SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1131 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-33

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

6. READ FREEZE FRAME DATA FOR ENGINE. (OBD MODE)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-33

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

6. READ FREEZE FRAME DATA FOR ENGINE. (OBD MODE)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.](/img/17/57426/w960_57426-1130.png)

EN(H4SO)-33

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

6. READ FREEZE FRAME DATA FOR ENGINE. (OBD MODE)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Engine} and press the [YES] key.

3) Press the [YES] key after the information of engine type was displayed.

4) On the «Engine Diagnosis» display screen, select the {OBD System} and press the [YES] key.

5) On the «OBD Menu» display screen, select the {Freeze Frame Data} and press the [YES] key.

A list of the support data is shown in the following table.

NOTE:

For detailed operation procedure, refer to the SUBARU SELECT MONITOR OPERATION MANUAL.

Description Display Unit of measure

DTC of freeze frame data Freeze frame data DTC

Air fuel ratio control system for bank 1 Fuel system for Bank 1 ON or OFF

Engine load data Engine load %

Engine coolant temperature signal Engine coolant temperature°C or (°F)

Short term fuel trim by front oxygen (A/F) sensor Short term fuel trim B1 %

Long term fuel trim by front oxygen (A/F) sensor Long term fuel trim B1 %

Intake manifold absolute pressure signalIntake manifold absolute pres-

suremmHg, kPa, inHg or psi

Engine speed signal Engine speed rpm

Vehicle speed signal Meter vehicle speed km/h or MPH

Page 1132 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-34

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «Syste SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-34

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «Syste](/img/17/57426/w960_57426-1131.png)

EN(H4SO)-34

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Engine} and press the [YES] key.

3) Press the [YES] key after the information of engine type was displayed.

4) On the «Engine Diagnosis» display screen, select the {Current Data Display/Save}, and then press the

[YES] key.

5) On the «Data Display Menu» display screen, select the {Data & LED Display} and press the [YES] key.

6) Using the scroll key, scroll the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

NOTE:

For detailed operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MANUAL”.

Description Display Message LED “ON” requirements

Ignition switch signal Ignition SW ON or OFF When ignition switch is ON

Test mode connector signal Test mode signal ON or OFF When test mode connector is connected.

Neutral position switch signal Neutral SW ON or OFF When neutral position signal is entered.

Air conditioning switch signal A/C SW ON or OFF When air conditioning switch is ON

Air conditioning relay signal A/C Compressor Relay ON or OFF When air conditioning relay is in function.

Radiator main fan relay signal Radiator fan relay 1 ON or OFF When radiator main fan relay is in function.

Fuel pump relay signal Fuel pump relay ON or OFF When fuel pump relay is in function.

Knocking signal Knock signal ON or OFF When knocking signal is input.

Radiator sub fan relay signal Radiator fan relay 2 ON or OFF When radiator sub fan relay is in function.

Engine torque control signal #1 AT coordinate request signal 1 ON or OFFWhen engine torque control signal 1 is

entered

Engine torque control signal #2 AT coordinate request signal 2 ON or OFFWhen engine torque control signal 2 is

entered

Engine torque control permission

signalAT coordinate permission sig-

nalON or OFFWhen engine torque control permission sig-

nal is entered.

Front oxygen (A/F) sensor rich sig-

nalFront O2 Rich Signal #1 ON or OFFWhen front oxygen (A/F) sensor mixture ratio

is rich.

Rear oxygen sensor rich signal RrO2 monitor ON or OFFWhen rear oxygen sensor mixture ratio is

rich.

Starter switch signal Starter SW ON or OFF When starter switch signal is entered.

Idle switch signal Idle Switch Signal ON or OFF When idle switch signal is entered.

Crankshaft position sensor signal Crankshaft position signal ON or OFFWhen crankshaft position sensor signal is

input.

Camshaft position sensor signal Camshaft position signal ON or OFFWhen camshaft position sensor signal is

entered.

Page 1133 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sel SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sel](/img/17/57426/w960_57426-1132.png)

EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Transmission} and press the [YES] key.

3) Press the [YES] key after the information of transmission type is displayed.

4) On the «Transmission Diagnosis» display screen, select the {Current Data Display & Save} and press the

[YES] key.

5) On the «Transmission Diagnosis» display screen, select the {Data Display} and press the [YES] key.

