SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1511 of 2870

ME(H4DOTC)-53

MECHANICAL

V-belt

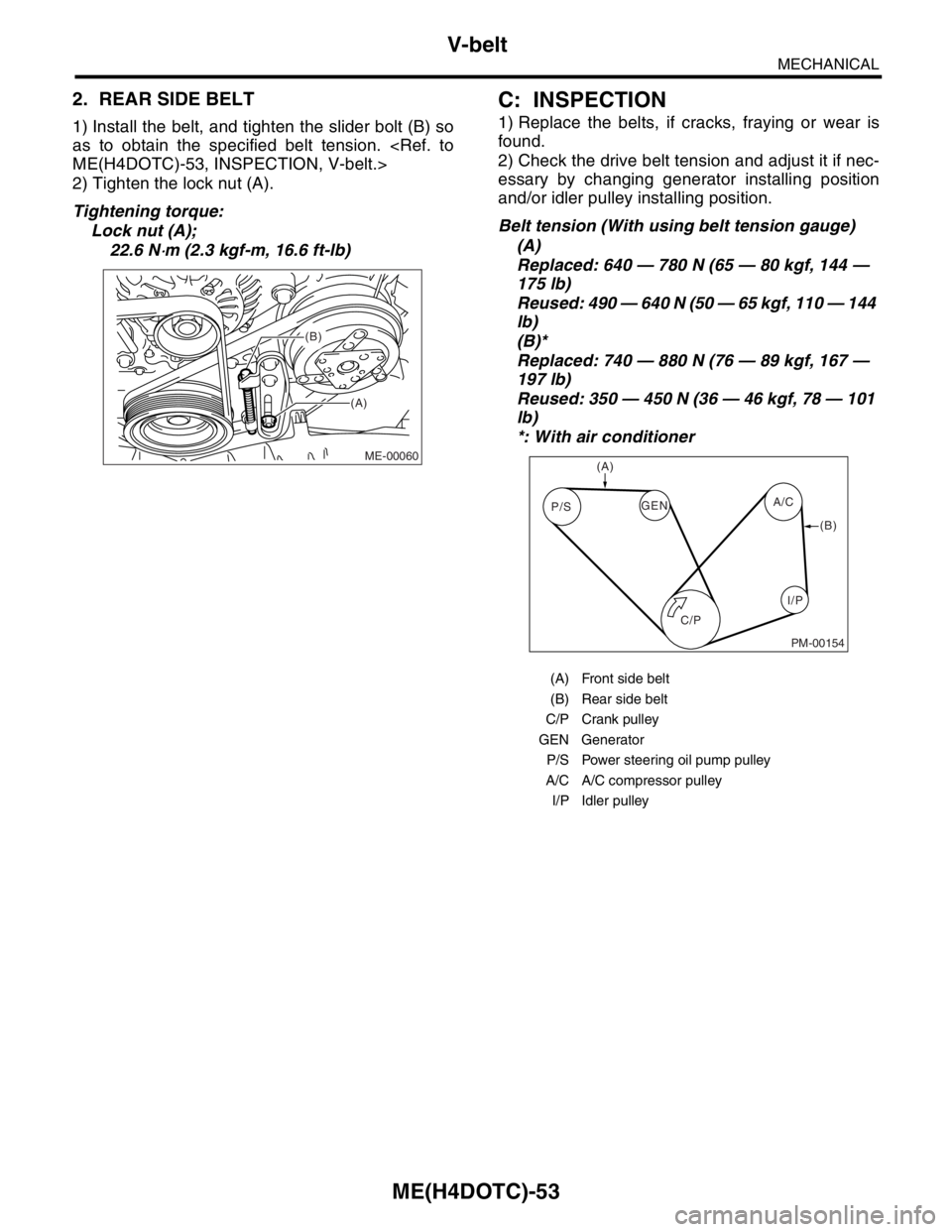

2. REAR SIDE BELT

1) Install the belt, and tighten the slider bolt (B) so

as to obtain the specified belt tension.

2) Tighten the lock nut (A).

Tightening torque:

Lock nut (A);

22.6 N

⋅m (2.3 kgf-m, 16.6 ft-lb)

C: INSPECTION

1) Replace the belts, if cracks, fraying or wear is

found.

2) Check the drive belt tension and adjust it if nec-

essary by changing generator installing position

and/or idler pulley installing position.

