lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 913 of 2870

ME(H4SO)-44

MECHANICAL

V-belt

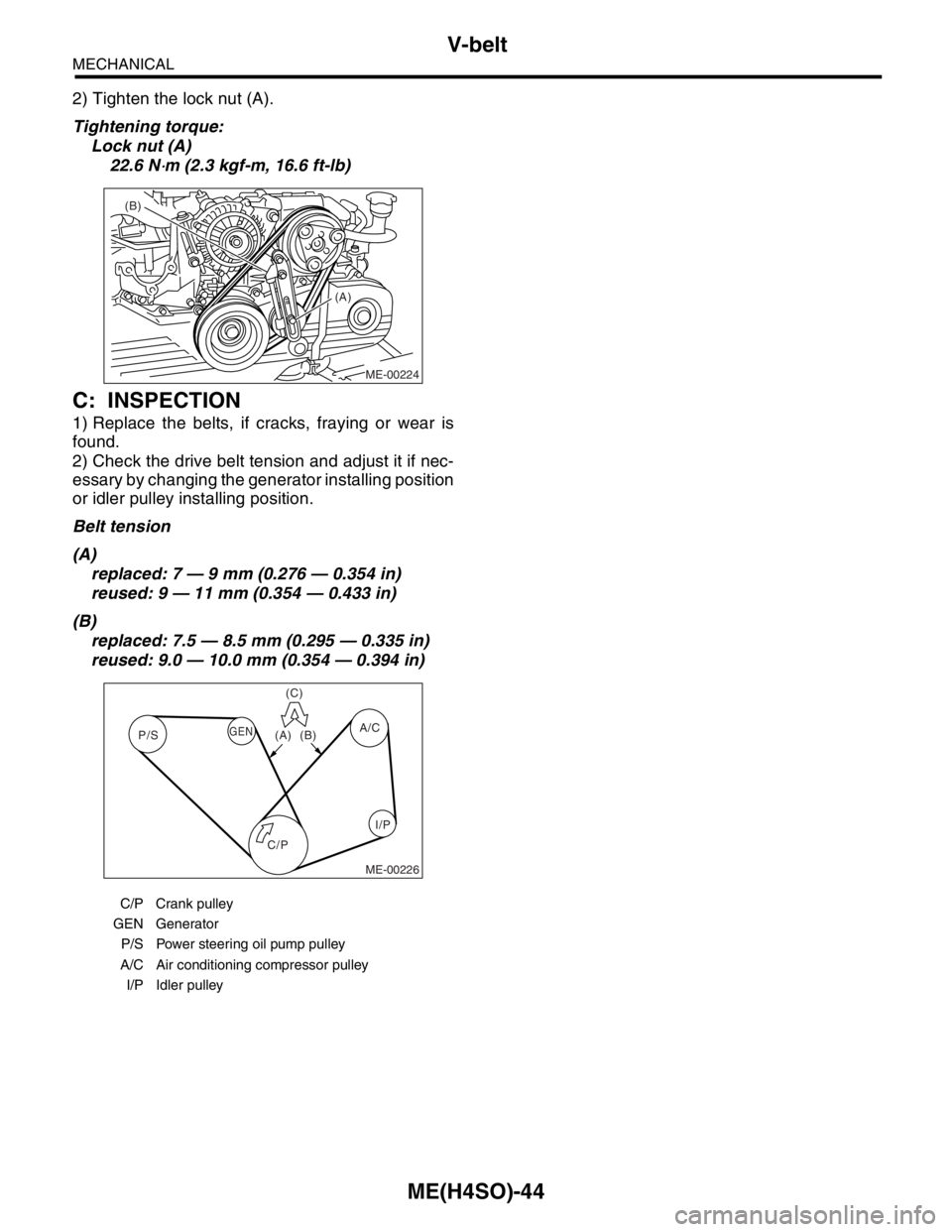

2) Tighten the lock nut (A).

Tightening torque:

Lock nut (A)

22.6 N

⋅m (2.3 kgf-m, 16.6 ft-lb)

C: INSPECTION

1) Replace the belts, if cracks, fraying or wear is

found.

2) Check the drive belt tension and adjust it if nec-

essary by changing the generator installing position

or idler pulley installing position.

Belt tension

(A)

replaced: 7 — 9 mm (0.276 — 0.354 in)

reused: 9 — 11 mm (0.354 — 0.433 in)

(B)

replaced: 7.5 — 8.5 mm (0.295 — 0.335 in)

reused: 9.0 — 10.0 mm (0.354 — 0.394 in)

C/P Crank pulley

GEN Generator

P/S Power steering oil pump pulley

A/C Air conditioning compressor pulley

I/P Idler pulley

ME-00224

(A) (B)

