SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1521 of 2870

ME(H4DOTC)-63

MECHANICAL

Timing Belt Assembly

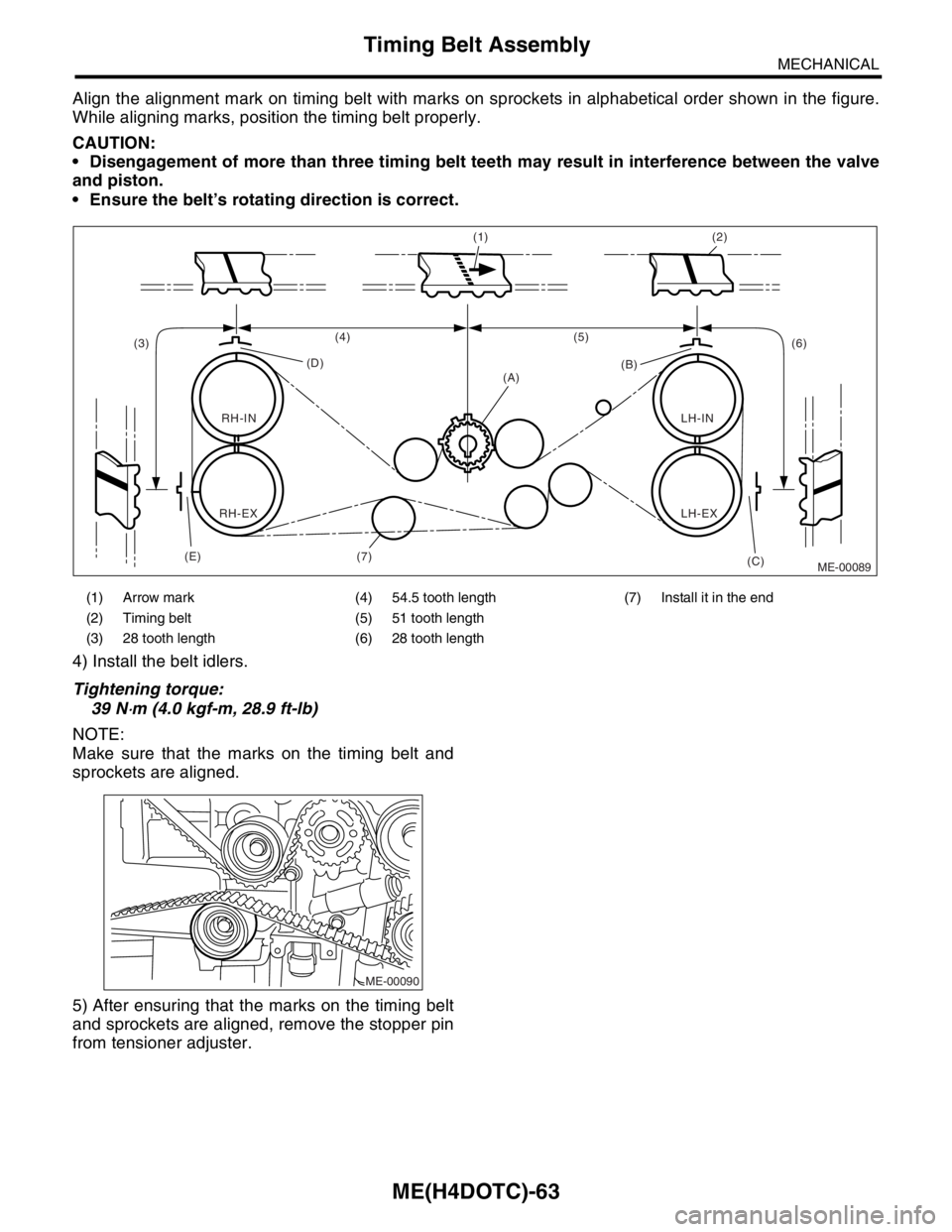

Align the alignment mark on timing belt with marks on sprockets in alphabetical order shown in the figure.

While aligning marks, position the timing belt properly.

CAUTION:

Disengagement of more than three timing belt teeth may result in interference between the valve

and piston.

Ensure the belt’s rotating direction is correct.

4) Install the belt idlers.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

NOTE:

Make sure that the marks on the timing belt and

sprockets are aligned.

5) After ensuring that the marks on the timing belt

and sprockets are aligned, remove the stopper pin

from tensioner adjuster.

(1) Arrow mark (4) 54.5 tooth length (7) Install it in the end

(2) Timing belt (5) 51 tooth length

(3) 28 tooth length (6) 28 tooth length

ME-00089 (1) (2)

(5)

(6) (4)

(D)

(A)

(C) (B)

(E) (3)

RH-IN

RH-EXLH-EX LH-IN

(7)

