lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1057 of 2870

SP(H4SO)-4

SPEED CONTROL SYSTEM

Accelerator Pedal

2. Accelerator Pedal

A: REMOVAL

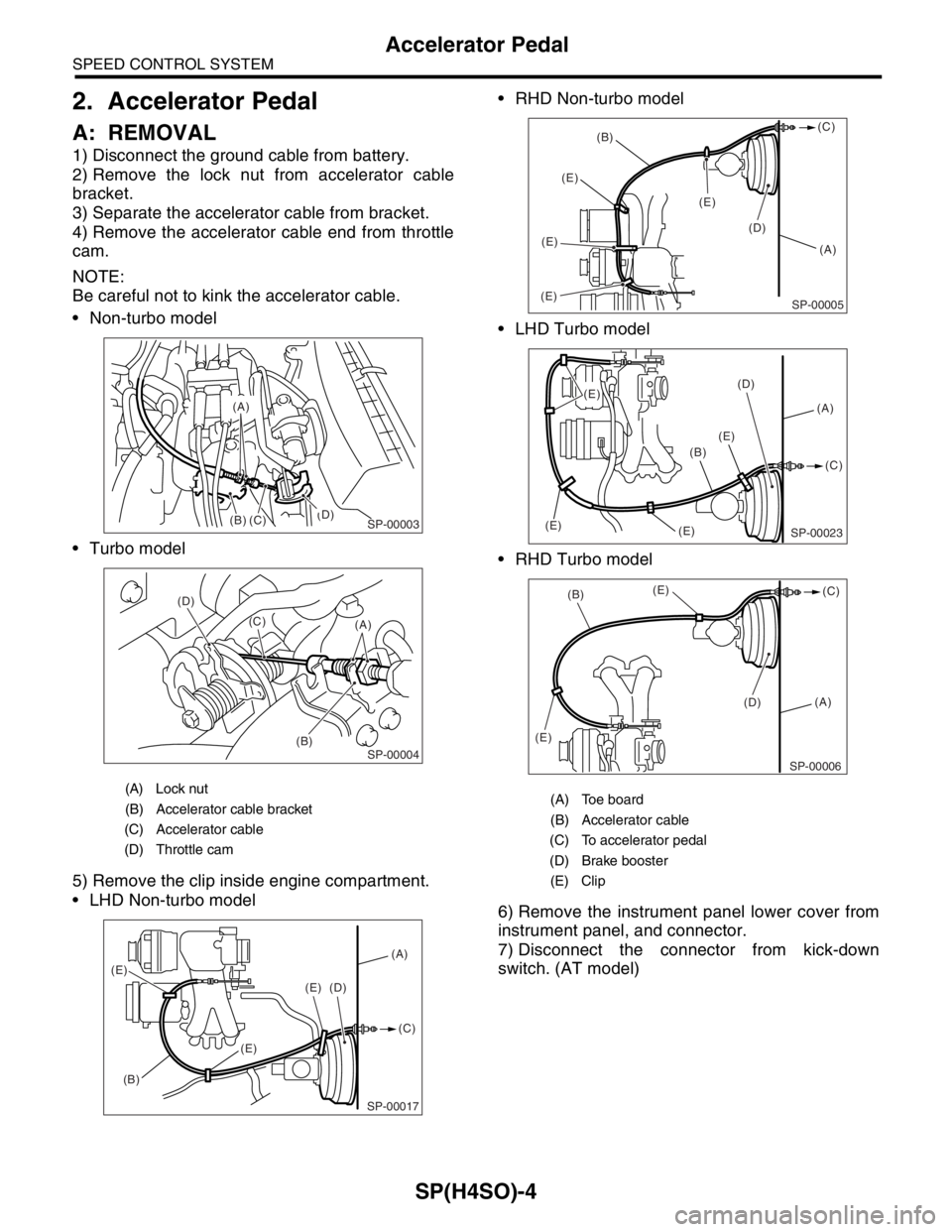

1) Disconnect the ground cable from battery.

2) Remove the lock nut from accelerator cable

bracket.

3) Separate the accelerator cable from bracket.

4) Remove the accelerator cable end from throttle

cam.

NOTE:

Be careful not to kink the accelerator cable.

Non-turbo model

Turbo model

5) Remove the clip inside engine compartment.

LHD Non-turbo model RHD Non-turbo model

LHD Turbo model

RHD Turbo model

6) Remove the instrument panel lower cover from

instrument panel, and connector.

7) Disconnect the connector from kick-down

switch. (AT model)

(A) Lock nut

(B) Accelerator cable bracket

(C) Accelerator cable

(D) Throttle cam

(B)(D)

(C)

(A)

SP-00003

(B) (D)

(C)

(A)SP-00004

SP-00017

(A)

(B)(C) (D)

(E)

(E)

(E)

(A) Toe board

(B) Accelerator cable

(C) To accelerator pedal

(D) Brake booster

(E) Clip

(A) (B)(C)

(E)(E)(E)

(E)

(D)

SP-00005

(A) (D)

(E)

(E) (E)(C)

(B)

(E)

SP-00023

(A)

(D) (E)

(E)(B)(C)