ME-00226

(A) (B)(C)GEN

C/P

I/P A/C

P/S

Page 914 of 2870

ME(H4SO)-45

MECHANICAL

Crank Pulley

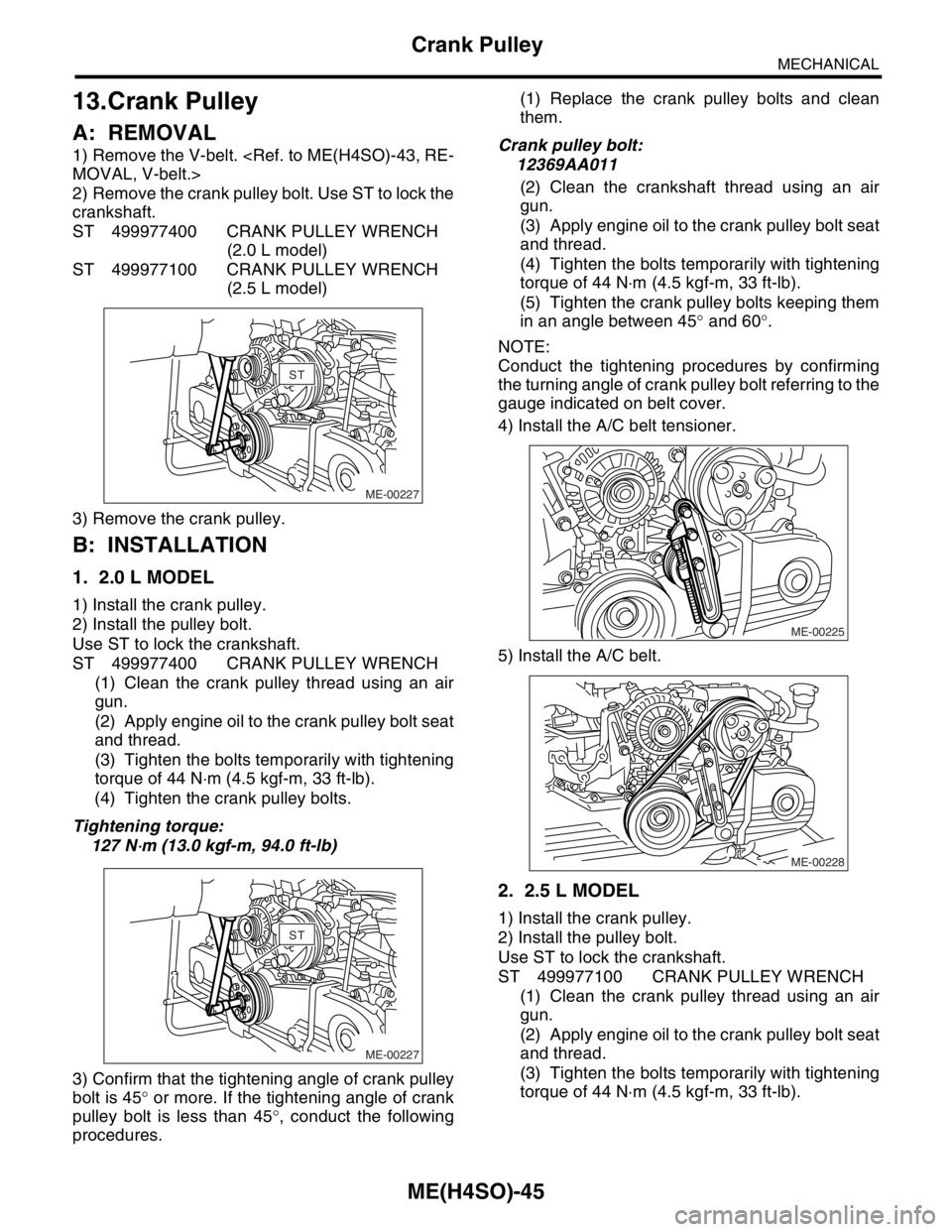

13.Crank Pulley

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley bolt. Use ST to lock the

crankshaft.

ST 499977400 CRANK PULLEY WRENCH

(2.0 L model)

ST 499977100 CRANK PULLEY WRENCH

(2.5 L model)

3) Remove the crank pulley.

B: INSTALLATION

1. 2.0 L MODEL

1) Install the crank pulley.

2) Install the pulley bolt.

Use ST to lock the crankshaft.

ST 499977400 CRANK PULLEY WRENCH

(1) Clean the crank pulley thread using an air

gun.

(2) Apply engine oil to the crank pulley bolt seat

and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crank pulley bolts.

Tightening torque:

127 N

⋅m (13.0 kgf-m, 94.0 ft-lb)

3) Confirm that the tightening angle of crank pulley

bolt is 45° or more. If the tightening angle of crank

pulley bolt is less than 45°, conduct the following

procedures.(1) Replace the crank pulley bolts and clean

them.

Crank pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Apply engine oil to the crank pulley bolt seat

and thread.

(4) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(5) Tighten the crank pulley bolts keeping them

in an angle between 45° and 60°.

NOTE:

Conduct the tightening procedures by confirming

the turning angle of crank pulley bolt referring to the

gauge indicated on belt cover.

4) Install the A/C belt tensioner.

5) Install the A/C belt.

2. 2.5 L MODEL

1) Install the crank pulley.

2) Install the pulley bolt.

Use ST to lock the crankshaft.

ST 499977100 CRANK PULLEY WRENCH

(1) Clean the crank pulley thread using an air

gun.

