SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1481 of 2870

ME(H4DOTC)-25

MECHANICAL

General Description

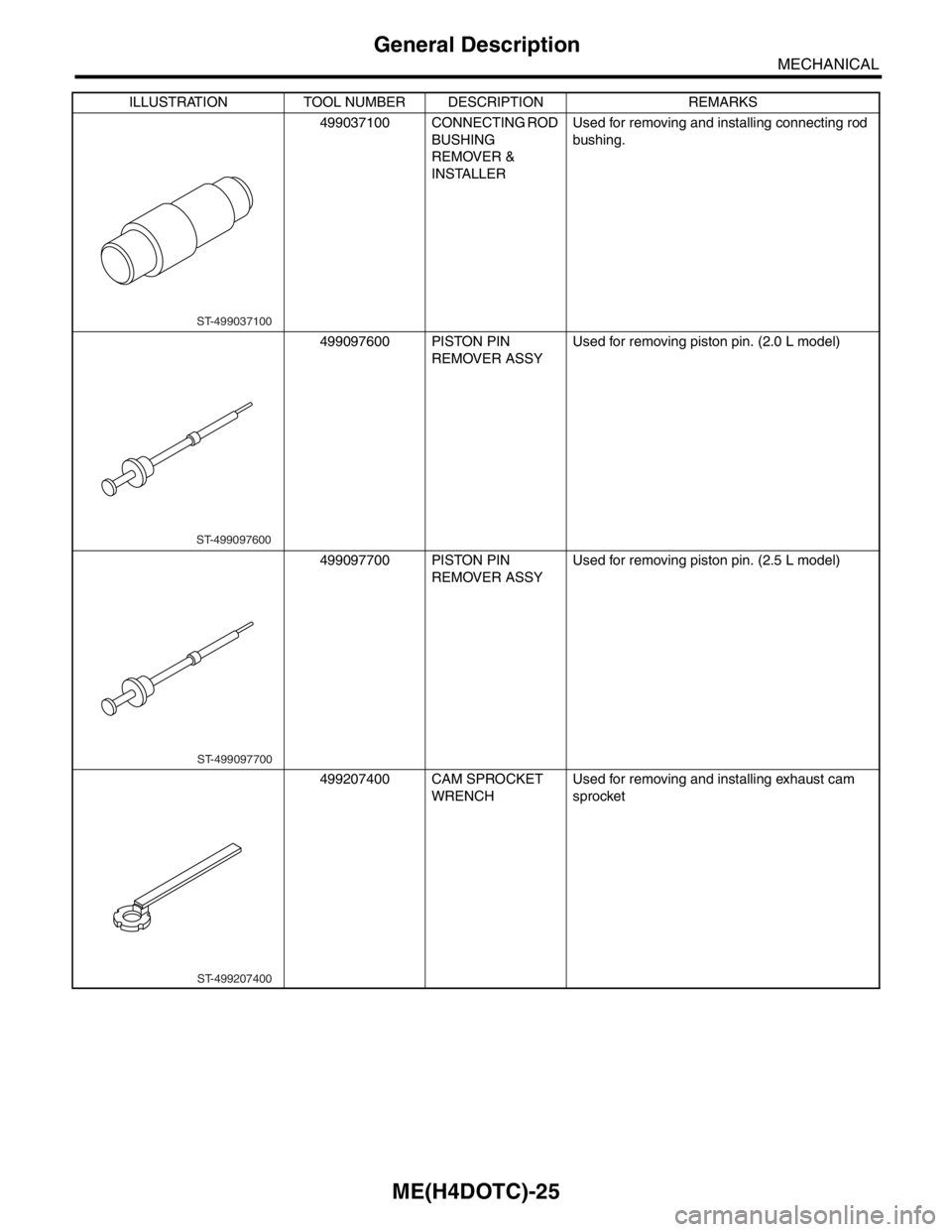

499037100 CONNECTING ROD

BUSHING

REMOVER &

INSTALLERUsed for removing and installing connecting rod

bushing.