ME-00090

Page 1522 of 2870

ME(H4DOTC)-64

MECHANICAL

Timing Belt Assembly

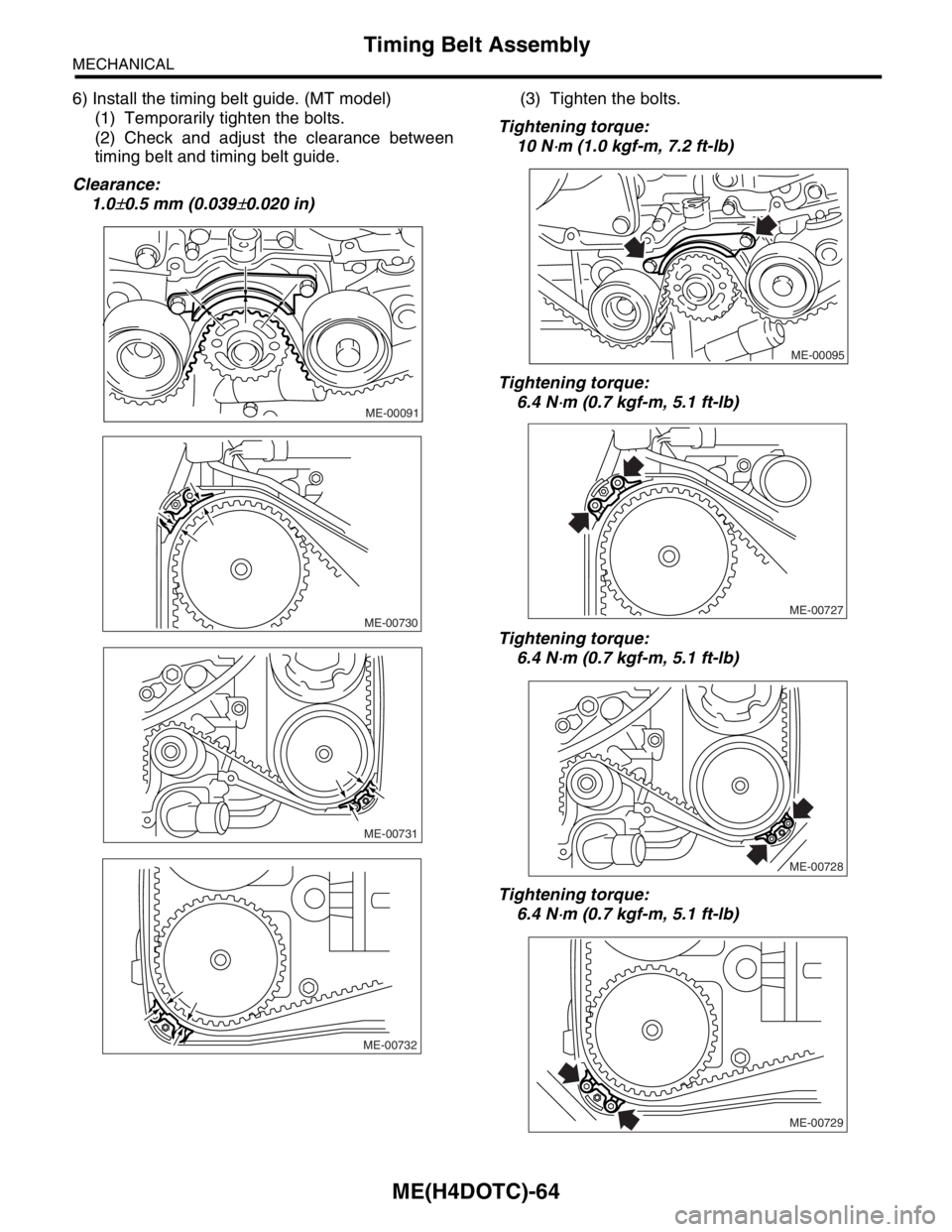

6) Install the timing belt guide. (MT model)

(1) Temporarily tighten the bolts.

(2) Check and adjust the clearance between

timing belt and timing belt guide.

Clearance:

1.0

±0.5 mm (0.039±0.020 in)(3) Tighten the bolts.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

Tightening torque:

6.4 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

Tightening torque:

6.4 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

Tightening torque:

6.4 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

ME-00091

ME-00730

ME-00731

ME-00732

ME-00095

ME-00727

ME-00728

ME-00729

Page 1523 of 2870

ME(H4DOTC)-65

MECHANICAL

Timing Belt Assembly

7) Install the timing belt cover.

Cover.>

8) Install the crank pulley.

9) Install the V-belt.

C: INSPECTION

1. TIMING BELT

1) Check the timing belt teeth for breaks, cracks,

and wear. If any fault is found, replace the belt.

2) Check the condition of back side of belt; if any

crack is found, replace the belt.

NOTE:

Be careful not to let oil, grease or coolant contact

the belt. Remove quickly and thoroughly if this hap-

pens.

Do not bend the belt sharply.

