SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1151 of 2870

EN(H4SO)-53

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

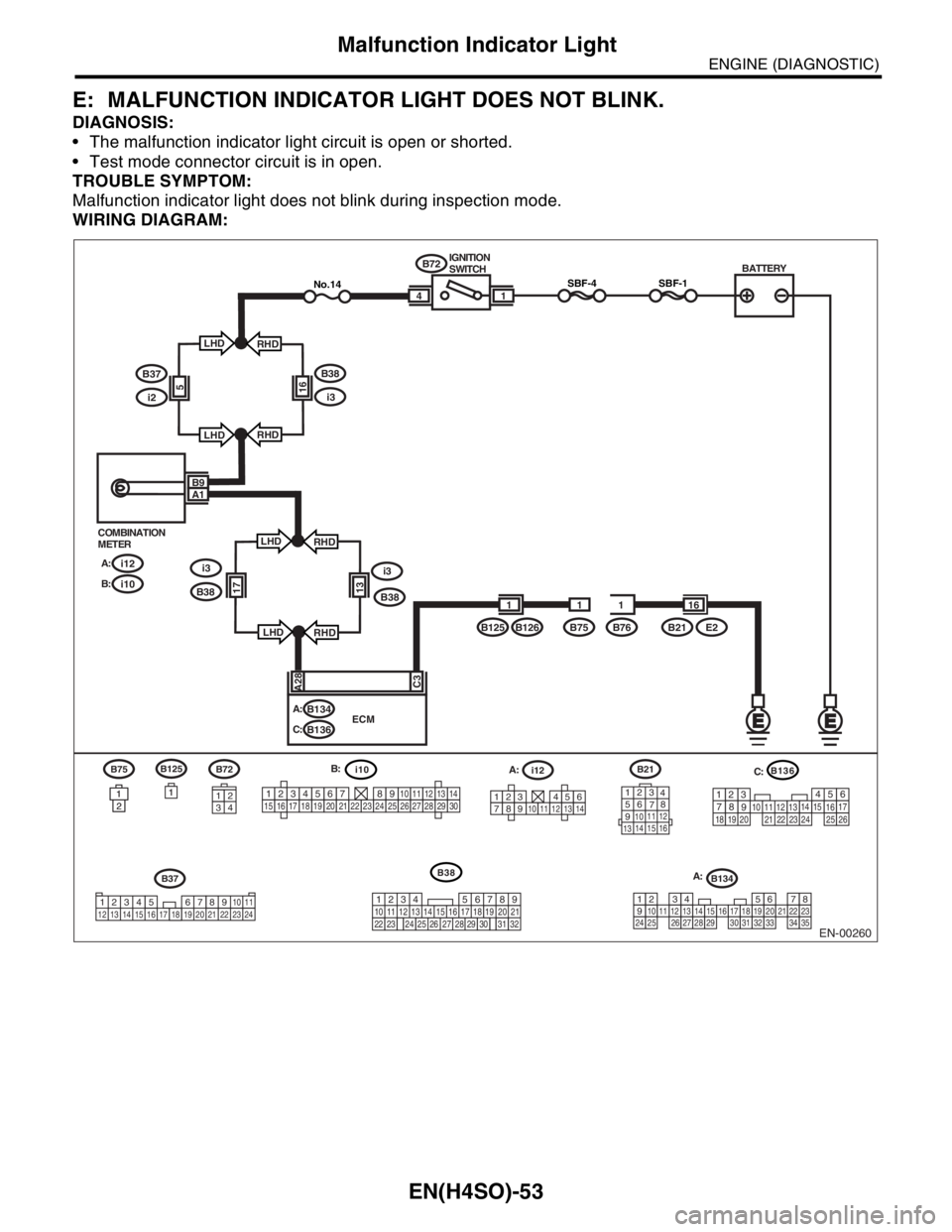

E: MALFUNCTION INDICATOR LIGHT DOES NOT BLINK.

DIAGNOSIS:

The malfunction indicator light circuit is open or shorted.

Test mode connector circuit is in open.

TROUBLE SYMPTOM:

Malfunction indicator light does not blink during inspection mode.

WIRING DIAGRAM:

EN-00260

i10

123456789101112131415161718192021222324252627282930

B37

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

BATTERY

1

B72

B125B75B76B126 IGNITION

SWITCH

i12 COMBINATION

METER

A:

i10 B:

B134 A:

B136 C:

SBF-44

A28C3

ECM

B9A1

i12

1234568791011121314

B134

1234567891011121314151617181920212223242526272829303132333435

B72

34

12

SBF-1No.14

1

B21E2

1611

1 B125

B75

1

21

21

B21

123

4

56

78

9

1011 12

1314 15 16

B136

5

2

84

3923 20 211011

221617

24

2512136

261915

14

1

7

18

B38

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

B37

i2

B38

i3165

LHD

LHDRHD

RHD

i3i3

B381317

LHD

LHDRHD

RHD B38

A:

C:

A: B:

Page 1152 of 2870

EN(H4SO)-54

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

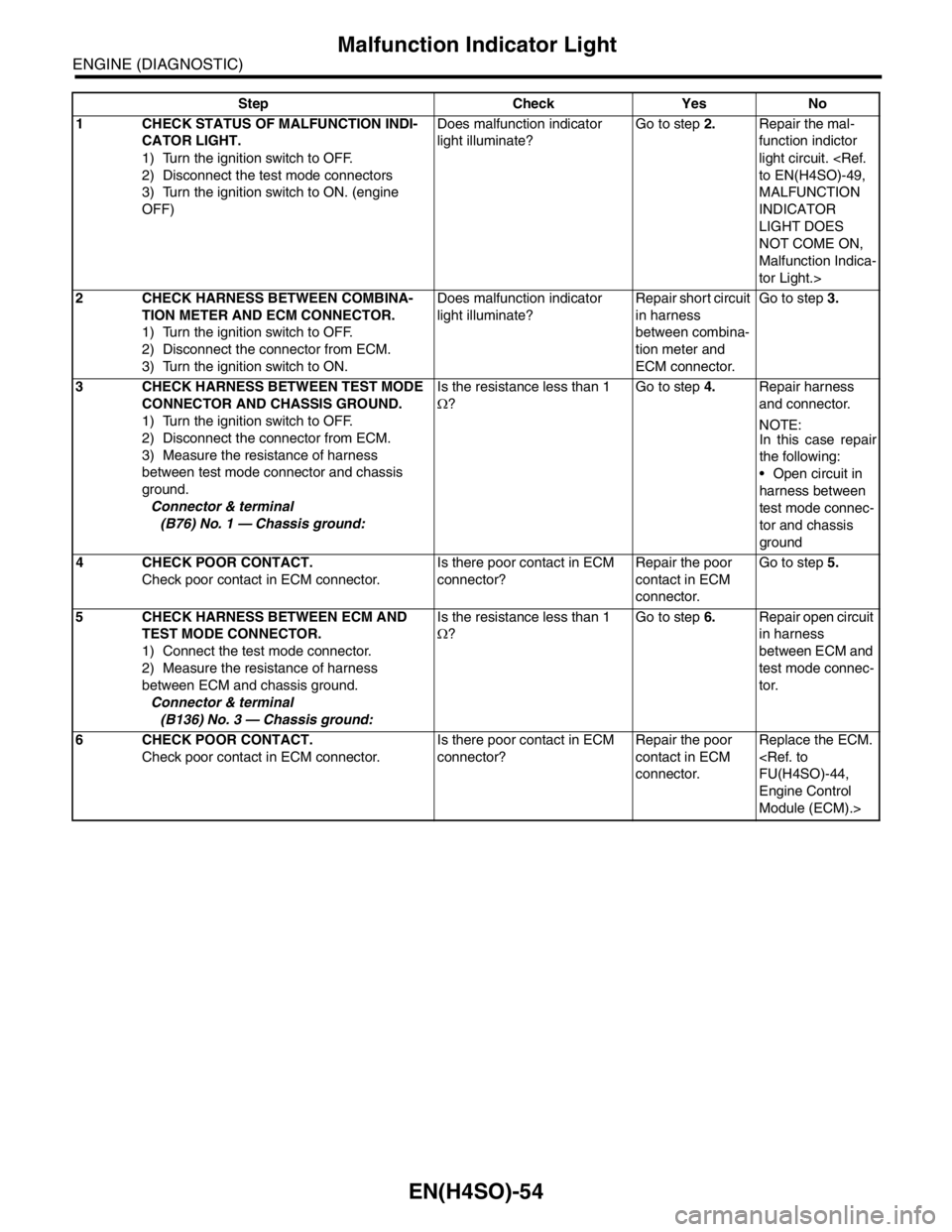

Step Check Yes No

1 CHECK STATUS OF MALFUNCTION INDI-

CATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Disconnect the test mode connectors

3) Turn the ignition switch to ON. (engine

OFF)Does malfunction indicator

light illuminate?Go to step 2.Repair the mal-

function indictor

light circuit.

MALFUNCTION

INDICATOR

LIGHT DOES

NOT COME ON,

Malfunction Indica-

tor Light.>

2 CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Turn the ignition switch to ON.Does malfunction indicator

light illuminate?Repair short circuit

in harness

between combina-

tion meter and

ECM connector.Go to step 3.

3 CHECK HARNESS BETWEEN TEST MODE

CONNECTOR AND CHASSIS GROUND.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance of harness

between test mode connector and chassis

ground.

Connector & terminal

(B76) No. 1 — Chassis ground:Is the resistance less than 1

Ω?Go to step 4.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

test mode connec-

tor and chassis

ground

4 CHECK POOR CONTACT.

Check poor contact in ECM connector.Is there poor contact in ECM

connector?Repair the poor

contact in ECM

connector.Go to step 5.

5 CHECK HARNESS BETWEEN ECM AND

TEST MODE CONNECTOR.

1) Connect the test mode connector.

2) Measure the resistance of harness

between ECM and chassis ground.

Connector & terminal

(B136) No. 3 — Chassis ground:Is the resistance less than 1

Ω?Go to step 6.Repair open circuit

in harness

between ECM and

test mode connec-

tor.

6 CHECK POOR CONTACT.

Check poor contact in ECM connector.Is there poor contact in ECM

connector?Repair the poor

contact in ECM

connector.Replace the ECM.