6) Using the scroll key, scroll the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

Description Display Unit of measure

Battery voltage Battery Voltage V

Rear vehicle speed sensor signal Rear Wheel Speed km/h or MPH

Front vehicle speed sensor signal Front Wheel Speed km/h or MPH

Engine speed signal Engine speed rpm

ATF temperature signal ATF Temp.°C or °F

Throttle position sensor Throttle Sensor Voltage V

Gear Position Gear position —

Line pressure control duty ratio Line pressure duty %

Lock up clutch control duty ratio L/U Duty %

Transfer clutch control duty ratio AWD duty %

Throttle position sensor power supply Throttle sensor power supply V

Turbine revolution signal Turbine Revolution Speed rpm

2-4 Brake timing pressure control duty ratio 2-4 B Pressure Duty %

Intake manifold pressure sensor voltage Mani. Relative Voltage V

FWD switch signal FWD SW ON or OFF

Kick down switch signal Kick Down Switch ON or OFF

Stop light switch signal Stop Light SW ON or OFF

Anti lock brake system signal ABS signal ON or OFF

Cruise control system signal Cruise Control Signal ON or OFF

Neutral/Parking range signal N/P range ON or OFF

Reverse range signal R Range ON or OFF

Drive range signal D Range ON or OFF

3rd range signal 3rd Range Signal ON or OFF

2nd range signal 2nd Range Signal ON or OFF

1st range signal 1st Range Signal ON or OFF

Shift control solenoid A Shift Solenoid #1 ON or OFF

Shift control solenoid B Shift Solenoid #2 ON or OFF

Torque control output signal #1 Torque control output signal 1 ON or OFF

Torque control output signal #2 Torque control output signal 2 ON or OFF

Torque control cut signal Torque Control Cut Sig ON or OFF

2-4 brake timing control solenoid valve 2-4B Timing Solenoid ON or OFF

Low clutch timing control solenoid valve L/C timing solenoid ON or OFF

Automatic transmission diagnosis light output signal Diagnosis Lamp ON or OFF

Page 1134 of 2870

EN(H4SO)-36

ENGINE (DIAGNOSTIC)

Read Diagnostic Trouble Code (DTC)

11.Read Diagnostic Trouble

Code (DTC)

A: OPERATION

1. SUBARU SELECT MONITOR (NORMAL

MODE)

1) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen,

select the {Engine} and press the [YES] key.

3) Press the [YES] key after the information of en-

gine type was displayed.

4) On the «Engine Diagnosis» screen, select the

{DTC Display}, and then press the [YES] key.

5) On the «Diagnostic Code(s) Display» screen,

select the {Current Diagnostic Code(s)} or {History

Diagnostic Code(s)}, and then press the [YES] key.

NOTE:

For detailed operation procedure, refer to the “SUB-

ARU SELECT MONITOR OPERATION MANUAL”.

For details concerning DTC, refer to the List of Di-

agnostic Trouble Code (DTC).

2. SUBARU SELECT MONITOR (OBD

MODE)

1) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen,

select the {Engine} and press the [YES] key.

3) Press the [YES] key after the information of en-

gine type was displayed.

4) On the «Engine Diagnosis» display screen, se-

lect the {OBD System} and press the [YES] key.

5) On the «OBD Menu» display screen, select the

{DTC Display} and press the [YES] key.

6) Make sure DTC is shown on the screen.

NOTE:

For detailed operation procedure, refer to the

“SUBARU SELECT MONITOR OPERATION

MANUAL”.

For details concerning DTC, refer to the List of Di-

agnostic Trouble Code (DTC).

3. OBD-II GENERAL SCAN TOOL

Refers to data denoting emission-related power-

train DTC.

For details concerning DTC, refer to the List of Di-

agnostic Trouble Code (DTC).

Refer to OBD-II general scan tool manufacturer’s

instruction manual to access powertrain DTC

(MODE $03).

Page 1135 of 2870

EN(H4SO)-37

ENGINE (DIAGNOSTIC)

Inspection Mode

12.Inspection Mode

A: OPERATION

Perform the diagnosis on the “Diagnosis Trouble Codes (DTC) List” below.

Refer to the item of drive cycle when perform the diagnosis not on the “Diagnosis Trouble Codes (DTC) List”

below.

DTC Item

P0030 HO2S Heater Control Circuit (Bank 1 Sensor 1)

P0031 HO2S Heater Control Circuit Low (Bank 1 Sensor 1)

P0032 HO2S Heater Control Circuit High (Bank 1 Sensor 1)

P0037 HO2S Heater Control Circuit Low (Bank 1 Sensor 2)

P0038 HO2S Heater Control Circuit High (Bank 1 Sensor 2)