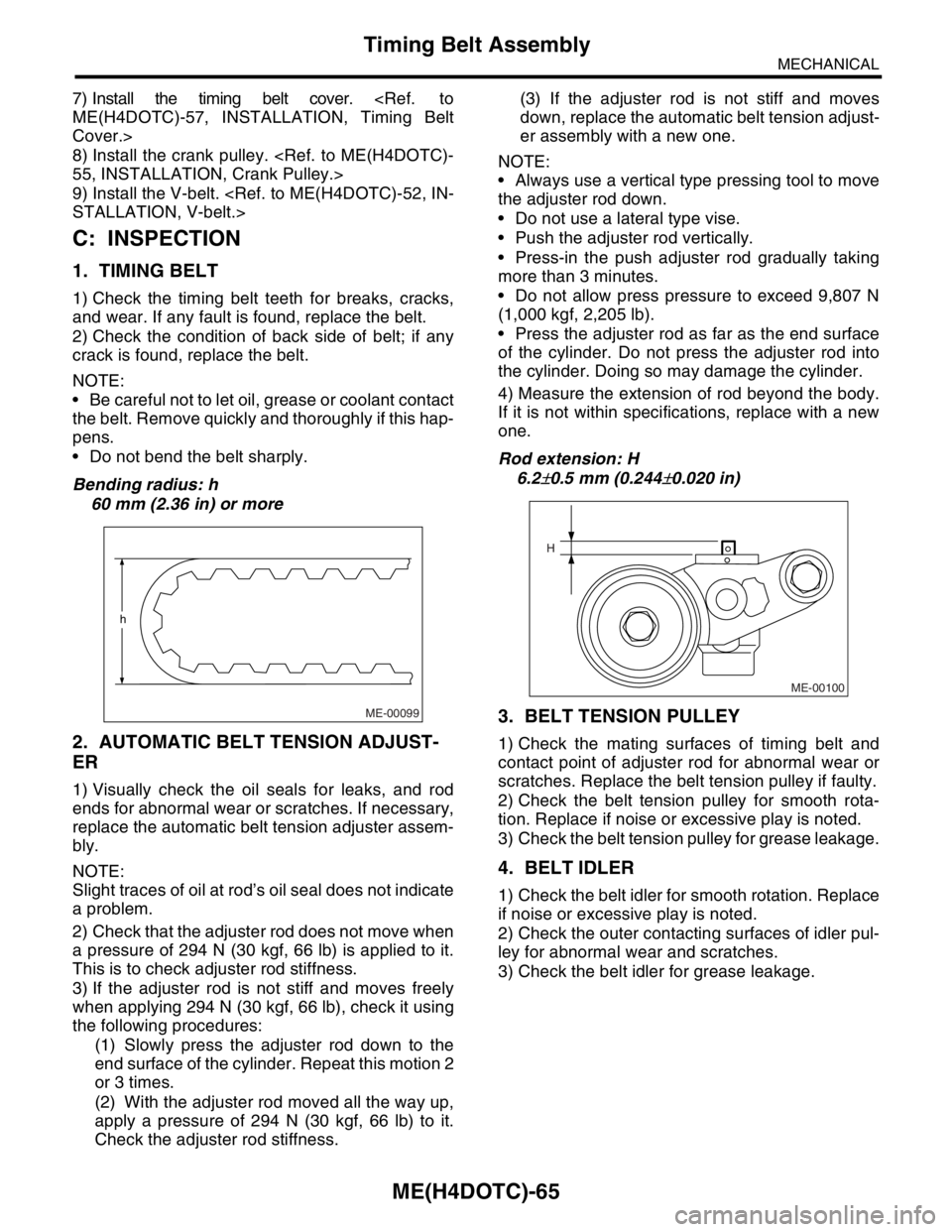

Bending radius: h

60 mm (2.36 in) or more

2. AUTOMATIC BELT TENSION ADJUST-

ER

1) Visually check the oil seals for leaks, and rod

ends for abnormal wear or scratches. If necessary,

replace the automatic belt tension adjuster assem-

bly.

NOTE:

Slight traces of oil at rod’s oil seal does not indicate

a problem.

2) Check that the adjuster rod does not move when

a pressure of 294 N (30 kgf, 66 lb) is applied to it.

This is to check adjuster rod stiffness.

3) If the adjuster rod is not stiff and moves freely

when applying 294 N (30 kgf, 66 lb), check it using

the following procedures:

(1) Slowly press the adjuster rod down to the

end surface of the cylinder. Repeat this motion 2

or 3 times.

(2) With the adjuster rod moved all the way up,

apply a pressure of 294 N (30 kgf, 66 lb) to it.

Check the adjuster rod stiffness.(3) If the adjuster rod is not stiff and moves

down, replace the automatic belt tension adjust-

er assembly with a new one.

NOTE:

Always use a vertical type pressing tool to move

the adjuster rod down.

Do not use a lateral type vise.

Push the adjuster rod vertically.

Press-in the push adjuster rod gradually taking

more than 3 minutes.

Do not allow press pressure to exceed 9,807 N

(1,000 kgf, 2,205 lb).

Press the adjuster rod as far as the end surface

of the cylinder. Do not press the adjuster rod into

the cylinder. Doing so may damage the cylinder.

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

6.2

±0.5 mm (0.244±0.020 in)

3. BELT TENSION PULLEY

1) Check the mating surfaces of timing belt and

contact point of adjuster rod for abnormal wear or

scratches. Replace the belt tension pulley if faulty.

2) Check the belt tension pulley for smooth rota-

tion. Replace if noise or excessive play is noted.

3) Check the belt tension pulley for grease leakage.

4. BELT IDLER

1) Check the belt idler for smooth rotation. Replace

if noise or excessive play is noted.

2) Check the outer contacting surfaces of idler pul-

ley for abnormal wear and scratches.

3) Check the belt idler for grease leakage.

ME-00099

h

ME-00100

H

Page 1524 of 2870

ME(H4DOTC)-66

MECHANICAL

Cam Sprocket

16.Cam Sprocket

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt assembly.

bly.>

5) Remove the camshaft position sensor. (2.0 L

model)

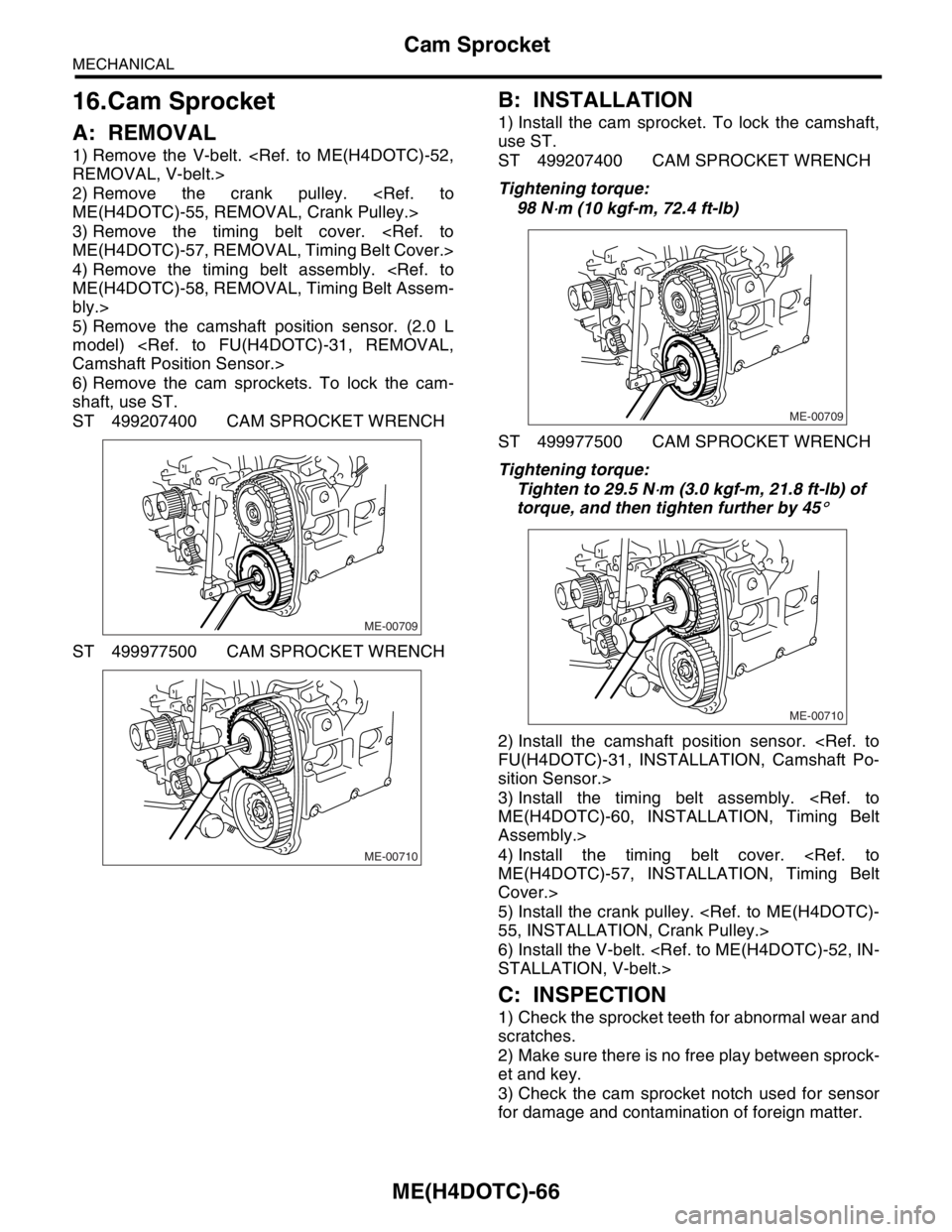

6) Remove the cam sprockets. To lock the cam-

shaft, use ST.