499097600 PISTON PIN

REMOVER ASSYUsed for removing piston pin. (2.0 L model)

499097700 PISTON PIN

REMOVER ASSYUsed for removing piston pin. (2.5 L model)

499207400 CAM SPROCKET

WRENCHUsed for removing and installing exhaust cam

sprocket ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-499037100

ST-499097600

ST-499097700

ST-499207400

Page 1482 of 2870

ME(H4DOTC)-26

MECHANICAL

General Description

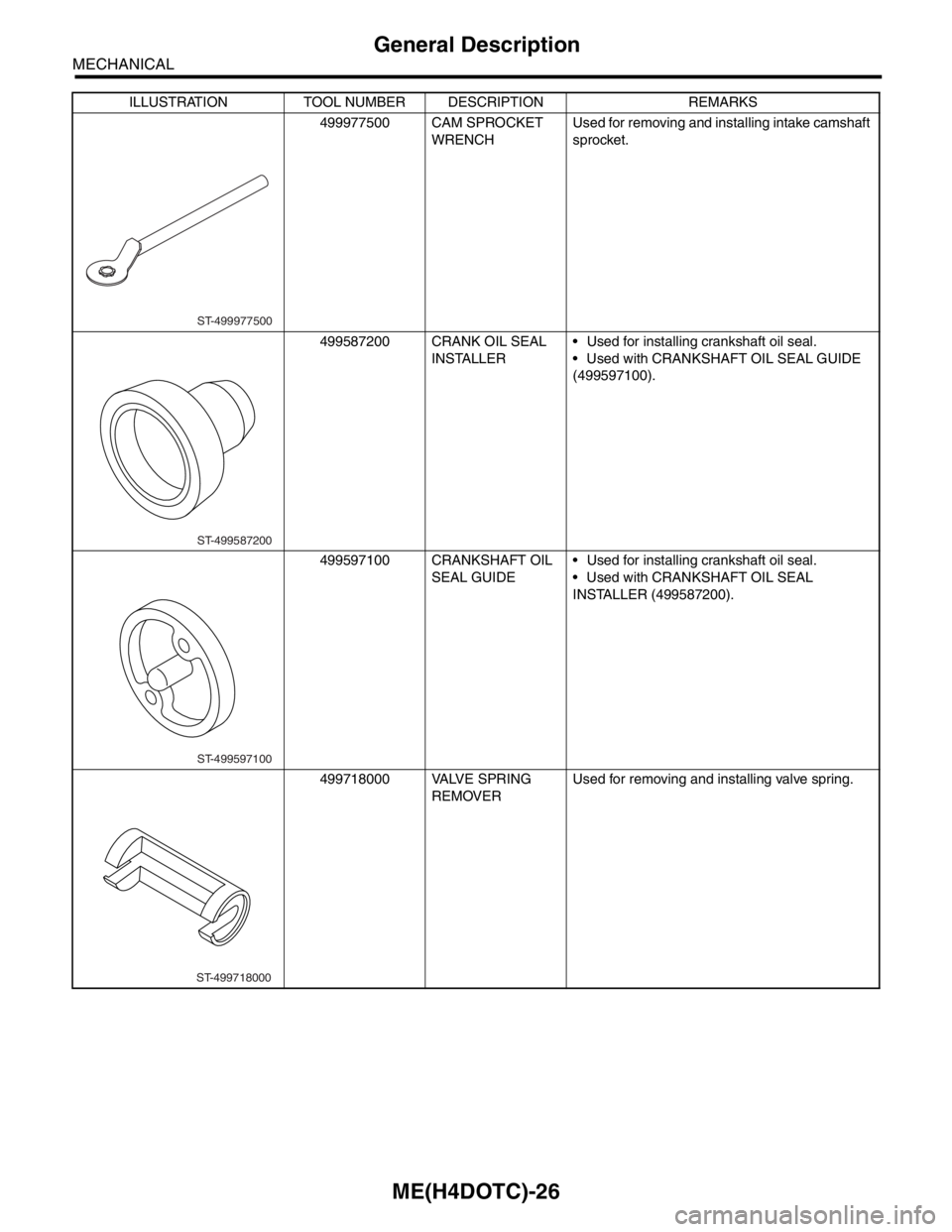

499977500 CAM SPROCKET

WRENCHUsed for removing and installing intake camshaft

sprocket.

499587200 CRANK OIL SEAL

INSTALLER Used for installing crankshaft oil seal.

Used with CRANKSHAFT OIL SEAL GUIDE

(499597100).

499597100 CRANKSHAFT OIL

SEAL GUIDE Used for installing crankshaft oil seal.

Used with CRANKSHAFT OIL SEAL

INSTALLER (499587200).