P0068 Manifold Pressure Sensor Range/Performance

P0107 Manifold Absolute Pressure/Barometric Pressure Circuit Low Input

P0108 Manifold Absolute Pressure/Barometric Pressure Circuit High Input

P0112 Intake Air Temperature Circuit Low Input

P0113 Intake Air Temperature Circuit High Input

P0117 Engine Coolant Temperature Circuit Low Input

P0118 Engine Coolant Temperature Circuit High Input

P0122 Throttle/Pedal Position Sensor/Switch “A” Circuit Low Input

P0123 Throttle/Pedal Position Sensor/Switch “A” Circuit High Input

P0129 Barometric Pressure Too Low

P0131 O

2 Sensor Circuit Low Voltage (Bank 1 Sensor 1)

P0132 O

2 Sensor Circuit High Voltage (Bank 1 Sensor 1)

P0134 O

2 Sensor Circuit No Activity Detected (Bank 1 Sensor 1)

P0137 O

2 Sensor Circuit Low Voltage (Bank 1 Sensor 2)

P0138 O

2 Sensor Circuit High Voltage (Bank 1 Sensor 2)

P0327 Knock Sensor 1 Circuit Low Input (Bank 1 or Single Sensor)

P0328 Knock Sensor 1 Circuit High Input (Bank 1 or Single Sensor)

P0335 Crankshaft Position Sensor “A” Circuit

P0336 Crankshaft Position Sensor “A” Circuit Range/Performance

P0340 Camshaft Position Sensor “A” Circuit (Bank 1 or Single Sensor)

P0341 Camshaft Position Sensor “A” Circuit Range/Performance (Bank 1 or Single Sensor)

P0458 Evaporative Emission Control System Purge Control Valve Circuit Low

P0462 Fuel Level Sensor Circuit Low Input

P0463 Fuel Level Sensor Circuit High Input

P0502 Vehicle Speed Sensor Circuit Low Input

P0503 Vehicle Speed Sensor Intermittent/Erratic/High

P0512 Starter Request Circuit

P0513 Incorrect Immobilizer Key

P0519 Idle Control System Malfunction (Fail-Safe)

P0565 Cruise Control On Signal

P0604 Internal Control Module Random Access Memory (RAM) Error

P0703 Torque Converter/Brake Switch “B” Circuit

P0705 Transmission Range Sensor Circuit (PRNDL Input)

P0710 Transmission Fluid Temperature Sensor Circuit

P0716 Torque converter turbine speed sensor

P0720 AT Vehicle Speed Sensor Circuit Malfunction

P0726 Engine Speed Input Circuit Malfunction

P0731 Gear 1 Incorrect Ratio

P0732 Gear 2 Incorrect Ratio

P0733 Gear 3 Incorrect Ratio

Page 1136 of 2870

EN(H4SO)-38

ENGINE (DIAGNOSTIC)

Inspection Mode

P0734 Gear 4 Incorrect Ratio

P0741 Torque Converter Clutch Circuit Performance or Stuck Off

P0743 Torque Converter Clutch Circuit Electrical

P0748 Pressure Control Solenoid “A” Electrical

P0753 Shift Solenoid “A” Electrical

P0758 Shift Solenoid “B” Electrical

P0771 Low clutch timing solenoid

P0778 Pressure Control Solenoid “B” Electrical

P0785 Shift/Timing Solenoid

P0851 Neutral Switch Input Circuit Low

P0852 Neutral Switch Input Circuit High

P0864 TCM Communication Circuit Range/Performance

P0865 TCM Communication Circuit Low

P0866 TCM Communication Circuit Low

P1110 Atmospheric Pressure Sensor Circuit Malfunction (Low Input)

P1111 Atmospheric Pressure Sensor Circuit Malfunction (High Input)

P1492 EGR Valve Signal #1 Circuit Malfunction (Low Input)

P1493 EGR Valve Signal #1 Circuit Malfunction (High Input)

P1494 EGR Valve Signal #2 Circuit Malfunction (Low Input)

P1495 EGR Valve Signal #2 Circuit Malfunction (High Input)

P1496 EGR Valve Signal #3 Circuit Malfunction (Low Input)

P1497 EGR Valve Signal #3 Circuit Malfunction (High Input)

P1498 EGR Valve Signal #4 Circuit Malfunction (Low Input)

P1499 EGR Valve Signal #4 Circuit Malfunction (High Input)

P1510 ISC Solenoid Valve Signal #1 Circuit Malfunction (Low Input)

P1511 ISC Solenoid Valve Signal #1 Circuit Malfunction (High Input)

P1512 ISC Solenoid Valve Signal #2 Circuit Malfunction (Low Input)

P1513 ISC Solenoid Valve Signal #2 Circuit Malfunction (High Input)

P1514 ISC Solenoid Valve Signal #3 Circuit Malfunction (Low Input)

P1515 ISC Solenoid Valve Signal #3 Circuit Malfunction (High Input)