ST 499207400 CAM SPROCKET WRENCH

ST 499977500 CAM SPROCKET WRENCH

B: INSTALLATION

1) Install the cam sprocket. To lock the camshaft,

use ST.

ST 499207400 CAM SPROCKET WRENCH

Tightening torque:

98 N

⋅m (10 kgf-m, 72.4 ft-lb)

ST 499977500 CAM SPROCKET WRENCH

Tightening torque:

Tighten to 29.5 N

⋅m (3.0 kgf-m, 21.8 ft-lb) of

torque, and then tighten further by 45

°

2) Install the camshaft position sensor.

sition Sensor.>

3) Install the timing belt assembly.

Assembly.>

4) Install the timing belt cover.

Cover.>

5) Install the crank pulley.

6) Install the V-belt.

C: INSPECTION

1) Check the sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between sprock-

et and key.

3) Check the cam sprocket notch used for sensor

for damage and contamination of foreign matter.

ME-00709

ME-00710

ME-00709

ME-00710

Page 1525 of 2870

ME(H4DOTC)-67

MECHANICAL

Crank Sprocket

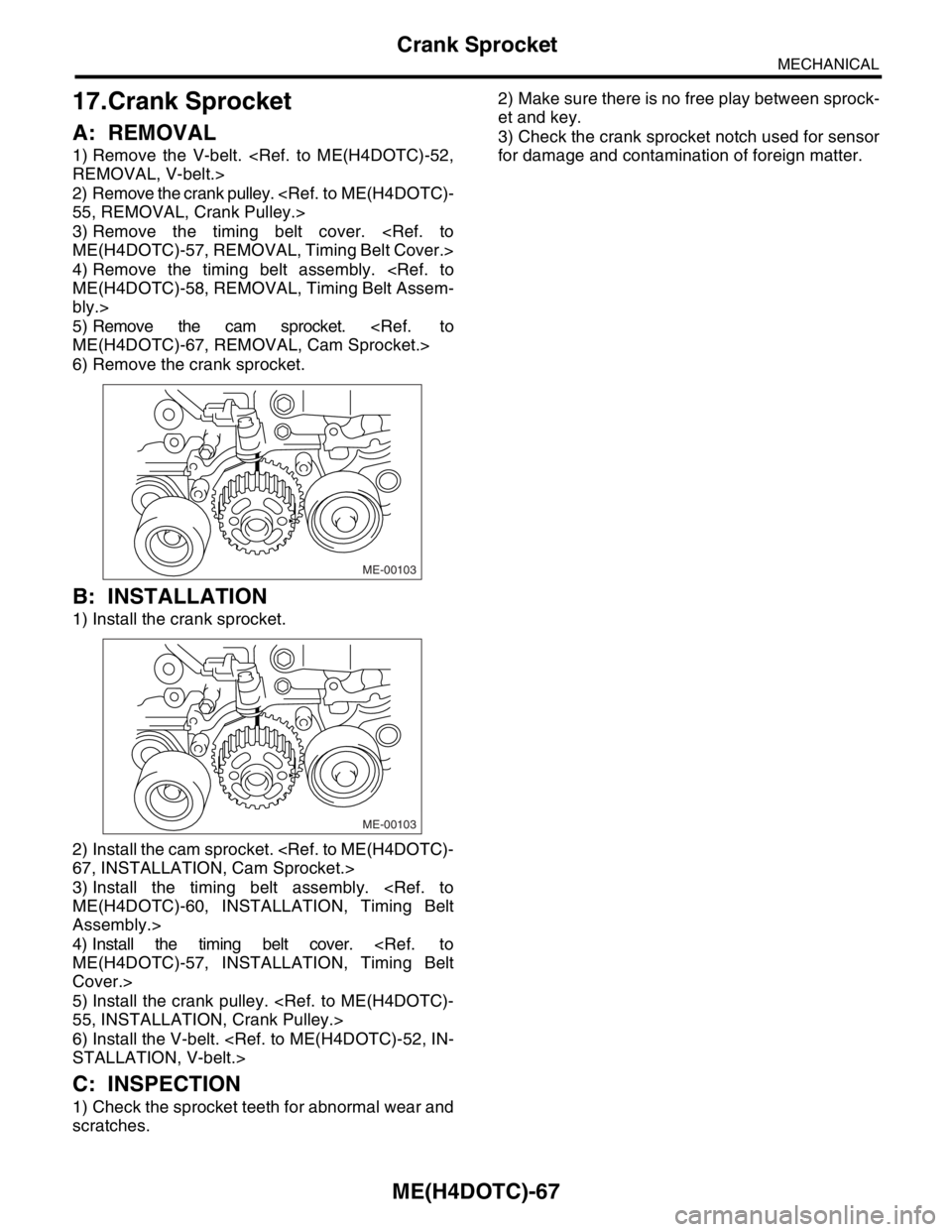

17.Crank Sprocket

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt assembly.

bly.>

5) Remove the cam sprocket.

6) Remove the crank sprocket.

B: INSTALLATION

1) Install the crank sprocket.

2) Install the cam sprocket.

3) Install the timing belt assembly.

Assembly.>

4) Install the timing belt cover.

Cover.>

5) Install the crank pulley.

6) Install the V-belt.

C: INSPECTION

1) Check the sprocket teeth for abnormal wear and

scratches.2) Make sure there is no free play between sprock-

et and key.