499718000 VALVE SPRING

REMOVERUsed for removing and installing valve spring. ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-499977500

ST-499587200

ST-499597100

ST-499718000

Page 1483 of 2870

ME(H4DOTC)-27

MECHANICAL

General Description

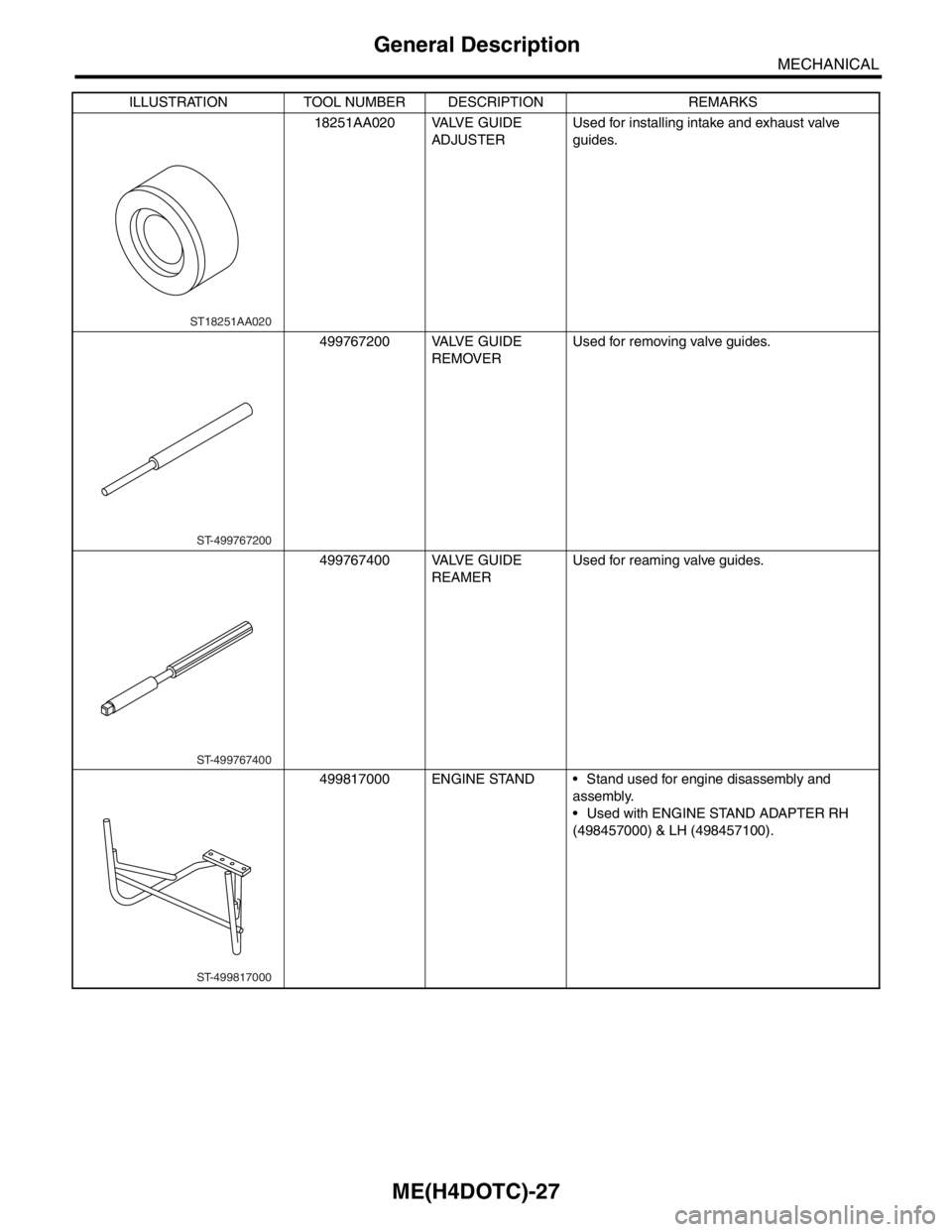

18251AA020 VALVE GUIDE

ADJUSTERUsed for installing intake and exhaust valve

guides.

499767200 VALVE GUIDE

REMOVERUsed for removing valve guides.

499767400 VALVE GUIDE

REAMERUsed for reaming valve guides.

499817000 ENGINE STAND Stand used for engine disassembly and

assembly.