Engine Control

Module (ECM).>

Page 1153 of 2870

EN(H4SO)-55

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

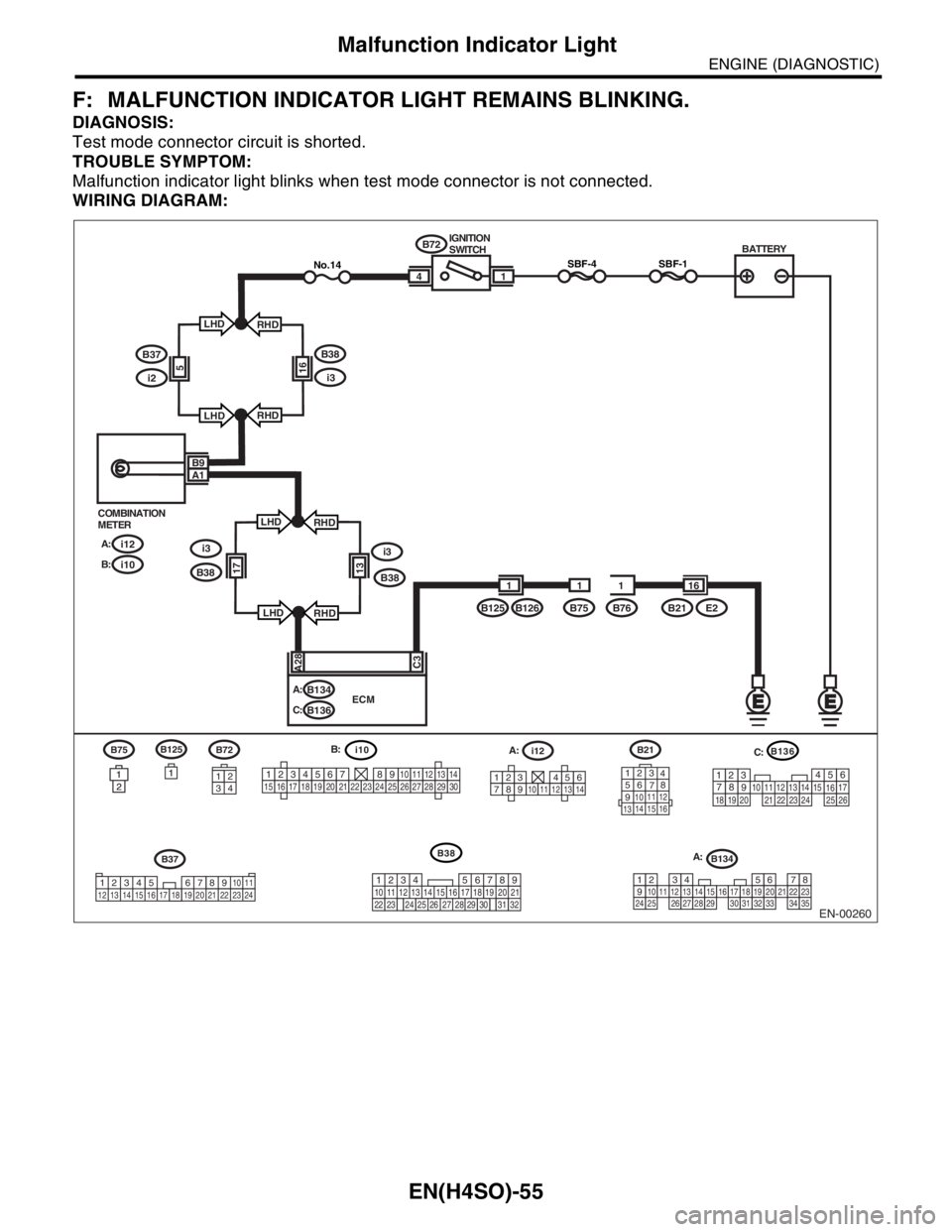

F: MALFUNCTION INDICATOR LIGHT REMAINS BLINKING.

DIAGNOSIS:

Test mode connector circuit is shorted.

TROUBLE SYMPTOM:

Malfunction indicator light blinks when test mode connector is not connected.

WIRING DIAGRAM:

EN-00260

i10

123456789101112131415161718192021222324252627282930

B37

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

BATTERY

1

B72

B125B75B76B126 IGNITION

SWITCH

i12 COMBINATION

METER

A:

i10 B:

B134 A:

B136 C:

SBF-44

A28C3

ECM

B9A1

i12

1234568791011121314

B134

1234567891011121314151617181920212223242526272829303132333435

B72

34

12

SBF-1No.14

1

B21E2

1611

1 B125

B75

1

21

21

B21

123

4

56

78

9

1011 12

1314 15 16

B136

5

2

84

3923 20 211011

221617

24

2512136

261915

14

1

7

18

B38

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

B37

i2

B38

i3165

LHD

LHDRHD

RHD

i3i3

B381317

LHD

LHDRHD

RHD B38

A:

C:

A: B:

Page 1154 of 2870

EN(H4SO)-56

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

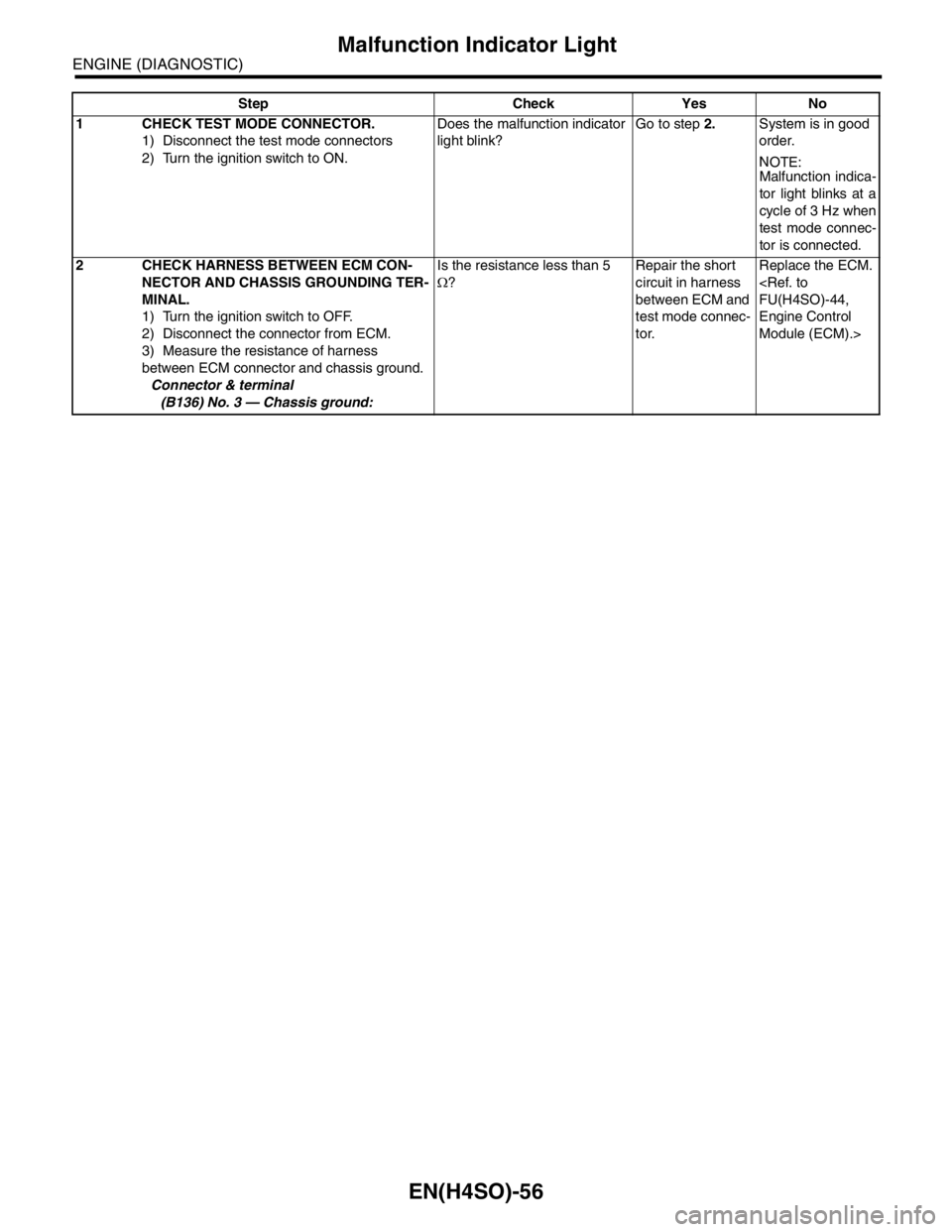

Step Check Yes No

1 CHECK TEST MODE CONNECTOR.

1) Disconnect the test mode connectors

2) Turn the ignition switch to ON.Does the malfunction indicator

light blink?Go to step 2.System is in good

order.

N

OTE:

Malfunction indica-

tor light blinks at a

cycle of 3 Hz when

test mode connec-

tor is connected.

2 CHECK HARNESS BETWEEN ECM CON-

NECTOR AND CHASSIS GROUNDING TER-

MINAL.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance of harness

between ECM connector and chassis ground.

Connector & terminal

(B136) No. 3 — Chassis ground:Is the resistance less than 5

Ω?Repair the short

circuit in harness

between ECM and

test mode connec-

tor.Replace the ECM.

