SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1161 of 2870

EN(H4SO)-63

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

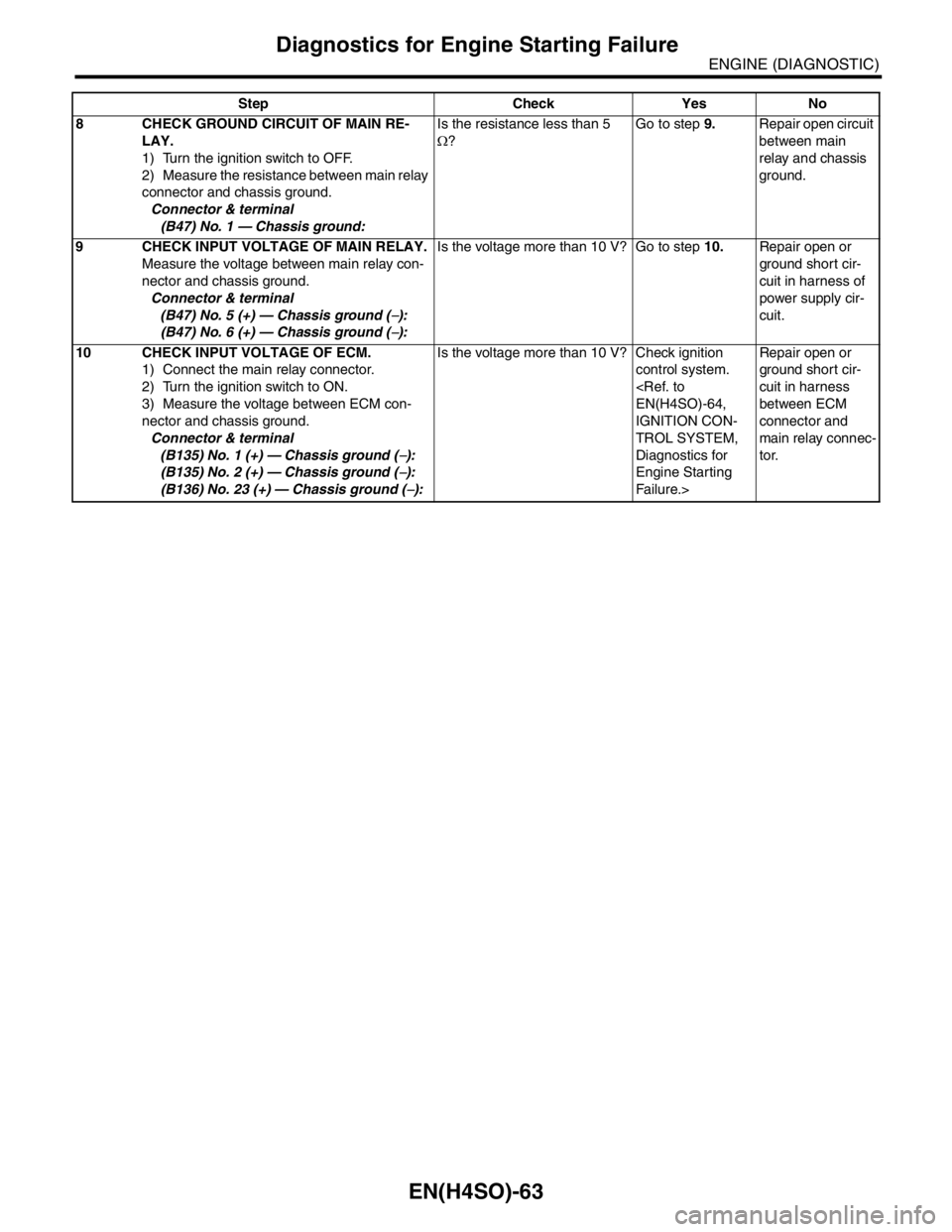

8 CHECK GROUND CIRCUIT OF MAIN RE-

LAY.

1) Turn the ignition switch to OFF.

2) Measure the resistance between main relay

connector and chassis ground.

Connector & terminal

(B47) No. 1 — Chassis ground:Is the resistance less than 5

Ω?Go to step 9.Repair open circuit

between main

relay and chassis

ground.

9 CHECK INPUT VOLTAGE OF MAIN RELAY.

Measure the voltage between main relay con-

nector and chassis ground.

Connector & terminal

(B47) No. 5 (+) — Chassis ground (

−):

(B47) No. 6 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 10.Repair open or

ground short cir-

cuit in harness of

power supply cir-

cuit.

10 CHECK INPUT VOLTAGE OF ECM.

1) Connect the main relay connector.

2) Turn the ignition switch to ON.

3) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B135) No. 1 (+) — Chassis ground (

−):

(B135) No. 2 (+) — Chassis ground (

−):

(B136) No. 23 (+) — Chassis ground (

−):Is the voltage more than 10 V? Check ignition

control system.

