lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 973 of 2870

EX(H4SO)-5

EXHAUST

General Description

(1) Front exhaust pipe upper cover

CTR(15) Rear exhaust upper cover (31) Front catalytic converter upper

cover

(16) Rear exhaust lower cover

(2) Front exhaust pipe lower cover

CTR(17) Rear catalytic lower converter

cover(32) Front oxygen (A/F) sensor

(33) Rear oxygen sensor

(3) Clamp (18) Clamp (34) Clamp

(4) Front exhaust pipe upper cover LH (19) Cushion rubber

(5) Front exhaust pipe lower cover LH (20) Rear exhaust pipeTightening torque: N

⋅m (kgf-m, ft-lb)

(6) Front exhaust pipe (21) GasketT1: 8 (0.8, 5.8)

(7) Front exhaust pipe lower cover RH (22) Self-locking nutT2: 13 (1.3, 9.4)

(8) Front exhaust pipe upper cover

RH(23) MufflerT3: 18 (1.8, 13.0)

(24) ProtectorT4: 21 (2.1, 15.2)

(9) Gasket (25) GasketT5: 30 (3.1, 22.4)

(10) Gasket (26) Front catalytic converterT6: 35 (3.6, 26.0)

(11) Spring (27) Center exhaust lower coverT7: 48 (4.9, 35.4)

(12) Chamber (28) Center exhaust upper cover

(13) Rear catalytic converter (29) Center exhaust pipe

(14) Rear catalytic converter upper

cover(30) Front catalytic converter lower

cover

Page 1006 of 2870

CO(H4SO)-23

COOLING

Water Pump

B: INSTALLATION

1. NON-TURBO MODEL

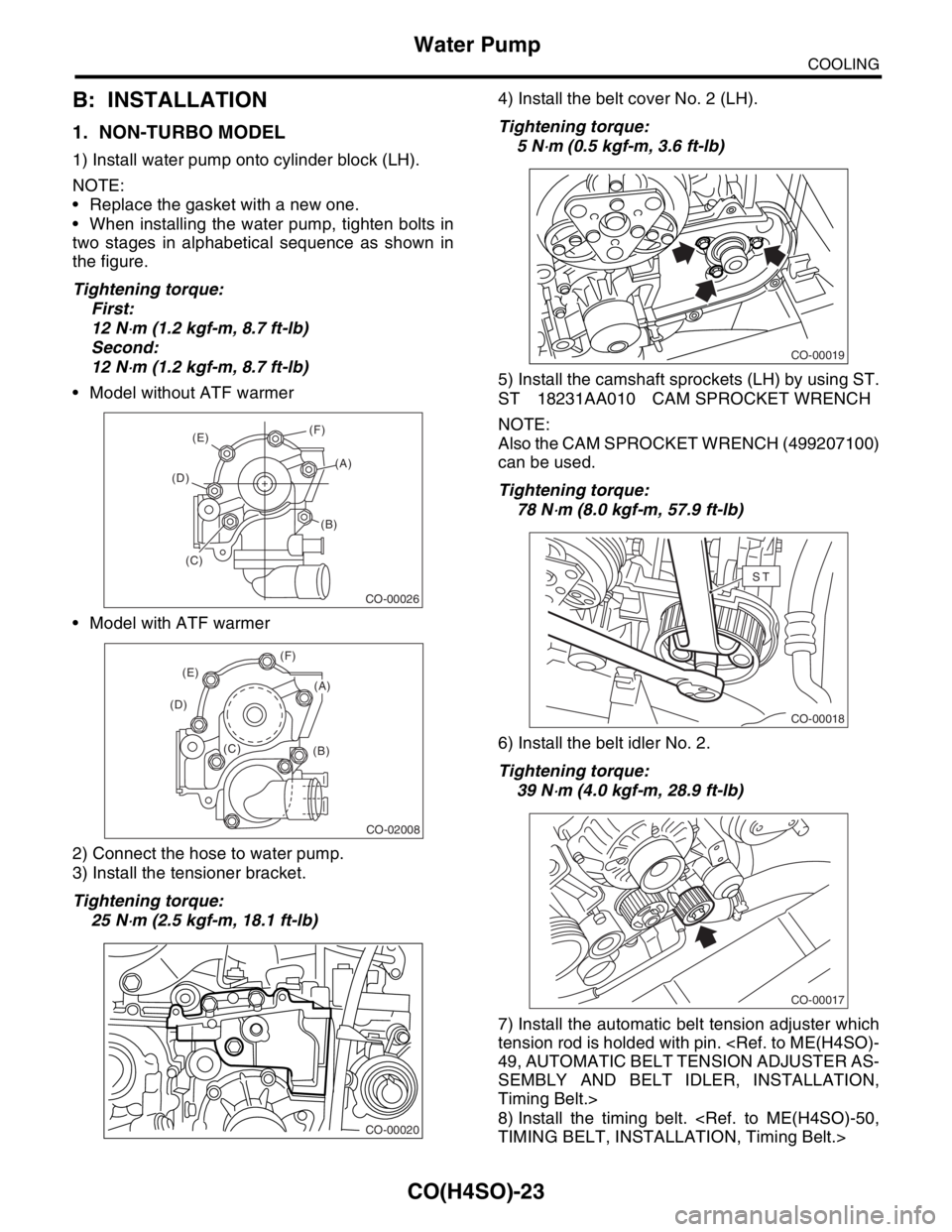

1) Install water pump onto cylinder block (LH).

NOTE:

Replace the gasket with a new one.

When installing the water pump, tighten bolts in

two stages in alphabetical sequence as shown in

the figure.

Tightening torque:

First:

12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Second:

12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Model without ATF warmer

Model with ATF warmer

2) Connect the hose to water pump.