P1516 ISC Solenoid Valve Signal #4 Circuit Malfunction (Low Input)

P1517 ISC Solenoid Valve Signal #4 Circuit Malfunction (High Input)

P1518 Starter Switch Circuit Low Input

P1560 Back-Up Voltage Circuit Malfunction

P1570 Antenna

P1571 Reference Code Incompatibility

P1572 EGI — Immobilizer Communication

P1574 Key — Communication Failure

P1576 EGI Control Module EEPROM

P1577 IMM Control Module EEPROM

P1698 Engine Torque Control Cut Signal Circuit Malfunction (Low Input)

P1699 Engine Torque Control Cut Signal Circuit Malfunction (High Input)

P1700 Throttle Position Sensor Circuit Malfunction For AT

P1711 Engine Torque Control Signal #1 Circuit Malfunction

P1712 Engine Torque Control Signal #2 Circuit MalfunctionDTC Item

Page 1137 of 2870

EN(H4SO)-39

ENGINE (DIAGNOSTIC)

Inspection Mode

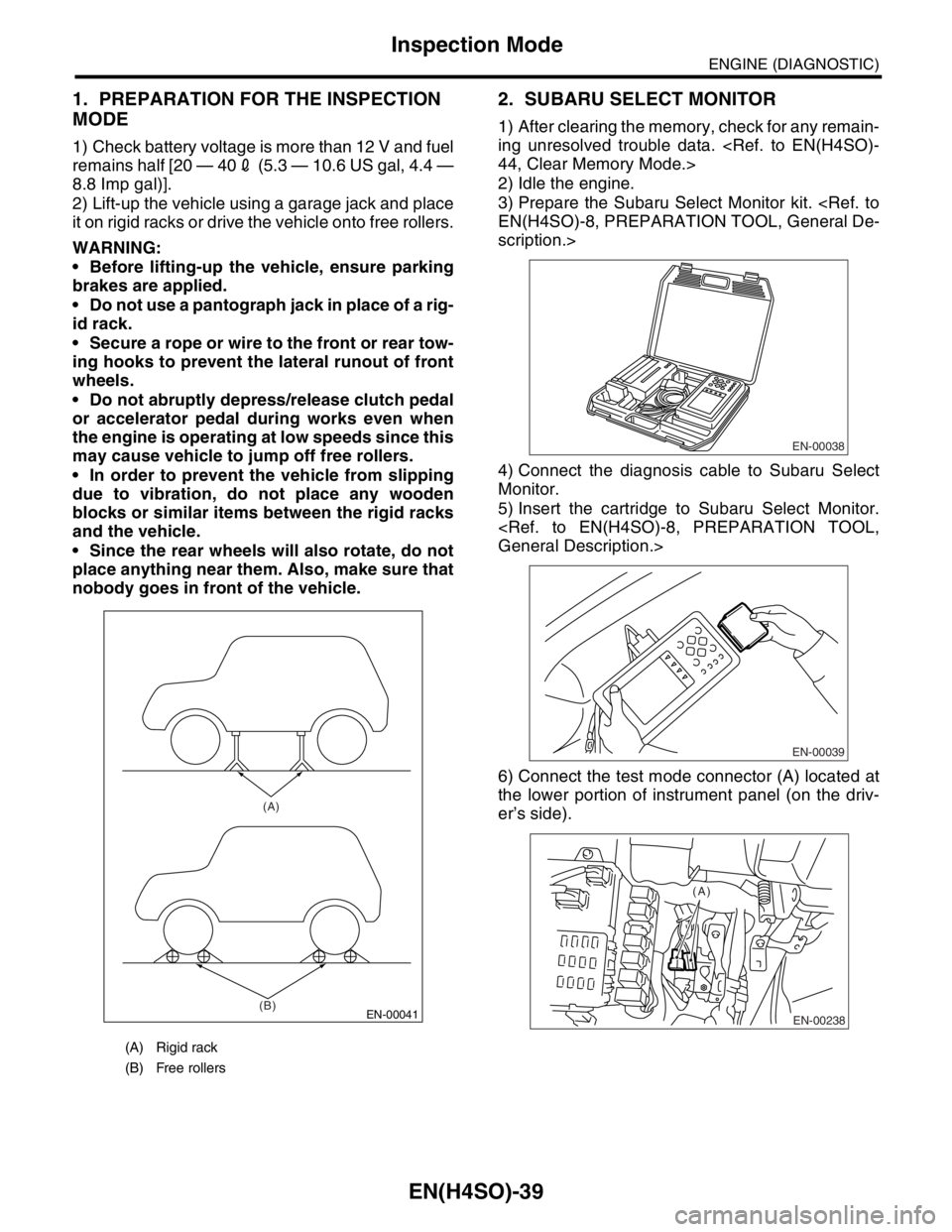

1. PREPARATION FOR THE INSPECTION

MODE

1) Check battery voltage is more than 12 V and fuel

remains half [20 — 402 (5.3 — 10.6 US gal, 4.4 —

8.8 Imp gal)].

2) Lift-up the vehicle using a garage jack and place

it on rigid racks or drive the vehicle onto free rollers.