IGNITION CON-

TROL SYSTEM,

Diagnostics for

Engine Starting

Fa il u r e. >Repair open or

ground short cir-

cuit in harness

between ECM

connector and

main relay connec-

tor. Step Check Yes No

Page 1162 of 2870

EN(H4SO)-64

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

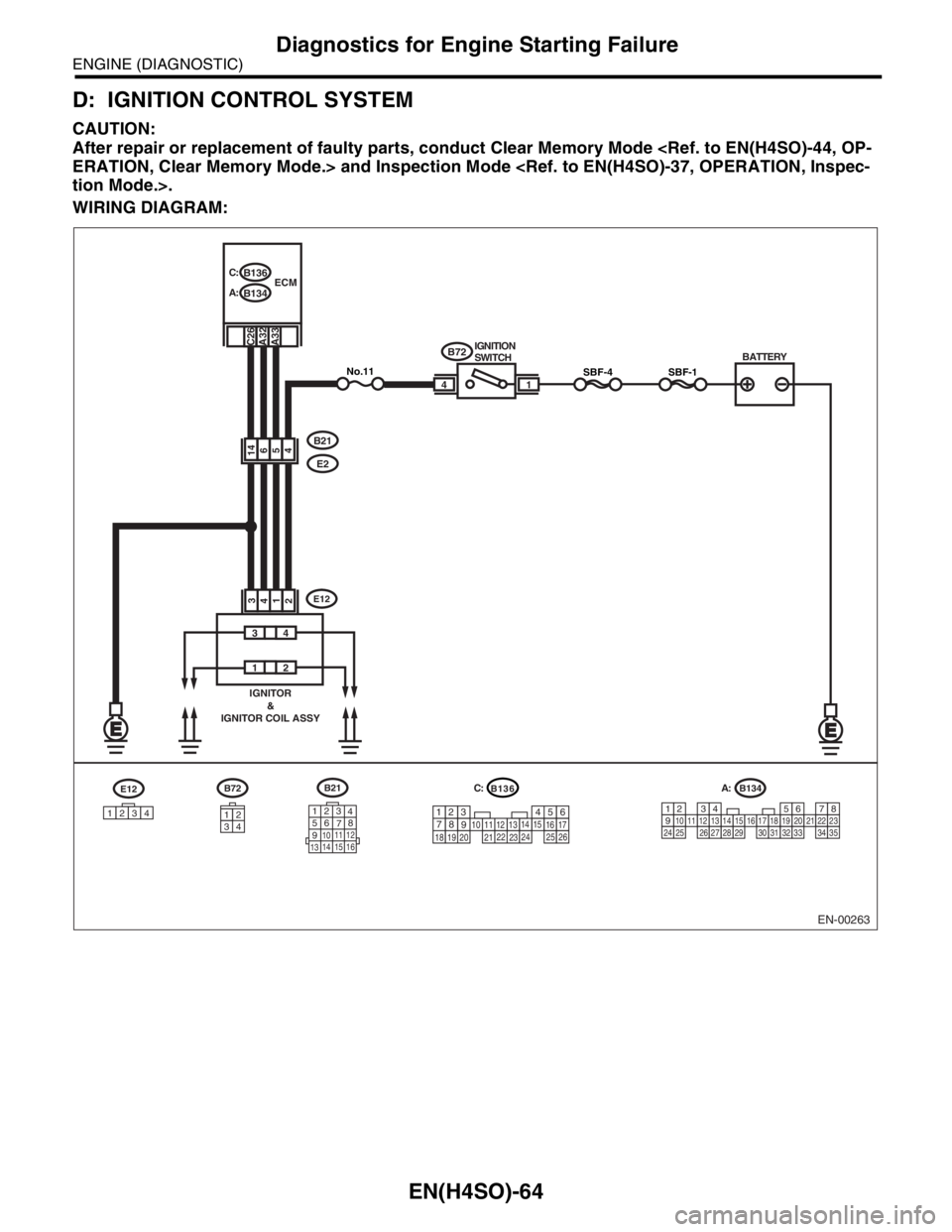

D: IGNITION CONTROL SYSTEM

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-00263

BATTERY

1 IGNITION

SWITCHSBF-44

A32

B21

E2

B134

1234567891011121314151617181920212223242526272829303132333435

B72

34

12

SBF-1No.11

54146

1234

B136 C:

B134 A:ECM

A33C26

34

12

IGNITOR

&

IGNITOR COIL ASSY

1234

E12B21

123

4

56

78

9

1011 12

1314 15 16

B72

B136

5

2

84

3923 20 211011

221617

24

2512136

261915

14

1

7

18

E12

C:

A:

Page 1163 of 2870

EN(H4SO)-65

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

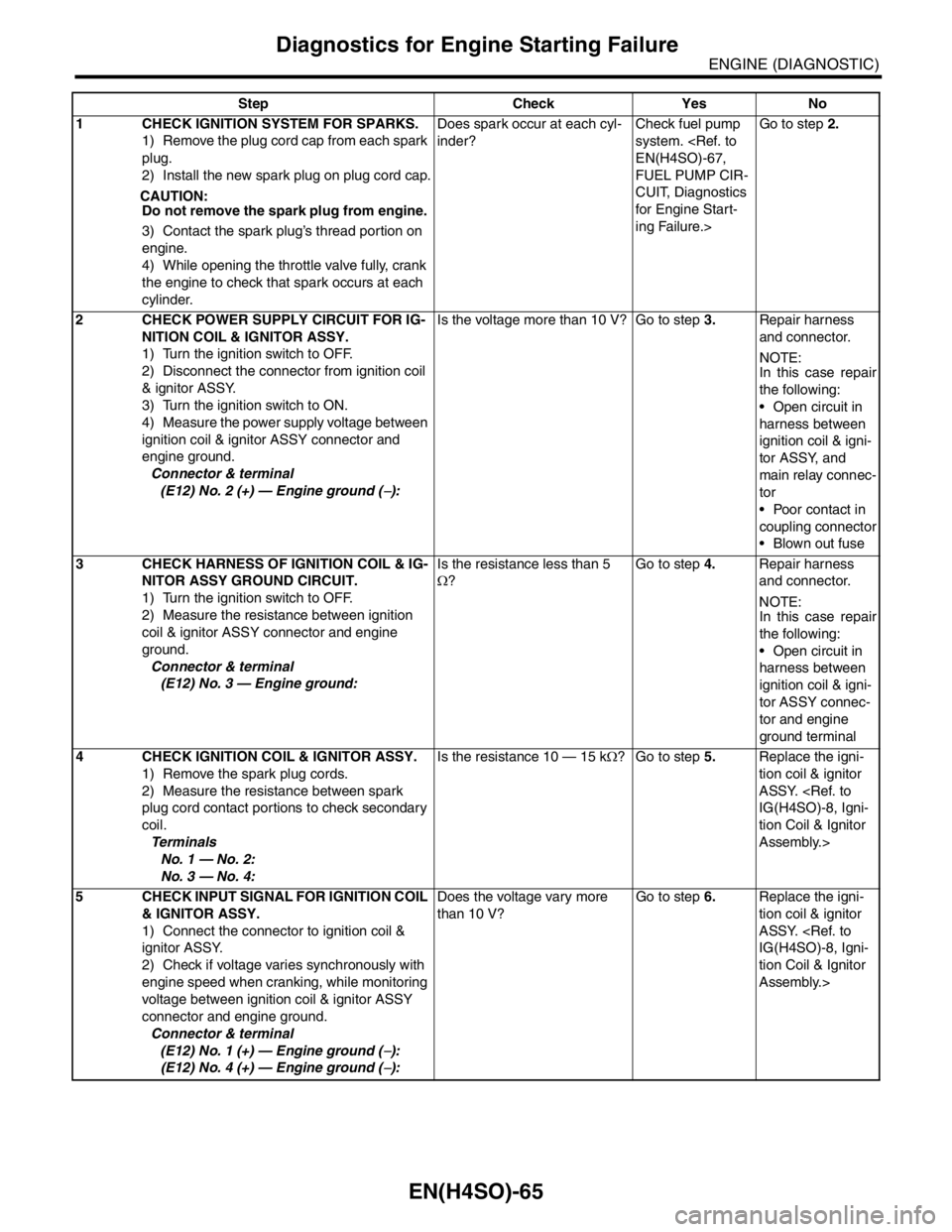

Step Check Yes No

1 CHECK IGNITION SYSTEM FOR SPARKS.

1) Remove the plug cord cap from each spark

plug.