3) Check the crank sprocket notch used for sensor

for damage and contamination of foreign matter.

ME-00103

ME-00103

Page 1526 of 2870

ME(H4DOTC)-68

MECHANICAL

Camshaft

18.Camshaft

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt assembly.

bly.>

5) Remove the cam sprocket.

6) Remove the crank sprocket.

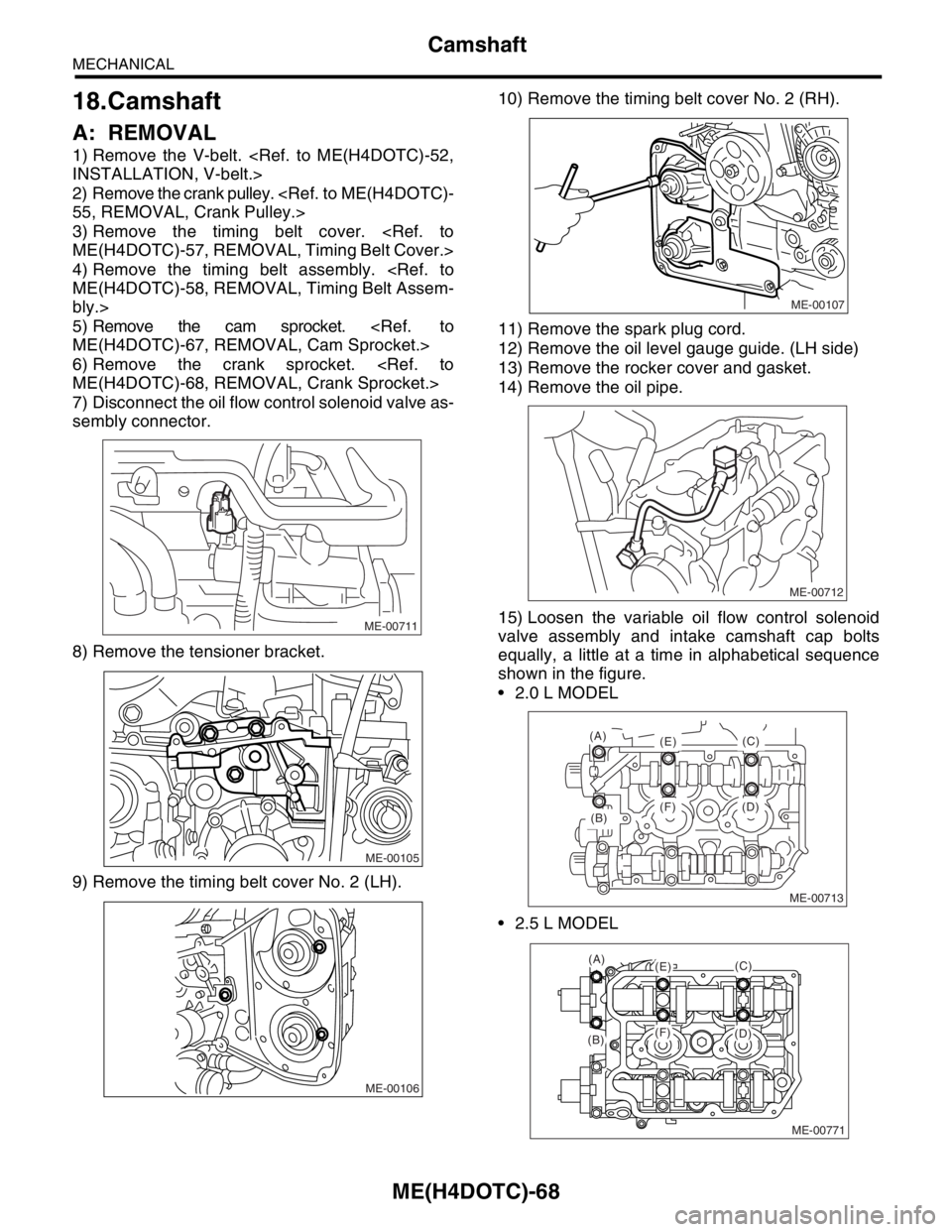

7) Disconnect the oil flow control solenoid valve as-

sembly connector.

8) Remove the tensioner bracket.

9) Remove the timing belt cover No. 2 (LH).10) Remove the timing belt cover No. 2 (RH).

11) Remove the spark plug cord.

12) Remove the oil level gauge guide. (LH side)

13) Remove the rocker cover and gasket.

14) Remove the oil pipe.

15) Loosen the variable oil flow control solenoid

valve assembly and intake camshaft cap bolts

equally, a little at a time in alphabetical sequence

shown in the figure.

2.0 L MODEL

2.5 L MODEL

ME-00711

ME-00105

ME-00106

ME-00107

ME-00712

ME-00713

(B)

(A)

(E)

(F) (D)(C)

ME-00771

(A)(E)

(F)(B)(D)

(C)

Page 1527 of 2870

ME(H4DOTC)-69

MECHANICAL

Camshaft

16) Remove the oil flow control solenoid valve as-

sembly, intake camshaft cap, and camshaft.

17) Loosen the exhaust camshaft cap bolts equal-

ly, a little at a time in alphabetical sequence shown

in the figure.

2.0 L MODEL

2.5 L MODEL

18) Remove the exhaust camshaft cap and cam-

shaft.

NOTE:

Arrange the camshaft caps in order so that they

can be installed in their original positions.