Used with ENGINE STAND ADAPTER RH

(498457000) & LH (498457100). ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST18251AA020

ST-499767200

ST-499767400

ST-499817000

Page 1484 of 2870

ME(H4DOTC)-28

MECHANICAL

General Description

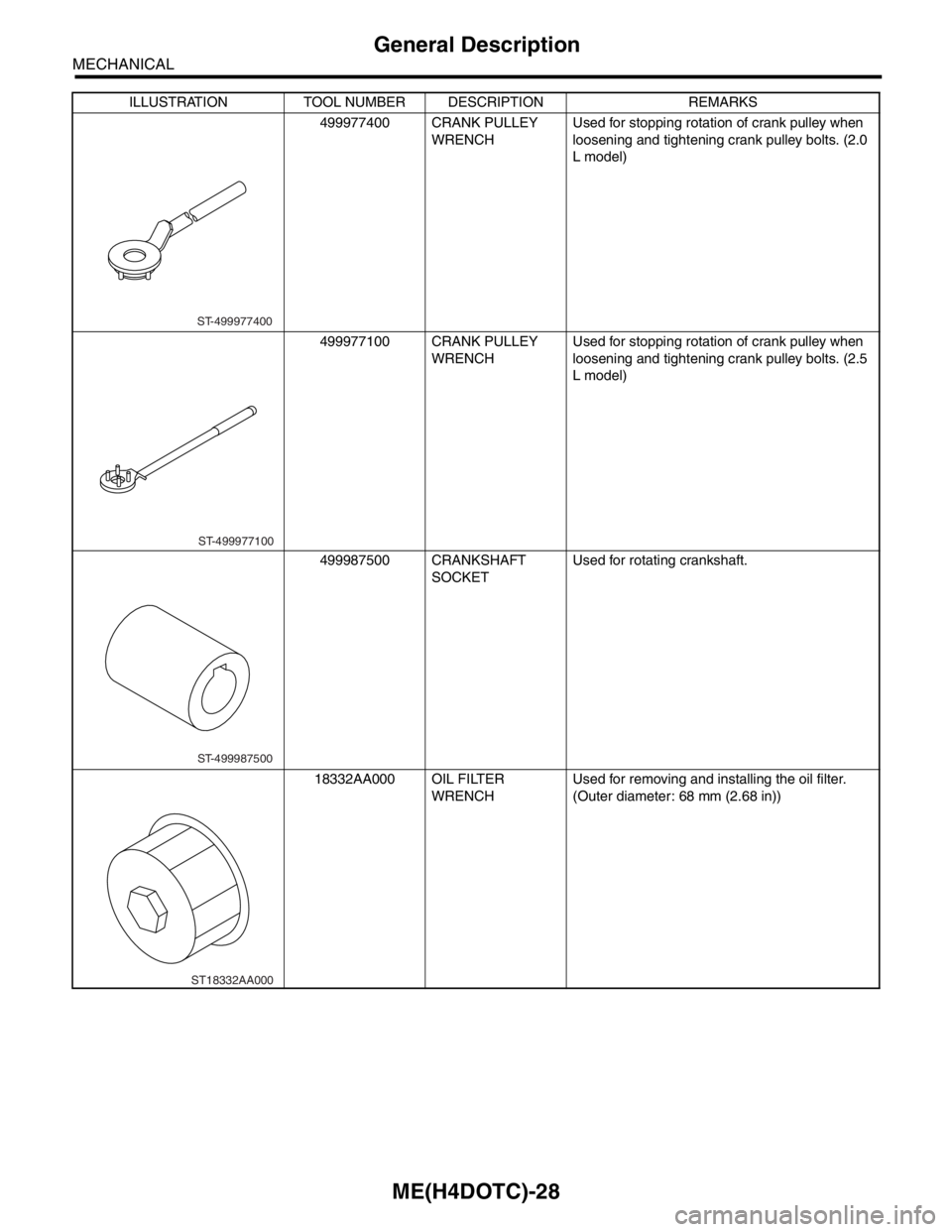

499977400 CRANK PULLEY

WRENCHUsed for stopping rotation of crank pulley when

loosening and tightening crank pulley bolts. (2.0

L model)

499977100 CRANK PULLEY

WRENCHUsed for stopping rotation of crank pulley when

loosening and tightening crank pulley bolts. (2.5

L model)

499987500 CRANKSHAFT

SOCKETUsed for rotating crankshaft.

18332AA000 OIL FILTER

WRENCHUsed for removing and installing the oil filter.