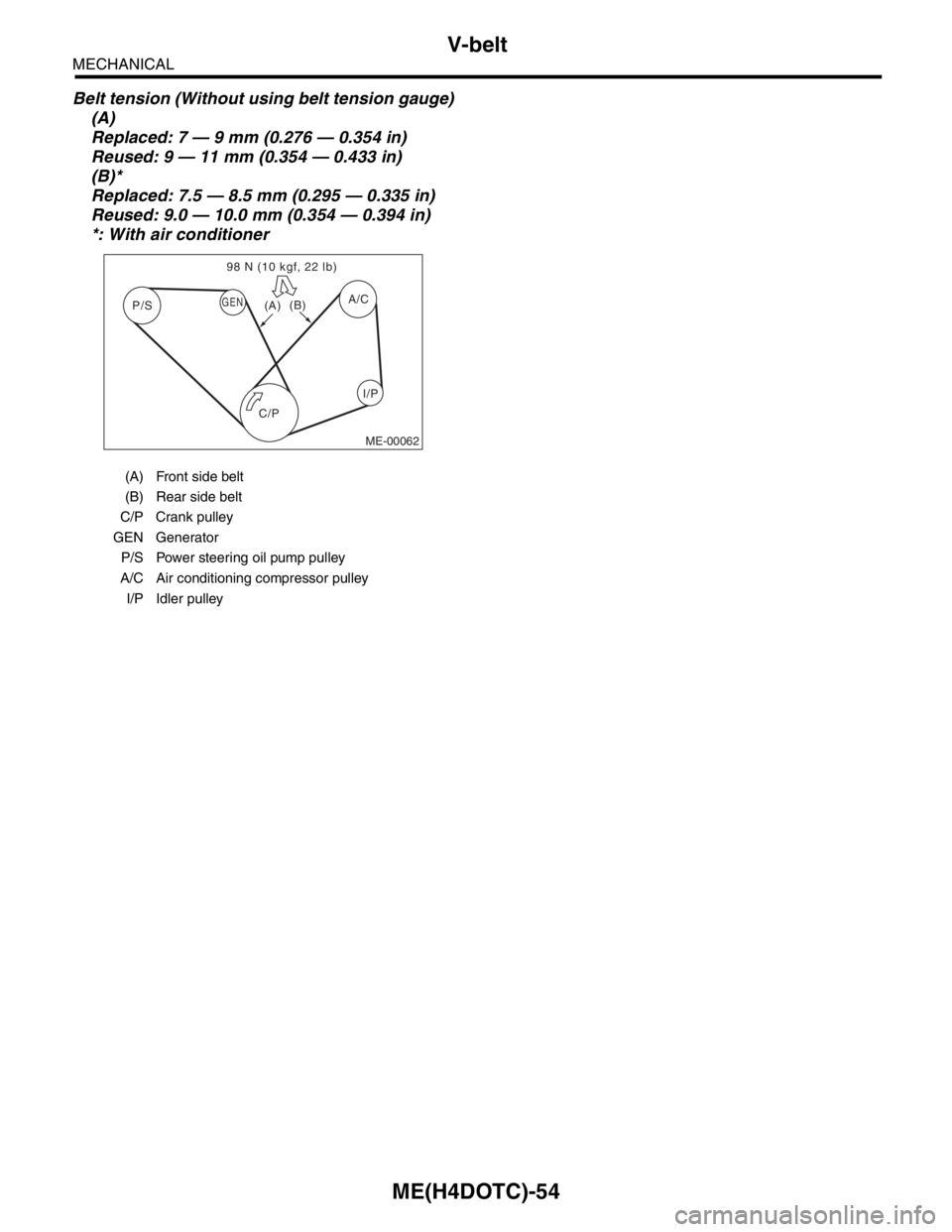

Belt tension (With using belt tension gauge)

(A)

Replaced: 640 — 780 N (65 — 80 kgf, 144 —

175 lb)

Reused: 490 — 640 N (50 — 65 kgf, 110 — 144

lb)

(B)*

Replaced: 740 — 880 N (76 — 89 kgf, 167 —

197 lb)

Reused: 350 — 450 N (36 — 46 kgf, 78 — 101

lb)

*: With air conditioner

(A)

(B)

ME-00060

(A) Front side belt

(B) Rear side belt

C/P Crank pulley

GEN Generator

P/S Power steering oil pump pulley

A/C A/C compressor pulley

I/P Idler pulley

C/P P/SA/C

GEN

(A)

(B)

I/P

PM-00154

Page 1512 of 2870

ME(H4DOTC)-54

MECHANICAL

V-belt

Belt tension (Without using belt tension gauge)

(A)

Replaced: 7 — 9 mm (0.276 — 0.354 in)

Reused: 9 — 11 mm (0.354 — 0.433 in)

(B)*

Replaced: 7.5 — 8.5 mm (0.295 — 0.335 in)

Reused: 9.0 — 10.0 mm (0.354 — 0.394 in)

*: With air conditioner

(A) Front side belt

(B) Rear side belt

C/P Crank pulley

GEN Generator

P/S Power steering oil pump pulley

A/C Air conditioning compressor pulley

I/P Idler pulley

ME-00062

P/S

C/PGEN

I/P A/C 98 N (10 kgf, 22 lb)

(A)(B)

