SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1751 of 2870

EN(H4DOTC)-118

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

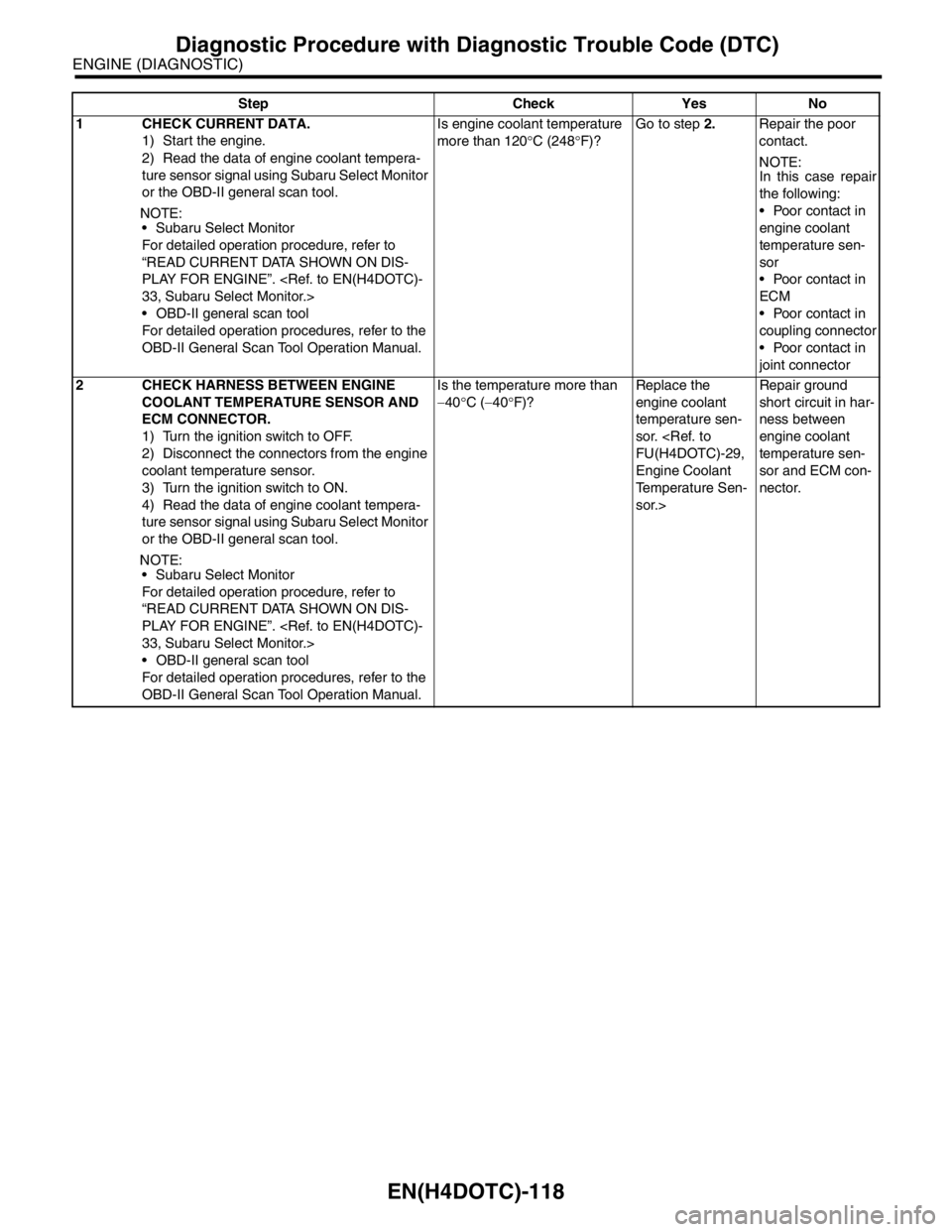

Step Check Yes No

1 CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of engine coolant tempera-

ture sensor signal using Subaru Select Monitor

or the OBD-II general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Is engine coolant temperature

more than 120°C (248°F)?Go to step 2.Repair the poor

contact.

N

OTE:

In this case repair

the following:

Poor contact in

engine coolant

temperature sen-

sor

Poor contact in

ECM

Poor contact in

coupling connector

Poor contact in

joint connector

2 CHECK HARNESS BETWEEN ENGINE

COOLANT TEMPERATURE SENSOR AND

ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from the engine

coolant temperature sensor.

3) Turn the ignition switch to ON.

4) Read the data of engine coolant tempera-

ture sensor signal using Subaru Select Monitor

or the OBD-II general scan tool.

NOTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Is the temperature more than

−40°C (−40°F)?Replace the

engine coolant

temperature sen-

sor.

Engine Coolant

Temperature Sen-

sor.>Repair ground

short circuit in har-

ness between

engine coolant

temperature sen-

sor and ECM con-

nector.