(Outer diameter: 68 mm (2.68 in)) ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-499977400

ST-499977100

ST-499987500

ST18332AA000

Page 1485 of 2870

ME(H4DOTC)-29

MECHANICAL

General Description

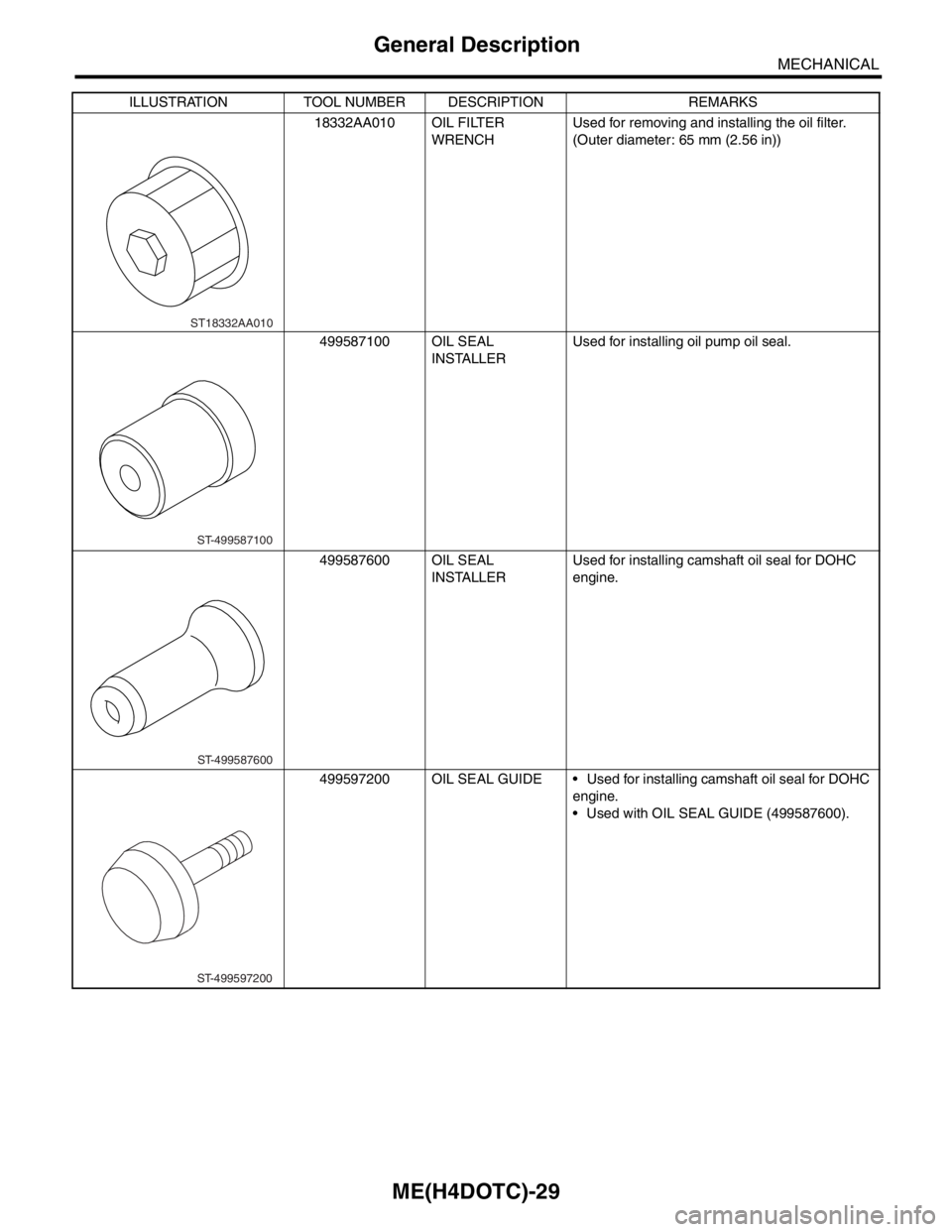

18332AA010 OIL FILTER

WRENCHUsed for removing and installing the oil filter.

(Outer diameter: 65 mm (2.56 in))

499587100 OIL SEAL

INSTALLERUsed for installing oil pump oil seal.

499587600 OIL SEAL

INSTALLERUsed for installing camshaft oil seal for DOHC

engine.

499597200 OIL SEAL GUIDE Used for installing camshaft oil seal for DOHC

engine.

Used with OIL SEAL GUIDE (499587600). ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST18332AA010

ST-499587100

ST-499587600

ST-499597200

Page 1486 of 2870

ME(H4DOTC)-30

MECHANICAL

General Description

2. GENERAL TOOL

E: PROCEDURE

It is possible to conduct the following service proce-

dures with engine on the vehicle, however, the pro-

cedures described in this section are based on the

condition that the engine is removed from the vehi-

cle.