3) Install the tensioner bracket.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)4) Install the belt cover No. 2 (LH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

5) Install the camshaft sprockets (LH) by using ST.

ST 18231AA010 CAM SPROCKET WRENCH

NOTE:

Also the CAM SPROCKET WRENCH (499207100)

can be used.

Tightening torque:

78 N

⋅m (8.0 kgf-m, 57.9 ft-lb)

6) Install the belt idler No. 2.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

7) Install the automatic belt tension adjuster which

tension rod is holded with pin.

SEMBLY AND BELT IDLER, INSTALLATION,

Timing Belt.>

8) Install the timing belt.

CO-00026

(E)

(D)

(B)

(C)(A) (F)

CO-02008

(B) (C) (D)(E)(F)

(A)

CO-00020

CO-00019

CO-00018

ST

CO-00017

Page 1007 of 2870

CO(H4SO)-24

COOLING

Water Pump

9) Install the V-belts.

10) Install the radiator.

2. TURBO MODEL

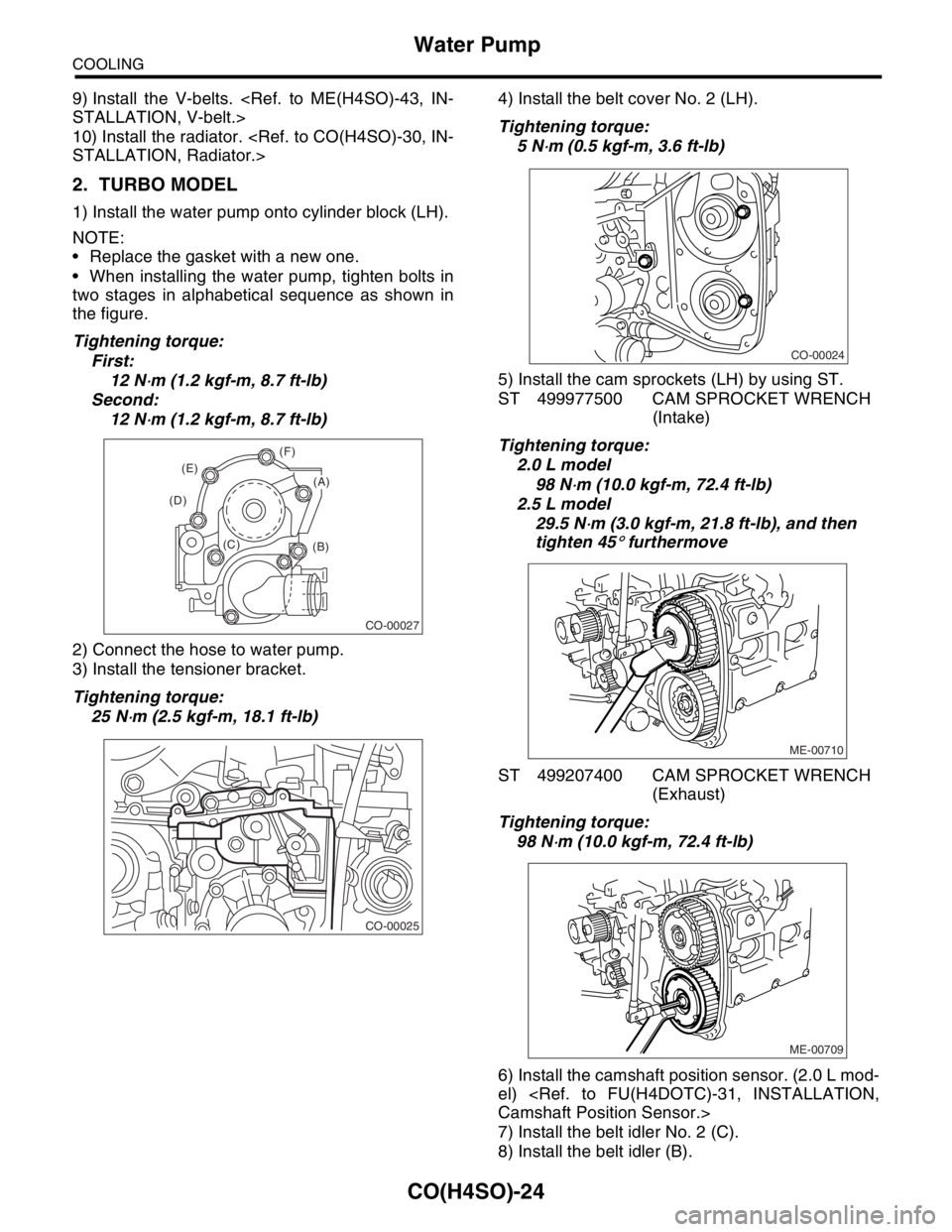

1) Install the water pump onto cylinder block (LH).

NOTE:

Replace the gasket with a new one.

When installing the water pump, tighten bolts in

two stages in alphabetical sequence as shown in

the figure.

Tightening torque:

First:

12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Second:

12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

2) Connect the hose to water pump.

3) Install the tensioner bracket.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)4) Install the belt cover No. 2 (LH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

5) Install the cam sprockets (LH) by using ST.

ST 499977500 CAM SPROCKET WRENCH

(Intake)

Tightening torque:

2.0 L model

98 N

⋅m (10.0 kgf-m, 72.4 ft-lb)

2.5 L model

29.5 N

⋅m (3.0 kgf-m, 21.8 ft-lb), and then

tighten 45

° furthermove

ST 499207400 CAM SPROCKET WRENCH

(Exhaust)

Tightening torque:

98 N

⋅m (10.0 kgf-m, 72.4 ft-lb)

6) Install the camshaft position sensor. (2.0 L mod-

el)

7) Install the belt idler No. 2 (C).