2) Install the new spark plug on plug cord cap.

CAUTION:

Do not remove the spark plug from engine.

3) Contact the spark plug’s thread portion on

engine.

4) While opening the throttle valve fully, crank

the engine to check that spark occurs at each

cylinder.Does spark occur at each cyl-

inder?Check fuel pump

system.

FUEL PUMP CIR-

CUIT, Diagnostics

for Engine Start-

ing Failure.>Go to step 2.

2 CHECK POWER SUPPLY CIRCUIT FOR IG-

NITION COIL & IGNITOR ASSY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ignition coil

& ignitor ASSY.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage between

ignition coil & ignitor ASSY connector and

engine ground.

Connector & terminal

(E12) No. 2 (+) — Engine ground (

−):Is the voltage more than 10 V? Go to step 3.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

ignition coil & igni-

tor ASSY, and

main relay connec-

tor

Poor contact in

coupling connector

Blown out fuse

3 CHECK HARNESS OF IGNITION COIL & IG-

NITOR ASSY GROUND CIRCUIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance between ignition

coil & ignitor ASSY connector and engine

ground.

Connector & terminal

(E12) No. 3 — Engine ground:Is the resistance less than 5

Ω?Go to step 4.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

ignition coil & igni-

tor ASSY connec-

tor and engine

ground terminal

4 CHECK IGNITION COIL & IGNITOR ASSY.

1) Remove the spark plug cords.

2) Measure the resistance between spark

plug cord contact portions to check secondary

coil.

Te r m i n a l s

No. 1 — No. 2:

No. 3 — No. 4:Is the resistance 10 — 15 kΩ? Go to step 5.Replace the igni-

tion coil & ignitor

ASSY.

tion Coil & Ignitor

Assembly.>

5 CHECK INPUT SIGNAL FOR IGNITION COIL

& IGNITOR ASSY.

1) Connect the connector to ignition coil &

ignitor ASSY.

2) Check if voltage varies synchronously with

engine speed when cranking, while monitoring

voltage between ignition coil & ignitor ASSY

connector and engine ground.

Connector & terminal

(E12) No. 1 (+) — Engine ground (

−):

(E12) No. 4 (+) — Engine ground (

−):Does the voltage vary more

than 10 V?Go to step 6.Replace the igni-

tion coil & ignitor

ASSY.

tion Coil & Ignitor

Assembly.>

Page 1164 of 2870

EN(H4SO)-66

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

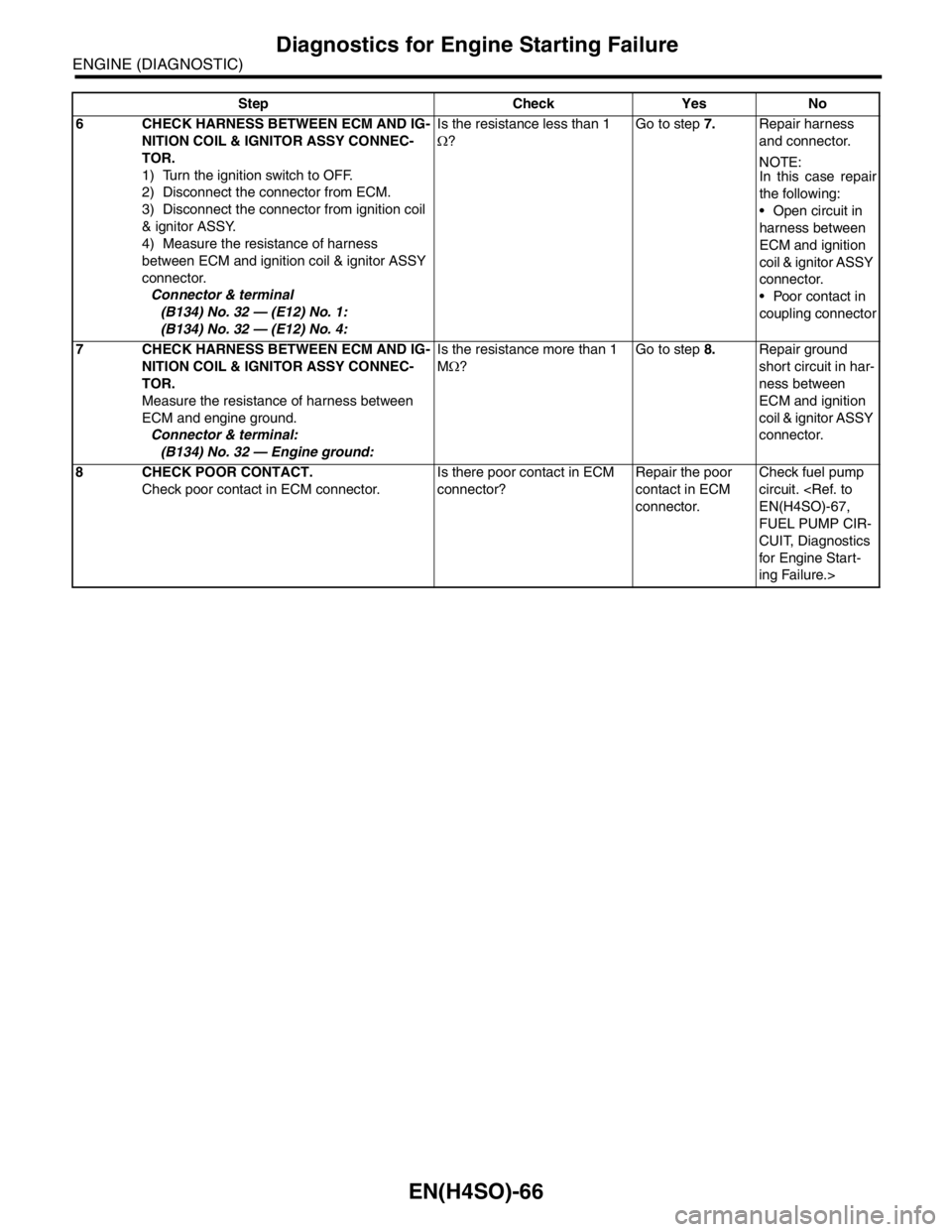

6 CHECK HARNESS BETWEEN ECM AND IG-

NITION COIL & IGNITOR ASSY CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connector from ignition coil

& ignitor ASSY.