V-belt

Timing Belt

Camshaft

Cylinder Head

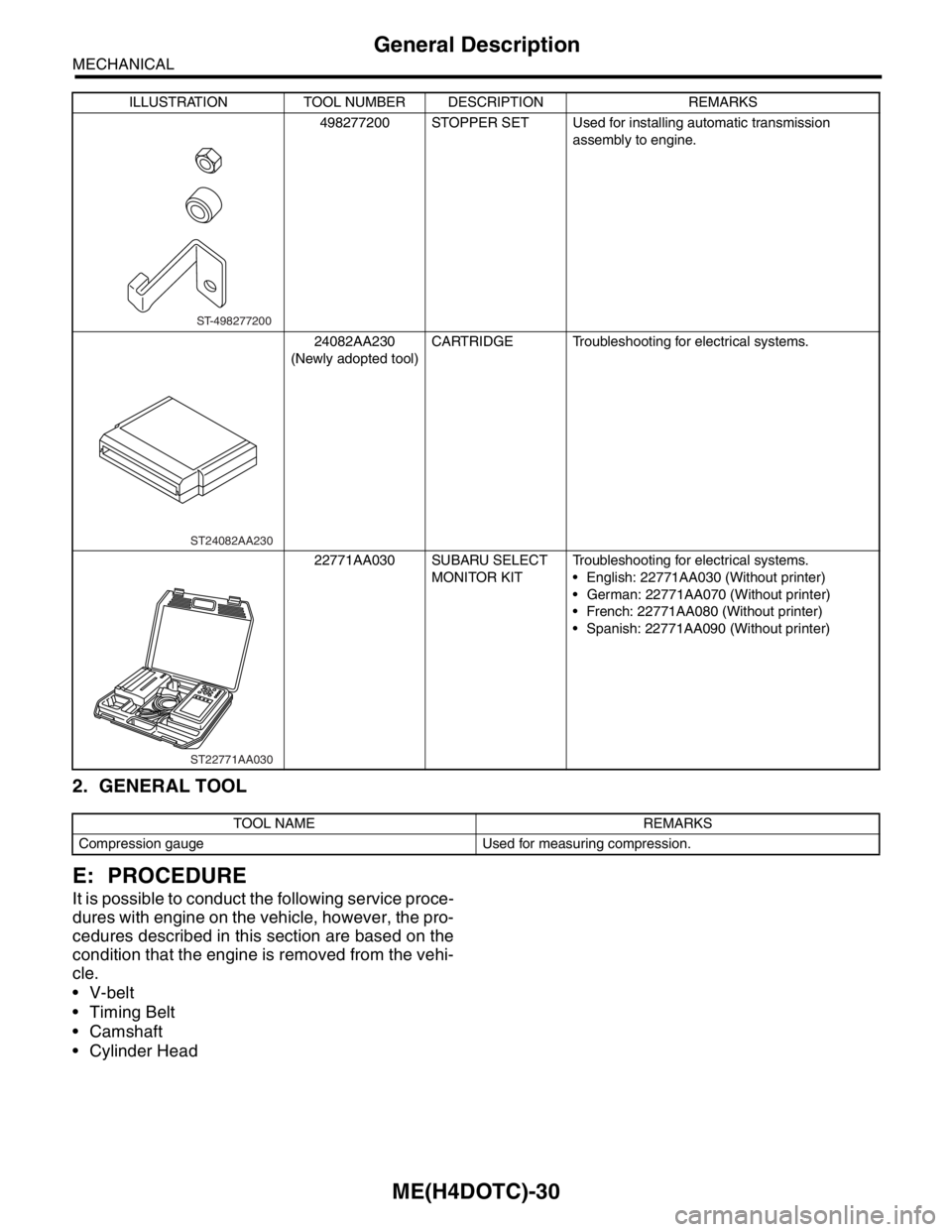

498277200 STOPPER SET Used for installing automatic transmission

assembly to engine.

24082AA230

(Newly adopted tool)CARTRIDGE Troubleshooting for electrical systems.

22771AA030 SUBARU SELECT

MONITOR KITTroubleshooting for electrical systems.

English: 22771AA030 (Without printer)

German: 22771AA070 (Without printer)

French: 22771AA080 (Without printer)

Spanish: 22771AA090 (Without printer)

TOOL NAME REMARKS

Compression gauge Used for measuring compression.ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-498277200