8) Install the belt idler (B).

CO-00027

(B) (C) (D)(E)(F)

(A)

CO-00025

CO-00024

ME-00710

ME-00709

Page 1038 of 2870

LU(H4SO)-10

LUBRICATION

Engine Oil

3. Engine Oil

A: INSPECTION

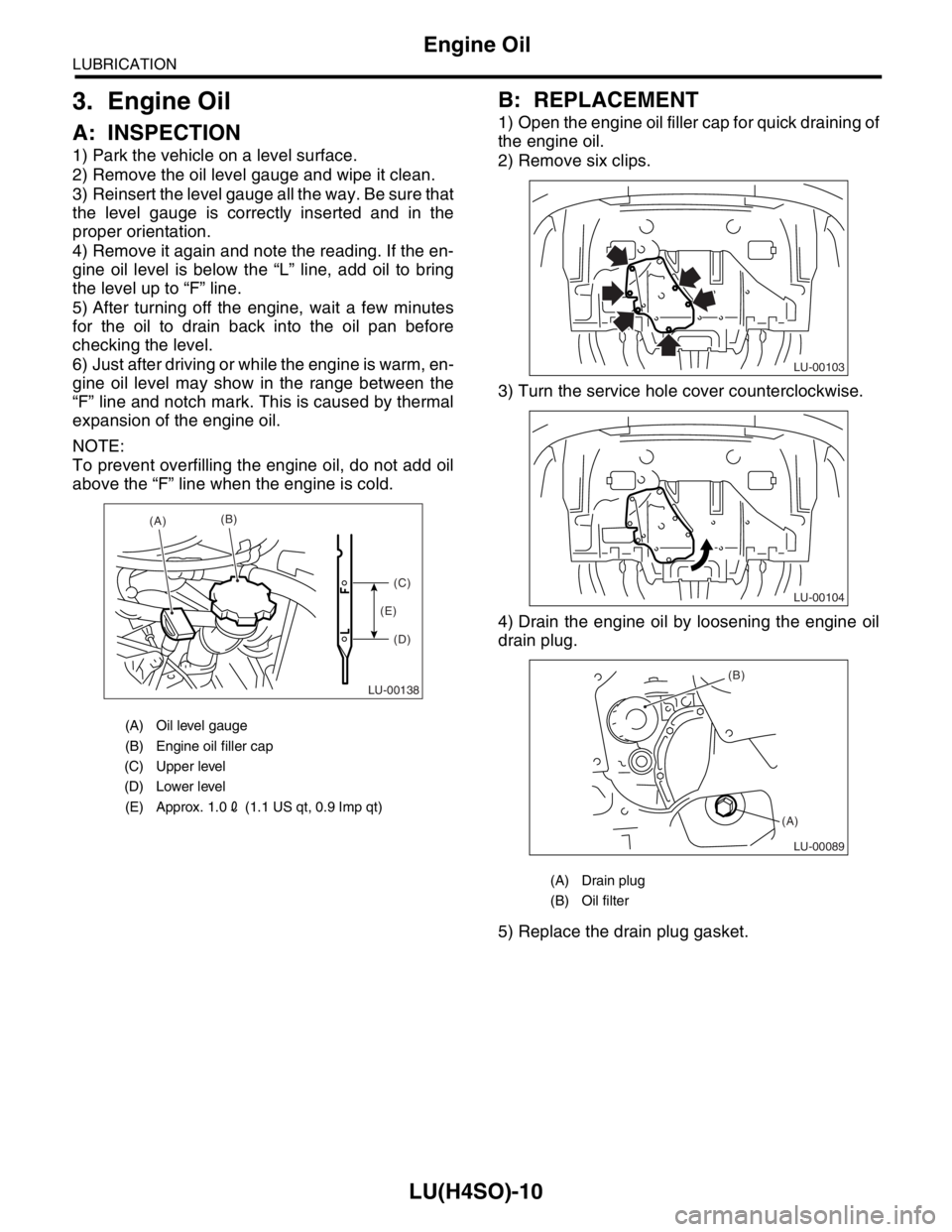

1) Park the vehicle on a level surface.

2) Remove the oil level gauge and wipe it clean.

3) Reinsert the level gauge all the way. Be sure that

the level gauge is correctly inserted and in the

proper orientation.

4) Remove it again and note the reading. If the en-

gine oil level is below the “L” line, add oil to bring

the level up to “F” line.

5) After turning off the engine, wait a few minutes

for the oil to drain back into the oil pan before

checking the level.

6) Just after driving or while the engine is warm, en-

gine oil level may show in the range between the

“F” line and notch mark. This is caused by thermal

expansion of the engine oil.

NOTE:

To prevent overfilling the engine oil, do not add oil

above the “F” line when the engine is cold.

B: REPLACEMENT

1) Open the engine oil filler cap for quick draining of

the engine oil.

2) Remove six clips.

3) Turn the service hole cover counterclockwise.

4) Drain the engine oil by loosening the engine oil

drain plug.

5) Replace the drain plug gasket.