WARNING:

Before lifting-up the vehicle, ensure parking

brakes are applied.

Do not use a pantograph jack in place of a rig-

id rack.

Secure a rope or wire to the front or rear tow-

ing hooks to prevent the lateral runout of front

wheels.

Do not abruptly depress/release clutch pedal

or accelerator pedal during works even when

the engine is operating at low speeds since this

may cause vehicle to jump off free rollers.

In order to prevent the vehicle from slipping

due to vibration, do not place any wooden

blocks or similar items between the rigid racks

and the vehicle.

Since the rear wheels will also rotate, do not

place anything near them. Also, make sure that

nobody goes in front of the vehicle.

2. SUBARU SELECT MONITOR

1) After clearing the memory, check for any remain-

ing unresolved trouble data.

2) Idle the engine.

3) Prepare the Subaru Select Monitor kit.

scription.>

4) Connect the diagnosis cable to Subaru Select

Monitor.

5) Insert the cartridge to Subaru Select Monitor.

6) Connect the test mode connector (A) located at

the lower portion of instrument panel (on the driv-

er’s side).

(A) Rigid rack

(B) Free rollers

EN-00041

(A)

(B)

EN-00038

EN-00039

EN-00238

(A)

Page 1138 of 2870

EN(H4SO)-40

ENGINE (DIAGNOSTIC)

