bushing BoreBasic Bore at The Bearing Shell (D1)Basic Bore at The Bushing (d1) Bushing Inner Diameter (d) Clearance Between The Piston Pin and The BushingPeak-to-valley Height of Connecting Rod Bushing on Inside

Permissible Wwist of Connecting Rod Bearing Bore to Connecting Rod Bushing BorePermissible Deviation of Axial Paralleism of Connecting Rod Bearing Bore to Connecting Rod Bushing Core

Permissible Deviation of Connecting Rod Bearing Bore from Concentricity

Permissible Difference of Each Connecting Rod in Weight 145 ± 0.05 mm

21.940 - 22.000 mm

21.940 - 22.000 mm

51.600 - 51.614 mm

24.500 - 24.571 mm

22.007 - 22.013 mm 0.007 - 0.018 mm 0.005 mm0.15 mm

0.07 mm

0.01 mm

0.4 g

Page 125 of 1574

M162 ENGINE MECHANICAL 1B1-89

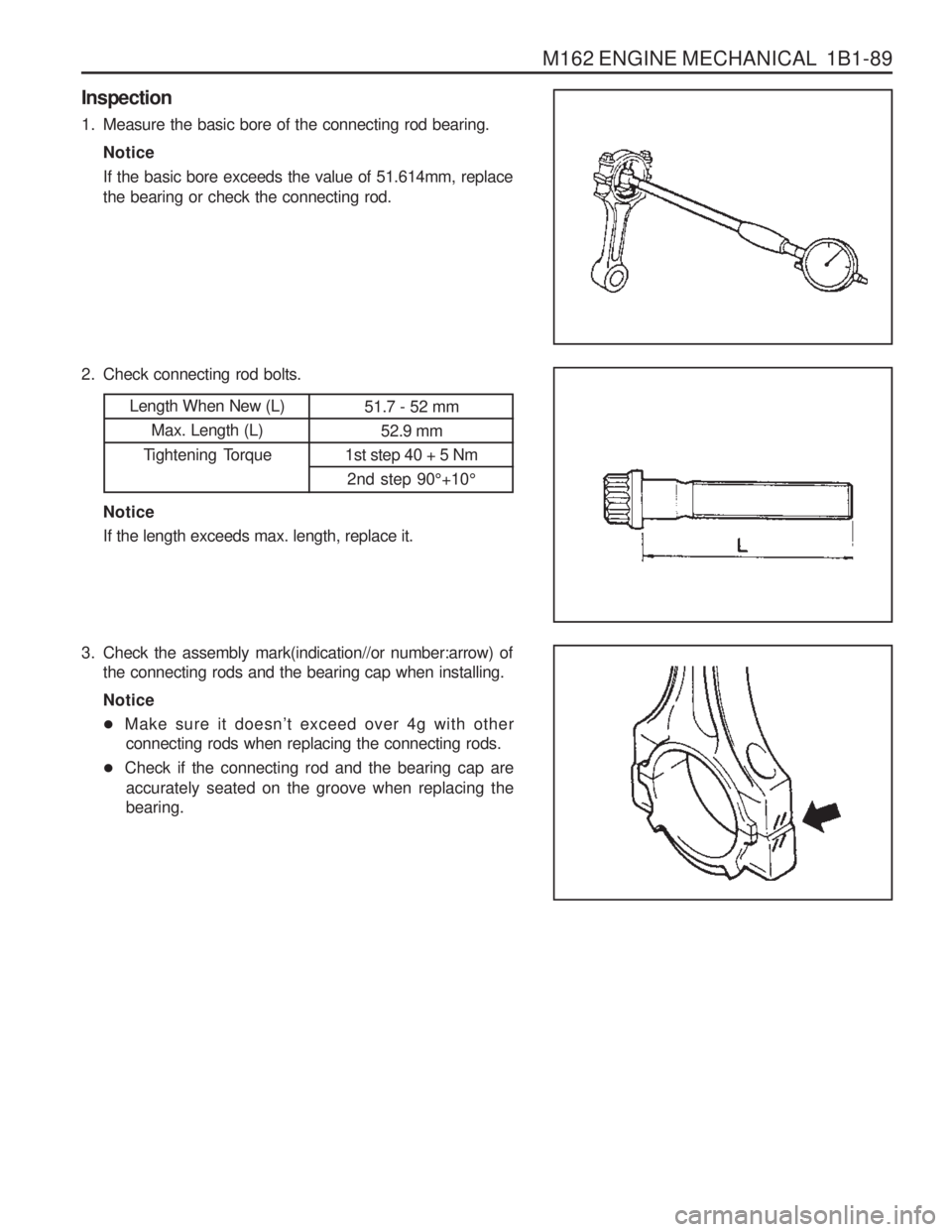

Inspection

1. Measure the basic bore of the connecting rod bearing.Notice If the basic bore exceeds the value of 51.614mm, replace the bearing or check the connecting rod.

2. Check connecting rod bolts.

3. Check the assembly mark(indication//or number:arrow) of the connecting rods and the bearing cap when installing. Notice

�Make sure it doesn ’t exceed over 4g with other

connecting rods when replacing the connecting rods.