Page 1513 of 2870

ME(H4DOTC)-55

MECHANICAL

Crank Pulley

13.Crank Pulley

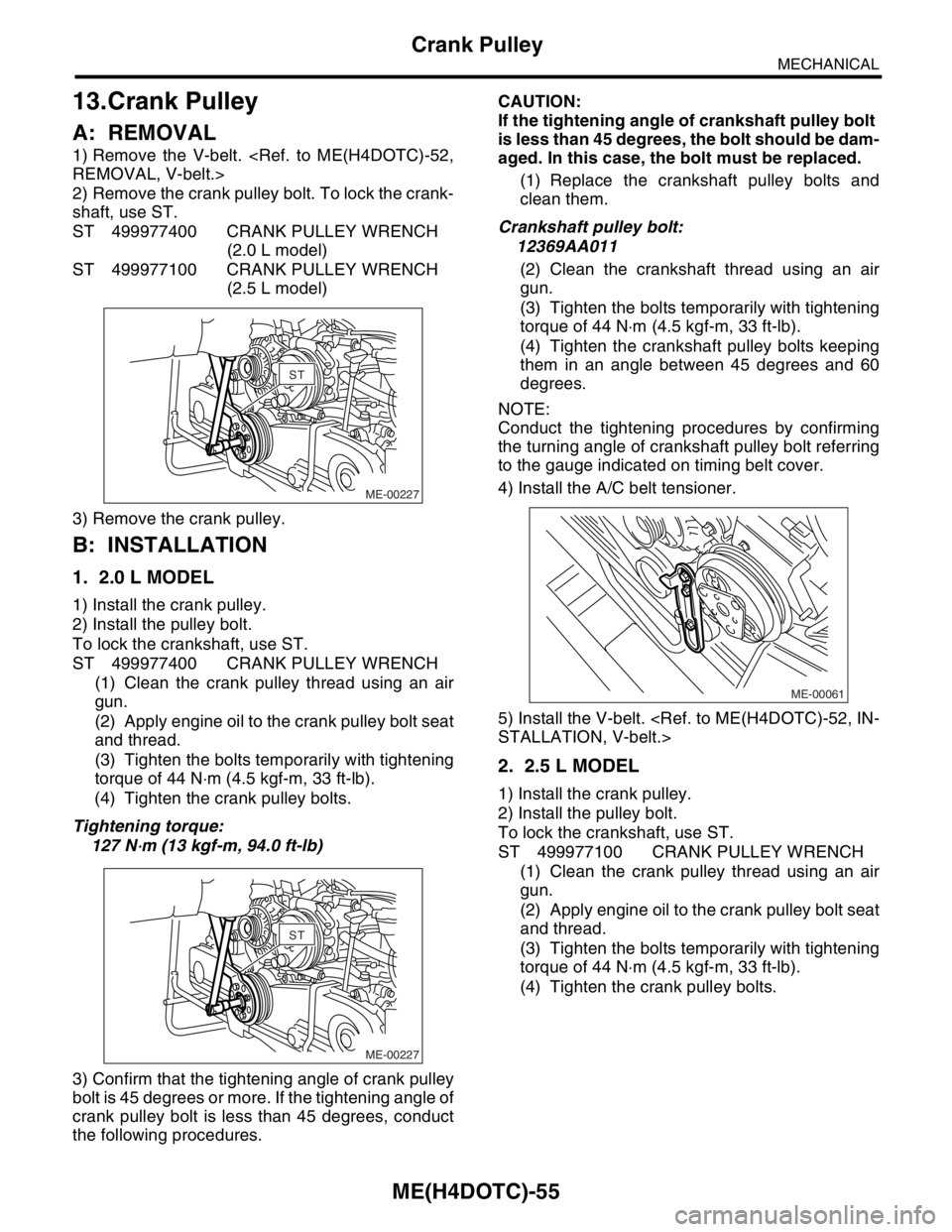

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley bolt. To lock the crank-

shaft, use ST.

ST 499977400 CRANK PULLEY WRENCH

(2.0 L model)

ST 499977100 CRANK PULLEY WRENCH

(2.5 L model)

3) Remove the crank pulley.

B: INSTALLATION

1. 2.0 L MODEL

1) Install the crank pulley.

2) Install the pulley bolt.

To lock the crankshaft, use ST.

ST 499977400 CRANK PULLEY WRENCH

(1) Clean the crank pulley thread using an air

gun.

(2) Apply engine oil to the crank pulley bolt seat

and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crank pulley bolts.

Tightening torque:

127 N

⋅m (13 kgf-m, 94.0 ft-lb)

3) Confirm that the tightening angle of crank pulley

bolt is 45 degrees or more. If the tightening angle of

crank pulley bolt is less than 45 degrees, conduct

the following procedures.CAUTION:

If the tightening angle of crankshaft pulley bolt

is less than 45 degrees, the bolt should be dam-

aged. In this case, the bolt must be replaced.

(1) Replace the crankshaft pulley bolts and

clean them.

Crankshaft pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crankshaft pulley bolts keeping

them in an angle between 45 degrees and 60

degrees.

NOTE:

Conduct the tightening procedures by confirming

the turning angle of crankshaft pulley bolt referring

to the gauge indicated on timing belt cover.

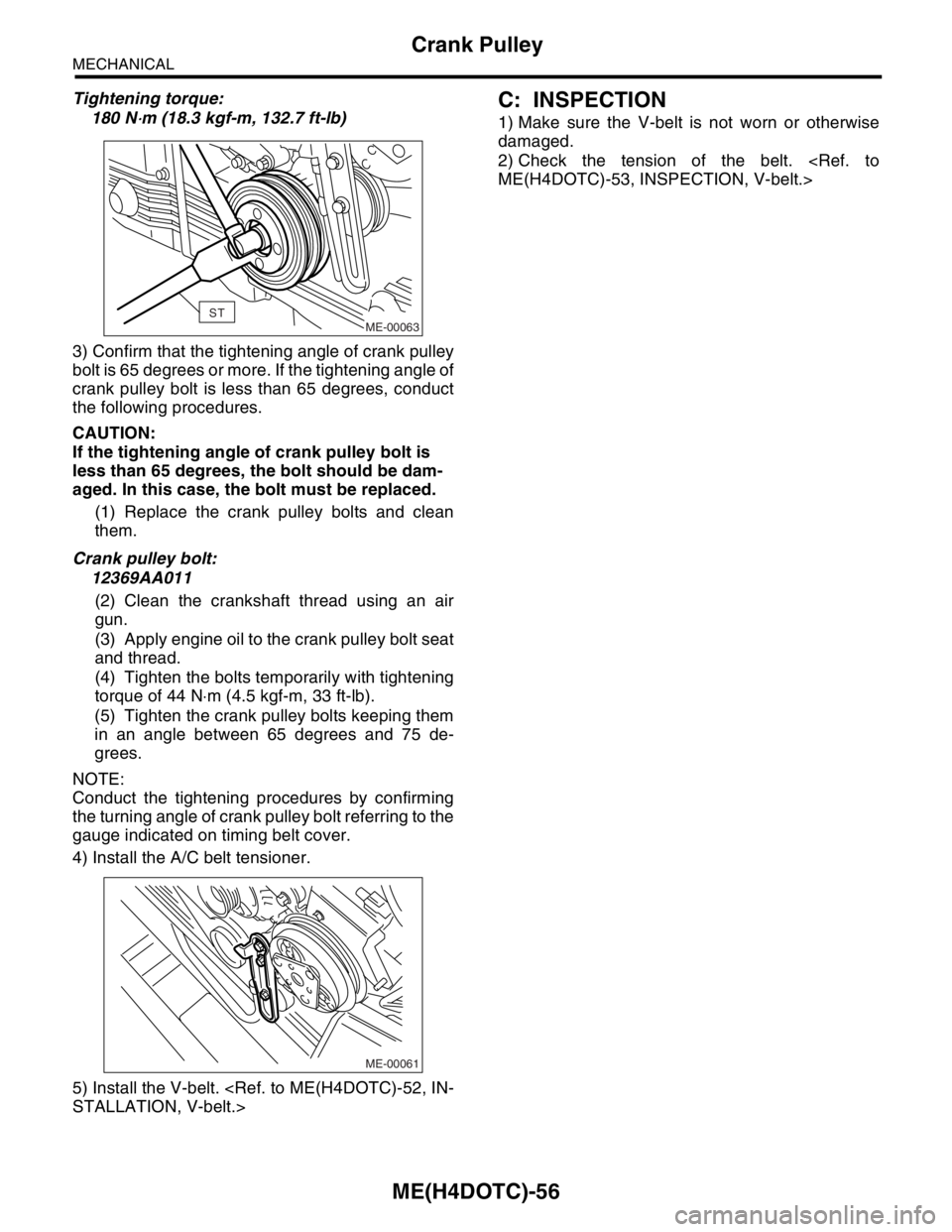

4) Install the A/C belt tensioner.

5) Install the V-belt.