Page 1752 of 2870

EN(H4DOTC)-119

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

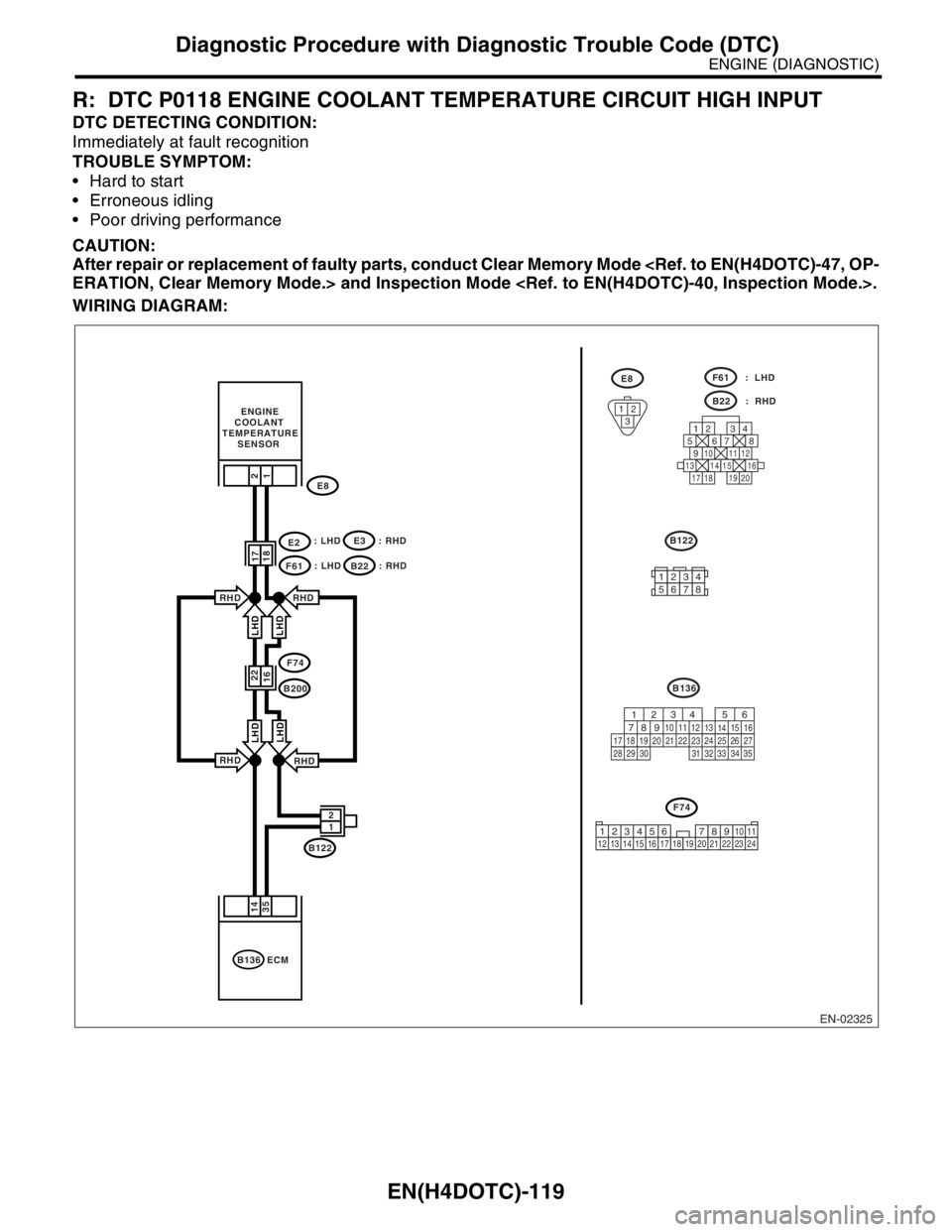

R: DTC P0118 ENGINE COOLANT TEMPERATURE CIRCUIT HIGH INPUT

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Hard to start

Erroneous idling

Poor driving performance

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02325

B122

B136 ECM

35 14

E8 ENGINE

COOLANT

TEMPERATURE

SENSOR2

1

1 2

17

18

22

16F74

B200

LHD

LHD

RHD

RHD

LHD LHD

RHD

RHD

E8

12

3

B136

125678

131415169101112

34

17181920

B122B22 : RHD

F61 : LHD

F61

E2

: LHD

B22: RHD

F74

34

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

12345678

: LHDE3: RHD

Page 1753 of 2870

EN(H4DOTC)-120

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

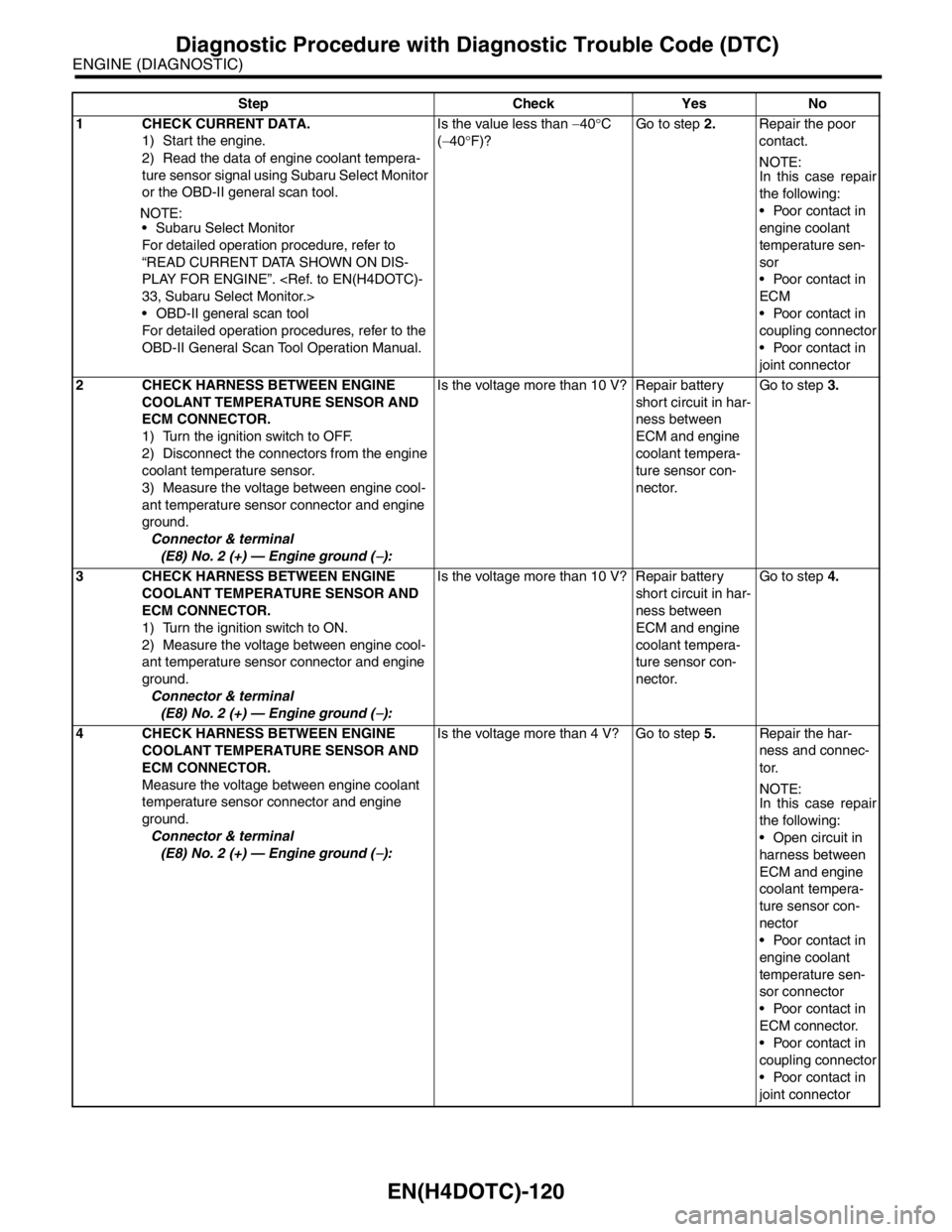

Step Check Yes No

1 CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of engine coolant tempera-

ture sensor signal using Subaru Select Monitor

or the OBD-II general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Is the value less than −40°C

(−40°F)?Go to step 2.Repair the poor

contact.

N

OTE:

In this case repair

the following:

Poor contact in

engine coolant

temperature sen-

sor

Poor contact in

ECM

Poor contact in

coupling connector

Poor contact in

joint connector

2 CHECK HARNESS BETWEEN ENGINE

COOLANT TEMPERATURE SENSOR AND

ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from the engine

coolant temperature sensor.

3) Measure the voltage between engine cool-

ant temperature sensor connector and engine

ground.

Connector & terminal

(E8) No. 2 (+) — Engine ground (

−):Is the voltage more than 10 V? Repair battery

short circuit in har-

ness between

ECM and engine

coolant tempera-

ture sensor con-

nector.Go to step 3.

3 CHECK HARNESS BETWEEN ENGINE

COOLANT TEMPERATURE SENSOR AND

ECM CONNECTOR.

1) Turn the ignition switch to ON.

2) Measure the voltage between engine cool-

ant temperature sensor connector and engine

ground.

Connector & terminal

(E8) No. 2 (+) — Engine ground (

−):Is the voltage more than 10 V? Repair battery

short circuit in har-

ness between

ECM and engine

coolant tempera-

ture sensor con-

nector.Go to step 4.

4 CHECK HARNESS BETWEEN ENGINE

COOLANT TEMPERATURE SENSOR AND

ECM CONNECTOR.

Measure the voltage between engine coolant

temperature sensor connector and engine

ground.

Connector & terminal

(E8) No. 2 (+) — Engine ground (

−):Is the voltage more than 4 V? Go to step 5.Repair the har-

ness and connec-

tor.

NOTE:

In this case repair

the following:

Open circuit in

harness between

ECM and engine

coolant tempera-

ture sensor con-

nector

Poor contact in

engine coolant

temperature sen-

sor connector

Poor contact in

ECM connector.