19) Similarly, remove the camshafts (RH) and re-

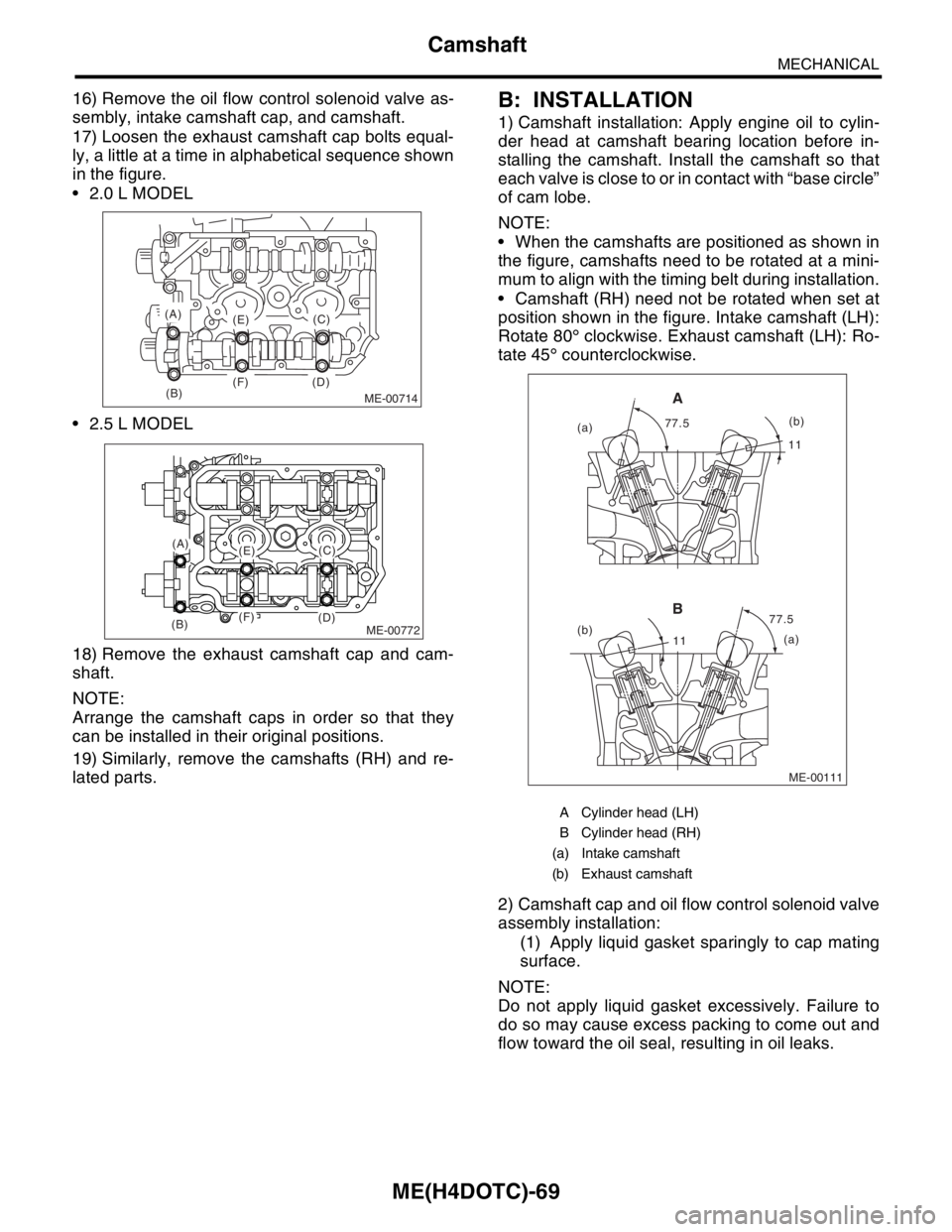

lated parts.B: INSTALLATION

1) Camshaft installation: Apply engine oil to cylin-

der head at camshaft bearing location before in-

stalling the camshaft. Install the camshaft so that

each valve is close to or in contact with “base circle”

of cam lobe.

NOTE:

When the camshafts are positioned as shown in

the figure, camshafts need to be rotated at a mini-

mum to align with the timing belt during installation.

Camshaft (RH) need not be rotated when set at

position shown in the figure. Intake camshaft (LH):

Rotate 80° clockwise. Exhaust camshaft (LH): Ro-

tate 45° counterclockwise.

2) Camshaft cap and oil flow control solenoid valve

assembly installation:

(1) Apply liquid gasket sparingly to cap mating

surface.

NOTE:

Do not apply liquid gasket excessively. Failure to

do so may cause excess packing to come out and

flow toward the oil seal, resulting in oil leaks.

ME-00714(B)

(A)

(E)

(F) (D)(C)

ME-00772

(A)(E)

(F)(B)(D)

(C)

A Cylinder head (LH)

B Cylinder head (RH)

(a) Intake camshaft

(b) Exhaust camshaft

ME-00111

1111

77.5 77.5

(a)

(b)

(a)(b)