Engine Control

Module (ECM).>

Page 1155 of 2870

EN(H4SO)-57

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

17.Diagnostics for Engine Starting Failure

A: PROCEDURE

1. Check for fuel amount.

↓

2. Inspection of starter motor circuit.

↓

3. Inspection of ECM power supply and ground line.

↓

4. Inspection of ignition control system.

↓

5. Inspection of fuel pump circuit.

↓

6. Inspection of fuel injector circuit.

Page 1156 of 2870

EN(H4SO)-58

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

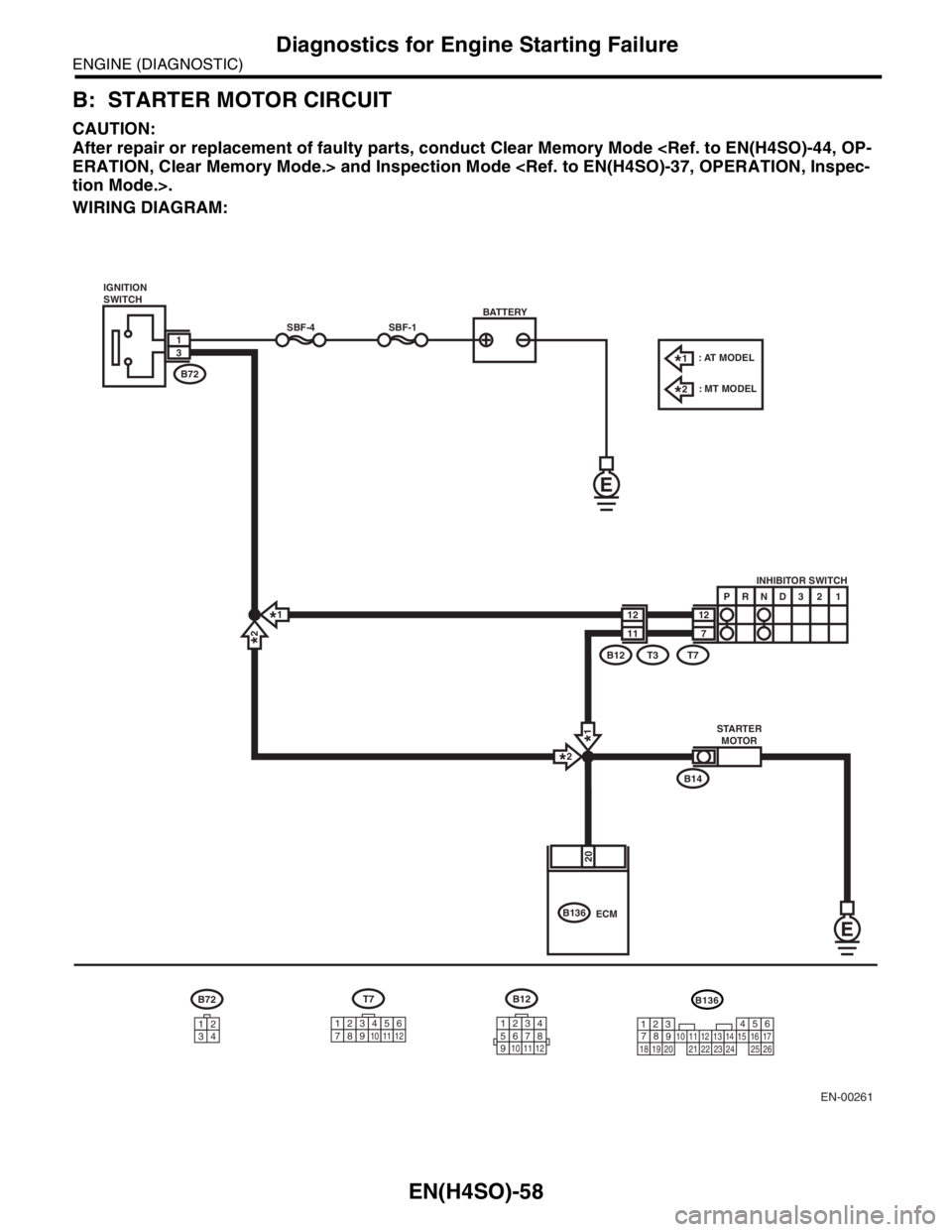

B: STARTER MOTOR CIRCUIT

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-00261

12INHIBITOR SWITCH

STARTER

MOTOR

7P

RND321

SBF-4SBF-1

B14

B72

12

11

T7T3B12

13

IGNITION

SWITCH

1*2*

1*

2*

T7

123456789101112

B72

34

12

20

B136ECM

: AT MODEL

: MT MODEL1*

2*

BATTERY

B12

123456789101112

B136

5

2

84

3923 20 211011

221617

24

2512136

261915

14

1

7

18

Page 1157 of 2870

EN(H4SO)-59

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

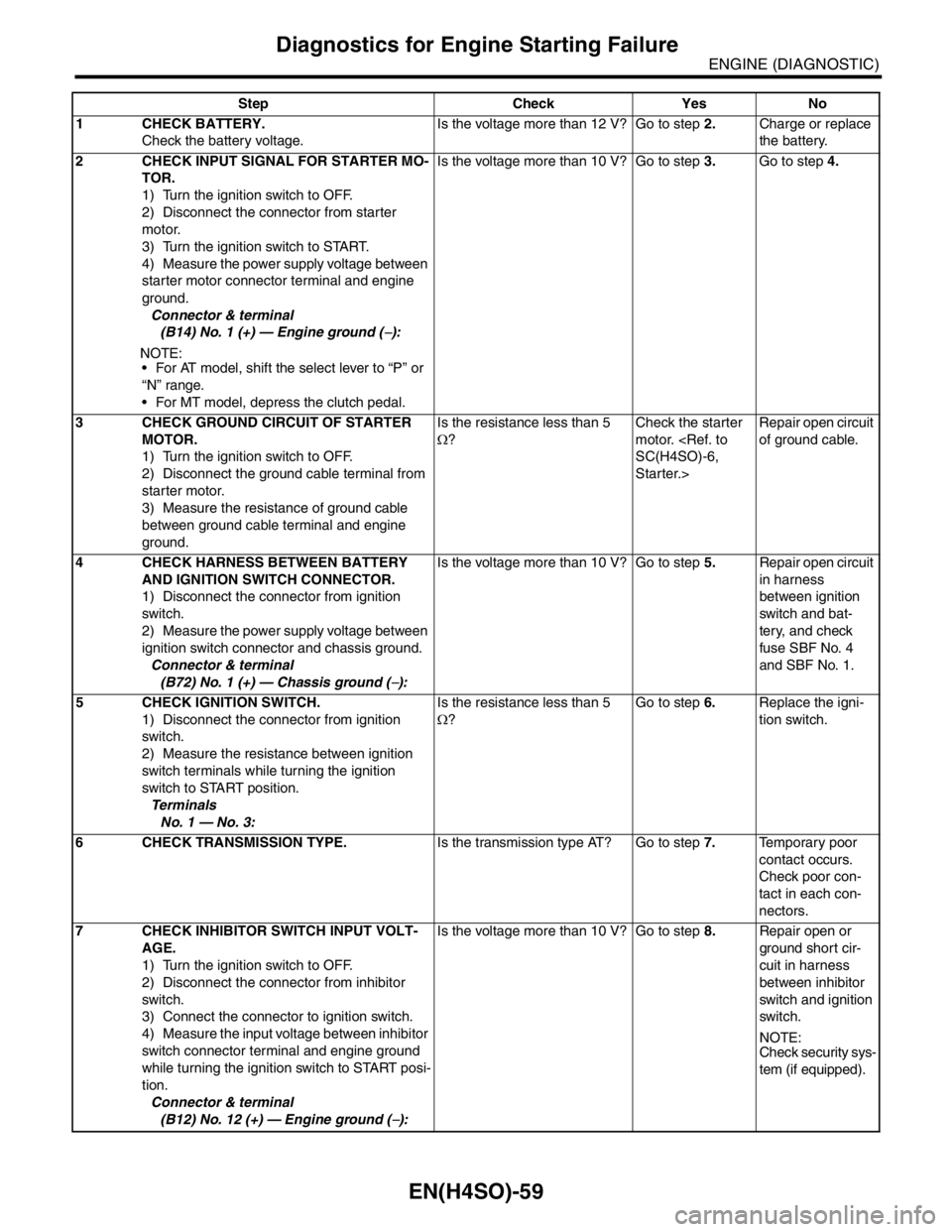

Step Check Yes No

1 CHECK BATTERY.

Check the battery voltage.Is the voltage more than 12 V? Go to step 2.Charge or replace

the battery.