Inspection Mode

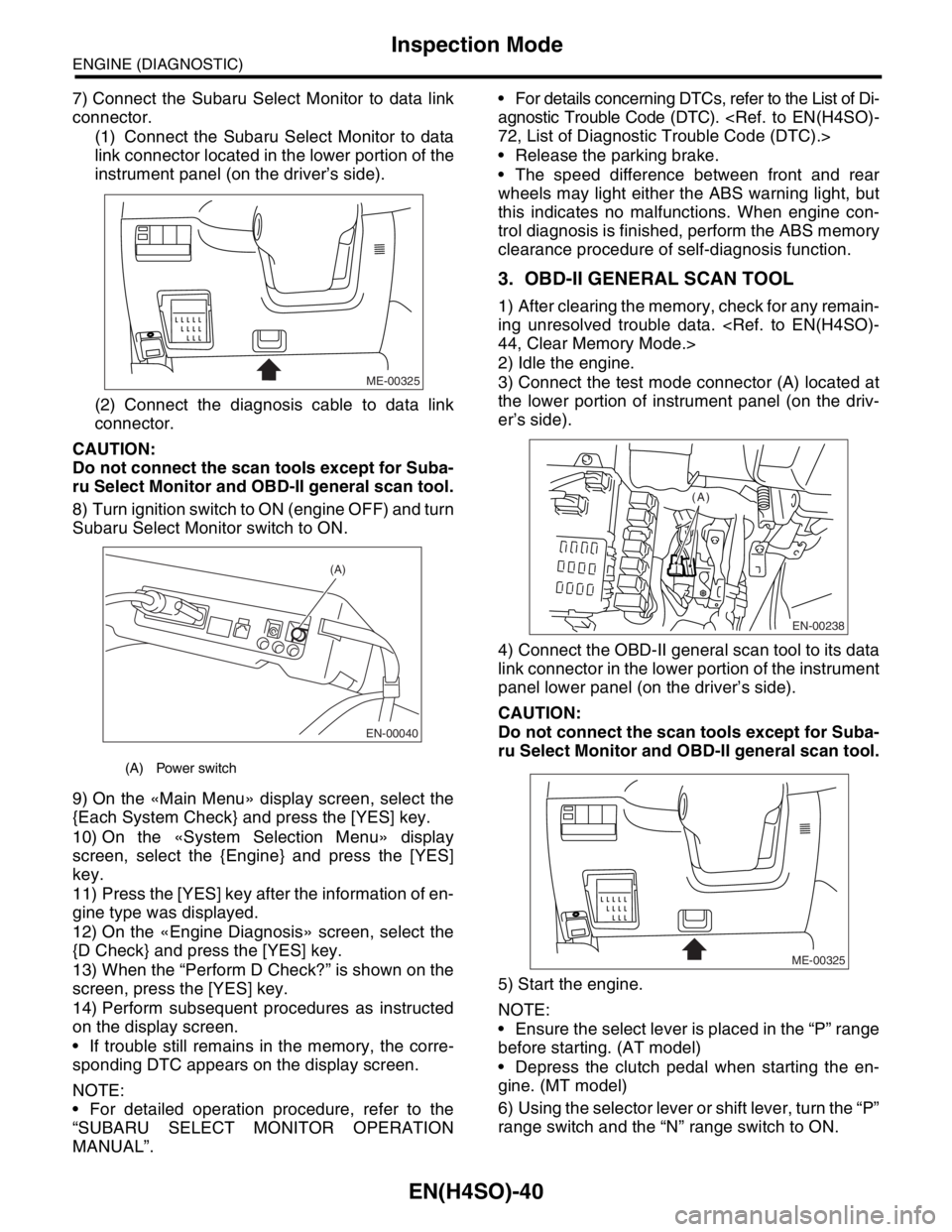

7) Connect the Subaru Select Monitor to data link

connector.

(1) Connect the Subaru Select Monitor to data

link connector located in the lower portion of the

instrument panel (on the driver’s side).

(2) Connect the diagnosis cable to data link

connector.

CAUTION:

Do not connect the scan tools except for Suba-

ru Select Monitor and OBD-II general scan tool.

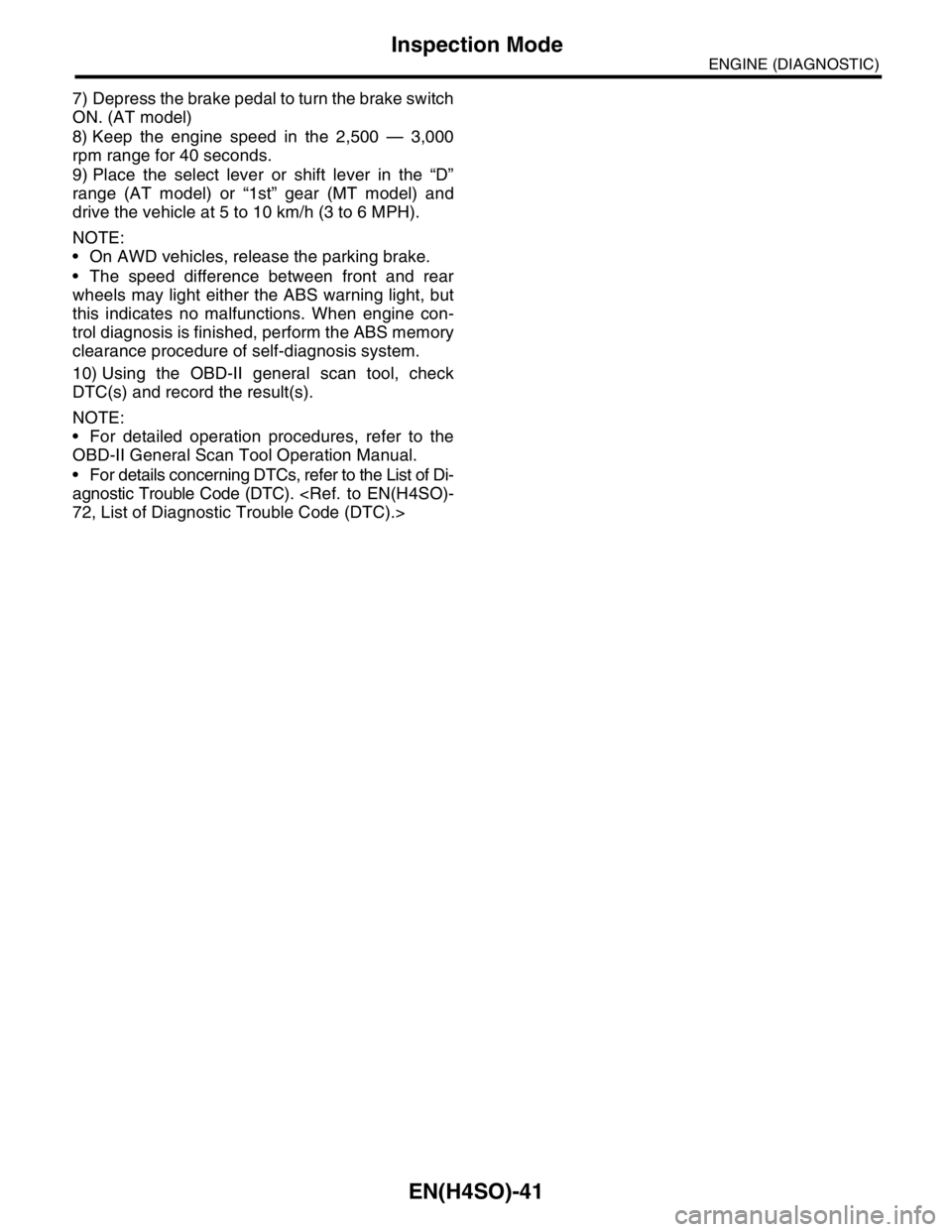

8) Turn ignition switch to ON (engine OFF) and turn

Subaru Select Monitor switch to ON.

9) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

10) On the «System Selection Menu» display

screen, select the {Engine} and press the [YES]

key.

11) Press the [YES] key after the information of en-

gine type was displayed.

12) On the «Engine Diagnosis» screen, select the

{D Check} and press the [YES] key.

13) When the “Perform D Check?” is shown on the

screen, press the [YES] key.

14) Perform subsequent procedures as instructed

on the display screen.

If trouble still remains in the memory, the corre-

sponding DTC appears on the display screen.

NOTE:

For detailed operation procedure, refer to the

“SUBARU SELECT MONITOR OPERATION

MANUAL”. For details concerning DTCs, refer to the List of Di-

agnostic Trouble Code (DTC).

Release the parking brake.

The speed difference between front and rear

wheels may light either the ABS warning light, but

this indicates no malfunctions. When engine con-

trol diagnosis is finished, perform the ABS memory

clearance procedure of self-diagnosis function.

3. OBD-II GENERAL SCAN TOOL

1) After clearing the memory, check for any remain-

ing unresolved trouble data.

2) Idle the engine.

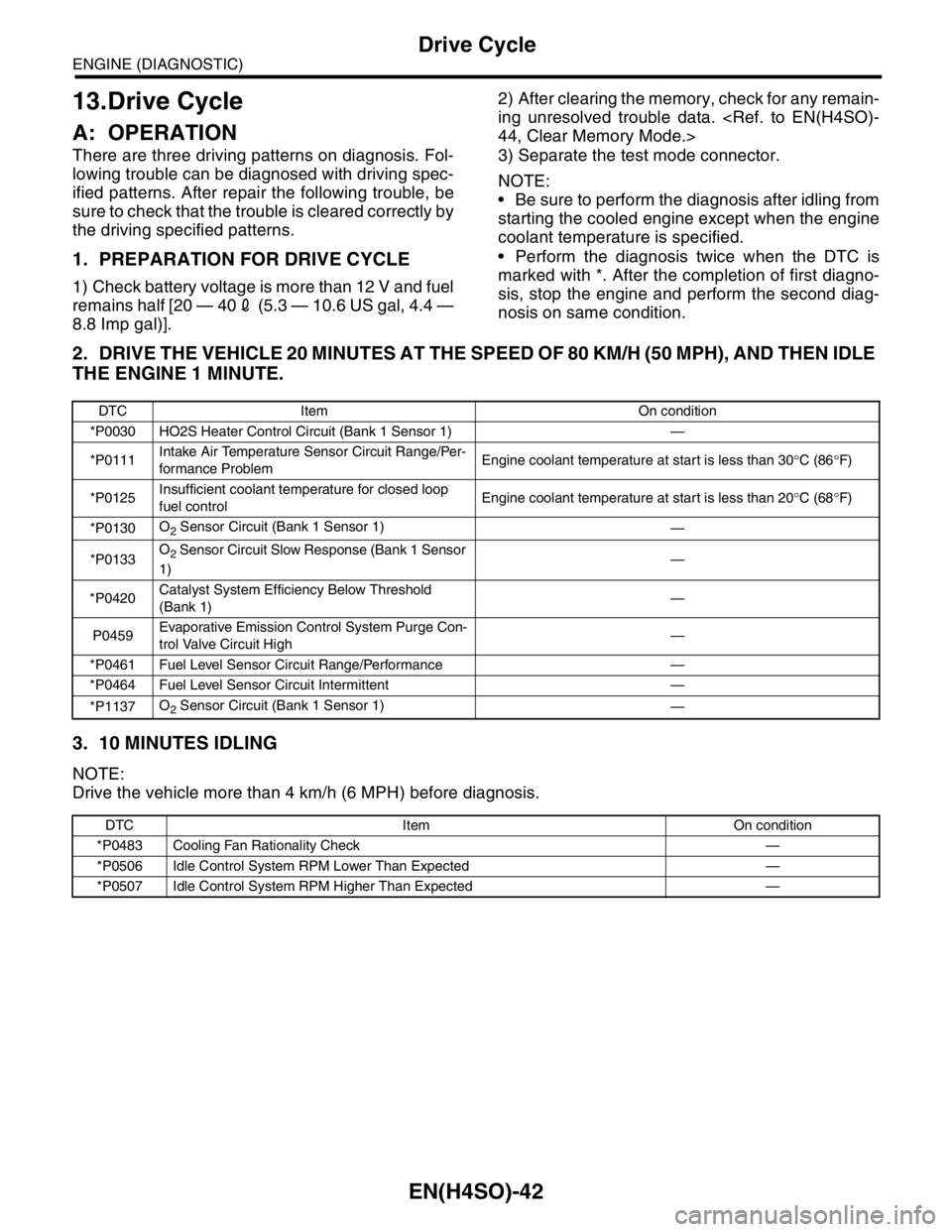

3) Connect the test mode connector (A) located at

the lower portion of instrument panel (on the driv-

er’s side).

4) Connect the OBD-II general scan tool to its data

link connector in the lower portion of the instrument

panel lower panel (on the driver’s side).

CAUTION:

Do not connect the scan tools except for Suba-

ru Select Monitor and OBD-II general scan tool.

5) Start the engine.

NOTE:

Ensure the select lever is placed in the “P” range

before starting. (AT model)

Depress the clutch pedal when starting the en-

gine. (MT model)

6) Using the selector lever or shift lever, turn the “P”

range switch and the “N” range switch to ON.

(A) Power switch

ME-00325

EN-00040

(A)

EN-00238

(A)

ME-00325

Page 1139 of 2870

EN(H4SO)-41

ENGINE (DIAGNOSTIC)

Inspection Mode

7) Depress the brake pedal to turn the brake switch

ON. (AT model)

8) Keep the engine speed in the 2,500 — 3,000

rpm range for 40 seconds.

9) Place the select lever or shift lever in the “D”

range (AT model) or “1st” gear (MT model) and

drive the vehicle at 5 to 10 km/h (3 to 6 MPH).

NOTE:

On AWD vehicles, release the parking brake.

The speed difference between front and rear

wheels may light either the ABS warning light, but