2. 2.5 L MODEL

1) Install the crank pulley.

2) Install the pulley bolt.

To lock the crankshaft, use ST.

ST 499977100 CRANK PULLEY WRENCH

(1) Clean the crank pulley thread using an air

gun.

(2) Apply engine oil to the crank pulley bolt seat

and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crank pulley bolts.

ME-00227

STST

ME-00227

STST

ME-00061

Page 1514 of 2870

ME(H4DOTC)-56

MECHANICAL

Crank Pulley

Tightening torque:

180 N

⋅m (18.3 kgf-m, 132.7 ft-lb)

3) Confirm that the tightening angle of crank pulley

bolt is 65 degrees or more. If the tightening angle of

crank pulley bolt is less than 65 degrees, conduct

the following procedures.

CAUTION:

If the tightening angle of crank pulley bolt is

less than 65 degrees, the bolt should be dam-

aged. In this case, the bolt must be replaced.

(1) Replace the crank pulley bolts and clean

them.

Crank pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Apply engine oil to the crank pulley bolt seat

and thread.

(4) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(5) Tighten the crank pulley bolts keeping them

in an angle between 65 degrees and 75 de-

grees.

NOTE:

Conduct the tightening procedures by confirming

the turning angle of crank pulley bolt referring to the

gauge indicated on timing belt cover.

4) Install the A/C belt tensioner.

5) Install the V-belt.

C: INSPECTION

1) Make sure the V-belt is not worn or otherwise

damaged.

2) Check the tension of the belt.

ME-00063ST

ME-00061

Page 1515 of 2870

ME(H4DOTC)-57

MECHANICAL

Timing Belt Cover

14.Timing Belt Cover

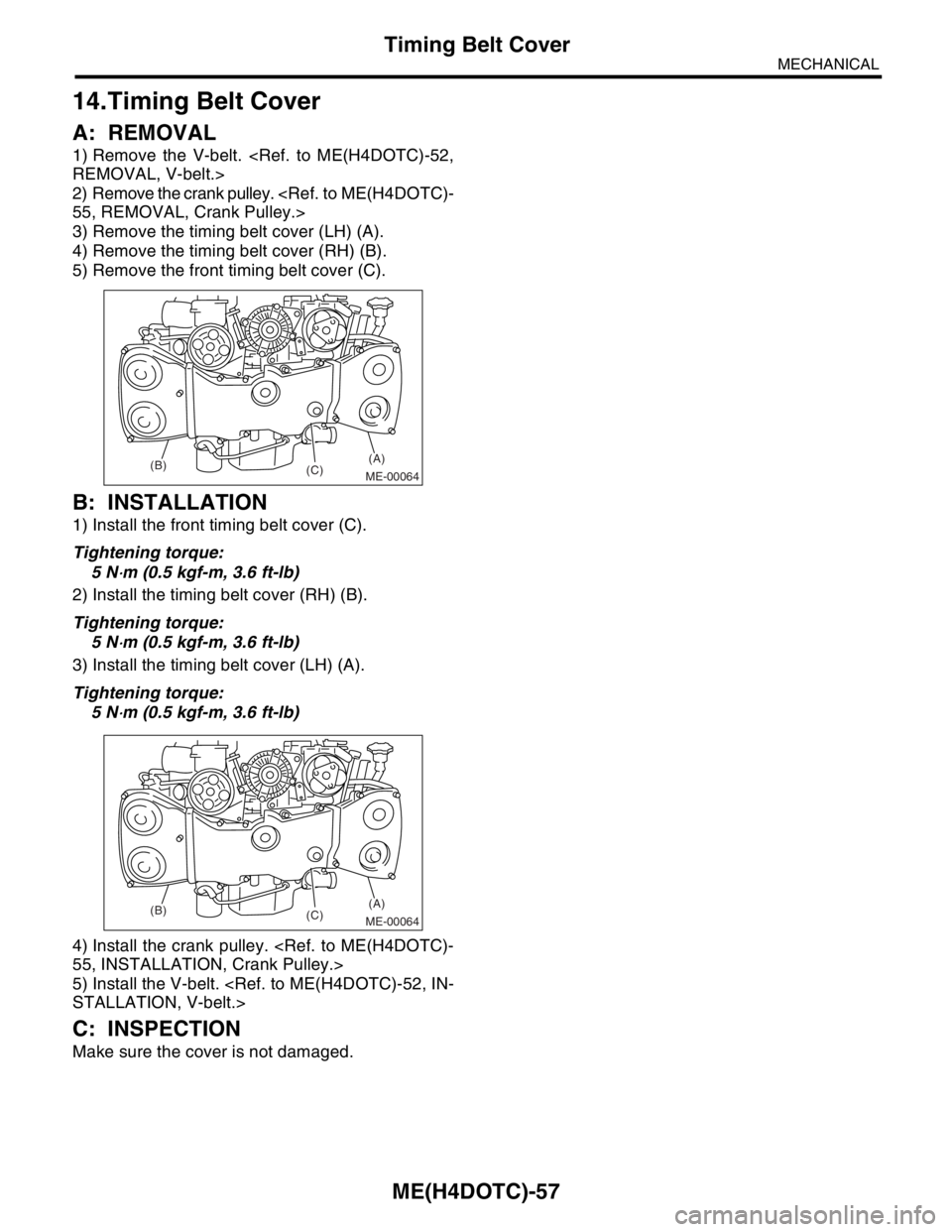

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover (LH) (A).

4) Remove the timing belt cover (RH) (B).

5) Remove the front timing belt cover (C).

B: INSTALLATION

1) Install the front timing belt cover (C).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

2) Install the timing belt cover (RH) (B).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

3) Install the timing belt cover (LH) (A).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

4) Install the crank pulley.

5) Install the V-belt.

C: INSPECTION

Make sure the cover is not damaged.

