lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1137 of 2870

EN(H4SO)-39

ENGINE (DIAGNOSTIC)

Inspection Mode

1. PREPARATION FOR THE INSPECTION

MODE

1) Check battery voltage is more than 12 V and fuel

remains half [20 — 402 (5.3 — 10.6 US gal, 4.4 —

8.8 Imp gal)].

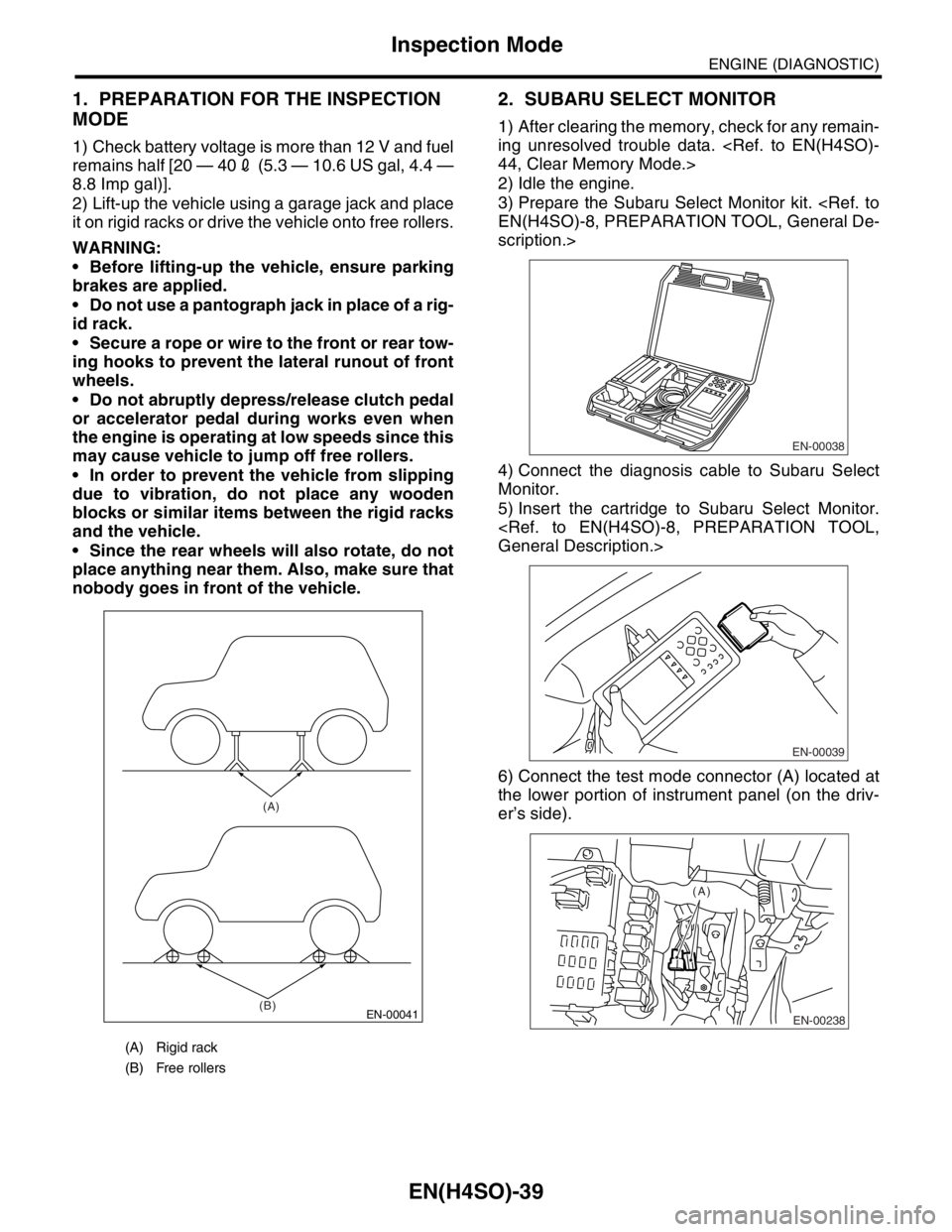

2) Lift-up the vehicle using a garage jack and place

it on rigid racks or drive the vehicle onto free rollers.

WARNING:

Before lifting-up the vehicle, ensure parking

brakes are applied.

Do not use a pantograph jack in place of a rig-

id rack.

Secure a rope or wire to the front or rear tow-

ing hooks to prevent the lateral runout of front

wheels.