2 CHECK INPUT SIGNAL FOR STARTER MO-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from starter

motor.

3) Turn the ignition switch to START.

4) Measure the power supply voltage between

starter motor connector terminal and engine

ground.

Connector & terminal

(B14) No. 1 (+) — Engine ground (

−):

N

OTE:

For AT model, shift the select lever to “P” or

“N” range.

For MT model, depress the clutch pedal.Is the voltage more than 10 V? Go to step 3.Go to step 4.

3 CHECK GROUND CIRCUIT OF STARTER

MOTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the ground cable terminal from

starter motor.

3) Measure the resistance of ground cable

between ground cable terminal and engine

ground.Is the resistance less than 5

Ω?Check the starter

motor.

Starter.>Repair open circuit

of ground cable.

4 CHECK HARNESS BETWEEN BATTERY

AND IGNITION SWITCH CONNECTOR.

1) Disconnect the connector from ignition

switch.

2) Measure the power supply voltage between

ignition switch connector and chassis ground.

Connector & terminal

(B72) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 5.Repair open circuit

in harness

between ignition

switch and bat-

tery, and check

fuse SBF No. 4

and SBF No. 1.

5 CHECK IGNITION SWITCH.

1) Disconnect the connector from ignition

switch.

2) Measure the resistance between ignition

switch terminals while turning the ignition

switch to START position.

Te r m i n a l s

No. 1 — No. 3:Is the resistance less than 5

Ω?Go to step 6.Replace the igni-

tion switch.

6 CHECK TRANSMISSION TYPE.Is the transmission type AT? Go to step 7.Temporary poor

contact occurs.

Check poor con-

tact in each con-

nectors.

7 CHECK INHIBITOR SWITCH INPUT VOLT-

AGE.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from inhibitor

switch.

3) Connect the connector to ignition switch.

4) Measure the input voltage between inhibitor

switch connector terminal and engine ground

while turning the ignition switch to START posi-

tion.

Connector & terminal

(B12) No. 12 (+) — Engine ground (

−):Is the voltage more than 10 V? Go to step 8.Repair open or

ground short cir-

cuit in harness

between inhibitor

switch and ignition

switch.

N

OTE:

Check security sys-

tem (if equipped).

Page 1158 of 2870

EN(H4SO)-60

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

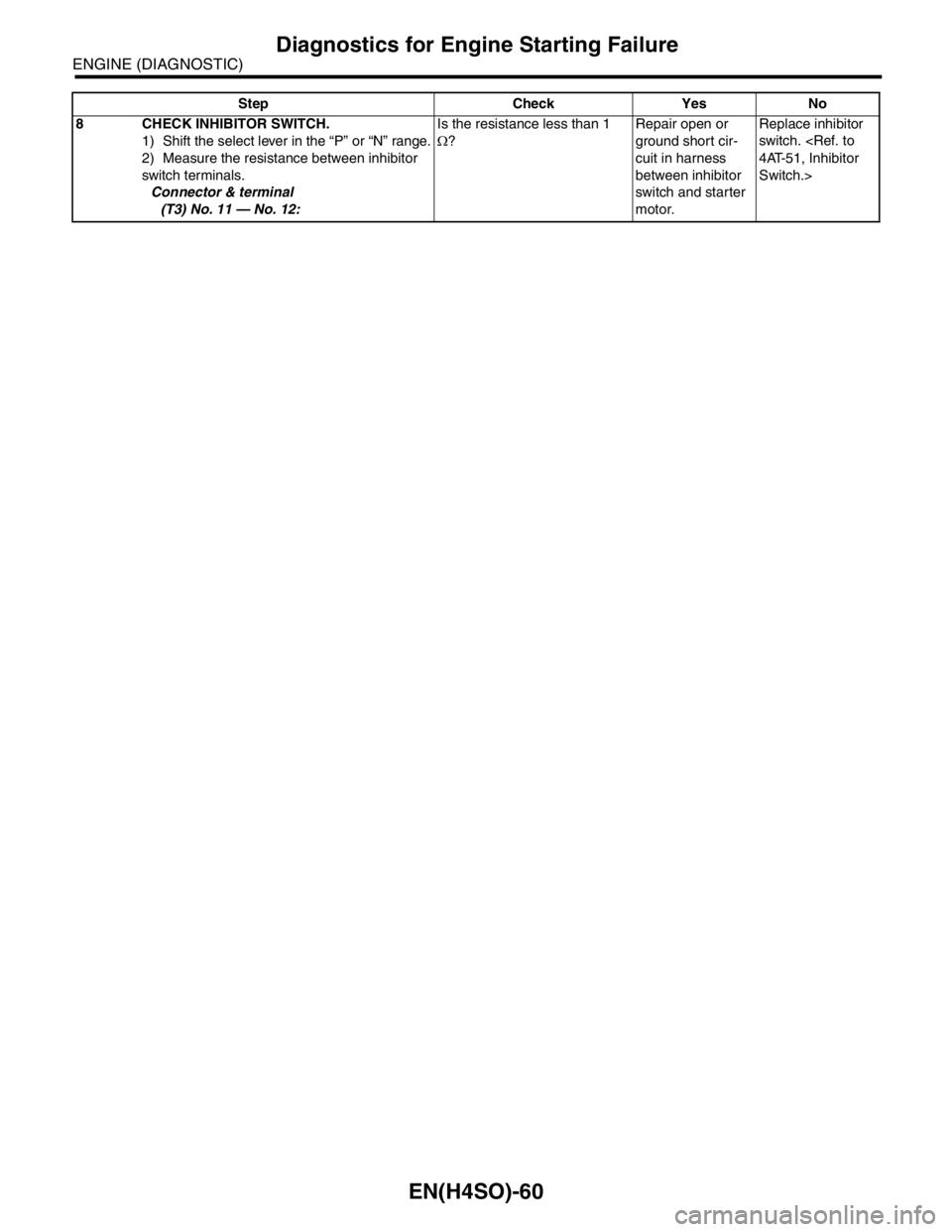

8 CHECK INHIBITOR SWITCH.

1) Shift the select lever in the “P” or “N” range.