4) Measure the resistance of harness

between ECM and ignition coil & ignitor ASSY

connector.

Connector & terminal

(B134) No. 32 — (E12) No. 1:

(B134) No. 32 — (E12) No. 4:Is the resistance less than 1

Ω?Go to step 7.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

ECM and ignition

coil & ignitor ASSY

connector.

Poor contact in

coupling connector

7 CHECK HARNESS BETWEEN ECM AND IG-

NITION COIL & IGNITOR ASSY CONNEC-

TOR.

Measure the resistance of harness between

ECM and engine ground.

Connector & terminal:

(B134) No. 32 — Engine ground:Is the resistance more than 1

MΩ?Go to step 8.Repair ground

short circuit in har-

ness between

ECM and ignition

coil & ignitor ASSY

connector.

8 CHECK POOR CONTACT.

Check poor contact in ECM connector. Is there poor contact in ECM

connector?Repair the poor

contact in ECM

connector.Check fuel pump

circuit.

FUEL PUMP CIR-

CUIT, Diagnostics

for Engine Start-

ing Failure.> Step Check Yes No

Page 1165 of 2870

EN(H4SO)-67

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

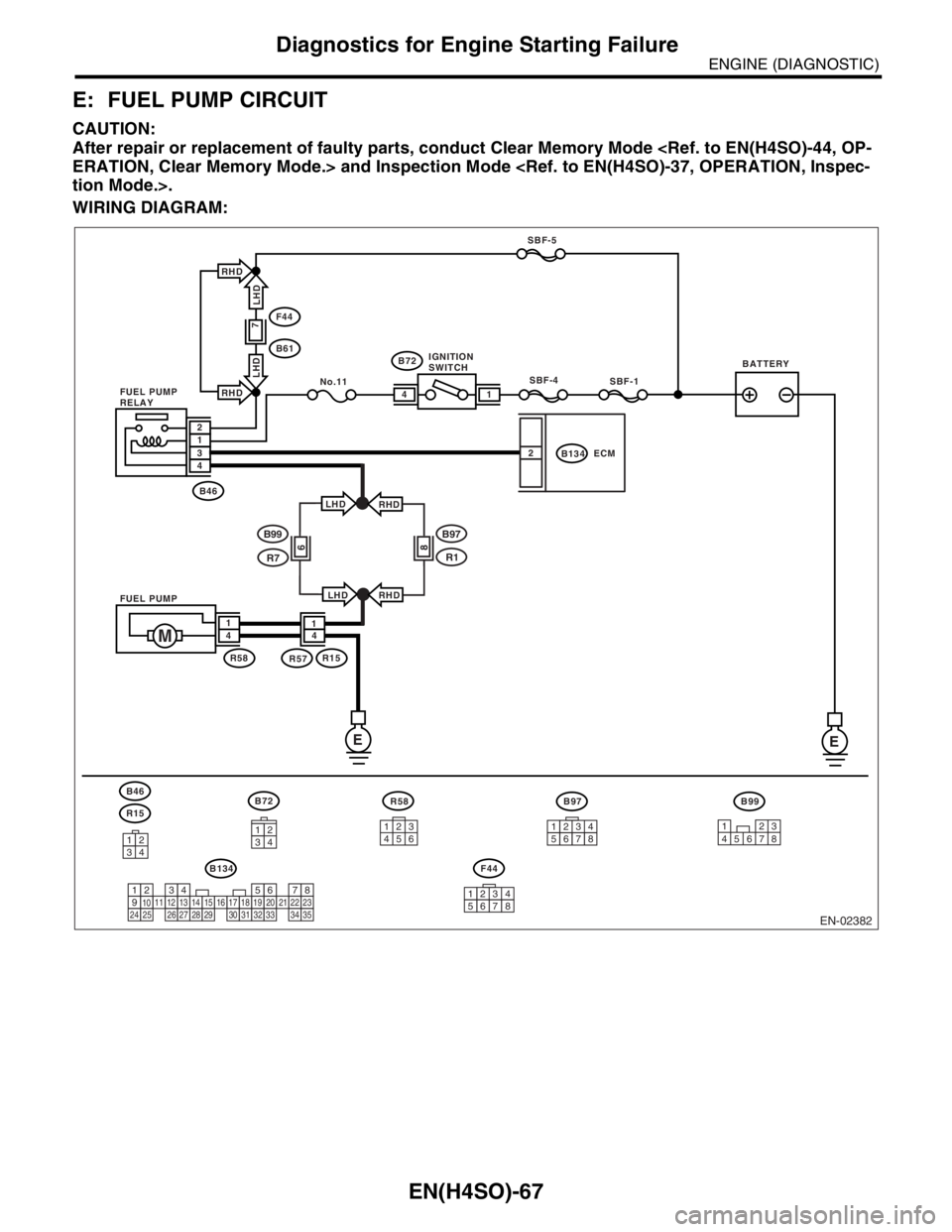

E: FUEL PUMP CIRCUIT

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02382

B72B46

R15

F44

B99

B134

R58

3412

SBF-1

No.11SBF-4

E

1

2 4

B72

F44

B61

B46

R58R57R15

SBF-5

2134

4M14 1

B134ECM

341213

4562

12345678

1234567891011121314151617181920212223242526272829303132333435

BATTERY IGNITION

SWITCH

FUEL PUMP

RELAY

FUEL PUMP

7

B99

R7

B97

R186

LHD

LHDRHD

RHD

B97

12345678

RHD

LHD

LHD

RHD

E

123

45678

Page 1166 of 2870

EN(H4SO)-68

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

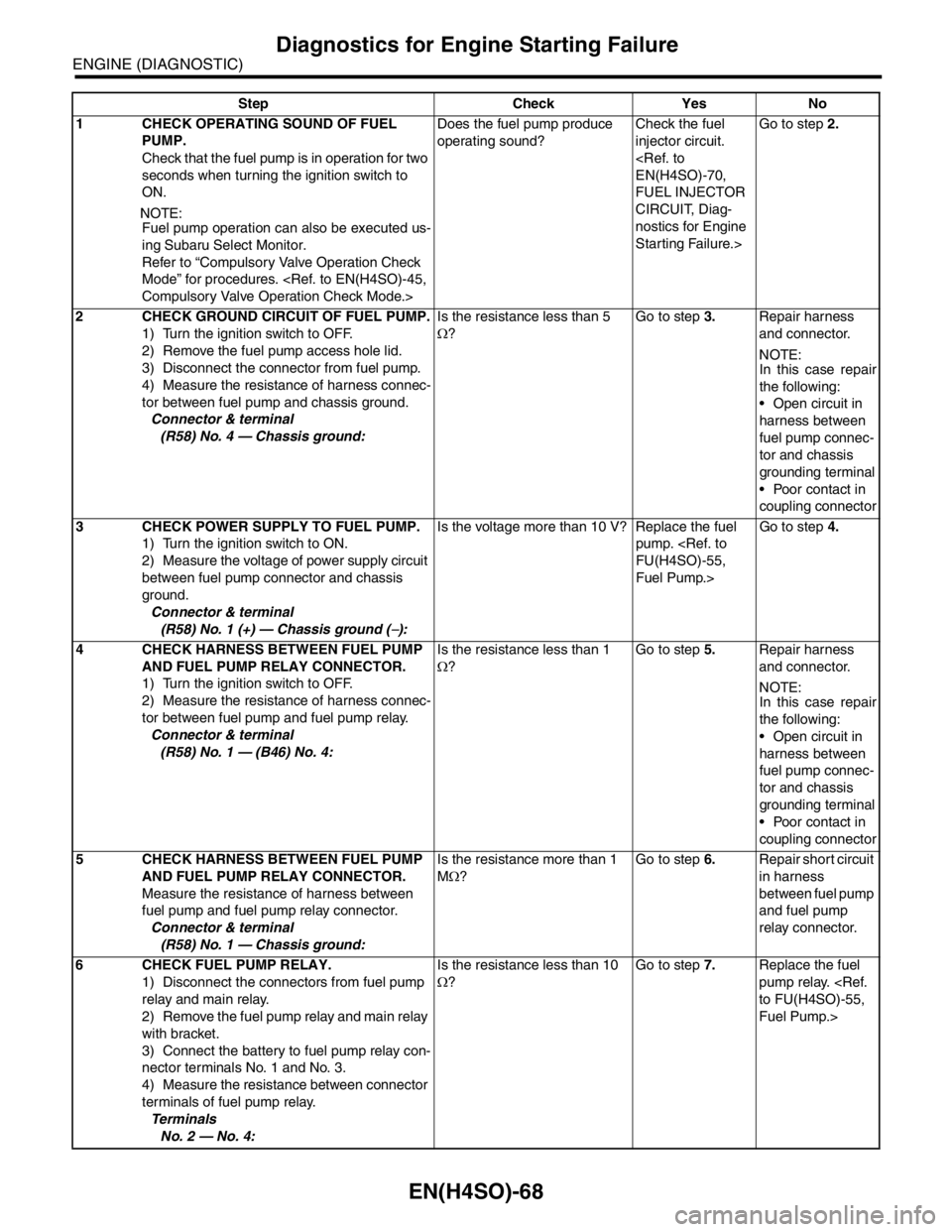

Step Check Yes No

1 CHECK OPERATING SOUND OF FUEL

PUMP.

Check that the fuel pump is in operation for two

seconds when turning the ignition switch to

ON.

N

OTE:

Fuel pump operation can also be executed us-

ing Subaru Select Monitor.

Refer to “Compulsory Valve Operation Check

Mode” for procedures.

operating sound?Check the fuel

injector circuit.