SP-00006

Page 1060 of 2870

SP(H4SO)-7

SPEED CONTROL SYSTEM

Accelerator Pedal

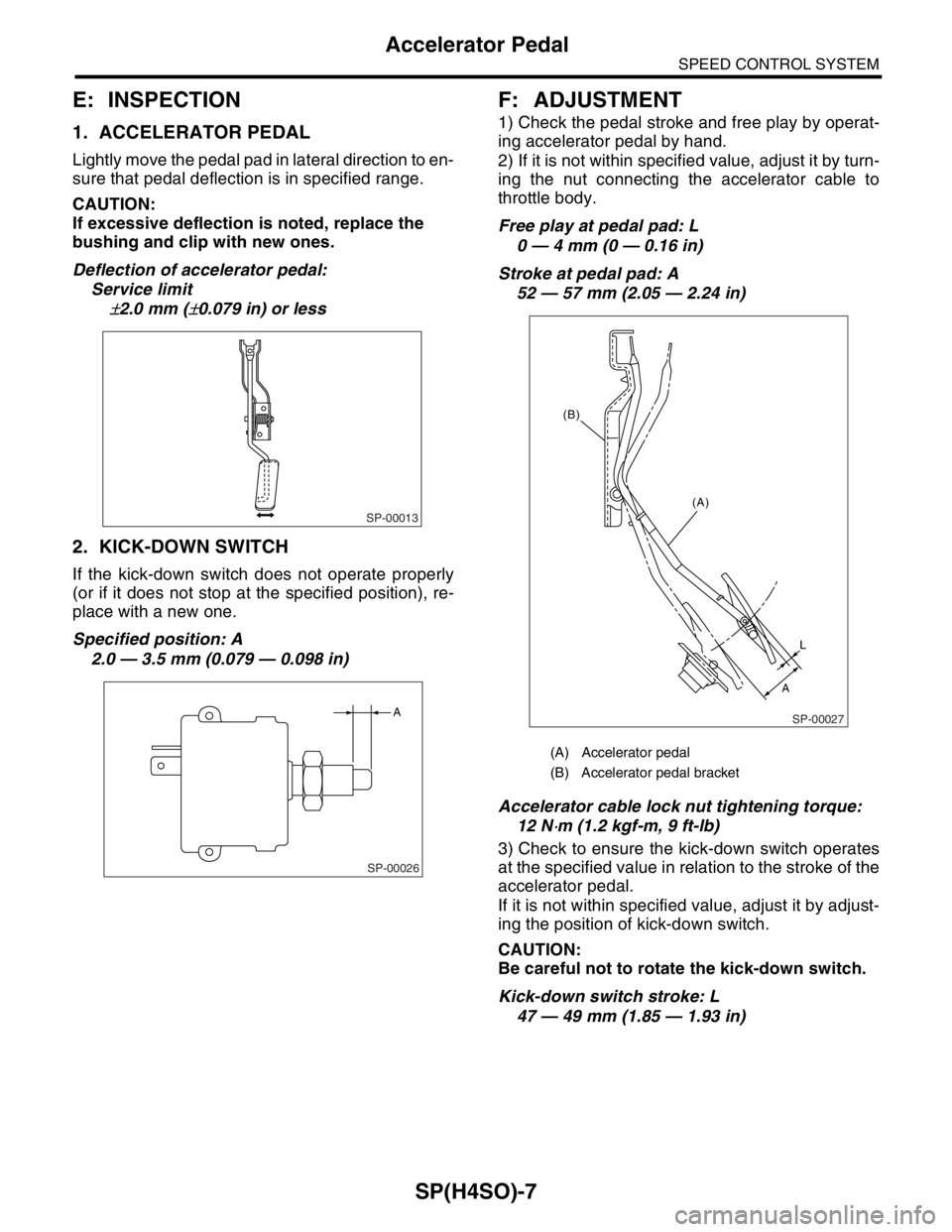

E: INSPECTION

1. ACCELERATOR PEDAL

Lightly move the pedal pad in lateral direction to en-

sure that pedal deflection is in specified range.

CAUTION:

If excessive deflection is noted, replace the

bushing and clip with new ones.

Deflection of accelerator pedal:

Service limit

±2.0 mm (±0.079 in) or less

2. KICK-DOWN SWITCH

If the kick-down switch does not operate properly

(or if it does not stop at the specified position), re-

place with a new one.

Specified position: A

2.0 — 3.5 mm (0.079 — 0.098 in)

F: ADJUSTMENT

1) Check the pedal stroke and free play by operat-

ing accelerator pedal by hand.

2) If it is not within specified value, adjust it by turn-

ing the nut connecting the accelerator cable to

throttle body.

Free play at pedal pad: L

0 — 4 mm (0 — 0.16 in)

Stroke at pedal pad: A

52 — 57 mm (2.05 — 2.24 in)

Accelerator cable lock nut tightening torque:

12 N

⋅m (1.2 kgf-m, 9 ft-lb)

3) Check to ensure the kick-down switch operates

at the specified value in relation to the stroke of the

accelerator pedal.

If it is not within specified value, adjust it by adjust-

ing the position of kick-down switch.

CAUTION:

Be careful not to rotate the kick-down switch.

Kick-down switch stroke: L

47 — 49 mm (1.85 — 1.93 in)

SP-00013

SP-00026

A

(A) Accelerator pedal

(B) Accelerator pedal bracket

SP-00027

(A)

L

A (B)