2) Measure the resistance between inhibitor

switch terminals.

Connector & terminal

(T3) No. 11 — No. 12:Is the resistance less than 1

Ω?Repair open or

ground short cir-

cuit in harness

between inhibitor

switch and starter

motor.Replace inhibitor

switch.

Switch.> Step Check Yes No

Page 1159 of 2870

EN(H4SO)-61

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

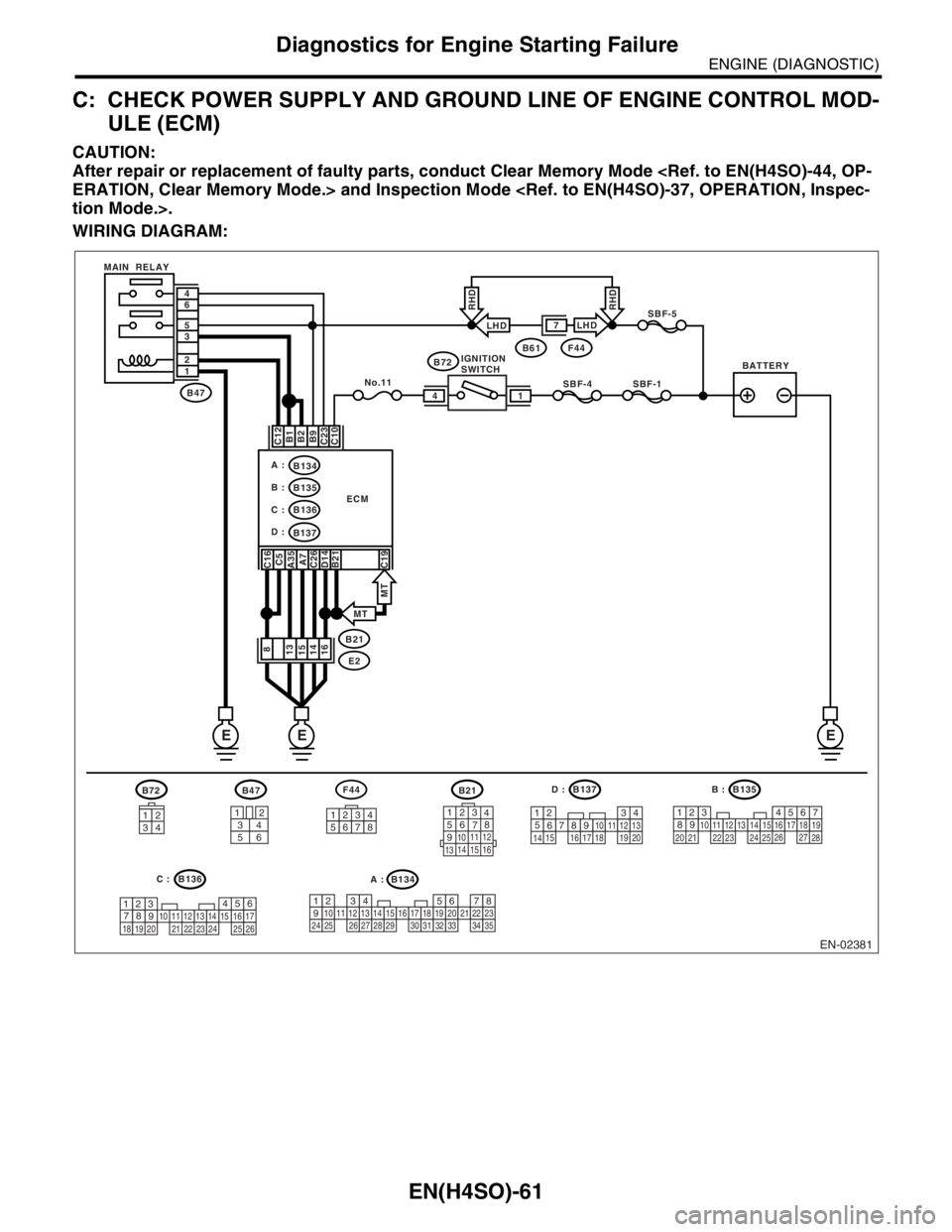

C: CHECK POWER SUPPLY AND GROUND LINE OF ENGINE CONTROL MOD-

ULE (ECM)

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02381

B72

3412

BATTERYIGNITION

SWITCH MAIN RELAY

SBF-4SBF-1

SBF-5

B72B61F44

B2 B1 C12 C16

B21C5

A35

A7

C26

D14B9

C10 C23

No.11B47

E2 B21 1 2 3 5 6 4

ECM

EE

1

7

4

B134

B135

B136 A :

C :

D :B137 B :

C19

8

15

16 14 13

E

3412

56

123

4

56

78

9

1011 12

1314 15 16

B137B135B21B47

MT

MT

F44

B134

12345678

1234567891011121314151617181920212223242526272829303132333435

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

4

1

53

2618 15 167891011

17 19

20121314

B136

5

2

84

3923 20 211011

221617

24

2512136

261915

14

1

7

18

A : C :D :B :