(A) Oil level gauge

(B) Engine oil filler cap

(C) Upper level

(D) Lower level

(E) Approx. 1.02 (1.1 US qt, 0.9 Imp qt)

LU-00138

(A)(B)

(C)

(D) (E)

(A) Drain plug

(B) Oil filter

LU-00103

LU-00104

LU-00089

(B)

(A)

Page 1041 of 2870

LU(H4SO)-13

LUBRICATION

Oil Pump

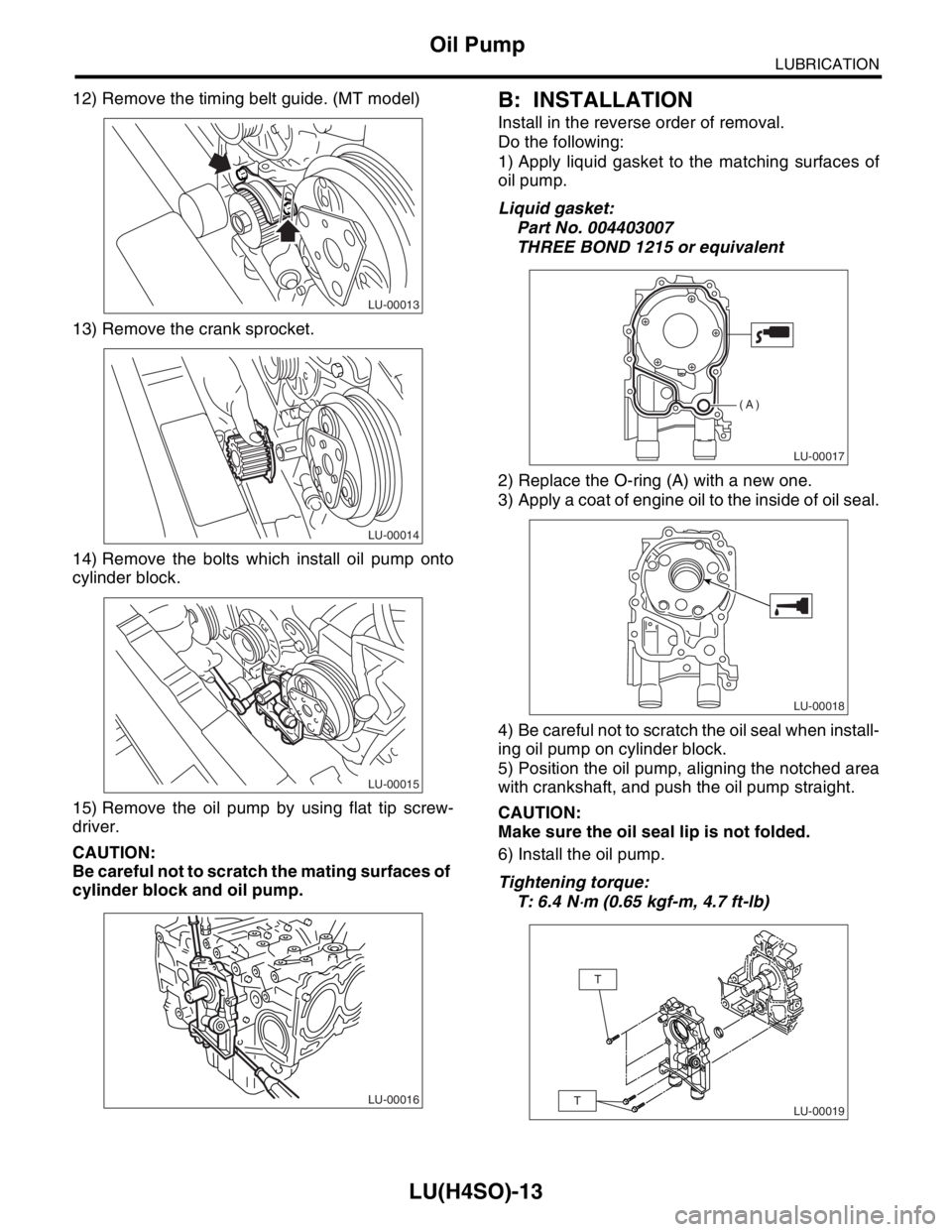

12) Remove the timing belt guide. (MT model)

13) Remove the crank sprocket.

14) Remove the bolts which install oil pump onto

cylinder block.

15) Remove the oil pump by using flat tip screw-

driver.

CAUTION:

Be careful not to scratch the mating surfaces of

cylinder block and oil pump.B: INSTALLATION

Install in the reverse order of removal.

Do the following:

1) Apply liquid gasket to the matching surfaces of

oil pump.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

2) Replace the O-ring (A) with a new one.

3) Apply a coat of engine oil to the inside of oil seal.

4) Be careful not to scratch the oil seal when install-

ing oil pump on cylinder block.

5) Position the oil pump, aligning the notched area

with crankshaft, and push the oil pump straight.

CAUTION:

Make sure the oil seal lip is not folded.

6) Install the oil pump.

Tightening torque:

T: 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

LU-00013

LU-00014

LU-00015

LU-00016

LU-00017

(A)