(2) Apply engine oil to the crank pulley bolt seat

and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

ME-00227

STST

ME-00227

STST

ME-00225

ME-00228

Page 917 of 2870

ME(H4SO)-48

MECHANICAL

Timing Belt

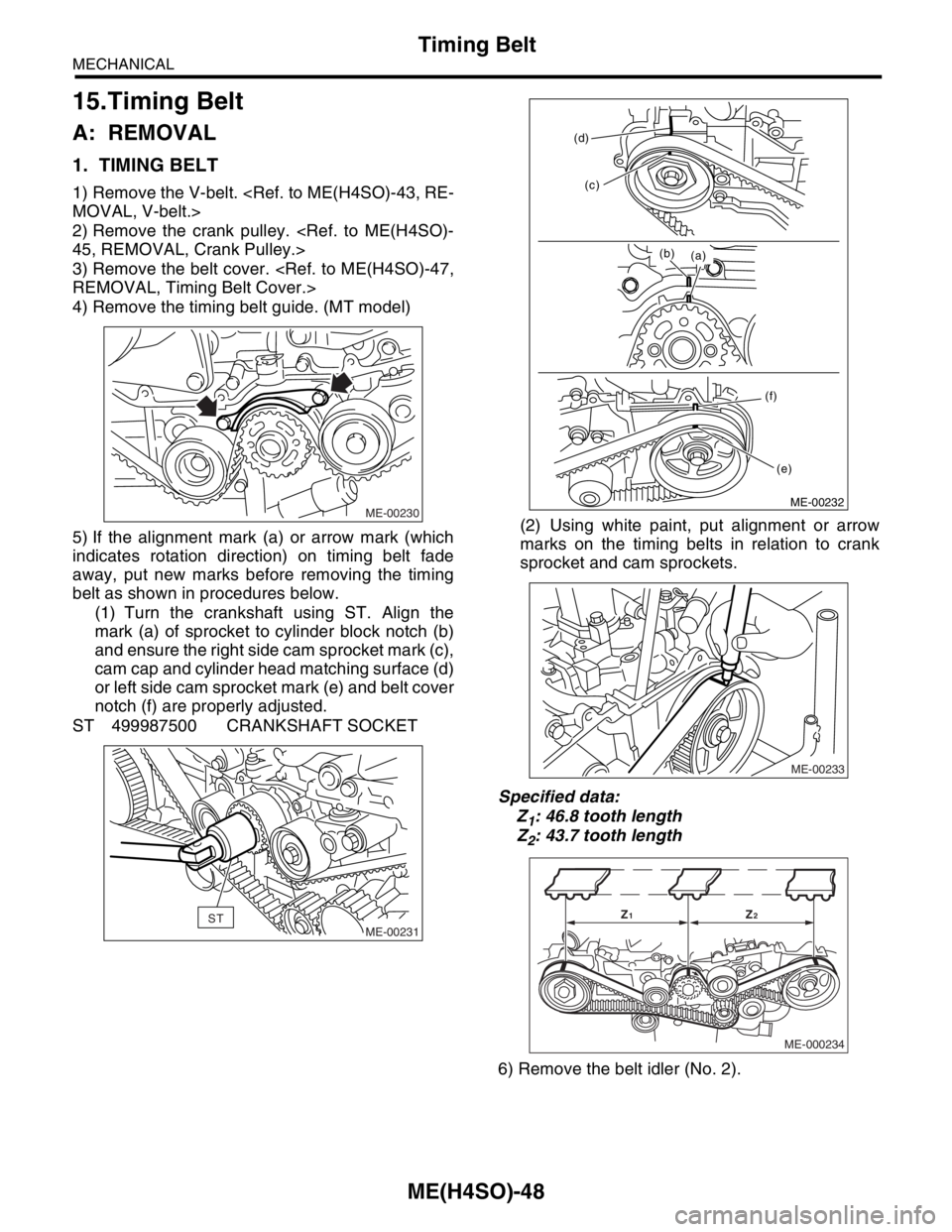

15.Timing Belt

A: REMOVAL

1. TIMING BELT

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the belt cover.

4) Remove the timing belt guide. (MT model)

5) If the alignment mark (a) or arrow mark (which

indicates rotation direction) on timing belt fade

away, put new marks before removing the timing

belt as shown in procedures below.

(1) Turn the crankshaft using ST. Align the

mark (a) of sprocket to cylinder block notch (b)

and ensure the right side cam sprocket mark (c),

cam cap and cylinder head matching surface (d)

or left side cam sprocket mark (e) and belt cover

notch (f) are properly adjusted.

ST 499987500 CRANKSHAFT SOCKET(2) Using white paint, put alignment or arrow

marks on the timing belts in relation to crank

sprocket and cam sprockets.

Specified data:

Z

1: 46.8 tooth length

Z

2: 43.7 tooth length

6) Remove the belt idler (No. 2).

ME-00230

ME-00231ST

ME-00232

(a) (b) (d)

(c)

(f)

(e)

ME-00233

ME-000234

Z1Z2

Page 923 of 2870

MECHANICAL

ME(H4SO)

Page

1. General Description ....................................................................................2

2. Compression .............................................................................................25

3. Idle Speed .................................................................................................26

4. Ignition Timing ...........................................................................................27

5. Intake Manifold Vacuum............................................................................28

6. Engine Oil Pressure ..................................................................................29

7. Fuel Pressure ............................................................................................30

8. Valve Clearance ........................................................................................31

9. Engine Assembly ......................................................................................34

10. Engine Mounting .......................................................................................41

11. Preparation for Overhaul ...........................................................................42

12. V-belt .........................................................................................................43

13. Crank Pulley ..............................................................................................45

14. Timing Belt Cover......................................................................................47

15. Timing Belt ................................................................................................48

16. Cam Sprocket ...........................................................................................53

17. Crank Sprocket .........................................................................................55

18. Valve Rocker Assembly ............................................................................56

19. Camshaft ...................................................................................................58

20. Cylinder Head ...........................................................................................62

21. Cylinder Block ...........................................................................................69

22. Engine Trouble in General ........................................................................91

23. Engine Noise .............................................................................................96

Page 924 of 2870

ME(H4SO)-53

MECHANICAL

Cam Sprocket

16.Cam Sprocket

A: REMOVAL

1. REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the belt cover.

4) Remove the timing belt assembly.

5) Remove the camshaft position sensor.