Page 1077 of 2870

SC(H4SO)-2

STARTING/CHARGING SYSTEM

General Description

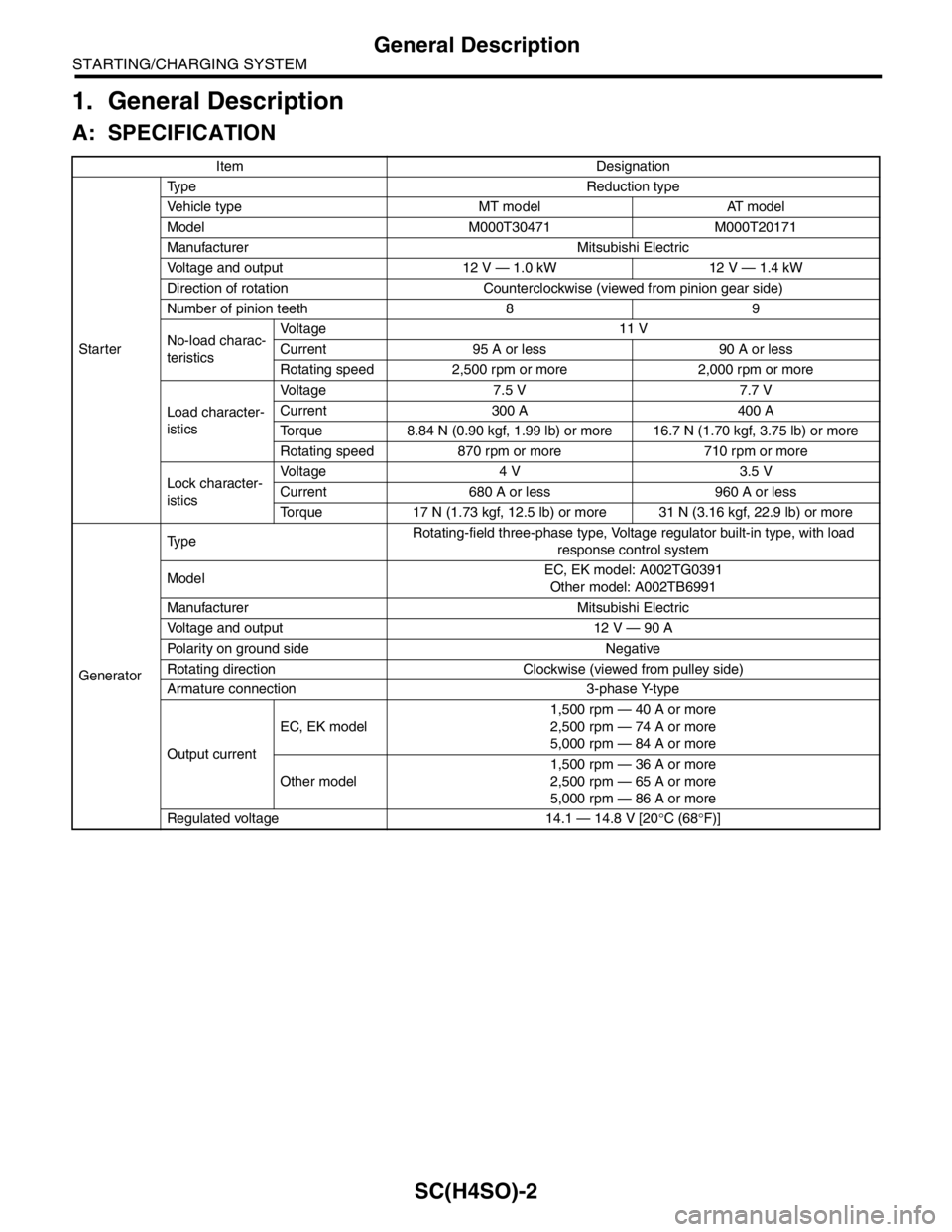

1. General Description

A: SPECIFICATION

Item Designation

StarterType Reduction type

Vehicle type MT model AT model

Model M000T30471 M000T20171

Manufacturer Mitsubishi Electric

Voltage and output 12 V — 1.0 kW 12 V — 1.4 kW

Direction of rotation Counterclockwise (viewed from pinion gear side)

Number of pinion teeth 8 9

No-load charac-

teristicsVo l t a g e 1 1 V

Current 95 A or less 90 A or less

Rotating speed 2,500 rpm or more 2,000 rpm or more

Load character-

isticsVoltage 7.5 V 7.7 V

Current 300 A 400 A

Torque 8.84 N (0.90 kgf, 1.99 lb) or more 16.7 N (1.70 kgf, 3.75 lb) or more

Rotating speed 870 rpm or more 710 rpm or more

Lock character-

isticsVo l t a g e 4 V 3 . 5 V

Current 680 A or less 960 A or less

Torque 17 N (1.73 kgf, 12.5 lb) or more 31 N (3.16 kgf, 22.9 lb) or more

GeneratorTy p eRotating-field three-phase type, Voltage regulator built-in type, with load

response control system

ModelEC, EK model: A002TG0391

Other model: A002TB6991

Manufacturer Mitsubishi Electric

Voltage and output 12 V — 90 A

Polarity on ground side Negative

Rotating direction Clockwise (viewed from pulley side)

Armature connection 3-phase Y-type

Output currentEC, EK model1,500 rpm — 40 A or more

2,500 rpm — 74 A or more

5,000 rpm — 84 A or more

Other model1,500 rpm — 36 A or more

2,500 rpm — 65 A or more

5,000 rpm — 86 A or more

Regulated voltage 14.1 — 14.8 V [20°C (68°F)]