ME-00064

(A)

(C) (B)

ME-00064

(A)

(C) (B)

Page 1516 of 2870

ME(H4DOTC)-58

MECHANICAL

Timing Belt Assembly

15.Timing Belt Assembly

A: REMOVAL

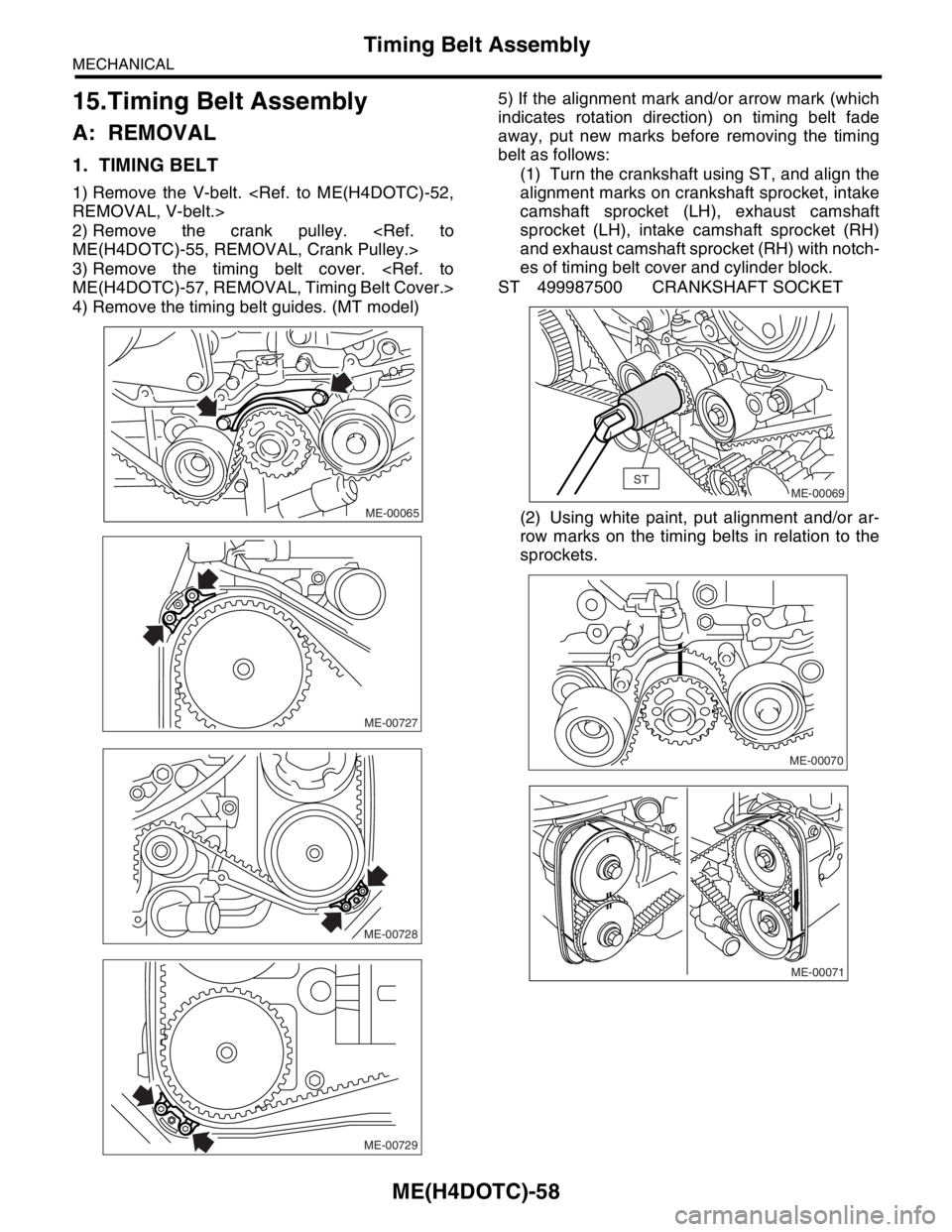

1. TIMING BELT

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt guides. (MT model)5) If the alignment mark and/or arrow mark (which

indicates rotation direction) on timing belt fade

away, put new marks before removing the timing

belt as follows:

(1) Turn the crankshaft using ST, and align the

alignment marks on crankshaft sprocket, intake

camshaft sprocket (LH), exhaust camshaft

sprocket (LH), intake camshaft sprocket (RH)

and exhaust camshaft sprocket (RH) with notch-

es of timing belt cover and cylinder block.

ST 499987500 CRANKSHAFT SOCKET

(2) Using white paint, put alignment and/or ar-

row marks on the timing belts in relation to the

sprockets.