Sensor.>

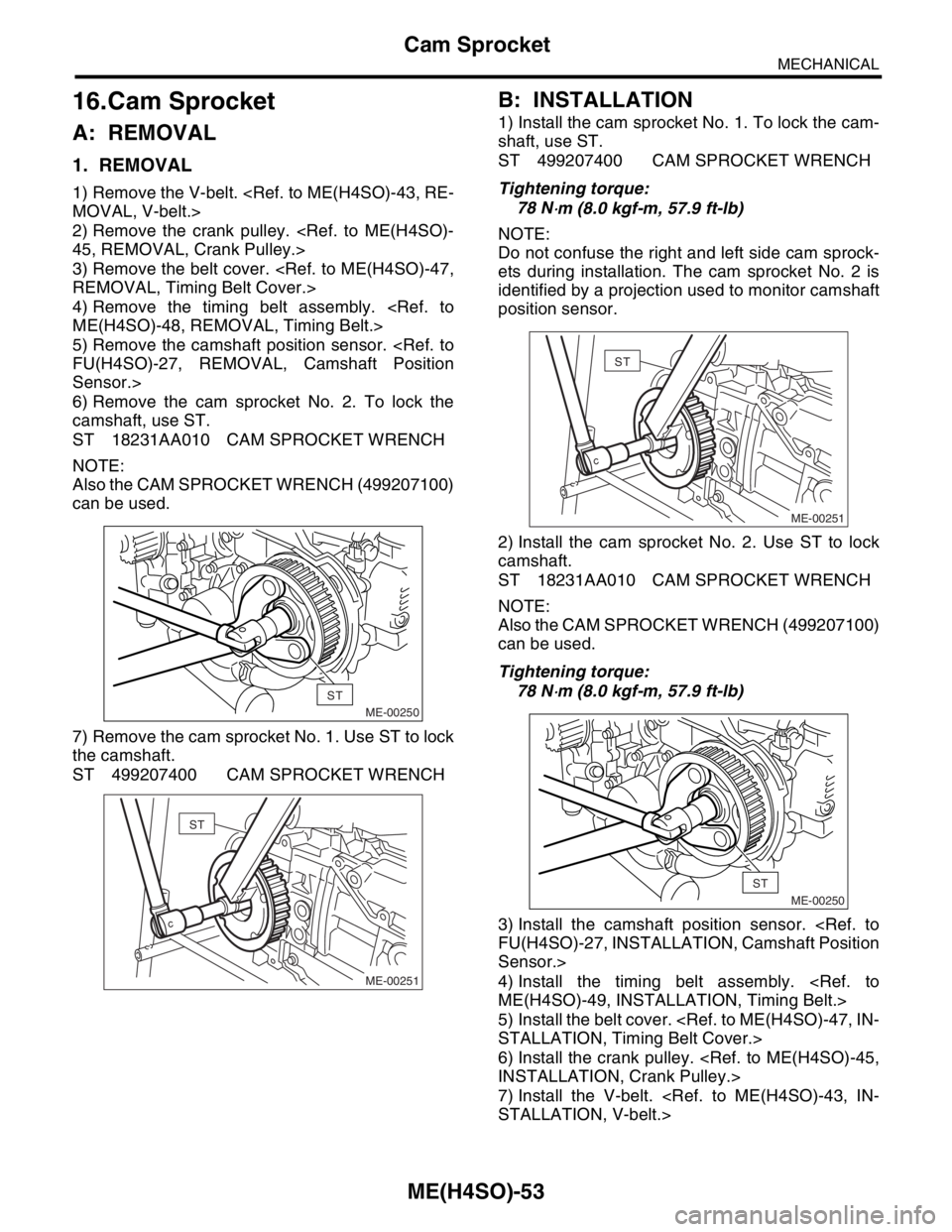

6) Remove the cam sprocket No. 2. To lock the

camshaft, use ST.

ST 18231AA010 CAM SPROCKET WRENCH

NOTE:

Also the CAM SPROCKET WRENCH (499207100)

can be used.

7) Remove the cam sprocket No. 1. Use ST to lock

the camshaft.

ST 499207400 CAM SPROCKET WRENCH

B: INSTALLATION

1) Install the cam sprocket No. 1. To lock the cam-

shaft, use ST.

ST 499207400 CAM SPROCKET WRENCH

Tightening torque:

78 N

⋅m (8.0 kgf-m, 57.9 ft-lb)

NOTE:

Do not confuse the right and left side cam sprock-

ets during installation. The cam sprocket No. 2 is

identified by a projection used to monitor camshaft

position sensor.

2) Install the cam sprocket No. 2. Use ST to lock

camshaft.

ST 18231AA010 CAM SPROCKET WRENCH

NOTE:

Also the CAM SPROCKET WRENCH (499207100)

can be used.

Tightening torque:

78 N

⋅m (8.0 kgf-m, 57.9 ft-lb)

3) Install the camshaft position sensor.

Sensor.>

4) Install the timing belt assembly.

5) Install the belt cover.

6) Install the crank pulley.

7) Install the V-belt.

ME-00250

ST

ME-00251

ST

ME-00251

ST

ME-00250

ST

Page 933 of 2870

ME(H4SO)-62

MECHANICAL

Cylinder Head

20.Cylinder Head

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt.

5) Remove the cam sprocket.

6) Remove the intake manifold.

7) Remove the bolt which installs A/C compressor

bracket on cylinder head.

8) Remove the valve rocker assembly.

bly.>

9) Remove the camshaft.