Page 1086 of 2870

SC(H4SO)-11

STARTING/CHARGING SYSTEM

Starter

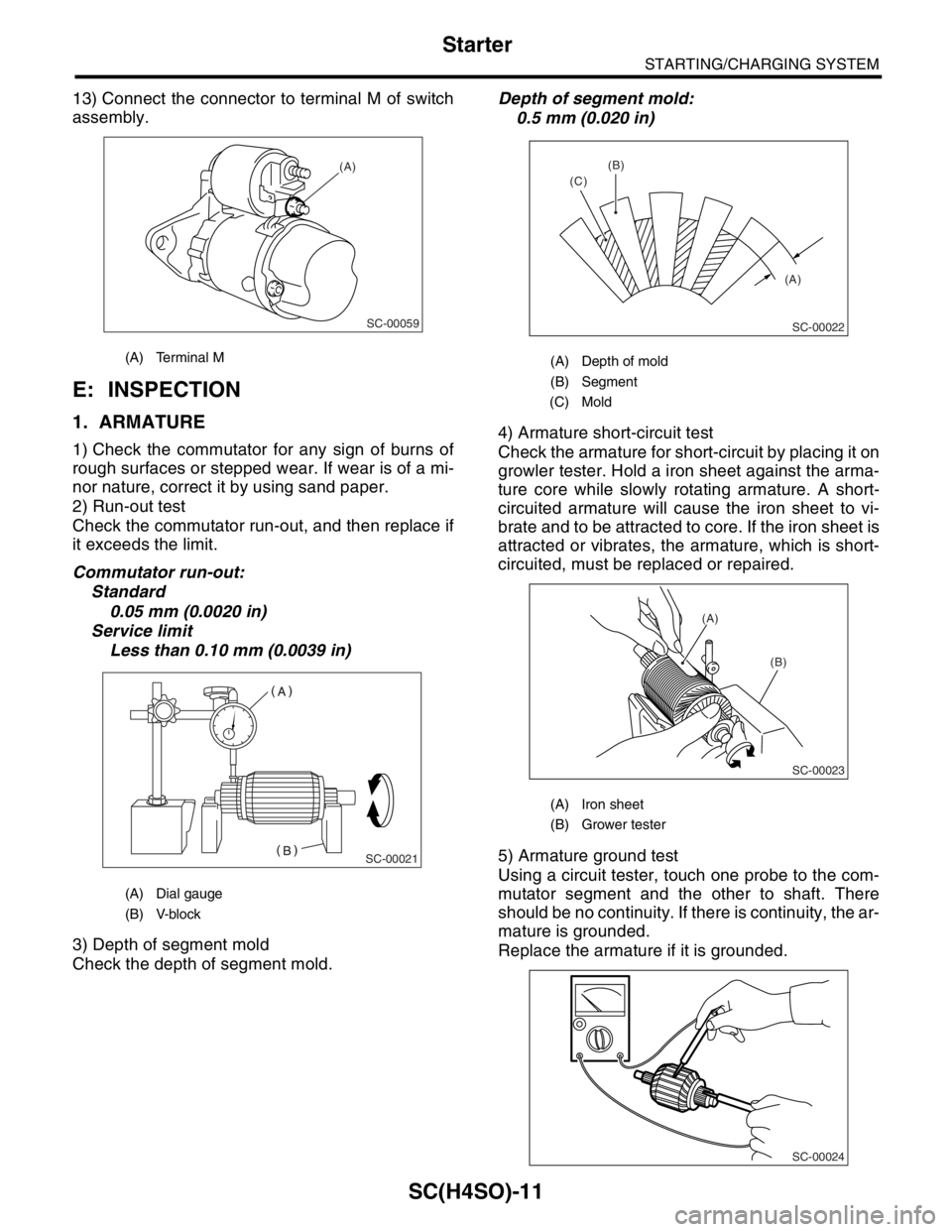

13) Connect the connector to terminal M of switch

assembly.

E: INSPECTION

1. ARMATURE

1) Check the commutator for any sign of burns of

rough surfaces or stepped wear. If wear is of a mi-

nor nature, correct it by using sand paper.

2) Run-out test

Check the commutator run-out, and then replace if

it exceeds the limit.

Commutator run-out:

Standard

0.05 mm (0.0020 in)

Service limit

Less than 0.10 mm (0.0039 in)

3) Depth of segment mold

Check the depth of segment mold.Depth of segment mold:

0.5 mm (0.020 in)

4) Armature short-circuit test

Check the armature for short-circuit by placing it on

growler tester. Hold a iron sheet against the arma-

ture core while slowly rotating armature. A short-

circuited armature will cause the iron sheet to vi-

brate and to be attracted to core. If the iron sheet is

attracted or vibrates, the armature, which is short-

circuited, must be replaced or repaired.

5) Armature ground test

Using a circuit tester, touch one probe to the com-

mutator segment and the other to shaft. There

should be no continuity. If there is continuity, the ar-

mature is grounded.

Replace the armature if it is grounded.

(A) Terminal M

(A) Dial gauge

(B) V-block

SC-00059

(A)

SC-00021

(A) Depth of mold

(B) Segment

(C) Mold

(A) Iron sheet

(B) Grower tester

(A) (B)

(C)

SC-00022

(A)

(B)

SC-00023

SC-00024

Page 1087 of 2870

SC(H4SO)-12

STARTING/CHARGING SYSTEM

Starter

2. YOKE

Make sure the pole is set in position.

3. OVERRUNNING CLUTCH

Inspect the teeth of pinion for wear and damage.

Replace if it is damaged. Rotate the pinion in direc-

tion of rotation (counterclockwise). It should rotate

smoothly. But in opposite direction, it should be

locked.

CAUTION:

Do not clean the overrunning clutch with oil to

prevent grease from flowing out.