� Check if the connecting rod and the bearing cap are

accurately seated on the groove when replacing the bearing.

Notice If the length exceeds max. length, replace it.

Length When New (L)

Max. Length (L)

Tightening Torque 51.7 - 52 mm

52.9 mm

1st step 40 + 5 Nm 2nd step 90 °+10 °

Page 126 of 1574

1B1-90 M162 ENGINE MECHANICAL PISTON RING Preceding Work : Removal of piston

1 Piston Compression Ring

2 Piston Compression Ring

3 Piston Oil Ring 4-

5 Coil Spring and Control Ring

6 Hook Spring

Notice If out of specification, replace the piston ring.

Tools Required

000 589 51 37 00 Clamping Strap

Replacement Procedure

1. Measure the piston ring ’s gap.

Gap Between

The Piston and

The Piston Ring

Groove 1 0.20 - 0.40 mm Groove 2 0.20 - 0.40 mm Groove 3 0.20 - 0.45 mm

Groove 1 0.015 - 0.050 mmGroove 2 0.020 - 0.040 mmGroove 3 0.010 - 0.045 mmEnd Gap of The Piston Ring

Page 127 of 1574

M162 ENGINE MECHANICAL 1B1-91

2. Remove the piston ring with a pliers.

3. For installation, position the piston ring to be the ‘TOP ’ mark

on the piston ring upward and arrange the piston ring ends to be 120 ° apart.

4. Adjust the hook spring joint in the oil ring 180 ° away from

the ring end.

Clamping Strap 000 589 51 37 00

Page 128 of 1574

1B1-92 M162 ENGINE MECHANICAL

ENGINE OIL SPECIFICATION

1 Drain Plug................................................. 25 Nm

2 Oil Filter 3 Engine Oil Filler Cap

4 Dipstick Gauge

Specifications

Application

Capacity Descrition

Min : 6.7L, Max : 8.2L

� API SH or above grade

� ACEA : A2 or A3

� Approved oil by MB Sheet 229.1

� Approved oil by MB Sheet 224.1

�� Initial at 1000-1500km, Replace every 15000km

Quality Viscosity Replacemant

Page 129 of 1574

M162 ENGINE MECHANICAL 1B1-93

OIL PAN

1 Gasket ................................................... Replace

2 Bolt (M6 x 22, 6 pieces)............................ 10 Nm

3 Drain Plug (M6 x 20) ................................. 25 Nm

4 Bolt (M6 x 20, 22 pieces) .......................... 10 Nm 5 Bolt (M6 x 85)

............................................ 10 Nm

6 Bolt (M8 x 40) ............................................ 25 Nm

7 Bolt (M10) ................................................. 40 Nm

8 Oil Pan

Removal & Installation Procedure

1. Remove the drain plug and drain the oil completely.

2. Disconnect the electric connector from oil level switch.

3. Unscrew the bolts (10) for oil level switch and check the O- ring (11) for wear or damage. And replace it if necessary.

4. Unscrew the bolts and remove the oil pan and gasket.

NoticeArrange the bolts according to each size.

5. Clean the inside of oil pan and sealing surface, then apply the sealant.

6. Replace the gasket with new one.

7. Install the oil pan with gasket, and tighten each bolt in specified torque.

8. Check for oil leaks while running the engine.

M8 X 40, 4 pieces M6 X 85, 3 piecesM6 X 35, 3 piecesM6 X 20, 28 pieces

the rest

Page 130 of 1574

1B1-94 M162 ENGINE MECHANICAL Oil Circulation

1 Oil Pump

2 Oil Gallery (to oil filter)

3 Oil Filter

4 Oil Pressure Switch

5 Main Oil Gallery

6 Cylinder Head Closing Cover

7 Oil Gallery (At Chain Tensioner)

8 Oil Non-return Valve

9 Chain Tensioner

10 Vent (Chain Tensioner)

11 Front Closing Cover (

�17 mm)

12 Oil Gallery (Perpendicular to The Shaft)

13 Ball (

�6 mm)

14 Oil Spray Nozzle (Timing Chain)

15 Oil Gallery (At Cylinder Head)

1 6 Ball (

� 15mm)

17 Oil Restriction Inner (

� 4mm)

18 Oil Supply (To Exhaust Camshaft) 19 Oil Supply (To Intake Camshaft)

20 Oil Supply (To Exhaust Camshaft Bearing)

21 Oil Supply (To Intake Camshaft Bearing)

22 Oil Gallery (Oil Supply to Exhaust Valve Tappet)

23 Oil Gallery (Oil Supply to Exhaust Valve Tappet)

24 Camshaft Closing Cover

25 Ball (

�8 mm)

26 Screw Plug

27 Camshaft Adjuster

28 Front Closing Cover (Intake Camshaft)

29 Front Treaded Bushing (Exhaust Camshaft)

30 Valve tappet

a Oil Gallery (From Oil Pump to Oil Filter)

b Main Oil Galleryc Oil Return Line (Oil Returns to the Oil Pan when Replacing the Filter Element)