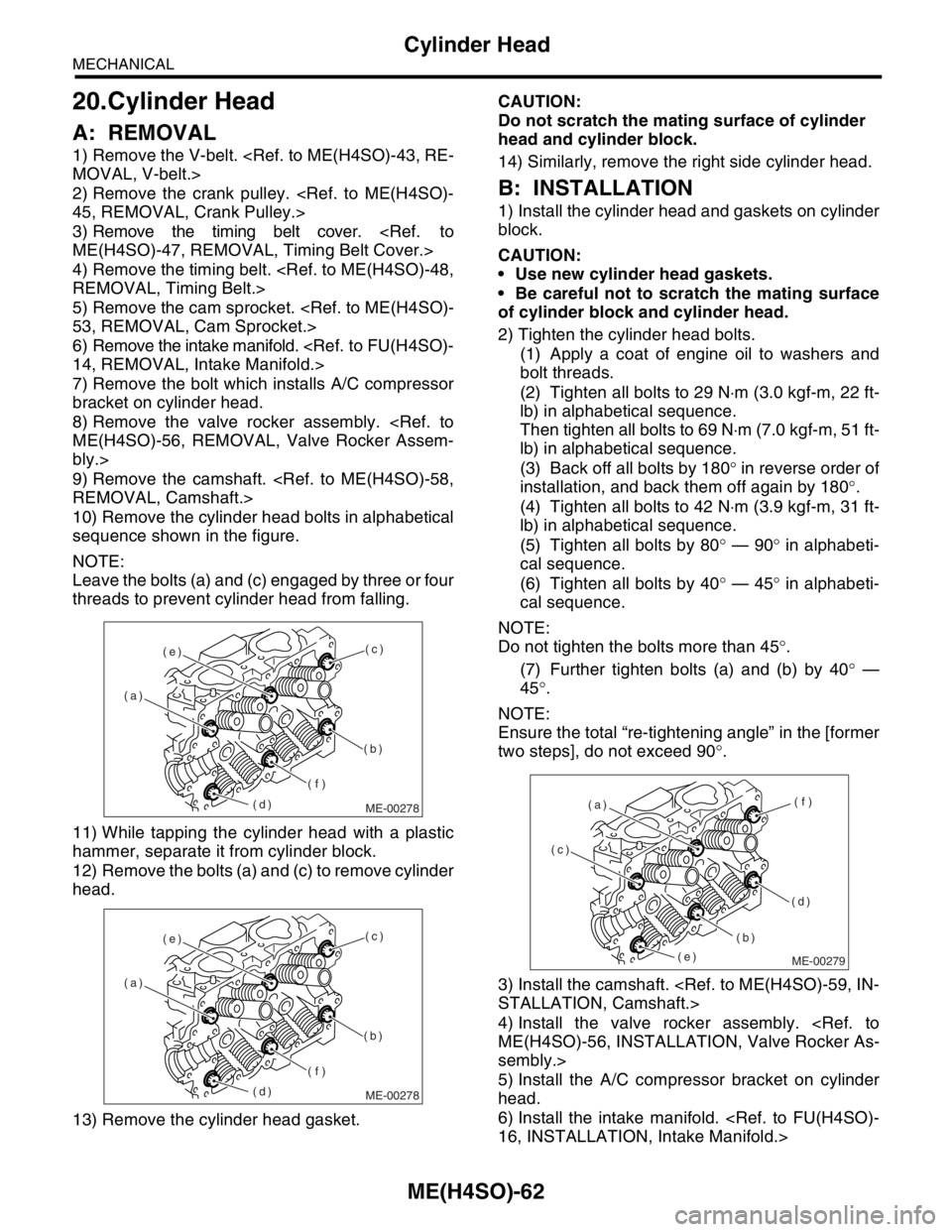

10) Remove the cylinder head bolts in alphabetical

sequence shown in the figure.

NOTE:

Leave the bolts (a) and (c) engaged by three or four

threads to prevent cylinder head from falling.

11) While tapping the cylinder head with a plastic

hammer, separate it from cylinder block.

12) Remove the bolts (a) and (c) to remove cylinder

head.

13) Remove the cylinder head gasket.CAUTION:

Do not scratch the mating surface of cylinder

head and cylinder block.

14) Similarly, remove the right side cylinder head.

B: INSTALLATION

1) Install the cylinder head and gaskets on cylinder

block.

CAUTION:

Use new cylinder head gaskets.

Be careful not to scratch the mating surface

of cylinder block and cylinder head.

2) Tighten the cylinder head bolts.

(1) Apply a coat of engine oil to washers and

bolt threads.

(2) Tighten all bolts to 29 N⋅m (3.0 kgf-m, 22 ft-

lb) in alphabetical sequence.

Then tighten all bolts to 69 N⋅m (7.0 kgf-m, 51 ft-

lb) in alphabetical sequence.

(3) Back off all bolts by 180° in reverse order of

installation, and back them off again by 180°.

(4) Tighten all bolts to 42 N⋅m (3.9 kgf-m, 31 ft-

lb) in alphabetical sequence.

(5) Tighten all bolts by 80° — 90° in alphabeti-

cal sequence.

(6) Tighten all bolts by 40° — 45° in alphabeti-

cal sequence.

NOTE:

Do not tighten the bolts more than 45°.

(7) Further tighten bolts (a) and (b) by 40° —

45°.

NOTE:

Ensure the total “re-tightening angle” in the [former

two steps], do not exceed 90°.

3) Install the camshaft.

4) Install the valve rocker assembly.

sembly.>

5) Install the A/C compressor bracket on cylinder

head.

6) Install the intake manifold.