LHDLHD

RHDRHD

Page 1160 of 2870

EN(H4SO)-62

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

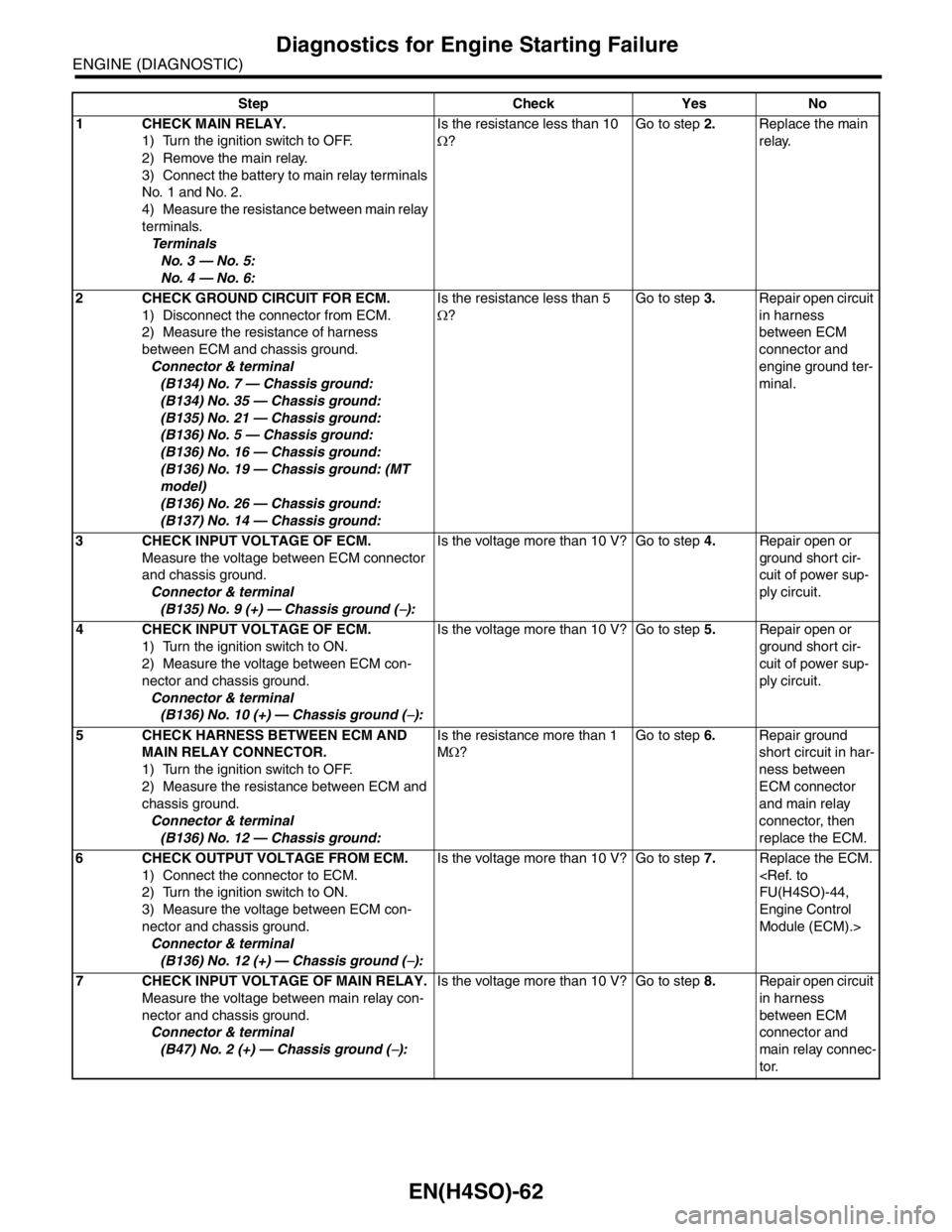

Step Check Yes No

1 CHECK MAIN RELAY.

1) Turn the ignition switch to OFF.

2) Remove the main relay.

3) Connect the battery to main relay terminals

No. 1 and No. 2.

4) Measure the resistance between main relay

terminals.

Te r m i n a l s

No. 3 — No. 5:

No. 4 — No. 6:Is the resistance less than 10

Ω?Go to step 2.Replace the main

relay.

2 CHECK GROUND CIRCUIT FOR ECM.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness

between ECM and chassis ground.

Connector & terminal

(B134) No. 7 — Chassis ground:

(B134) No. 35 — Chassis ground:

(B135) No. 21 — Chassis ground:

(B136) No. 5 — Chassis ground:

(B136) No. 16 — Chassis ground:

(B136) No. 19 — Chassis ground: (MT

model)

(B136) No. 26 — Chassis ground:

(B137) No. 14 — Chassis ground:Is the resistance less than 5

Ω?Go to step 3.Repair open circuit

in harness

between ECM

connector and

engine ground ter-

minal.

3 CHECK INPUT VOLTAGE OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B135) No. 9 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 4.Repair open or

ground short cir-

cuit of power sup-

ply circuit.

4 CHECK INPUT VOLTAGE OF ECM.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 10 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 5.Repair open or

ground short cir-

cuit of power sup-

ply circuit.

5 CHECK HARNESS BETWEEN ECM AND

MAIN RELAY CONNECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between ECM and

chassis ground.

Connector & terminal

(B136) No. 12 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 6.Repair ground

short circuit in har-

ness between

ECM connector

and main relay

connector, then

replace the ECM.

6 CHECK OUTPUT VOLTAGE FROM ECM.

1) Connect the connector to ECM.

2) Turn the ignition switch to ON.

3) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 12 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 7.Replace the ECM.

Engine Control

Module (ECM).>

7 CHECK INPUT VOLTAGE OF MAIN RELAY.

Measure the voltage between main relay con-

nector and chassis ground.

Connector & terminal

(B47) No. 2 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 8.Repair open circuit

in harness

between ECM

connector and

main relay connec-

tor.