ST24082AA230

ST22771AA030

Page 1487 of 2870

ME(H4DOTC)-31

MECHANICAL

Compression

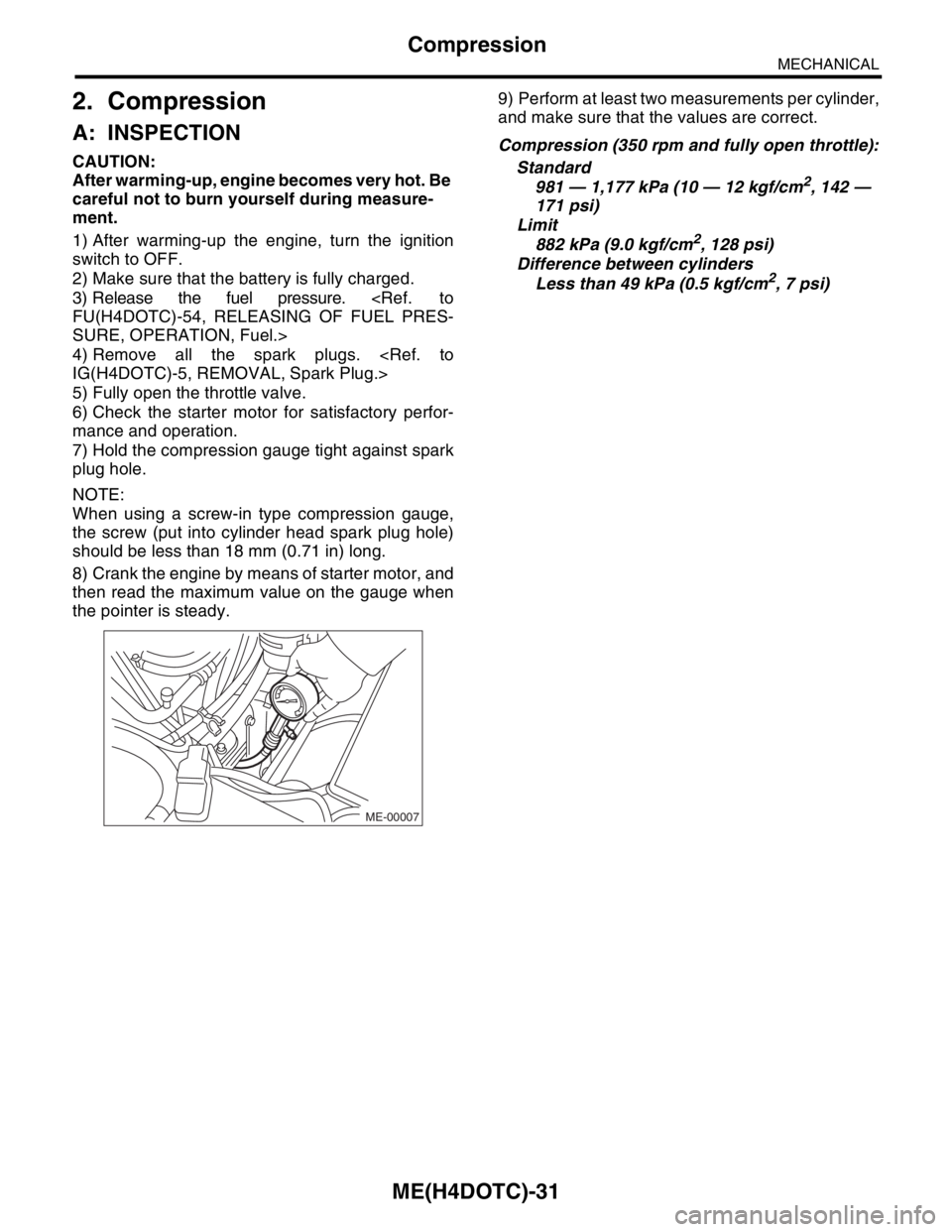

2. Compression

A: INSPECTION

CAUTION:

After warming-up, engine becomes very hot. Be

careful not to burn yourself during measure-

ment.

1) After warming-up the engine, turn the ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Release the fuel pressure.

SURE, OPERATION, Fuel.>

4) Remove all the spark plugs.

5) Fully open the throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against spark

plug hole.

NOTE:

When using a screw-in type compression gauge,

the screw (put into cylinder head spark plug hole)

should be less than 18 mm (0.71 in) long.

8) Crank the engine by means of starter motor, and

then read the maximum value on the gauge when

the pointer is steady.9) Perform at least two measurements per cylinder,

and make sure that the values are correct.

Compression (350 rpm and fully open throttle):

Standard

981 — 1,177 kPa (10 — 12 kgf/cm

2, 142 —

171 psi)

Limit

882 kPa (9.0 kgf/cm

2, 128 psi)

Difference between cylinders

Less than 49 kPa (0.5 kgf/cm

2, 7 psi)

ME-00007

Page 1488 of 2870

ME(H4DOTC)-32

MECHANICAL

Idle Speed

3. Idle Speed

A: INSPECTION

1. USING SUBARU SELECT MONITOR

1) Before checking the idle speed, check the fol-

lowing:

(1) Ensure the air cleaner element is free from

clogging, ignition timing is correct, spark plugs

are in good condition, and that the hoses are

connected properly.