ME-00278

(c)

(b)

(f)

(d) (a)(e)

ME-00278

(c)

(b)

(f)

(d) (a)(e)

ME-00279

(c)

(b)(f)

(d) (a)

(e)

Page 938 of 2870

ME(H4SO)-67

MECHANICAL

Cylinder Head

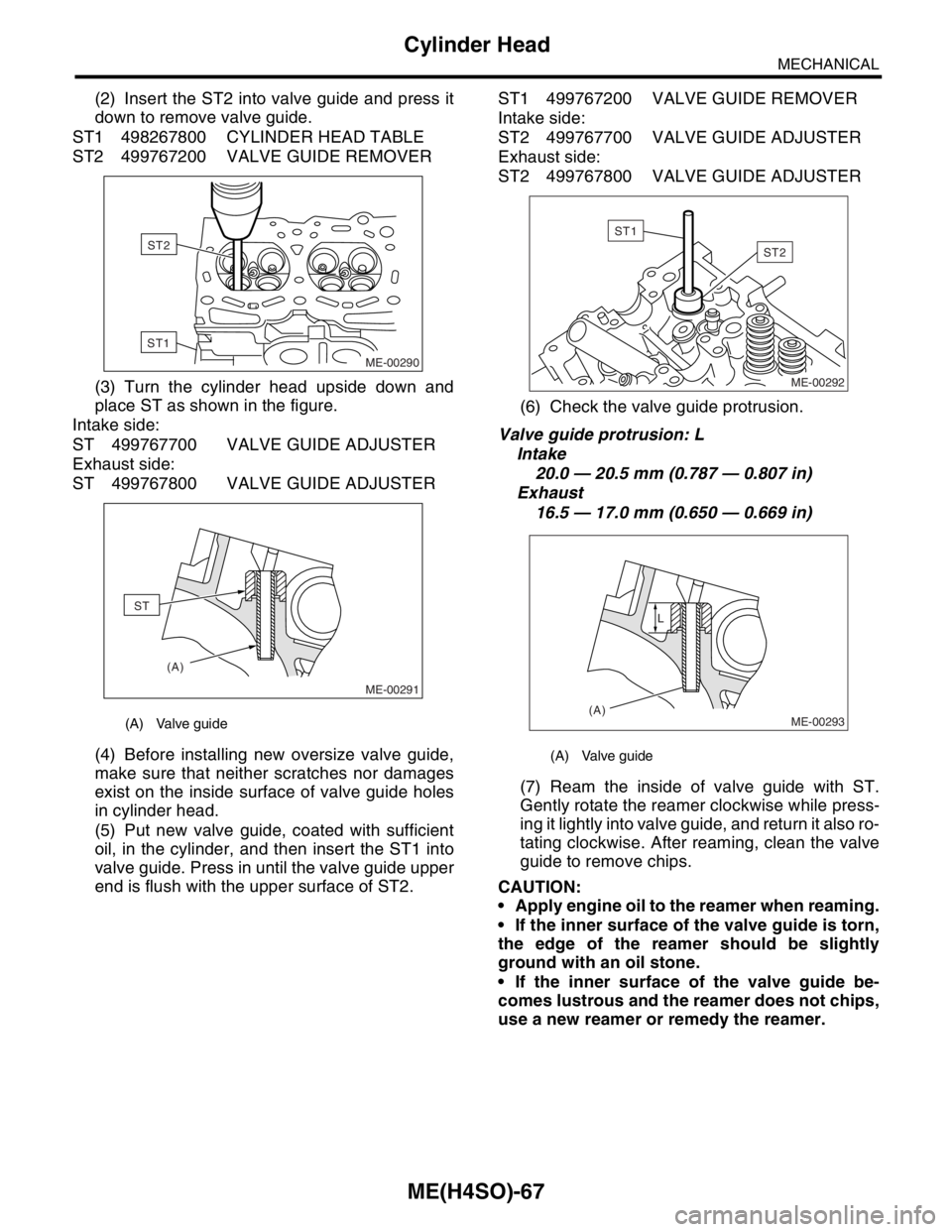

(2) Insert the ST2 into valve guide and press it

down to remove valve guide.

ST1 498267800 CYLINDER HEAD TABLE

ST2 499767200 VALVE GUIDE REMOVER

(3) Turn the cylinder head upside down and

place ST as shown in the figure.

Intake side:

ST 499767700 VALVE GUIDE ADJUSTER

Exhaust side:

ST 499767800 VALVE GUIDE ADJUSTER

(4) Before installing new oversize valve guide,

make sure that neither scratches nor damages

exist on the inside surface of valve guide holes

in cylinder head.

(5) Put new valve guide, coated with sufficient

oil, in the cylinder, and then insert the ST1 into

valve guide. Press in until the valve guide upper

end is flush with the upper surface of ST2.ST1 499767200 VALVE GUIDE REMOVER

Intake side:

ST2 499767700 VALVE GUIDE ADJUSTER

Exhaust side:

ST2 499767800 VALVE GUIDE ADJUSTER

(6) Check the valve guide protrusion.

Valve guide protrusion: L

Intake

20.0 — 20.5 mm (0.787 — 0.807 in)

Exhaust

16.5 — 17.0 mm (0.650 — 0.669 in)

(7) Ream the inside of valve guide with ST.

Gently rotate the reamer clockwise while press-

ing it lightly into valve guide, and return it also ro-

tating clockwise. After reaming, clean the valve

guide to remove chips.

CAUTION:

Apply engine oil to the reamer when reaming.

If the inner surface of the valve guide is torn,

the edge of the reamer should be slightly

ground with an oil stone.

If the inner surface of the valve guide be-

comes lustrous and the reamer does not chips,

use a new reamer or remedy the reamer.

(A) Valve guide

ME-00290

ST2

ST1

(A)

ME-00291

ST

(A) Valve guide

ST2

ME-00292

ST1

ME-00293(A)L

Page 940 of 2870

ME(H4SO)-69

MECHANICAL

Cylinder Block

21.Cylinder Block

A: REMOVAL

NOTE:

Before conducting this procedure, drain the engine

oil completely.

1) Remove the intake manifold.