Poor contact in

coupling connector

Poor contact in

joint connector

Page 1754 of 2870

EN(H4DOTC)-121

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

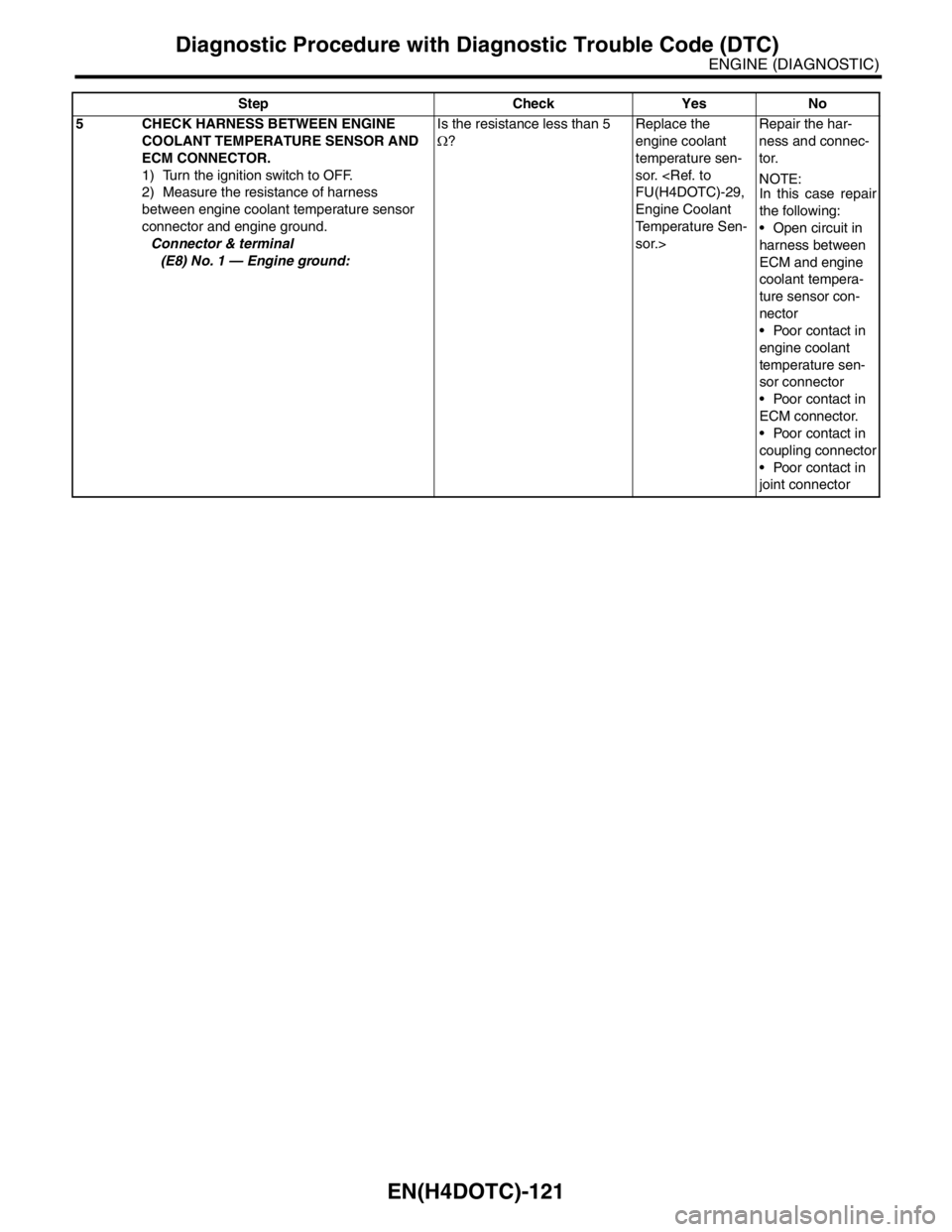

5 CHECK HARNESS BETWEEN ENGINE

COOLANT TEMPERATURE SENSOR AND

ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between engine coolant temperature sensor

connector and engine ground.

Connector & terminal

(E8) No. 1 — Engine ground:Is the resistance less than 5

Ω?Replace the

engine coolant

temperature sen-

sor.

Engine Coolant

Temperature Sen-

sor.>Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

ECM and engine

coolant tempera-

ture sensor con-

nector

Poor contact in

engine coolant

temperature sen-

sor connector

Poor contact in

ECM connector.

Poor contact in

coupling connector

Poor contact in

joint connector Step Check Yes No

Page 1755 of 2870

EN(H4DOTC)-122

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

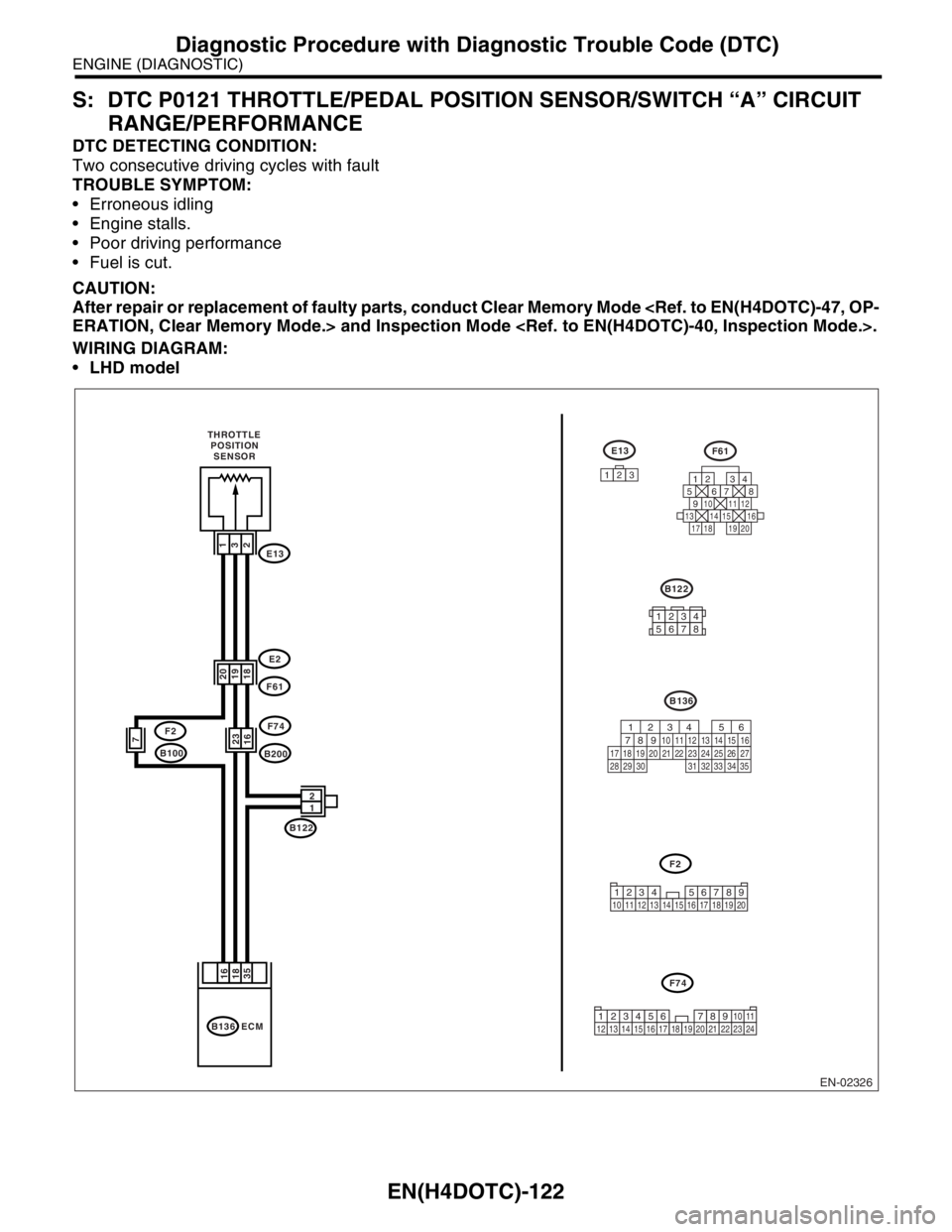

S: DTC P0121 THROTTLE/PEDAL POSITION SENSOR/SWITCH “A” CIRCUIT

RANGE/PERFORMANCE

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

Erroneous idling

Engine stalls.

Poor driving performance

Fuel is cut.