FUEL INJECTOR

CIRCUIT, Diag-

nostics for Engine

Starting Failure.>Go to step 2.

2 CHECK GROUND CIRCUIT OF FUEL PUMP.

1) Turn the ignition switch to OFF.

2) Remove the fuel pump access hole lid.

3) Disconnect the connector from fuel pump.

4) Measure the resistance of harness connec-

tor between fuel pump and chassis ground.

Connector & terminal

(R58) No. 4 — Chassis ground:Is the resistance less than 5

Ω?Go to step 3.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

fuel pump connec-

tor and chassis

grounding terminal

Poor contact in

coupling connector

3 CHECK POWER SUPPLY TO FUEL PUMP.

1) Turn the ignition switch to ON.

2) Measure the voltage of power supply circuit

between fuel pump connector and chassis

ground.

Connector & terminal

(R58) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Replace the fuel

pump.

Fuel Pump.>Go to step 4.

4 CHECK HARNESS BETWEEN FUEL PUMP

AND FUEL PUMP RELAY CONNECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness connec-

tor between fuel pump and fuel pump relay.

Connector & terminal

(R58) No. 1 — (B46) No. 4:Is the resistance less than 1

Ω?Go to step 5.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

fuel pump connec-

tor and chassis

grounding terminal

Poor contact in

coupling connector

5 CHECK HARNESS BETWEEN FUEL PUMP

AND FUEL PUMP RELAY CONNECTOR.

Measure the resistance of harness between

fuel pump and fuel pump relay connector.

Connector & terminal

(R58) No. 1 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 6.Repair short circuit

in harness

between fuel pump

and fuel pump

relay connector.

6 CHECK FUEL PUMP RELAY.

1) Disconnect the connectors from fuel pump

relay and main relay.

2) Remove the fuel pump relay and main relay

with bracket.

3) Connect the battery to fuel pump relay con-

nector terminals No. 1 and No. 3.

4) Measure the resistance between connector

terminals of fuel pump relay.

Te r m i n a l s

No. 2 — No. 4:Is the resistance less than 10

Ω?Go to step 7.Replace the fuel

pump relay.