(2) Ensure the malfunction indicator light does

not illuminate.

2) Warm-up the engine.

3) Stop the engine, and then turn the ignition switch

to OFF.

4) Insert the cartridge to Subaru Select Monitor.

5) Connect the Subaru Select Monitor to data link

connector.

6) Turn the ignition switch to ON, and Subaru Se-

lect Monitor switch to ON.

7) Select the {2. Each System Check} in Main

Menu.

8) Select the {Engine Control System} in Selection

Menu.

9) Select the {1. Current Data Display & Save} in

Engine Control System Diagnosis.

10) Select the {1.12 Data Display} in Data Display

Menu.

11) Start the engine, and then read the engine idle

speed.

12) Check the idle speed when unloaded. (With

headlights, heater fan, rear defroster, radiator fan,

air conditioning, etc. OFF)

Idle speed [No load and gears in neutral]:

700

±100 rpm

13) Check the idle speed when loaded. (Turn the

air conditioning switch to “ON” and operate the

compressor for at least 1 minute before measure-

ment.)

Idle speed [A/C “ON”, no load and gears in neu-

tral]:

A/C Refrigerant pressure (LOW)

MT: 725

±100 rpm

AT: 750

±100 rpm

A/C Refrigerant pressure (HIGH)

MT: 800

±100 rpm

AT: 825

±100 rpm

NOTE:

As idle speed is controlled by the automatic adjust-

ment type, it can not be adjusted manually. If the

idle speed is out of specifications, refer to General

On-board Diagnosis Table under “Engine Control

System”.

Page 1489 of 2870

ME(H4DOTC)-33

MECHANICAL

Ignition Timing

4. Ignition Timing

A: INSPECTION

1. USING SUBARU SELECT MONITOR

1) Before checking the ignition timing speed, check

the following:

(1) Ensure the air cleaner element is free from

clogging, spark plugs are in good condition, and

that hoses are connected properly.

(2) Ensure the malfunction indicator light does

not illuminate.

2) Warm-up the engine.

3) Stop the engine, and then turn the ignition switch

to OFF.

4) Insert the cartridge to Subaru Select Monitor.

5) Connect the Subaru Select Monitor to data link

connector.

6) Turn the ignition switch to ON, and Subaru Se-

lect Monitor switch to ON.

7) Select the {2. Each System Check} in Main

Menu.

8) Select the {Engine Control System} in Selection

Menu.

9) Select the {1. Current Data Display & Save} in

Engine Control System Diagnosis.

10) Select the {1.12 Data Display} in Data Display

Menu.

11) Start the engine and check the ignition timing at

idle speed.

Ignition timing [BTDC/rpm]:

2.0 L model

12

°±10°/700

2.5 L model

17

°±10°/700

If the timing is not correct, check the ignition control

system. Refer to Engine Control System.

Page 1490 of 2870

ME(H4DOTC)-34

MECHANICAL

Intake Manifold Vacuum

5. Intake Manifold Vacuum

A: INSPECTION

1) Warm-up the engine.

2) Disconnect the brake vacuum hose, and then in-

stall the vacuum gauge to hose fitting on manifold.

3) Keep the engine at the idle speed, and then read

the vacuum gauge indication.

By observing the gauge needle movement, the in-

ternal condition of engine can be diagnosed as de-

scribed below.

Vacuum pressure (at idling, A/C “OFF”):

Less than

−60.0 kPa (−450 mmHg, −17.72 inHg)

ME-00008

Diagnosis of engine condition by measurement of manifold vacuum

Vacuum gauge indication Possible engine condition

1. Needle is steady but lower than normal position. This ten-

dency becomes more evident as engine temperature rises.Leakage around intake manifold gasket or disconnection or

damaged vacuum hose

2. When engine speed is reduced slowly from higher speed,

needle stops temporarily when it is lowering or becomes steady

above normal position.Back pressure too high, or exhaust system clogged

3. Needle intermittently drops to position lower than normal

position.Leakage around cylinder

4. Needle drops suddenly and intermittently from normal posi-

tion.Sticky valves

5. When engine speed is gradually increased, needle begins to

vibrate rapidly at certain speed, and then vibration increases as

engine speed increases.Weak or broken valve springs

6. Needle vibrates above and below normal position in narrow

range.Defective ignition system or throttle chamber idle adjustment