LU-00018

LU-00019

T

T

Page 1045 of 2870

LU(H4SO)-17

LUBRICATION

Oil Pan and Strainer

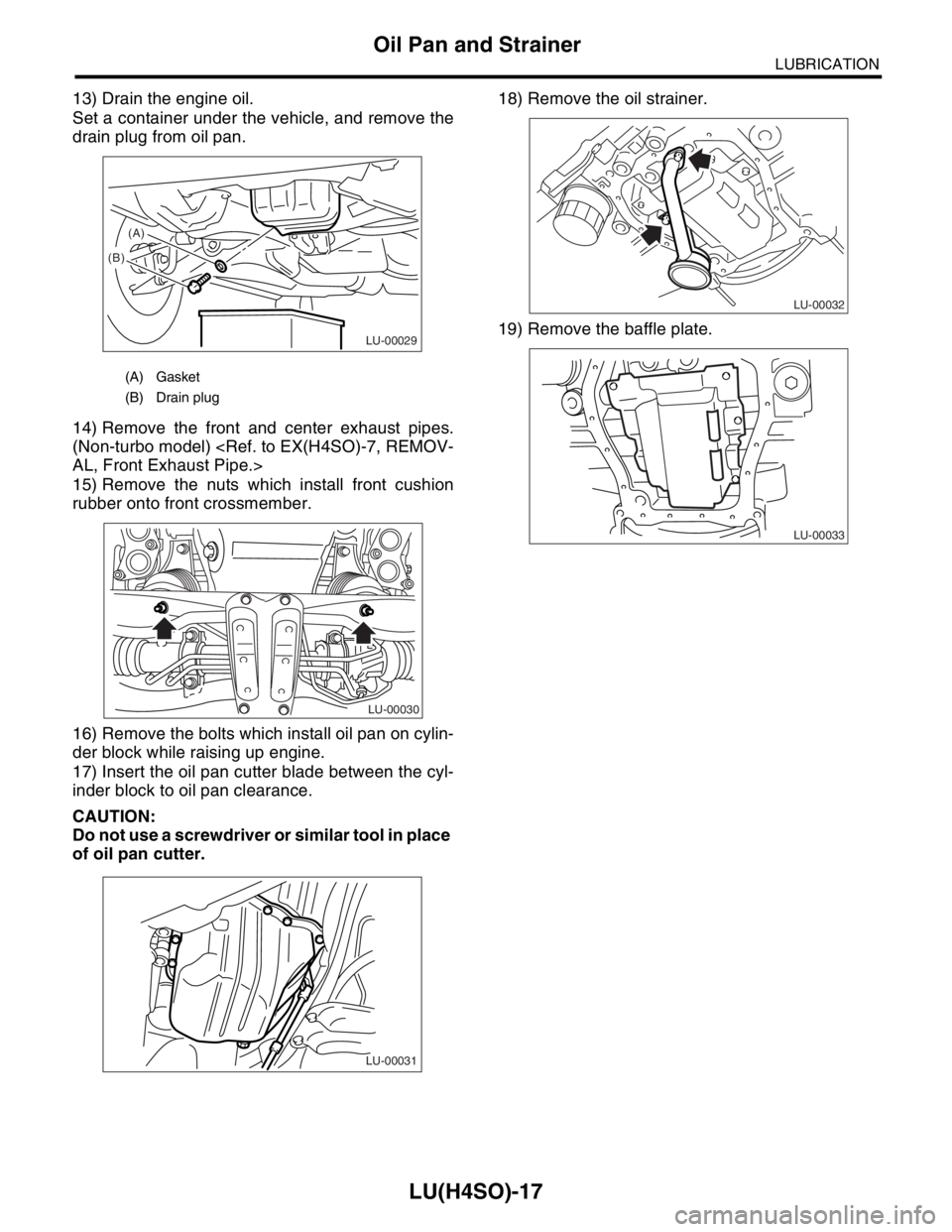

13) Drain the engine oil.

Set a container under the vehicle, and remove the

drain plug from oil pan.

14) Remove the front and center exhaust pipes.

(Non-turbo model)

15) Remove the nuts which install front cushion

rubber onto front crossmember.

16) Remove the bolts which install oil pan on cylin-

der block while raising up engine.

17) Insert the oil pan cutter blade between the cyl-

inder block to oil pan clearance.

CAUTION:

Do not use a screwdriver or similar tool in place

of oil pan cutter.18) Remove the oil strainer.

19) Remove the baffle plate.

(A) Gasket

(B) Drain plug

LU-00029

(B)(A)