Fuel Pump.>

Page 1167 of 2870

EN(H4SO)-69

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

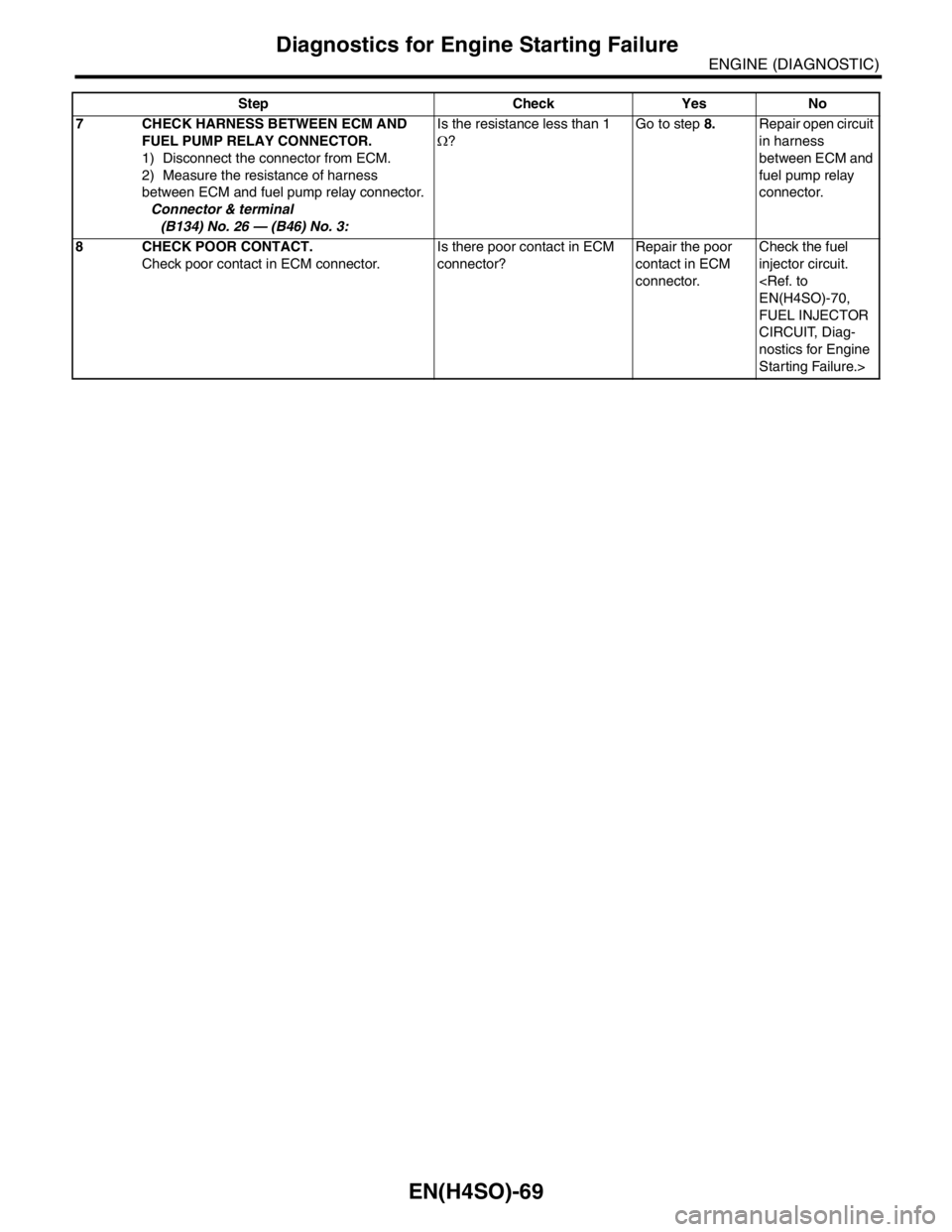

7 CHECK HARNESS BETWEEN ECM AND

FUEL PUMP RELAY CONNECTOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness

between ECM and fuel pump relay connector.

Connector & terminal

(B134) No. 26 — (B46) No. 3:Is the resistance less than 1

Ω?Go to step 8.Repair open circuit

in harness

between ECM and

fuel pump relay

connector.

8 CHECK POOR CONTACT.

Check poor contact in ECM connector.Is there poor contact in ECM

connector?Repair the poor

contact in ECM

connector.Check the fuel

injector circuit.

FUEL INJECTOR

CIRCUIT, Diag-

nostics for Engine

Starting Failure.> Step Check Yes No

Page 1168 of 2870

EN(H4SO)-70

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

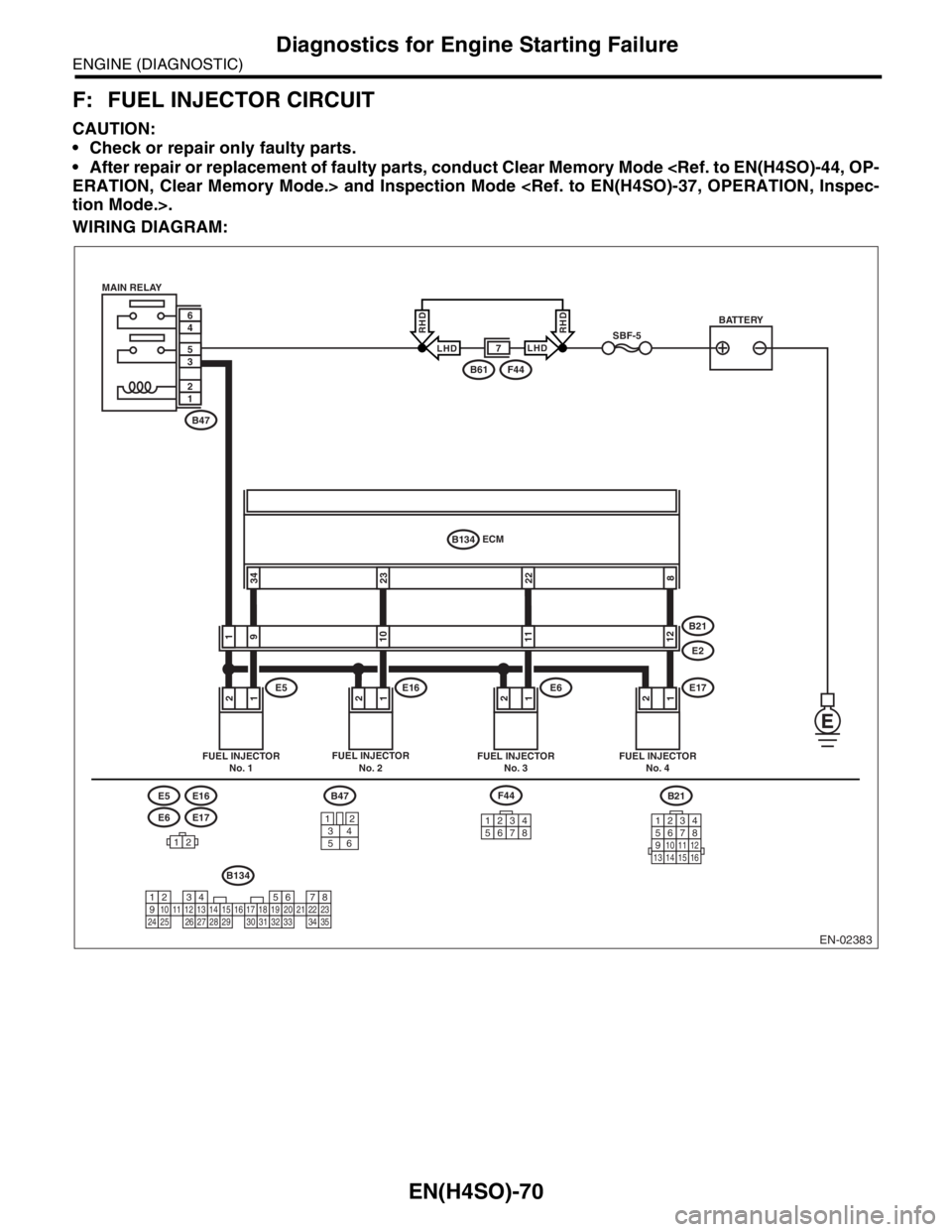

F: FUEL INJECTOR CIRCUIT

CAUTION:

Check or repair only faulty parts.