this indicates no malfunctions. When engine con-

trol diagnosis is finished, perform the ABS memory

clearance procedure of self-diagnosis system.

10) Using the OBD-II general scan tool, check

DTC(s) and record the result(s).

NOTE:

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.

For details concerning DTCs, refer to the List of Di-

agnostic Trouble Code (DTC).

Page 1140 of 2870

EN(H4SO)-42

ENGINE (DIAGNOSTIC)

Drive Cycle

13.Drive Cycle

A: OPERATION

There are three driving patterns on diagnosis. Fol-

lowing trouble can be diagnosed with driving spec-

ified patterns. After repair the following trouble, be

sure to check that the trouble is cleared correctly by

the driving specified patterns.

1. PREPARATION FOR DRIVE CYCLE

1) Check battery voltage is more than 12 V and fuel

remains half [20 — 402 (5.3 — 10.6 US gal, 4.4 —

8.8 Imp gal)].2) After clearing the memory, check for any remain-

ing unresolved trouble data.

3) Separate the test mode connector.

NOTE:

Be sure to perform the diagnosis after idling from

starting the cooled engine except when the engine

coolant temperature is specified.

Perform the diagnosis twice when the DTC is

marked with *. After the completion of first diagno-

sis, stop the engine and perform the second diag-

nosis on same condition.

2. DRIVE THE VEHICLE 20 MINUTES AT THE SPEED OF 80 KM/H (50 MPH), AND THEN IDLE

THE ENGINE 1 MINUTE.

3. 10 MINUTES IDLING

NOTE:

Drive the vehicle more than 4 km/h (6 MPH) before diagnosis.

DTC Item On condition

*P0030 HO2S Heater Control Circuit (Bank 1 Sensor 1) —

*P0111Intake Air Temperature Sensor Circuit Range/Per-

formance ProblemEngine coolant temperature at start is less than 30°C (86°F)

*P0125Insufficient coolant temperature for closed loop

fuel controlEngine coolant temperature at start is less than 20°C (68°F)

*P0130O

2 Sensor Circuit (Bank 1 Sensor 1)

—

*P0133O

2 Sensor Circuit Slow Response (Bank 1 Sensor

1)—

*P0420Catalyst System Efficiency Below Threshold

(Bank 1)—

P0459Evaporative Emission Control System Purge Con-

trol Valve Circuit High—

*P0461 Fuel Level Sensor Circuit Range/Performance —

*P0464 Fuel Level Sensor Circuit Intermittent —

*P1137O

2 Sensor Circuit (Bank 1 Sensor 1)

—

DTC Item On condition

*P0483 Cooling Fan Rationality Check —

*P0506 Idle Control System RPM Lower Than Expected —

*P0507 Idle Control System RPM Higher Than Expected —