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

LHD model

EN-02326

E2

E13

F61

F74

B200

B122 THROTTLE

POSITION

SENSOR

1

32

20

1918

1 2

B136 ECM

16

35 18

B136

E13

123

F61

125678

131415169101112

34

17181920

B122

F2

F2

B100

F74

12345678

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

34

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

1234 5678910 11 12 13 14 15 16 17 18 19 20

723

16

Page 1756 of 2870

EN(H4DOTC)-123

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

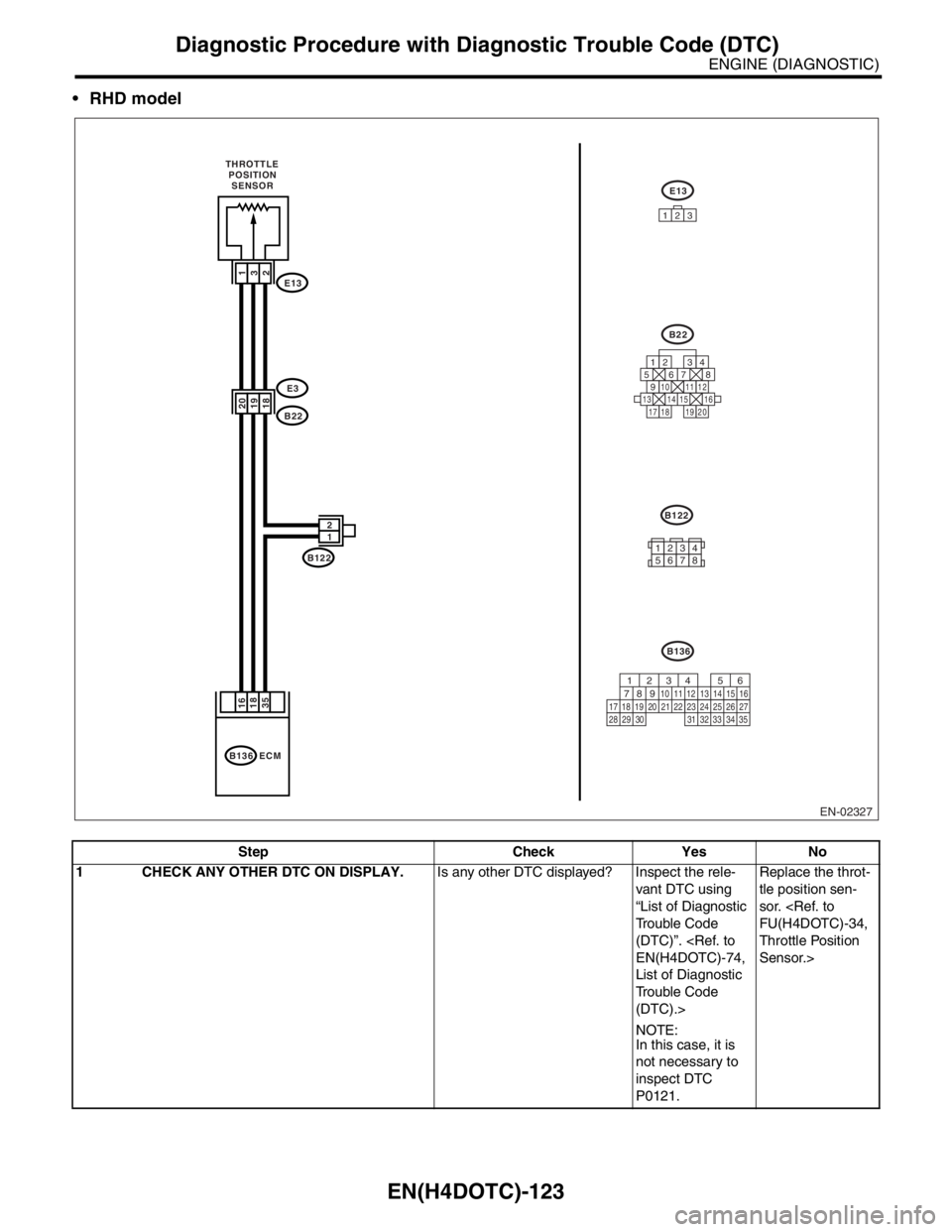

RHD model

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

List of Diagnostic

Trouble Code

(DTC).>

N

OTE:

In this case, it is

not necessary to

inspect DTC

P0121.Replace the throt-

tle position sen-

sor.