A

B

Page 1528 of 2870

ME(H4DOTC)-70

MECHANICAL

Camshaft

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

2.0 L MODEL

2.5 L MODEL

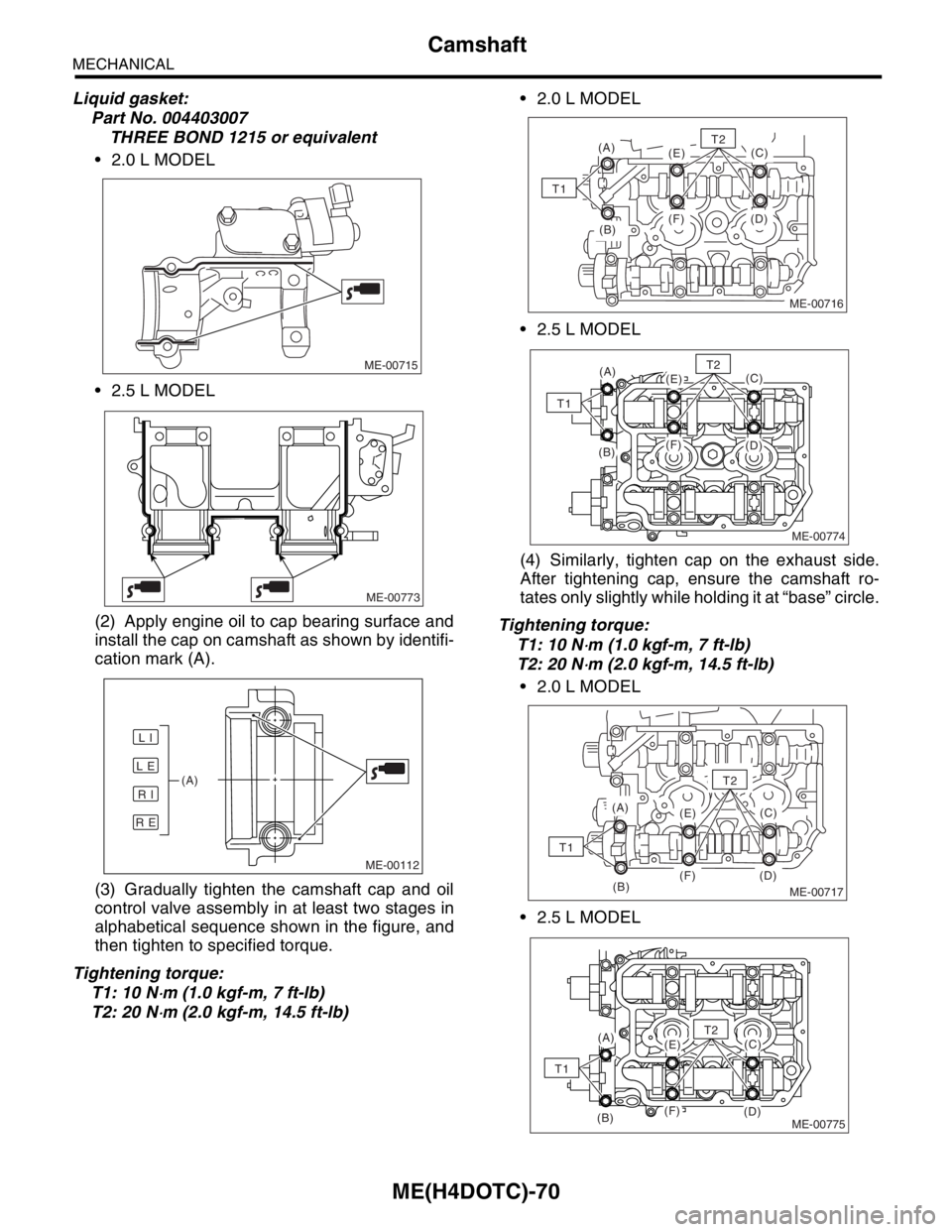

(2) Apply engine oil to cap bearing surface and

install the cap on camshaft as shown by identifi-

cation mark (A).

(3) Gradually tighten the camshaft cap and oil

control valve assembly in at least two stages in

alphabetical sequence shown in the figure, and

then tighten to specified torque.

Tightening torque:

T1: 10 N

⋅m (1.0 kgf-m, 7 ft-lb)

T2: 20 N

⋅m (2.0 kgf-m, 14.5 ft-lb) 2.0 L MODEL

2.5 L MODEL

(4) Similarly, tighten cap on the exhaust side.

After tightening cap, ensure the camshaft ro-

tates only slightly while holding it at “base” circle.

Tightening torque:

T1: 10 N

⋅m (1.0 kgf-m, 7 ft-lb)

T2: 20 N

⋅m (2.0 kgf-m, 14.5 ft-lb)

2.0 L MODEL

2.5 L MODEL

ME-00715

ME-00773

ME-00112

L E

R E

R I

L I

(A)

(B)

(A)

(E)

(F) (D)(C)

T1

ME-00716

T2

ME-00774

(A)(E)

(F)(B)(D)

(C)T2

T1

ME-00717(B)

(A)

(E)

(F) (D)(C)

T2

T1

ME-00775

(A)(E)

(F)(B)(D)

(C)T2

T1

Page 1529 of 2870

ME(H4DOTC)-71

MECHANICAL

Camshaft

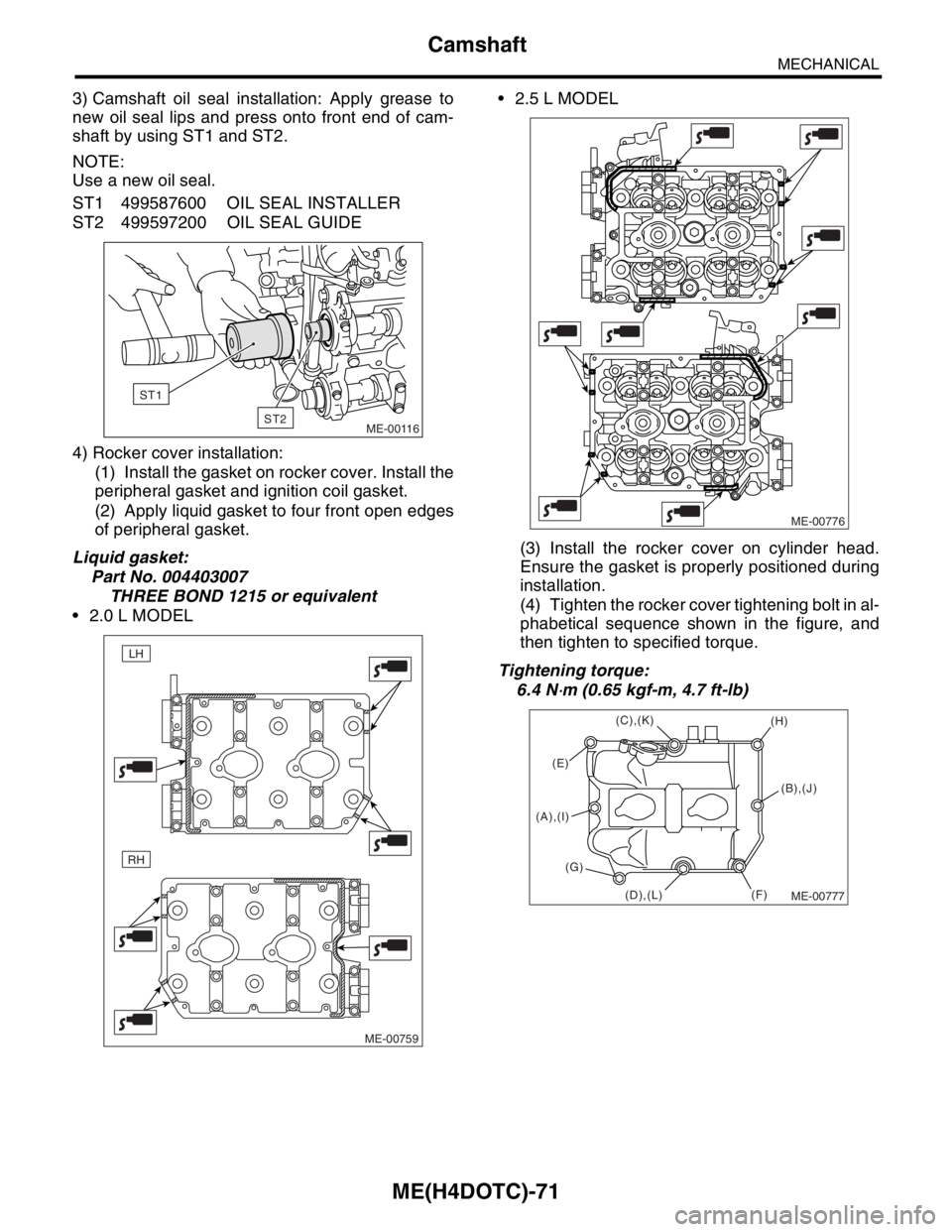

3) Camshaft oil seal installation: Apply grease to

new oil seal lips and press onto front end of cam-

shaft by using ST1 and ST2.