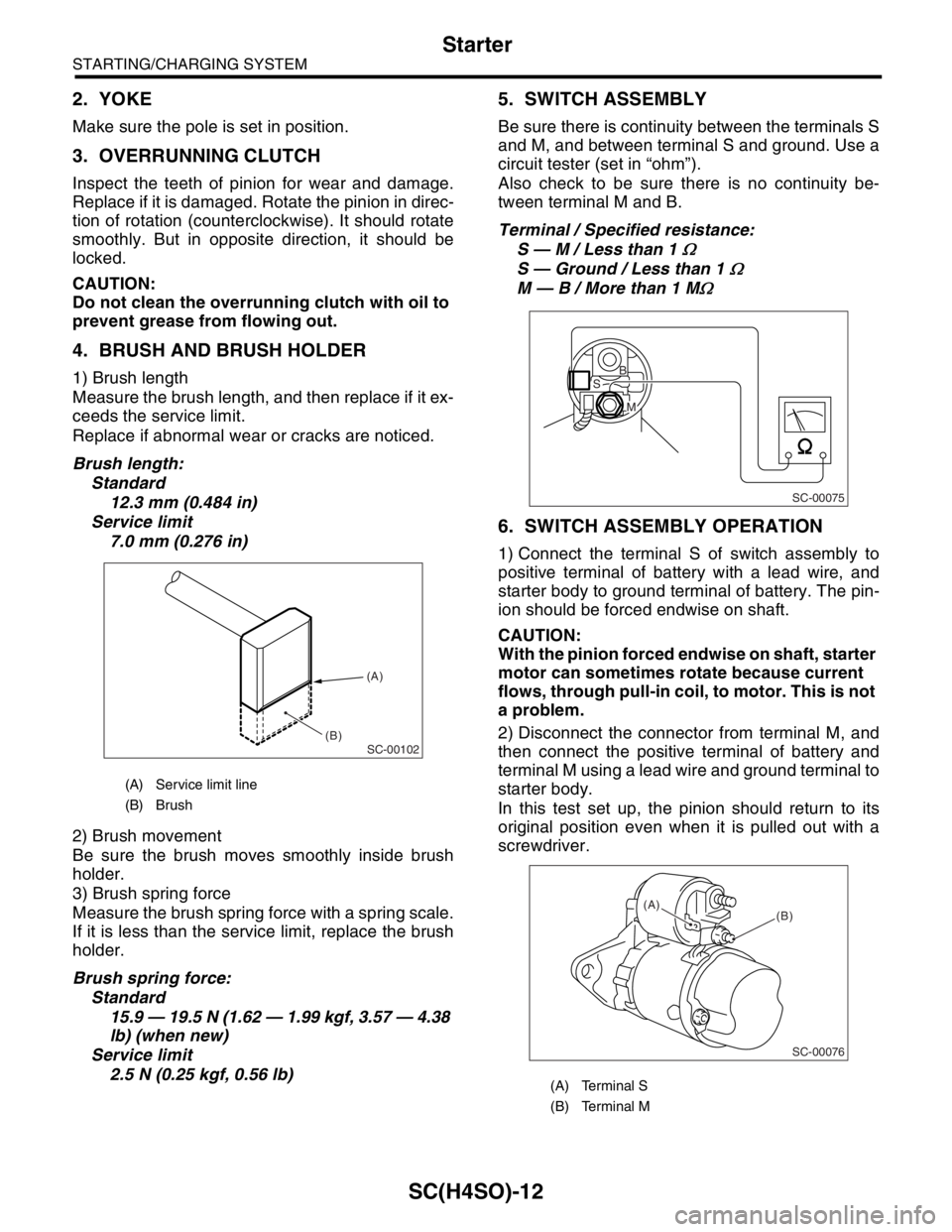

4. BRUSH AND BRUSH HOLDER

1) Brush length

Measure the brush length, and then replace if it ex-

ceeds the service limit.

Replace if abnormal wear or cracks are noticed.

Brush length:

Standard

12.3 mm (0.484 in)

Service limit

7.0 mm (0.276 in)

2) Brush movement

Be sure the brush moves smoothly inside brush

holder.

3) Brush spring force

Measure the brush spring force with a spring scale.

If it is less than the service limit, replace the brush

holder.

Brush spring force:

Standard

15.9 — 19.5 N (1.62 — 1.99 kgf, 3.57 — 4.38

lb) (when new)

Service limit

2.5 N (0.25 kgf, 0.56 lb)

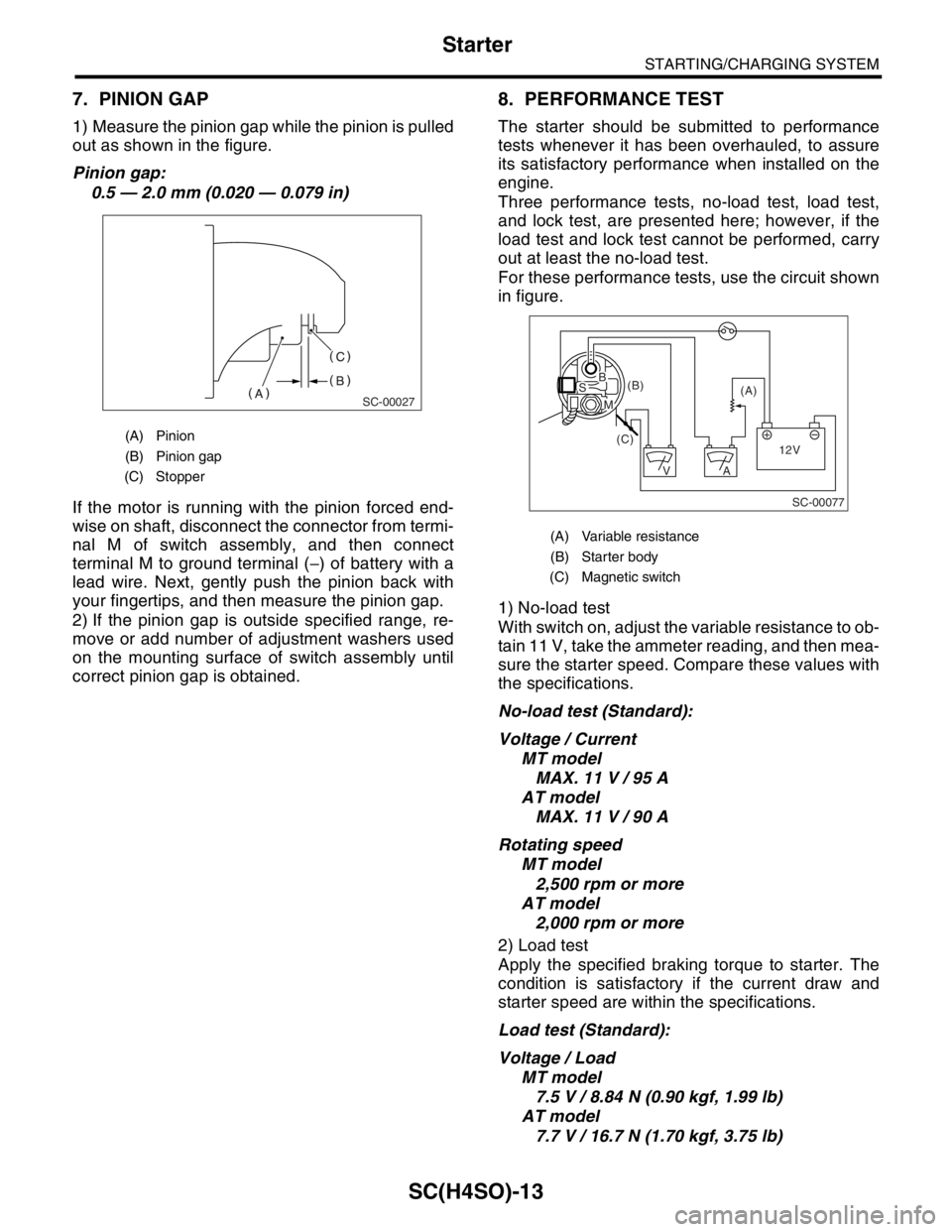

5. SWITCH ASSEMBLY

Be sure there is continuity between the terminals S

and M, and between terminal S and ground. Use a

circuit tester (set in “ohm”).