Throttle Position

Sensor.>

EN-02327

E3

E13

B22

B122 THROTTLE

POSITION

SENSOR

1

32

20

1918

1 2

B136 ECM

16

35 18

B136

E13

123

B22

125678

131415169101112

34

17181920

B122

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

12345678

Page 1757 of 2870

EN(H4DOTC)-124

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

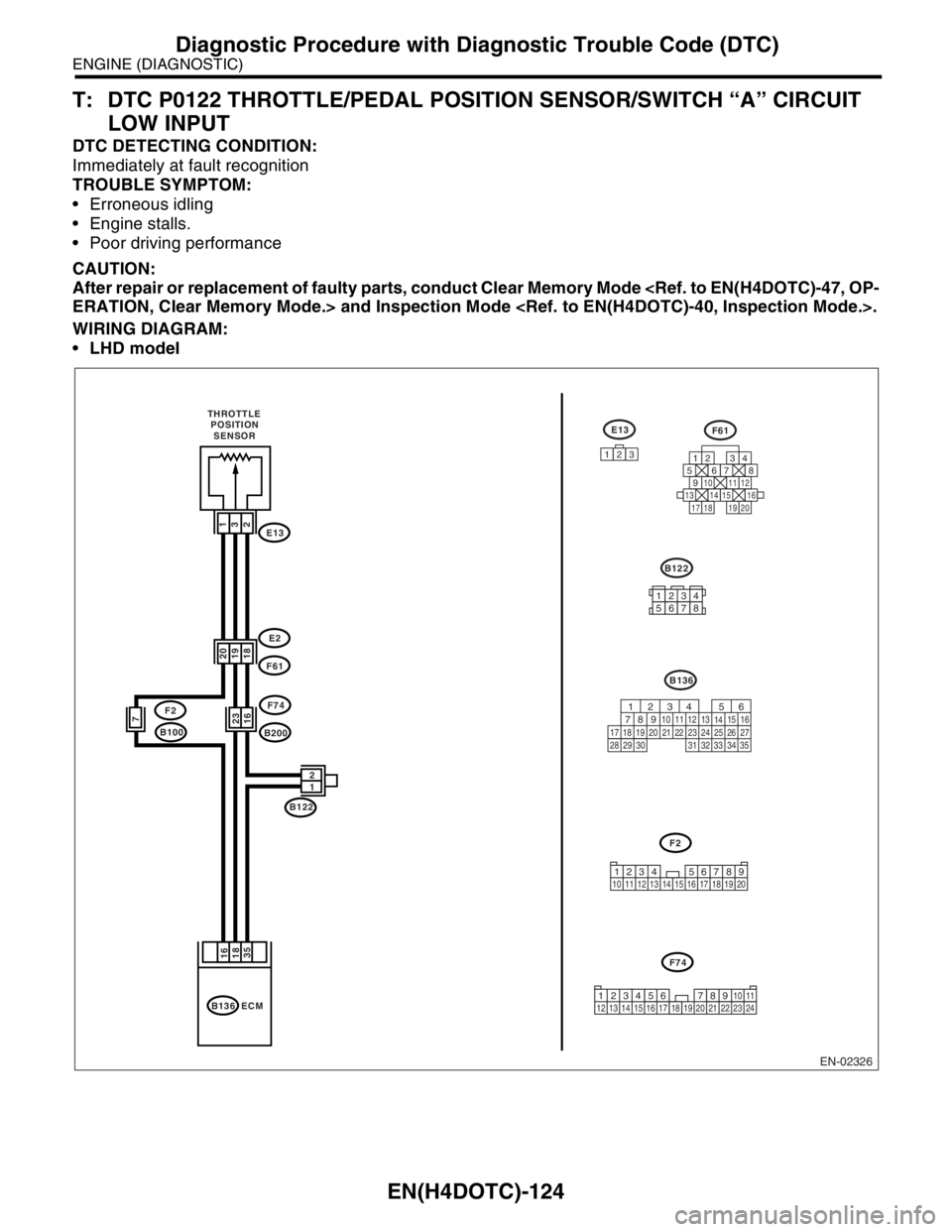

T: DTC P0122 THROTTLE/PEDAL POSITION SENSOR/SWITCH “A” CIRCUIT

LOW INPUT

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Erroneous idling

Engine stalls.