ME-00065

ME-00727

ME-00728

ME-00729

ME-00069ST

ME-00070

ME-00071

Page 1517 of 2870

ME(H4DOTC)-59

MECHANICAL

Timing Belt Assembly

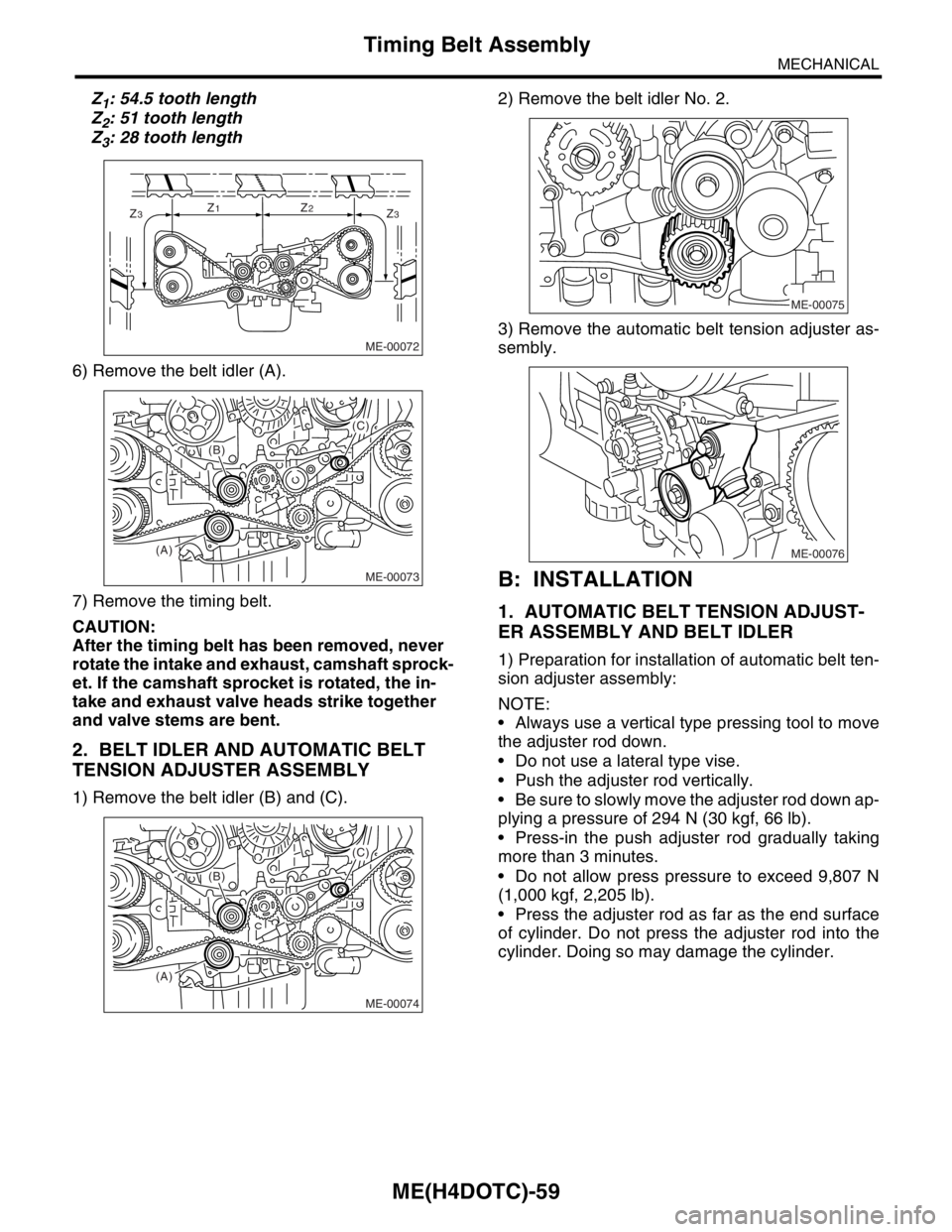

Z1: 54.5 tooth length

Z

2: 51 tooth length

Z

3: 28 tooth length

6) Remove the belt idler (A).

7) Remove the timing belt.

CAUTION:

After the timing belt has been removed, never

rotate the intake and exhaust, camshaft sprock-

et. If the camshaft sprocket is rotated, the in-

take and exhaust valve heads strike together

and valve stems are bent.

2. BELT IDLER AND AUTOMATIC BELT

TENSION ADJUSTER ASSEMBLY

1) Remove the belt idler (B) and (C).2) Remove the belt idler No. 2.

3) Remove the automatic belt tension adjuster as-

sembly.

B: INSTALLATION

1. AUTOMATIC BELT TENSION ADJUST-

ER ASSEMBLY AND BELT IDLER

1) Preparation for installation of automatic belt ten-

sion adjuster assembly:

NOTE:

Always use a vertical type pressing tool to move

the adjuster rod down.

Do not use a lateral type vise.

Push the adjuster rod vertically.

Be sure to slowly move the adjuster rod down ap-

plying a pressure of 294 N (30 kgf, 66 lb).

Press-in the push adjuster rod gradually taking

more than 3 minutes.

Do not allow press pressure to exceed 9,807 N

(1,000 kgf, 2,205 lb).

Press the adjuster rod as far as the end surface

of cylinder. Do not press the adjuster rod into the

cylinder. Doing so may damage the cylinder.

ME-00072

Z3Z1Z2Z3

ME-00073

(A)(B)

(C)

ME-00074

(A)(B)

(C)