LU-00030

LU-00031

LU-00032

LU-00033

Page 1046 of 2870

LU(H4SO)-18

LUBRICATION

Oil Pan and Strainer

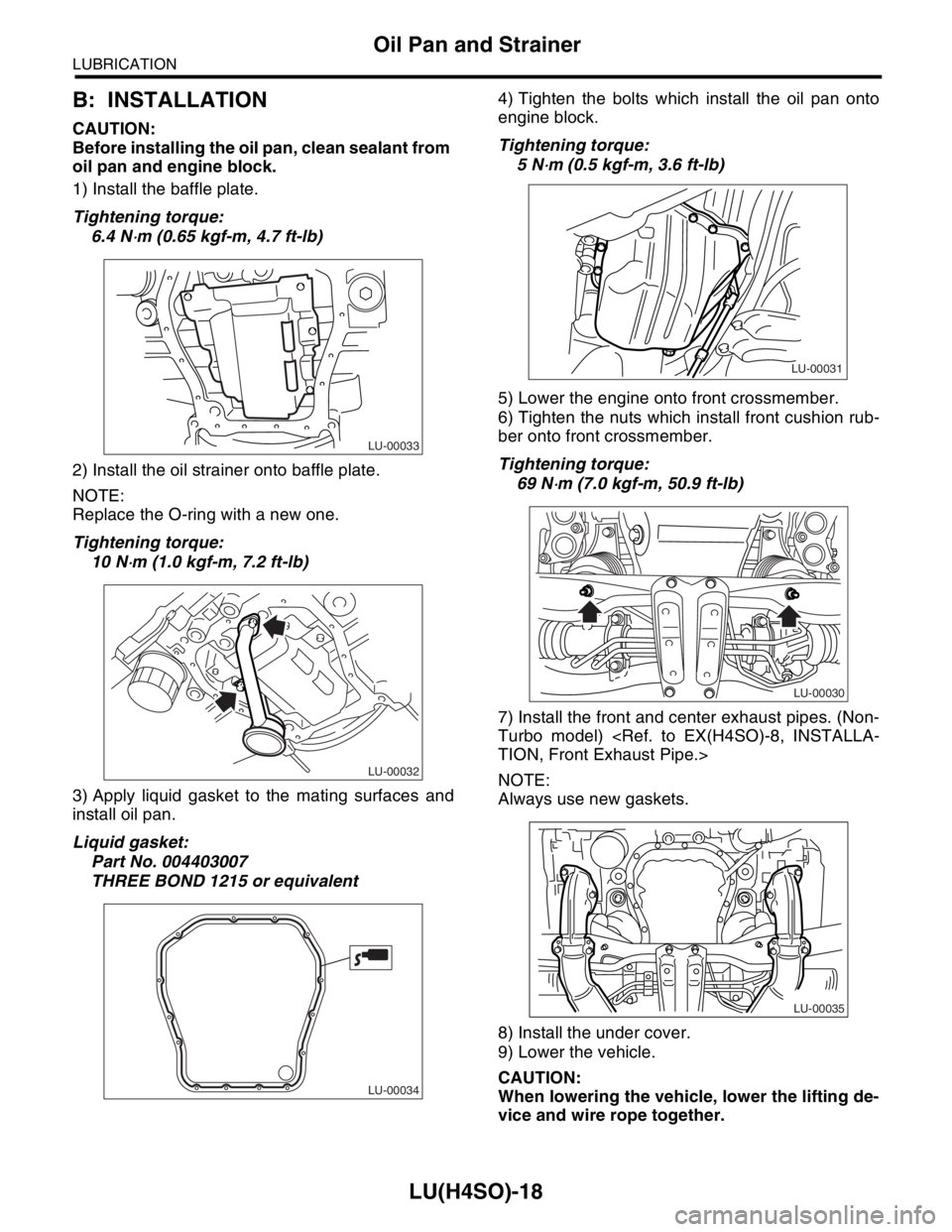

B: INSTALLATION

CAUTION:

Before installing the oil pan, clean sealant from

oil pan and engine block.

1) Install the baffle plate.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

2) Install the oil strainer onto baffle plate.

NOTE:

Replace the O-ring with a new one.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

3) Apply liquid gasket to the mating surfaces and

install oil pan.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent4) Tighten the bolts which install the oil pan onto

engine block.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

5) Lower the engine onto front crossmember.

6) Tighten the nuts which install front cushion rub-

ber onto front crossmember.

Tightening torque:

69 N

⋅m (7.0 kgf-m, 50.9 ft-lb)

7) Install the front and center exhaust pipes. (Non-

Turbo model)

NOTE:

Always use new gaskets.

8) Install the under cover.

9) Lower the vehicle.

CAUTION:

When lowering the vehicle, lower the lifting de-

vice and wire rope together.

LU-00033

LU-00032

LU-00034

LU-00031

LU-00030

LU-00035

Page 1048 of 2870

LU(H4SO)-20

LUBRICATION

Oil Pressure Switch

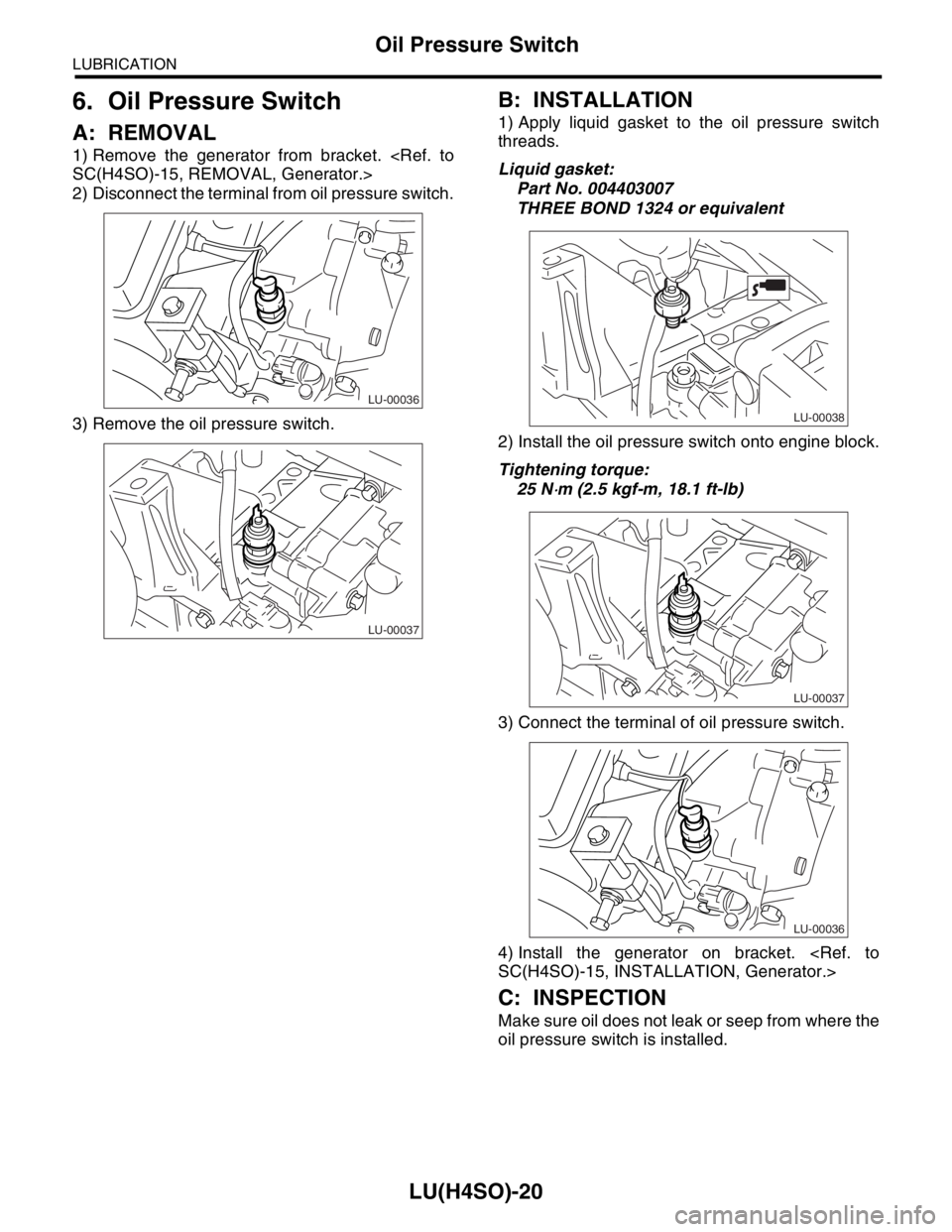

6. Oil Pressure Switch

A: REMOVAL

1) Remove the generator from bracket.