Also check to be sure there is no continuity be-

tween terminal M and B.

Terminal / Specified resistance:

S — M / Less than 1

Ω

S — Ground / Less than 1 Ω

M — B / More than 1 MΩ

6. SWITCH ASSEMBLY OPERATION

1) Connect the terminal S of switch assembly to

positive terminal of battery with a lead wire, and

starter body to ground terminal of battery. The pin-

ion should be forced endwise on shaft.

CAUTION:

With the pinion forced endwise on shaft, starter

motor can sometimes rotate because current

flows, through pull-in coil, to motor. This is not

a problem.

2) Disconnect the connector from terminal M, and

then connect the positive terminal of battery and

terminal M using a lead wire and ground terminal to

starter body.

In this test set up, the pinion should return to its

original position even when it is pulled out with a

screwdriver.

(A) Service limit line

(B) Brush

SC-00102

(A)

(B)

(A) Terminal S

(B) Terminal M

SC-00075

B

M

S

SC-00076

(B) (A)

Page 1088 of 2870

SC(H4SO)-13

STARTING/CHARGING SYSTEM

Starter

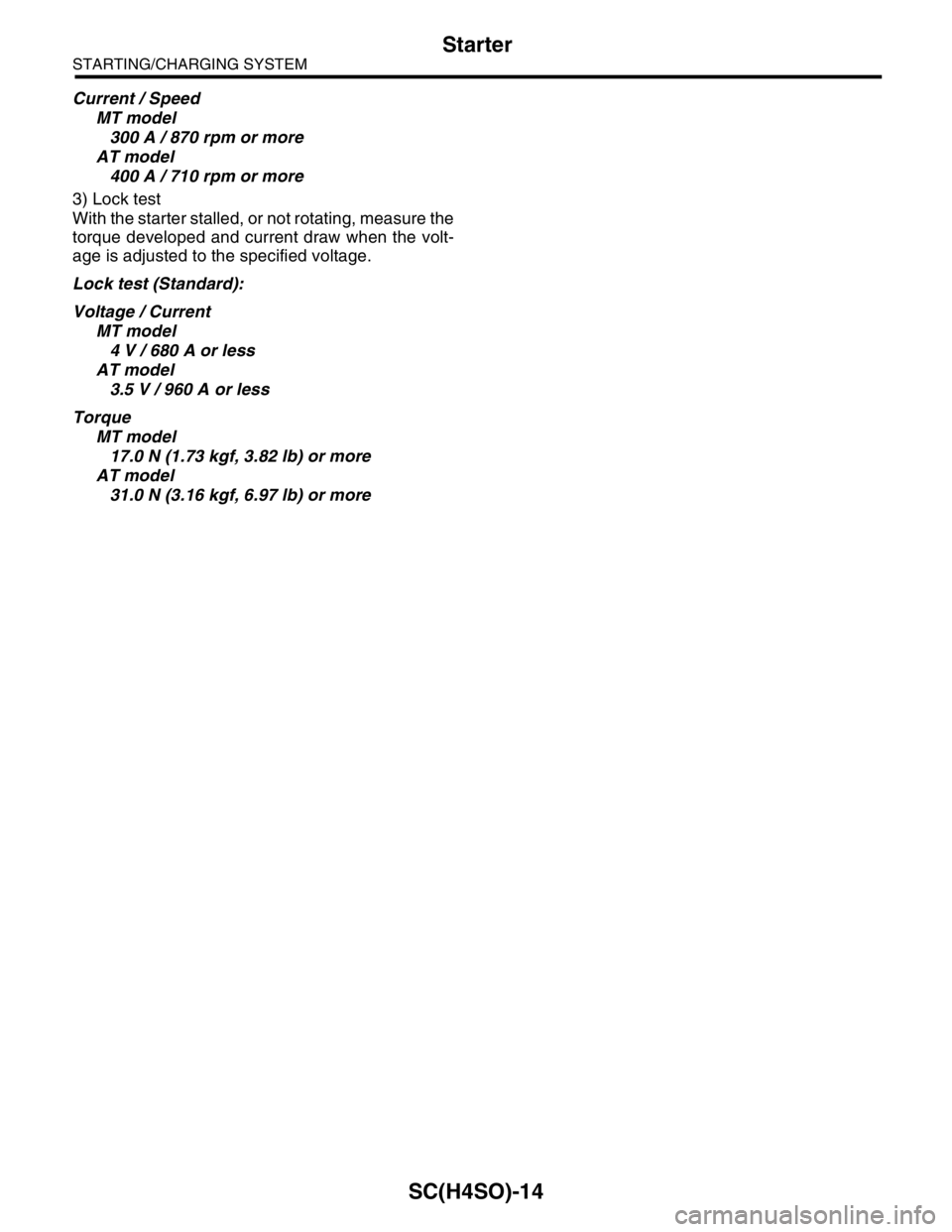

7. PINION GAP

1) Measure the pinion gap while the pinion is pulled

out as shown in the figure.