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02383

B21

12345678910111213141516

E6E17

E5E16

12

12121212

2223348

91101112

ECM

B134

E5E16E6E17

B21

E2

FUEL INJECTOR

No. 1FUEL INJECTOR

No. 2FUEL INJECTOR

No. 3FUEL INJECTOR

No. 4

BATTERY

F44B61

SBF-5

B47 MAIN RELAY

12

35

46

B47

34

12

56

F44

12345678

B134

1234567891011121314151617181920212223242526272829303132333435

LHDLHD

RHDRHD

7

Page 1169 of 2870

EN(H4SO)-71

ENGINE (DIAGNOSTIC)

Diagnostics for Engine Starting Failure

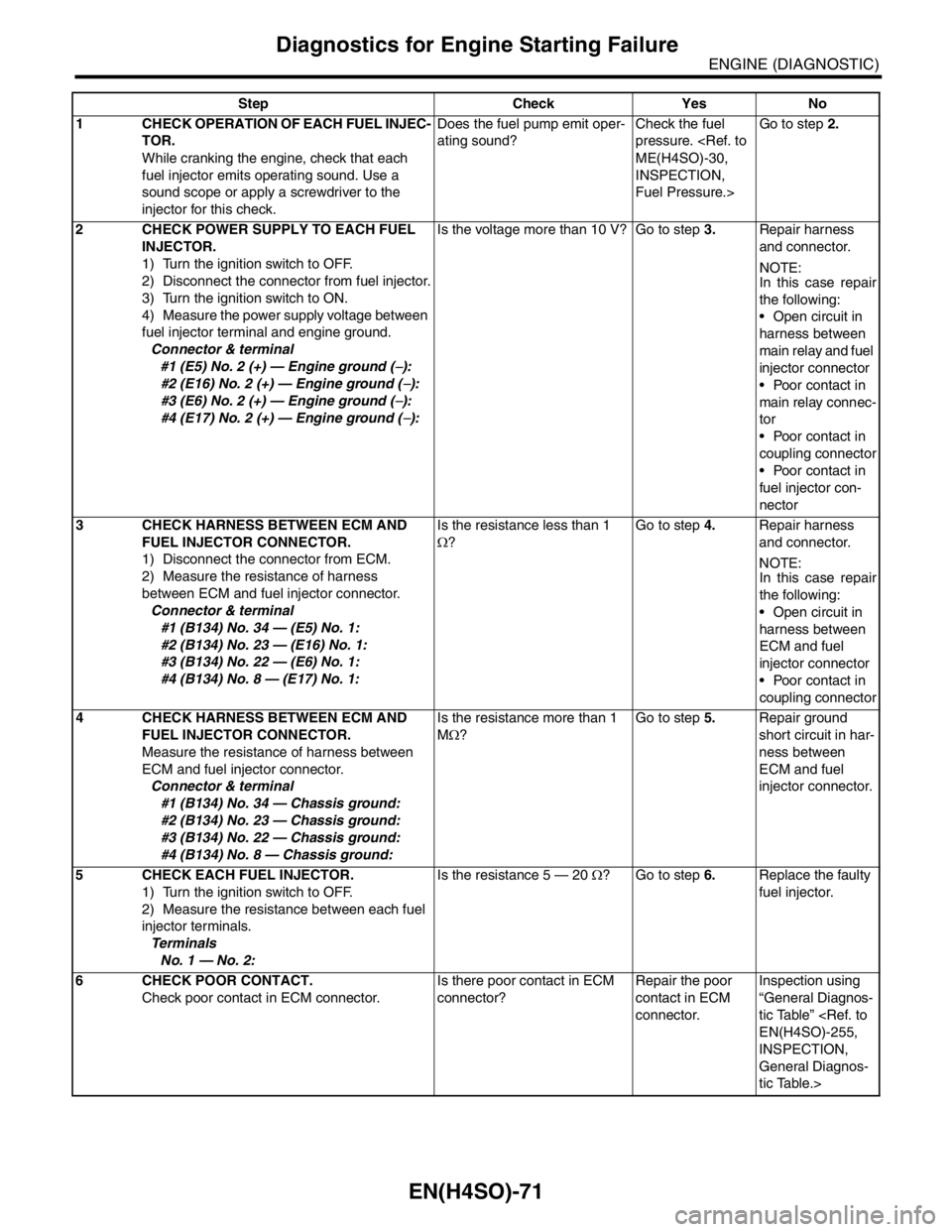

Step Check Yes No

1 CHECK OPERATION OF EACH FUEL INJEC-

TOR.

While cranking the engine, check that each

fuel injector emits operating sound. Use a

sound scope or apply a screwdriver to the

injector for this check.Does the fuel pump emit oper-

ating sound?Check the fuel

pressure.

INSPECTION,

Fuel Pressure.>Go to step 2.

2 CHECK POWER SUPPLY TO EACH FUEL

INJECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel injector.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage between

fuel injector terminal and engine ground.

Connector & terminal

#1 (E5) No. 2 (+) — Engine ground (

−):

#2 (E16) No. 2 (+) — Engine ground (

−):

#3 (E6) No. 2 (+) — Engine ground (

−):

#4 (E17) No. 2 (+) — Engine ground (

−):Is the voltage more than 10 V? Go to step 3.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

main relay and fuel

injector connector

Poor contact in

main relay connec-

tor

Poor contact in

coupling connector

Poor contact in

fuel injector con-

nector

3 CHECK HARNESS BETWEEN ECM AND

FUEL INJECTOR CONNECTOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness

between ECM and fuel injector connector.

Connector & terminal

#1 (B134) No. 34 — (E5) No. 1:

#2 (B134) No. 23 — (E16) No. 1:

#3 (B134) No. 22 — (E6) No. 1:

#4 (B134) No. 8 — (E17) No. 1:Is the resistance less than 1

Ω?Go to step 4.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

ECM and fuel

injector connector

Poor contact in

coupling connector

4 CHECK HARNESS BETWEEN ECM AND

FUEL INJECTOR CONNECTOR.