2) Disconnect the terminal from oil pressure switch.

3) Remove the oil pressure switch.

B: INSTALLATION

1) Apply liquid gasket to the oil pressure switch

threads.

Liquid gasket:

Part No. 004403007

THREE BOND 1324 or equivalent

2) Install the oil pressure switch onto engine block.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

3) Connect the terminal of oil pressure switch.

4) Install the generator on bracket.

C: INSPECTION

Make sure oil does not leak or seep from where the

oil pressure switch is installed.

LU-00036

LU-00037

LU-00038

LU-00037

LU-00036

Page 1050 of 2870

LU(H4SO)-22

LUBRICATION

Engine Oil Cooler

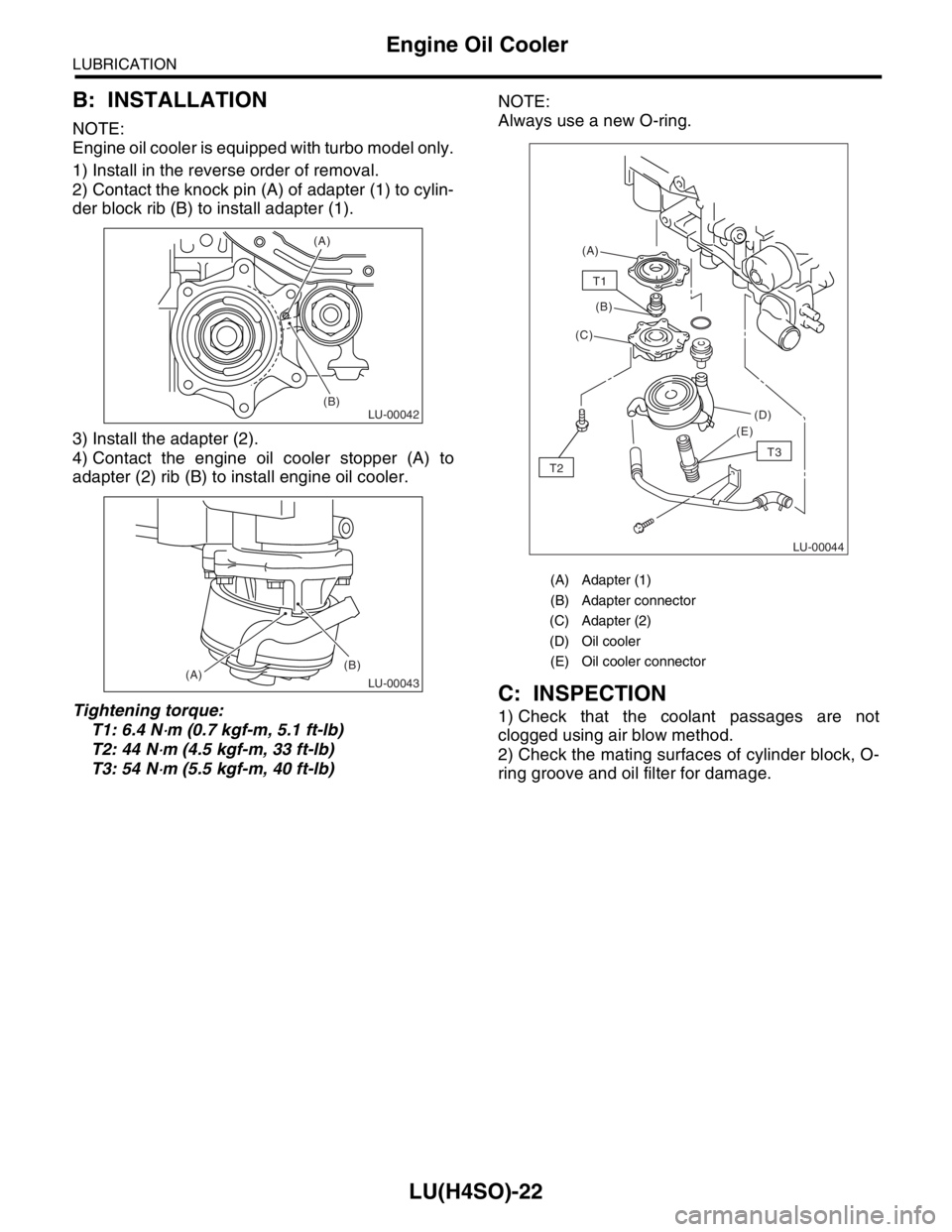

B: INSTALLATION

NOTE:

Engine oil cooler is equipped with turbo model only.

1) Install in the reverse order of removal.

2) Contact the knock pin (A) of adapter (1) to cylin-

der block rib (B) to install adapter (1).

3) Install the adapter (2).

4) Contact the engine oil cooler stopper (A) to

adapter (2) rib (B) to install engine oil cooler.

Tightening torque:

T1: 6.4 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

T2: 44 N

⋅m (4.5 kgf-m, 33 ft-lb)

T3: 54 N

⋅m (5.5 kgf-m, 40 ft-lb)NOTE:

Always use a new O-ring.

C: INSPECTION

1) Check that the coolant passages are not

clogged using air blow method.

2) Check the mating surfaces of cylinder block, O-

ring groove and oil filter for damage.