ME-00075

ME-00076

Page 1518 of 2870

ME(H4DOTC)-60

MECHANICAL

Timing Belt Assembly

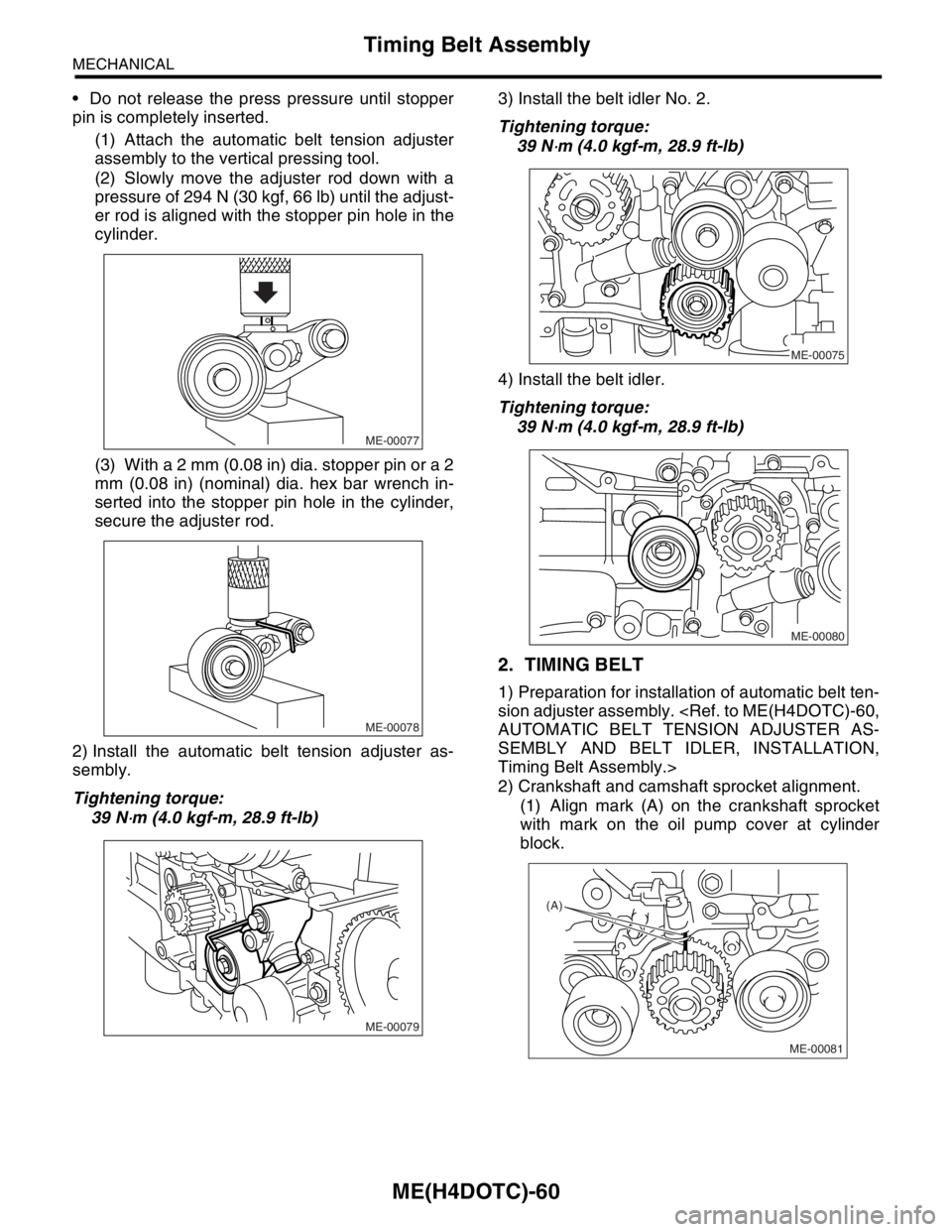

Do not release the press pressure until stopper

pin is completely inserted.

(1) Attach the automatic belt tension adjuster

assembly to the vertical pressing tool.

(2) Slowly move the adjuster rod down with a

pressure of 294 N (30 kgf, 66 lb) until the adjust-

er rod is aligned with the stopper pin hole in the

cylinder.

(3) With a 2 mm (0.08 in) dia. stopper pin or a 2

mm (0.08 in) (nominal) dia. hex bar wrench in-

serted into the stopper pin hole in the cylinder,

secure the adjuster rod.

2) Install the automatic belt tension adjuster as-

sembly.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)3) Install the belt idler No. 2.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

4) Install the belt idler.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

2. TIMING BELT

1) Preparation for installation of automatic belt ten-

sion adjuster assembly.

SEMBLY AND BELT IDLER, INSTALLATION,

Timing Belt Assembly.>

2) Crankshaft and camshaft sprocket alignment.

(1) Align mark (A) on the crankshaft sprocket

with mark on the oil pump cover at cylinder

block.

ME-00077

ME-00078

ME-00079

ME-00075

ME-00080

(A)

ME-00081

Page 1519 of 2870

ME(H4DOTC)-61

MECHANICAL

Timing Belt Assembly

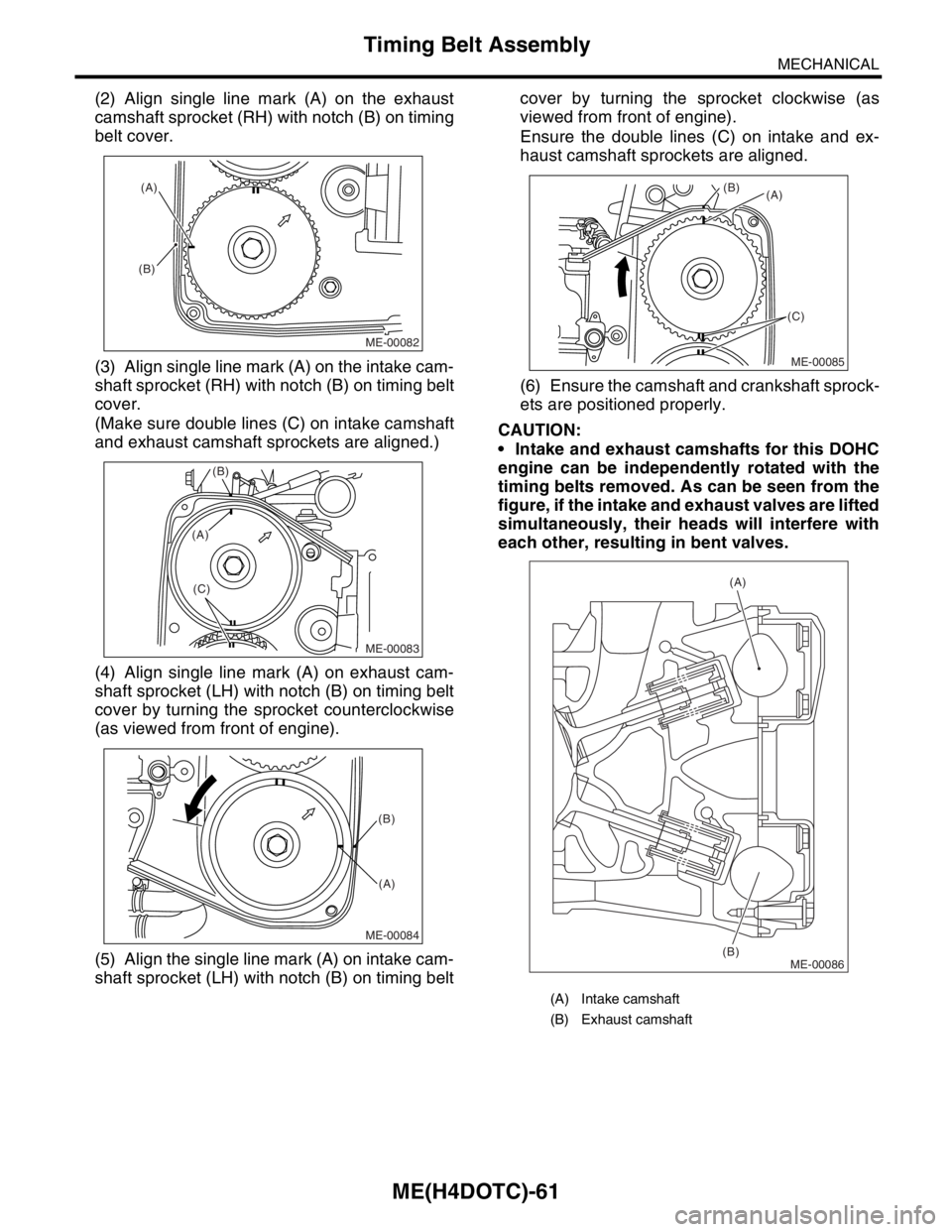

(2) Align single line mark (A) on the exhaust

camshaft sprocket (RH) with notch (B) on timing

belt cover.