Pinion gap:

0.5 — 2.0 mm (0.020 — 0.079 in)

If the motor is running with the pinion forced end-

wise on shaft, disconnect the connector from termi-

nal M of switch assembly, and then connect

terminal M to ground terminal (−) of battery with a

lead wire. Next, gently push the pinion back with

your fingertips, and then measure the pinion gap.

2) If the pinion gap is outside specified range, re-

move or add number of adjustment washers used

on the mounting surface of switch assembly until

correct pinion gap is obtained.

8. PERFORMANCE TEST

The starter should be submitted to performance

tests whenever it has been overhauled, to assure

its satisfactory performance when installed on the

engine.

Three performance tests, no-load test, load test,

and lock test, are presented here; however, if the

load test and lock test cannot be performed, carry

out at least the no-load test.

For these performance tests, use the circuit shown

in figure.

1) No-load test

With switch on, adjust the variable resistance to ob-

tain 11 V, take the ammeter reading, and then mea-

sure the starter speed. Compare these values with

the specifications.

No-load test (Standard):

Voltage / Current

MT model

MAX. 11 V / 95 A

AT model

MAX. 11 V / 90 A

Rotating speed

MT model

2,500 rpm or more

AT model

2,000 rpm or more

2) Load test

Apply the specified braking torque to starter. The

condition is satisfactory if the current draw and

starter speed are within the specifications.

Load test (Standard):

Voltage / Load

MT model

7.5 V / 8.84 N (0.90 kgf, 1.99 lb)

AT model

7.7 V / 16.7 N (1.70 kgf, 3.75 lb)

(A) Pinion

(B) Pinion gap

(C) Stopper

SC-00027

(A) Variable resistance

(B) Starter body

(C) Magnetic switch

SC-00077

(A) (B)

(C)

12V +

AV

BS

M

Page 1089 of 2870

SC(H4SO)-14

STARTING/CHARGING SYSTEM

Starter

Current / Speed

MT model

300 A / 870 rpm or more

AT model

400 A / 710 rpm or more

3) Lock test

With the starter stalled, or not rotating, measure the

torque developed and current draw when the volt-

age is adjusted to the specified voltage.

Lock test (Standard):

Voltage / Current

MT model

4 V / 680 A or less

AT model

3.5 V / 960 A or less

Torque

MT model

17.0 N (1.73 kgf, 3.82 lb) or more

AT model

31.0 N (3.16 kgf, 6.97 lb) or more

Page 1106 of 2870

EN(H4SO)-8

ENGINE (DIAGNOSTIC)

General Description

The OBD-II diagnostics procedure is different

from the usual diagnosis procedure. When trouble-

shooting the OBD-II models, connect Subaru Se-

lect Monitor or the OBD-II general scan tool to the

vehicle.

2. ENGINE AND EMISSION CONTROL SYS-

TEM

MFI system is a system that supplies the opti-

mum air-fuel mixture to the engine for all the vari-

ous operating conditions through the use of the

latest electronic technology.

With this system fuel, which is pressurized at a con-

stant pressure, is injected into the intake air pas-

sage of the cylinder head. The injection quantity of

fuel is controlled by an intermittent injection system

where the electro-magnetic injection valve (fuel in-

jector) opens only for a short period of time, de-

pending on the quantity of air required for one cycle

of operation. In actual operation, the injection quan-

tity is determined by the duration of an electric sig-

nal applied to the fuel injector and this permits

simple, yet highly precise metering of the fuel.

Further, all the operating conditions of the engine

are converted into electric signals, and this results

in additional features of the system, such as large

improved adaptability, easier addition of compen-

sating element, etc.The MFI system also has the following features:

Reduced emission of harmful exhaust gases.

Reduced in fuel consumption.

Increased engine output.

Superior acceleration and deceleration.

Excellent engine start and warm-up perfor-

mance by the correction of engine coolant tem-

perature and intake air temperature.3. AUTOMATIC TRANSMISSION AND

ELECTRONIC-HYDRAULIC CONTROL SYS-

TEM

The electronic-hydraulic control system consists of

various sensors and switches, TCM and the hy-

draulic controller including solenoid valves. The

system controls the transmission body including

shift control, lock-up control, overrunning clutch

control, line pressure control and shift timing con-

trol. It also controls the AWD transfer clutch. In oth-

er words, the system detects various operating

conditions from various input signals and sends

output signals to shift solenoids 1, 2 and low clutch

timing solenoid and 2-4 brake timing solenoid, line

pressure duty solenoid, lock-up duty solenoid,

transfer duty solenoid and 2-4 brake duty solenoid

(a total of eight solenoids).

D: PREPARATION TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

24082AA230

(Newly adopted tool)CARTRIDGE Troubleshooting for electrical system.

22771AA030 SUBARU SELECT

MONITOR KITTroubleshooting for electrical system.

English: 22771AA030 (Without printer)

German: 22771AA070 (Without printer)

French: 22771AA080 (Without printer)

Spanish: 22771AA090 (Without printer)

ST24082AA230

ST22771AA030

Page 1118 of 2870

EN(H4SO)-20

ENGINE (DIAGNOSTIC)