Poor driving performance

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

LHD model

EN-02326

E2

E13

F61

F74

B200

B122 THROTTLE

POSITION

SENSOR

1

32

20

1918

1 2

B136 ECM

16

35 18

B136

E13

123

F61

125678

131415169101112

34

17181920

B122

F2

F2

B100

F74

12345678

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

34

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

1234 5678910 11 12 13 14 15 16 17 18 19 20

723

16

Page 1758 of 2870

EN(H4DOTC)-125

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

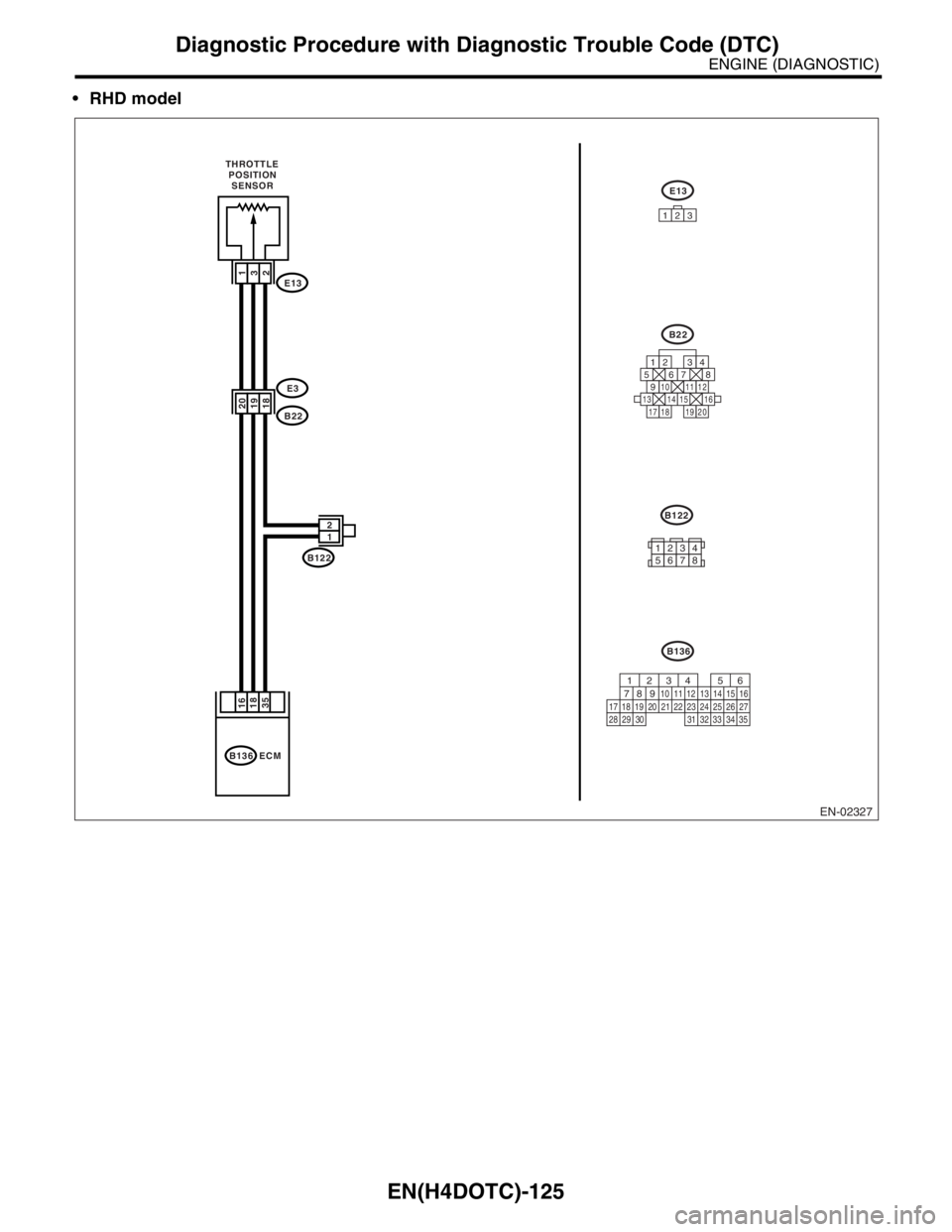

RHD model

EN-02327

E3

E13

B22

B122 THROTTLE

POSITION

SENSOR

1

32

20

1918

1 2

B136 ECM

16

35 18

B136

E13

123

B22

125678

131415169101112

34

17181920

B122

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

12345678

Page 1759 of 2870

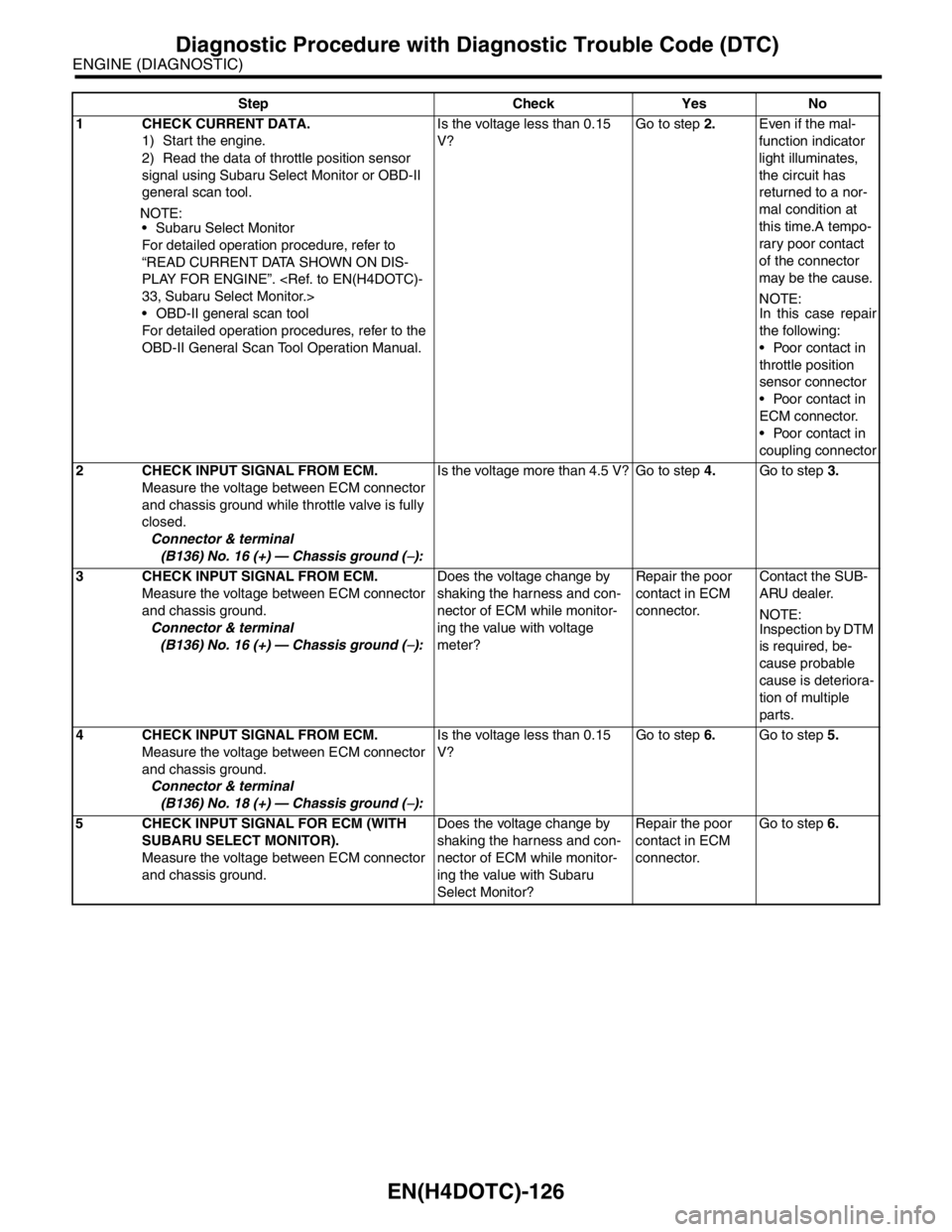

EN(H4DOTC)-126

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of throttle position sensor

signal using Subaru Select Monitor or OBD-II

general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Is the voltage less than 0.15

V?Go to step 2.Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.A tempo-

rary poor contact

of the connector

may be the cause.

N

OTE:

In this case repair

the following:

Poor contact in

throttle position

sensor connector

Poor contact in

ECM connector.

Poor contact in

coupling connector

2 CHECK INPUT SIGNAL FROM ECM.

Measure the voltage between ECM connector

and chassis ground while throttle valve is fully

closed.

Connector & terminal

(B136) No. 16 (+) — Chassis ground (

−):Is the voltage more than 4.5 V? Go to step 4.Go to step 3.

3 CHECK INPUT SIGNAL FROM ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B136) No. 16 (+) — Chassis ground (

−):Does the voltage change by

shaking the harness and con-

nector of ECM while monitor-

ing the value with voltage

meter?Repair the poor

contact in ECM

connector.Contact the SUB-

ARU dealer.

N

OTE:

Inspection by DTM

is required, be-

cause probable

cause is deteriora-

tion of multiple

parts.