(3) Align single line mark (A) on the intake cam-

shaft sprocket (RH) with notch (B) on timing belt

cover.

(Make sure double lines (C) on intake camshaft

and exhaust camshaft sprockets are aligned.)

(4) Align single line mark (A) on exhaust cam-

shaft sprocket (LH) with notch (B) on timing belt

cover by turning the sprocket counterclockwise

(as viewed from front of engine).

(5) Align the single line mark (A) on intake cam-

shaft sprocket (LH) with notch (B) on timing beltcover by turning the sprocket clockwise (as

viewed from front of engine).

Ensure the double lines (C) on intake and ex-

haust camshaft sprockets are aligned.

(6) Ensure the camshaft and crankshaft sprock-

ets are positioned properly.

CAUTION:

Intake and exhaust camshafts for this DOHC

engine can be independently rotated with the

timing belts removed. As can be seen from the

figure, if the intake and exhaust valves are lifted

simultaneously, their heads will interfere with

each other, resulting in bent valves.

ME-00082

(A)

(B)

ME-00083

(B)

(C)

(A)

ME-00084

(B)

(A)

(A) Intake camshaft

(B) Exhaust camshaft

ME-00085

(A) (B)

(C)

ME-00086

(A)

(B)

Page 1520 of 2870

ME(H4DOTC)-62

MECHANICAL

Timing Belt Assembly

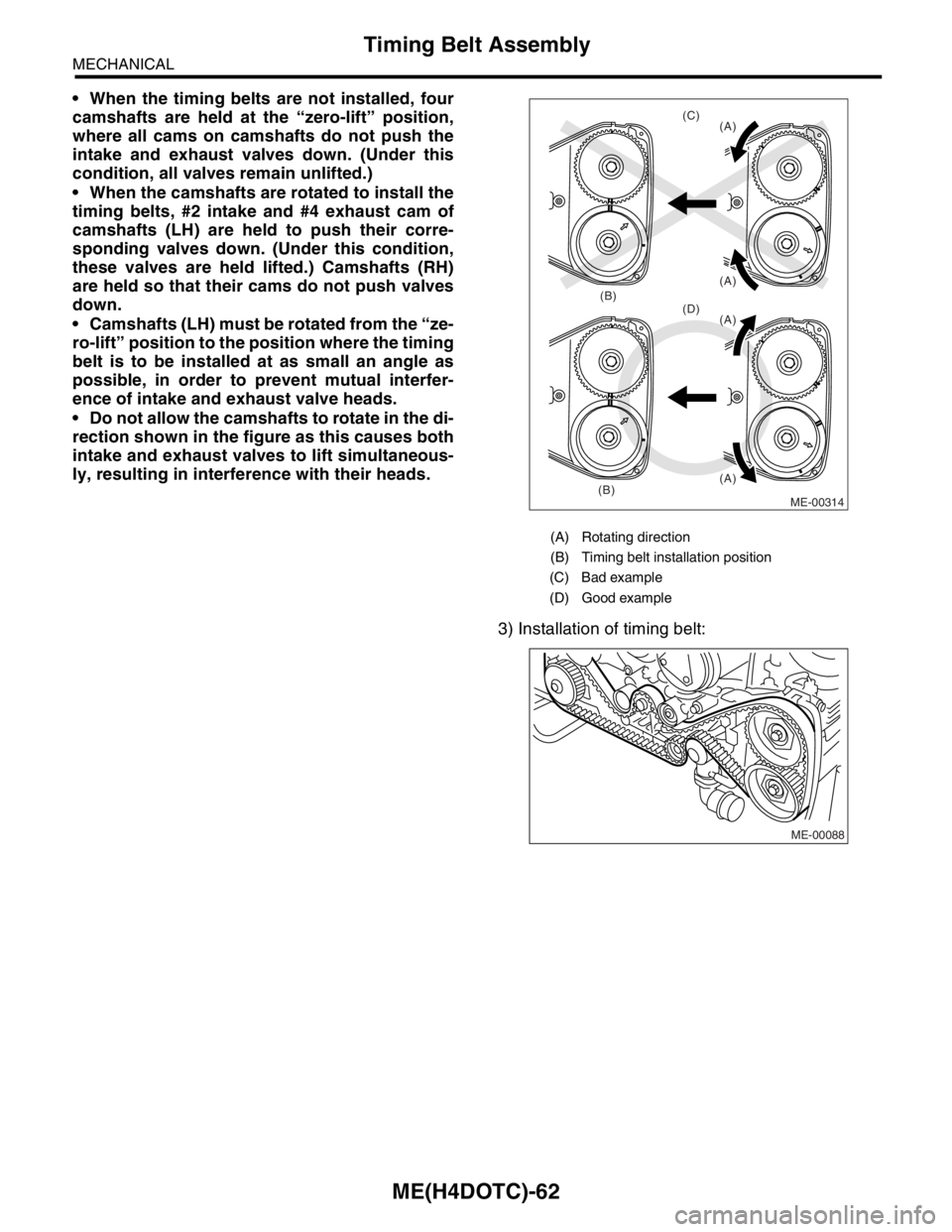

When the timing belts are not installed, four

camshafts are held at the “zero-lift” position,

where all cams on camshafts do not push the

intake and exhaust valves down. (Under this

condition, all valves remain unlifted.)

When the camshafts are rotated to install the

timing belts, #2 intake and #4 exhaust cam of

camshafts (LH) are held to push their corre-

sponding valves down. (Under this condition,

these valves are held lifted.) Camshafts (RH)

are held so that their cams do not push valves

down.

Camshafts (LH) must be rotated from the “ze-

ro-lift” position to the position where the timing

belt is to be installed at as small an angle as

possible, in order to prevent mutual interfer-

ence of intake and exhaust valve heads.

Do not allow the camshafts to rotate in the di-

rection shown in the figure as this causes both

intake and exhaust valves to lift simultaneous-

ly, resulting in interference with their heads.

3) Installation of timing belt:

(A) Rotating direction

(B) Timing belt installation position

(C) Bad example

(D) Good example

(A) (A) (A) (A)

(D) (C)

(B)(B)

ME-00314

ME-00088