2) Remove the V-belt.

3) Remove the crank pulley.

4) Remove the timing belt cover.

5) Remove the timing belt.

6) Remove the cam sprocket.

7) Remove the crank sprocket.

8) Remove the generator and A/C compressor with

their brackets.

9) Remove the rocker cover.

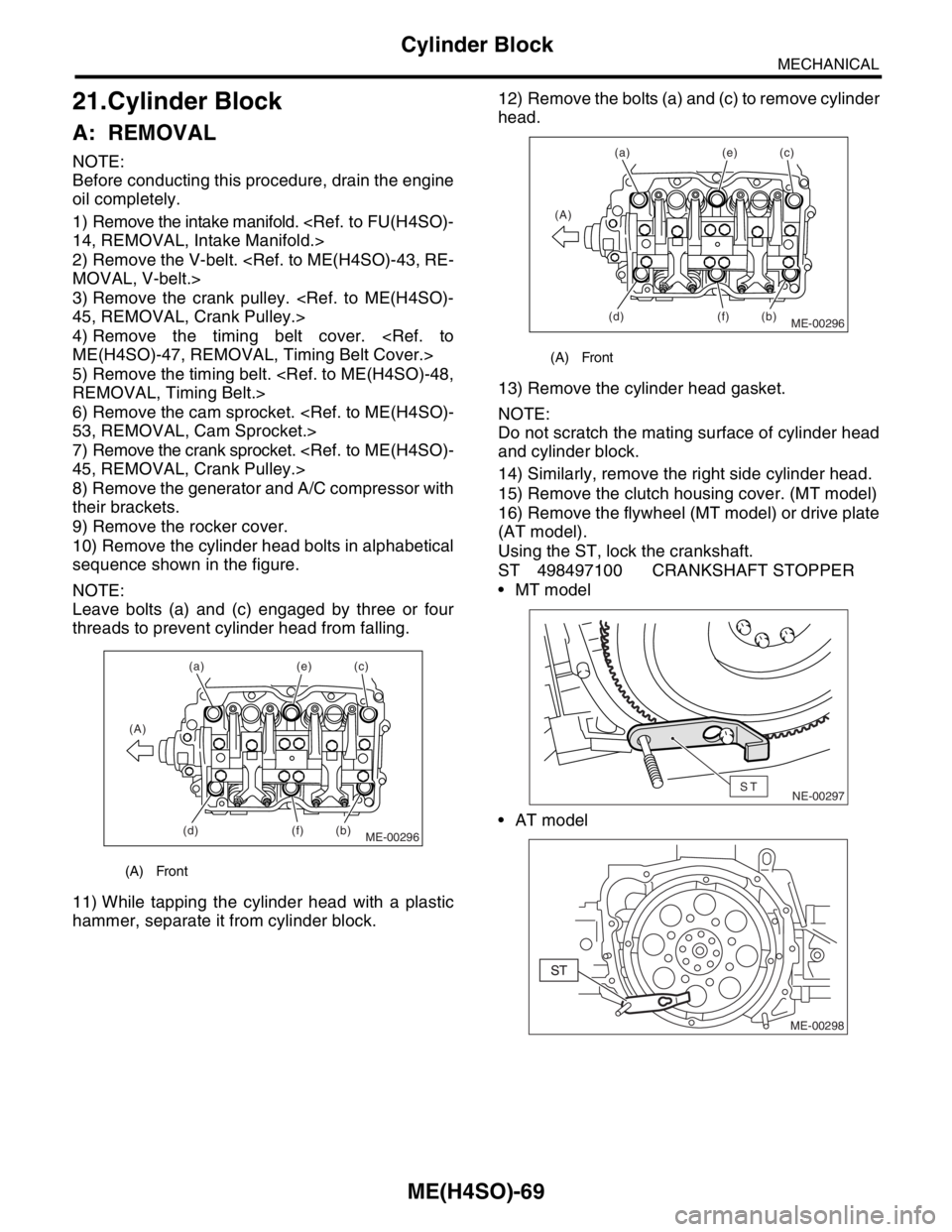

10) Remove the cylinder head bolts in alphabetical

sequence shown in the figure.

NOTE:

Leave bolts (a) and (c) engaged by three or four

threads to prevent cylinder head from falling.

11) While tapping the cylinder head with a plastic

hammer, separate it from cylinder block.12) Remove the bolts (a) and (c) to remove cylinder

head.

13) Remove the cylinder head gasket.

NOTE:

Do not scratch the mating surface of cylinder head

and cylinder block.

14) Similarly, remove the right side cylinder head.

15) Remove the clutch housing cover. (MT model)

16) Remove the flywheel (MT model) or drive plate

(AT model).

Using the ST, lock the crankshaft.

ST 498497100 CRANKSHAFT STOPPER

MT model

AT model

(A) Front

ME-00296

(a)

(b)(c) (e)

(f) (A)

(d)

(A) Front

ME-00296

(a)

(b)(c) (e)

(f) (A)

(d)