Measure the resistance of harness between

ECM and fuel injector connector.

Connector & terminal

#1 (B134) No. 34 — Chassis ground:

#2 (B134) No. 23 — Chassis ground:

#3 (B134) No. 22 — Chassis ground:

#4 (B134) No. 8 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 5.Repair ground

short circuit in har-

ness between

ECM and fuel

injector connector.

5 CHECK EACH FUEL INJECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between each fuel

injector terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance 5 — 20 Ω? Go to step 6.Replace the faulty

fuel injector.

6 CHECK POOR CONTACT.

Check poor contact in ECM connector.Is there poor contact in ECM

connector?Repair the poor

contact in ECM

connector.Inspection using

“General Diagnos-

tic Table”

INSPECTION,

General Diagnos-

tic Table.>

Page 1170 of 2870

EN(H4SO)-72

ENGINE (DIAGNOSTIC)

List of Diagnostic Trouble Code (DTC)

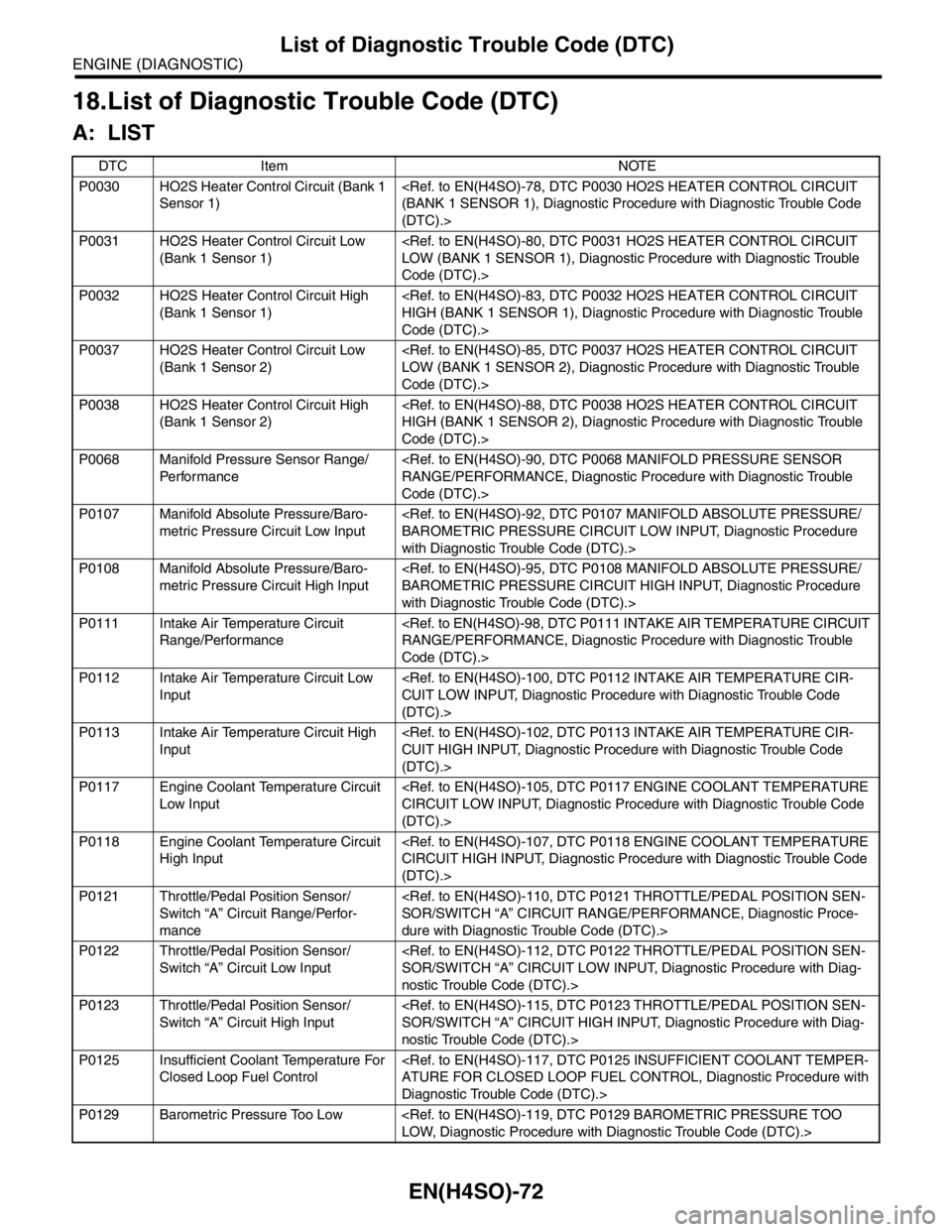

18.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Item NOTE

P0030 HO2S Heater Control Circuit (Bank 1

Sensor 1)

(DTC).>

P0031 HO2S Heater Control Circuit Low

(Bank 1 Sensor 1)

Code (DTC).>

P0032 HO2S Heater Control Circuit High

(Bank 1 Sensor 1)

Code (DTC).>

P0037 HO2S Heater Control Circuit Low

(Bank 1 Sensor 2)

Code (DTC).>

P0038 HO2S Heater Control Circuit High

(Bank 1 Sensor 2)

Code (DTC).>

P0068 Manifold Pressure Sensor Range/

Pe r fo r ma nc e

Code (DTC).>

P0107 Manifold Absolute Pressure/Baro-

metric Pressure Circuit Low Input

with Diagnostic Trouble Code (DTC).>

P0108 Manifold Absolute Pressure/Baro-

metric Pressure Circuit High Input

with Diagnostic Trouble Code (DTC).>

P0111 Intake Air Temperature Circuit

Range/Performance

Code (DTC).>

P0112 Intake Air Temperature Circuit Low

Input

(DTC).>

P0113 Intake Air Temperature Circuit High

Input

(DTC).>

P0117 Engine Coolant Temperature Circuit

Low Input

(DTC).>

P0118 Engine Coolant Temperature Circuit

High Input

(DTC).>

P0121 Throttle/Pedal Position Sensor/

Switch “A” Circuit Range/Perfor-

mance

dure with Diagnostic Trouble Code (DTC).>

P0122 Throttle/Pedal Position Sensor/

Switch “A” Circuit Low Input

nostic Trouble Code (DTC).>

P0123 Throttle/Pedal Position Sensor/

Switch “A” Circuit High Input

nostic Trouble Code (DTC).>

P0125 Insufficient Coolant Temperature For

Closed Loop Fuel Control

Diagnostic Trouble Code (DTC).>

P0129 Barometric Pressure Too Low