4 CHECK INPUT SIGNAL FROM ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B136) No. 18 (+) — Chassis ground (

−):Is the voltage less than 0.15

V?Go to step 6.Go to step 5.

5 CHECK INPUT SIGNAL FOR ECM (WITH

SUBARU SELECT MONITOR).

Measure the voltage between ECM connector

and chassis ground.Does the voltage change by

shaking the harness and con-

nector of ECM while monitor-

ing the value with Subaru

Select Monitor?Repair the poor

contact in ECM

connector.Go to step 6.

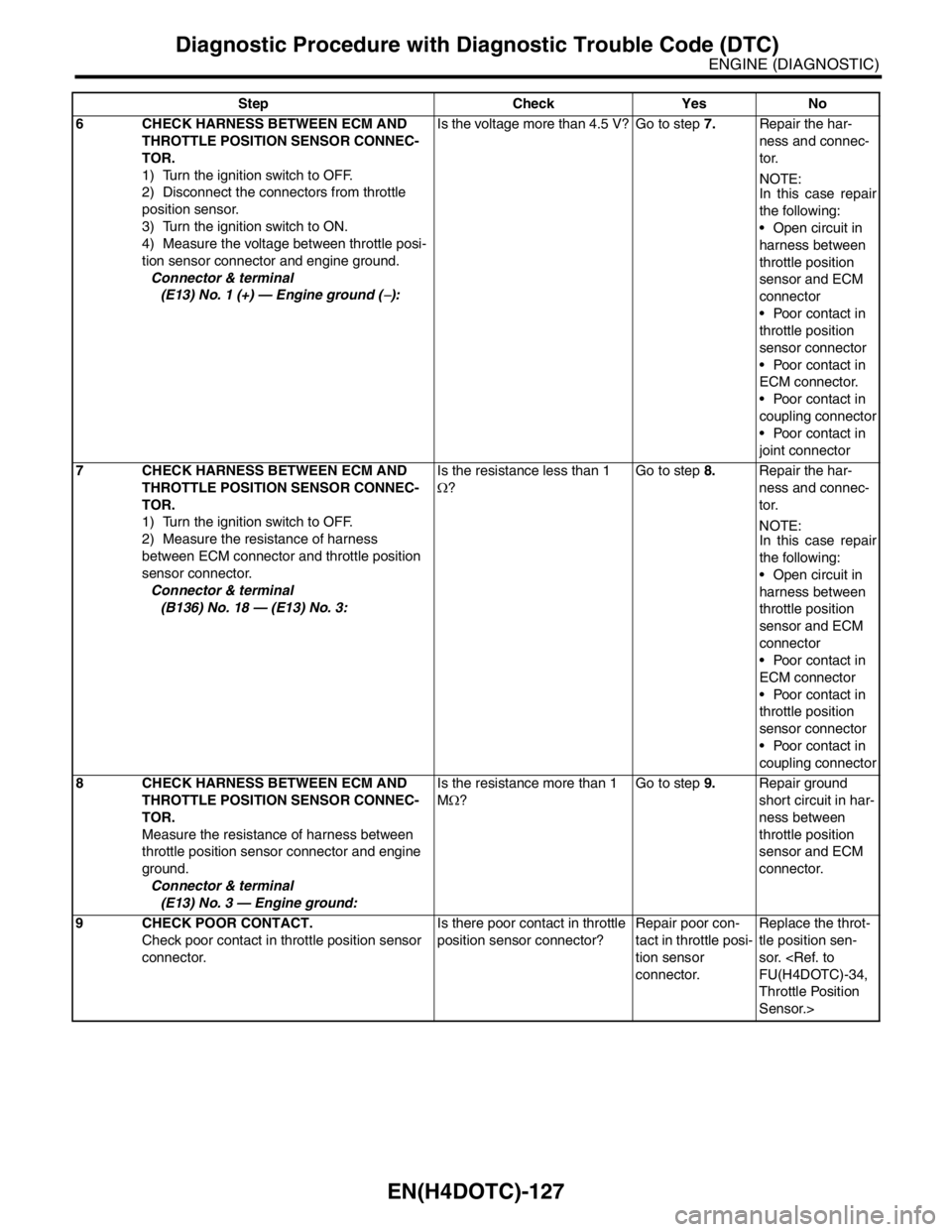

Page 1760 of 2870

EN(H4DOTC)-127

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

6 CHECK HARNESS BETWEEN ECM AND

THROTTLE POSITION SENSOR CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from throttle

position sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between throttle posi-

tion sensor connector and engine ground.

Connector & terminal

(E13) No. 1 (+) — Engine ground (

−):Is the voltage more than 4.5 V? Go to step 7.Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

throttle position

sensor and ECM

connector

Poor contact in

throttle position

sensor connector

Poor contact in

ECM connector.

Poor contact in

coupling connector

Poor contact in

joint connector

7 CHECK HARNESS BETWEEN ECM AND

THROTTLE POSITION SENSOR CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between ECM connector and throttle position

sensor connector.

Connector & terminal

(B136) No. 18 — (E13) No. 3:Is the resistance less than 1

Ω?Go to step 8.Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

throttle position

sensor and ECM

connector

Poor contact in

ECM connector

Poor contact in

throttle position

sensor connector

Poor contact in

coupling connector

8 CHECK HARNESS BETWEEN ECM AND

THROTTLE POSITION SENSOR CONNEC-

TOR.

Measure the resistance of harness between

throttle position sensor connector and engine

ground.

Connector & terminal

(E13) No. 3 — Engine ground:Is the resistance more than 1

MΩ?Go to step 9.Repair ground

short circuit in har-

ness between

throttle position

sensor and ECM

connector.

9 CHECK POOR CONTACT.

Check poor contact in throttle position sensor

connector.Is there poor contact in throttle

position sensor connector?Repair poor con-

tact in throttle posi-

tion sensor

connector.Replace the throt-

tle position sen-

sor.

Throttle Position

Sensor.> Step Check Yes No