NE-00297ST

ME-00298

Page 941 of 2870

ME(H4SO)-70

MECHANICAL

Cylinder Block

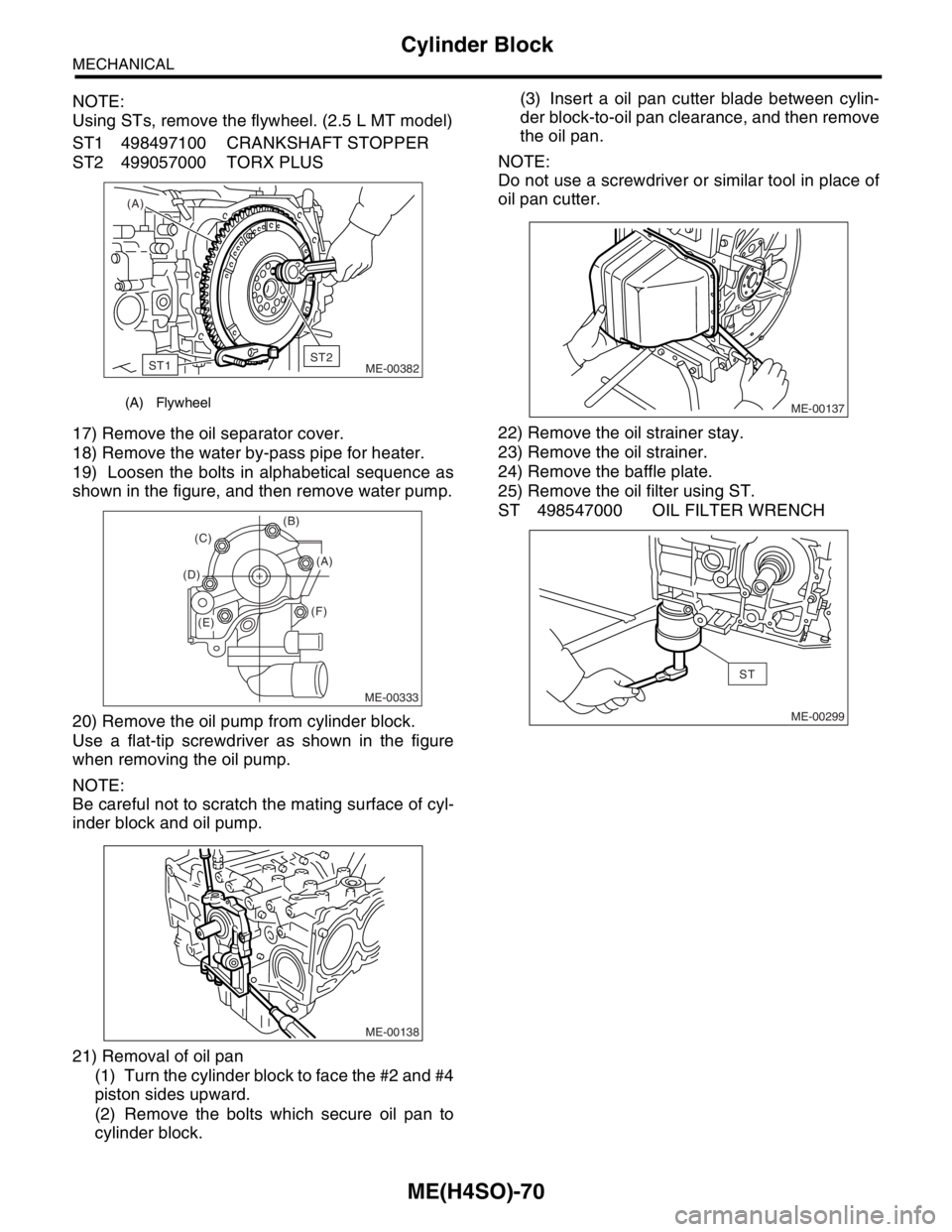

NOTE:

Using STs, remove the flywheel. (2.5 L MT model)

ST1 498497100 CRANKSHAFT STOPPER

ST2 499057000 TORX PLUS

17) Remove the oil separator cover.

18) Remove the water by-pass pipe for heater.

19) Loosen the bolts in alphabetical sequence as

shown in the figure, and then remove water pump.

20) Remove the oil pump from cylinder block.

Use a flat-tip screwdriver as shown in the figure

when removing the oil pump.

NOTE:

Be careful not to scratch the mating surface of cyl-

inder block and oil pump.

21) Removal of oil pan

(1) Turn the cylinder block to face the #2 and #4

piston sides upward.

(2) Remove the bolts which secure oil pan to

cylinder block.(3) Insert a oil pan cutter blade between cylin-

der block-to-oil pan clearance, and then remove

the oil pan.

NOTE:

Do not use a screwdriver or similar tool in place of

oil pan cutter.

22) Remove the oil strainer stay.

23) Remove the oil strainer.

24) Remove the baffle plate.

25) Remove the oil filter using ST.

ST 498547000 OIL FILTER WRENCH

(A) Flywheel

(A)

ME-00382

ST1ST2

ME-00333

(B)

(F) (D)(C)

(A)

(E)

ME-00138

ME-00137

ME-00299

ST

Page 942 of 2870

![SUBARU FORESTER 2004 Service Repair Manual ME(H4SO)-71

MECHANICAL

Cylinder Block

26) Remove the water pipe.

27) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].28) Rotate the crankshaft to bring #1 a SUBARU FORESTER 2004 Service Repair Manual ME(H4SO)-71

MECHANICAL

Cylinder Block

26) Remove the water pipe.

27) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].28) Rotate the crankshaft to bring #1 a](/img/17/57426/w960_57426-941.png)

ME(H4SO)-71

MECHANICAL

Cylinder Block

26) Remove the water pipe.

27) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].28) Rotate the crankshaft to bring #1 and #2 pis-

tons to bottom dead center position, and then re-

move the piston snap ring through service hole of

#1 and #2 cylinders using needle nose plier.

ME-00300

(1) Service hole plug (3) Snap ring (5) Service hole cover

(2) Gasket (4) Piston pin (6) O-ring

ME-00139

(3)

(4) (2)(1)

(3)

(4)

(5)

(6)

(2)(3)

(2)

(1)(3)(4)

(4)

(1)

ME-00140

ME-00141