LU-00042

(A)

(B)

LU-00043

(B)(A)

(A) Adapter (1)

(B) Adapter connector

(C) Adapter (2)

(D) Oil cooler

(E) Oil cooler connector

LU-00044

(A)

(B)

(C)

(D)

(E)

T1

T2

T3

Page 1051 of 2870

LU(H4SO)-23

LUBRICATION

Engine Oil Filter

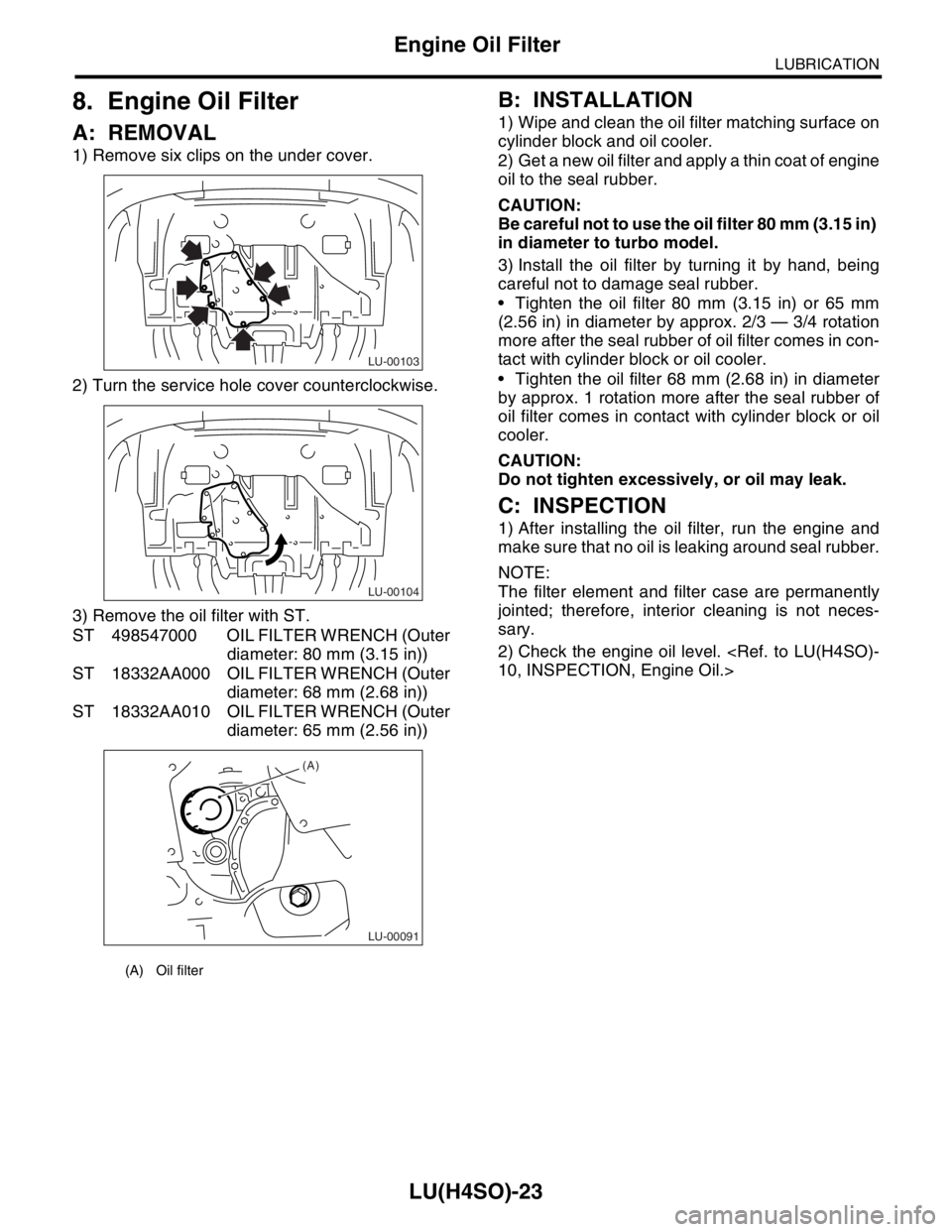

8. Engine Oil Filter

A: REMOVAL

1) Remove six clips on the under cover.

2) Turn the service hole cover counterclockwise.

3) Remove the oil filter with ST.

ST 498547000 OIL FILTER WRENCH (Outer

diameter: 80 mm (3.15 in))

ST 18332AA000 OIL FILTER WRENCH (Outer

diameter: 68 mm (2.68 in))

ST 18332AA010 OIL FILTER WRENCH (Outer

diameter: 65 mm (2.56 in))

B: INSTALLATION

1) Wipe and clean the oil filter matching surface on

cylinder block and oil cooler.

2) Get a new oil filter and apply a thin coat of engine

oil to the seal rubber.

CAUTION:

Be careful not to use the oil filter 80 mm (3.15 in)

in diameter to turbo model.

3) Install the oil filter by turning it by hand, being

careful not to damage seal rubber.

Tighten the oil filter 80 mm (3.15 in) or 65 mm

(2.56 in) in diameter by approx. 2/3 — 3/4 rotation

more after the seal rubber of oil filter comes in con-

tact with cylinder block or oil cooler.

Tighten the oil filter 68 mm (2.68 in) in diameter

by approx. 1 rotation more after the seal rubber of

oil filter comes in contact with cylinder block or oil

cooler.

CAUTION:

Do not tighten excessively, or oil may leak.

C: INSPECTION

1) After installing the oil filter, run the engine and

make sure that no oil is leaking around seal rubber.

NOTE:

The filter element and filter case are permanently

jointed; therefore, interior cleaning is not neces-

sary.

2) Check the engine oil level.

(A) Oil filter

LU-00103

LU-00104

LU-00091

(A)