NOTE:

Use a new oil seal.

ST1 499587600 OIL SEAL INSTALLER

ST2 499597200 OIL SEAL GUIDE

4) Rocker cover installation:

(1) Install the gasket on rocker cover. Install the

peripheral gasket and ignition coil gasket.

(2) Apply liquid gasket to four front open edges

of peripheral gasket.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

2.0 L MODEL 2.5 L MODEL

(3) Install the rocker cover on cylinder head.

Ensure the gasket is properly positioned during

installation.

(4) Tighten the rocker cover tightening bolt in al-

phabetical sequence shown in the figure, and

then tighten to specified torque.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

ME-00116

ST1

ST2

ME-00759

RH

LH

ME-00776

ME-00777

(E)

(F)(H)

(G)

(D),(L) (A),(I)(C),(K)

(B),(J)

Page 1530 of 2870

ME(H4DOTC)-72

MECHANICAL

Camshaft

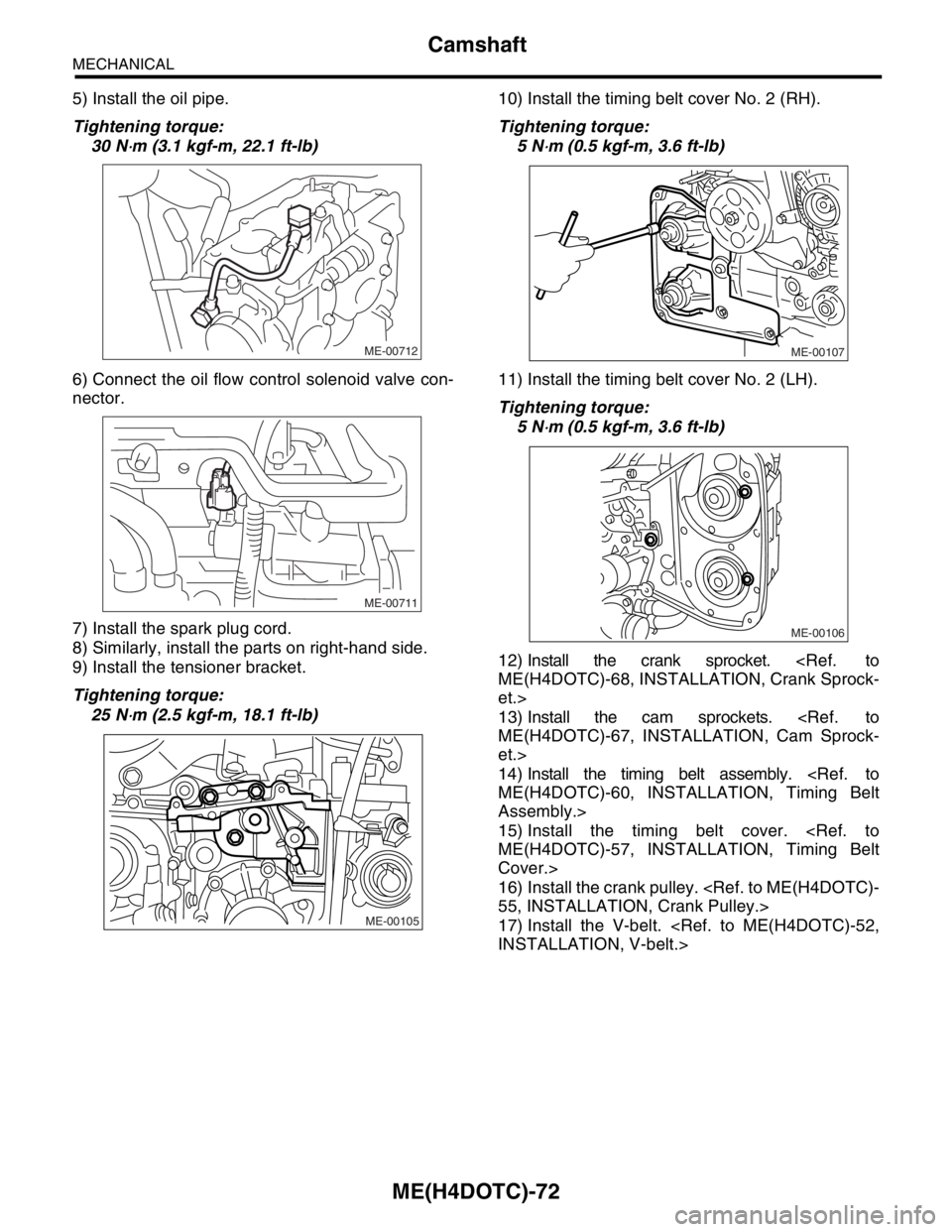

5) Install the oil pipe.

Tightening torque:

30 N

⋅m (3.1 kgf-m, 22.1 ft-lb)

6) Connect the oil flow control solenoid valve con-

nector.

7) Install the spark plug cord.

8) Similarly, install the parts on right-hand side.

9) Install the tensioner bracket.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)10) Install the timing belt cover No. 2 (RH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

11) Install the timing belt cover No. 2 (LH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

12) Install the crank sprocket.

et.>

13) Install the cam sprockets.

et.>

14) Install the timing belt assembly.

Assembly.>

15) Install the timing belt cover.

Cover.>

16) Install the crank pulley.

17) Install the V-belt.

ME-00712

ME-00711

ME-00105

ME-00107

ME-00106