Electrical Component Location

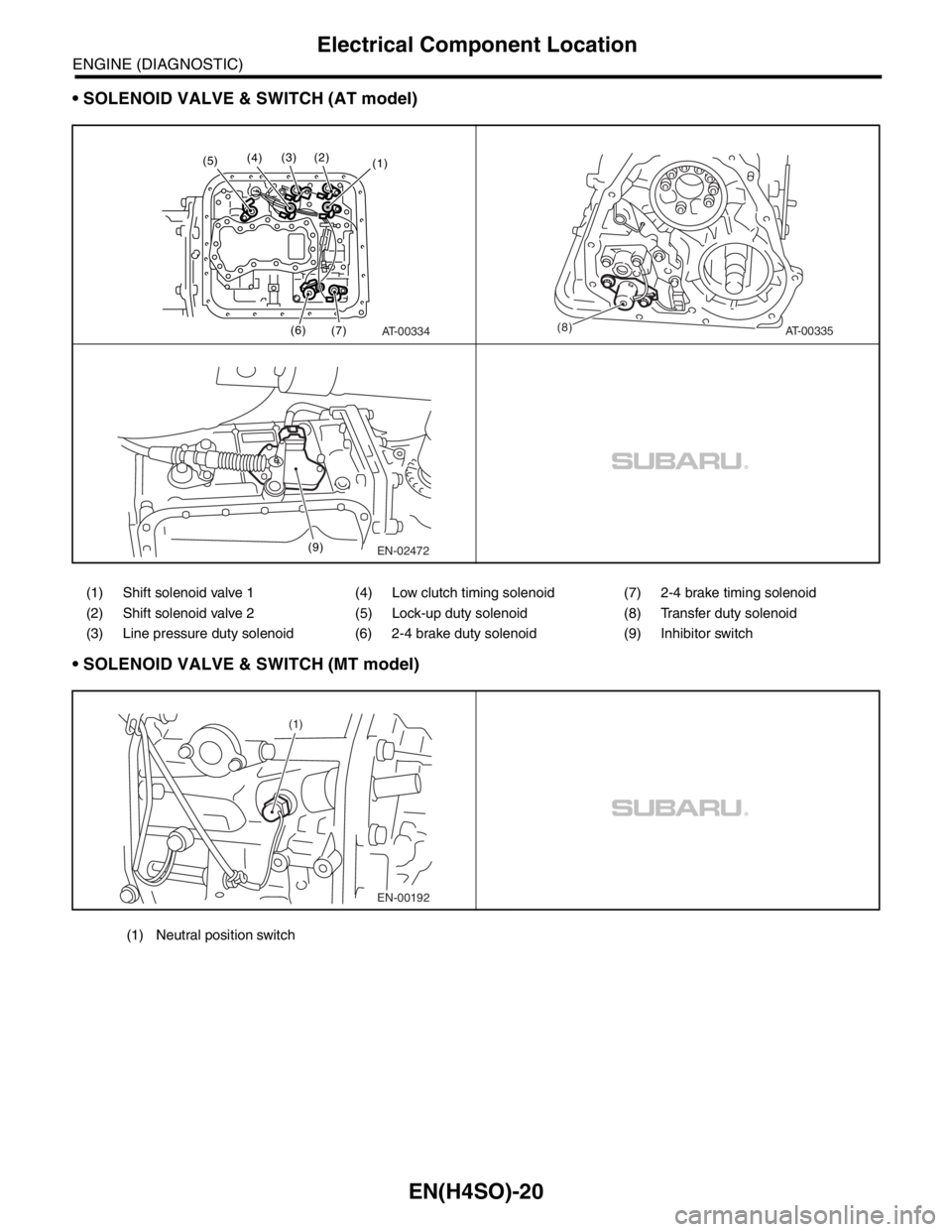

SOLENOID VALVE & SWITCH (AT model)

SOLENOID VALVE & SWITCH (MT model)

(1) Shift solenoid valve 1 (4) Low clutch timing solenoid (7) 2-4 brake timing solenoid

(2) Shift solenoid valve 2 (5) Lock-up duty solenoid (8) Transfer duty solenoid

(3) Line pressure duty solenoid (6) 2-4 brake duty solenoid (9) Inhibitor switch

AT-00334

(1)

(6)

(7) (2)(3)(4)(5)

AT-00335(8)

EN-02472 (9)

EN-00192 (1)

(1) Neutral position switch

Page 1133 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sel SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sel](/img/17/57426/w960_57426-1132.png)

EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Transmission} and press the [YES] key.

3) Press the [YES] key after the information of transmission type is displayed.

4) On the «Transmission Diagnosis» display screen, select the {Current Data Display & Save} and press the

[YES] key.

5) On the «Transmission Diagnosis» display screen, select the {Data Display} and press the [YES] key.

6) Using the scroll key, scroll the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

Description Display Unit of measure

Battery voltage Battery Voltage V

Rear vehicle speed sensor signal Rear Wheel Speed km/h or MPH

Front vehicle speed sensor signal Front Wheel Speed km/h or MPH

Engine speed signal Engine speed rpm

ATF temperature signal ATF Temp.°C or °F

Throttle position sensor Throttle Sensor Voltage V

Gear Position Gear position —

Line pressure control duty ratio Line pressure duty %

Lock up clutch control duty ratio L/U Duty %

Transfer clutch control duty ratio AWD duty %

Throttle position sensor power supply Throttle sensor power supply V

Turbine revolution signal Turbine Revolution Speed rpm

2-4 Brake timing pressure control duty ratio 2-4 B Pressure Duty %

Intake manifold pressure sensor voltage Mani. Relative Voltage V

FWD switch signal FWD SW ON or OFF

Kick down switch signal Kick Down Switch ON or OFF

Stop light switch signal Stop Light SW ON or OFF

Anti lock brake system signal ABS signal ON or OFF

Cruise control system signal Cruise Control Signal ON or OFF

Neutral/Parking range signal N/P range ON or OFF

Reverse range signal R Range ON or OFF

Drive range signal D Range ON or OFF

3rd range signal 3rd Range Signal ON or OFF

2nd range signal 2nd Range Signal ON or OFF

1st range signal 1st Range Signal ON or OFF

Shift control solenoid A Shift Solenoid #1 ON or OFF

Shift control solenoid B Shift Solenoid #2 ON or OFF

Torque control output signal #1 Torque control output signal 1 ON or OFF

Torque control output signal #2 Torque control output signal 2 ON or OFF

Torque control cut signal Torque Control Cut Sig ON or OFF

2-4 brake timing control solenoid valve 2-4B Timing Solenoid ON or OFF

Low clutch timing control solenoid valve L/C timing solenoid ON or OFF

Automatic transmission diagnosis light output signal Diagnosis Lamp ON or OFF