Do not abruptly depress/release clutch pedal

or accelerator pedal during works even when

the engine is operating at low speeds since this

may cause vehicle to jump off free rollers.

In order to prevent the vehicle from slipping

due to vibration, do not place any wooden

blocks or similar items between the rigid racks

and the vehicle.

Since the rear wheels will also rotate, do not

place anything near them. Also, make sure that

nobody goes in front of the vehicle.

2. SUBARU SELECT MONITOR

1) After clearing the memory, check for any remain-

ing unresolved trouble data.

2) Idle the engine.

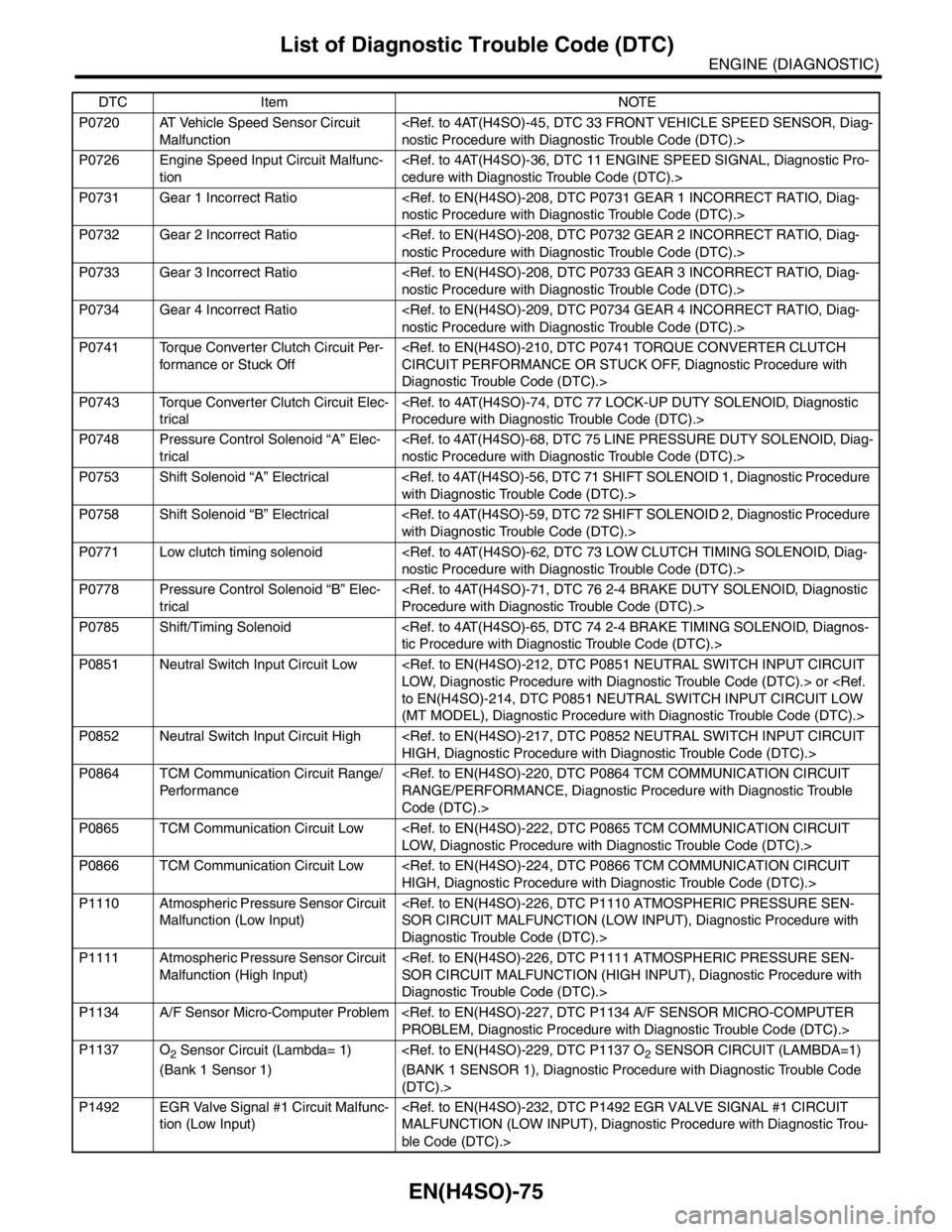

3) Prepare the Subaru Select Monitor kit.

scription.>

4) Connect the diagnosis cable to Subaru Select

Monitor.

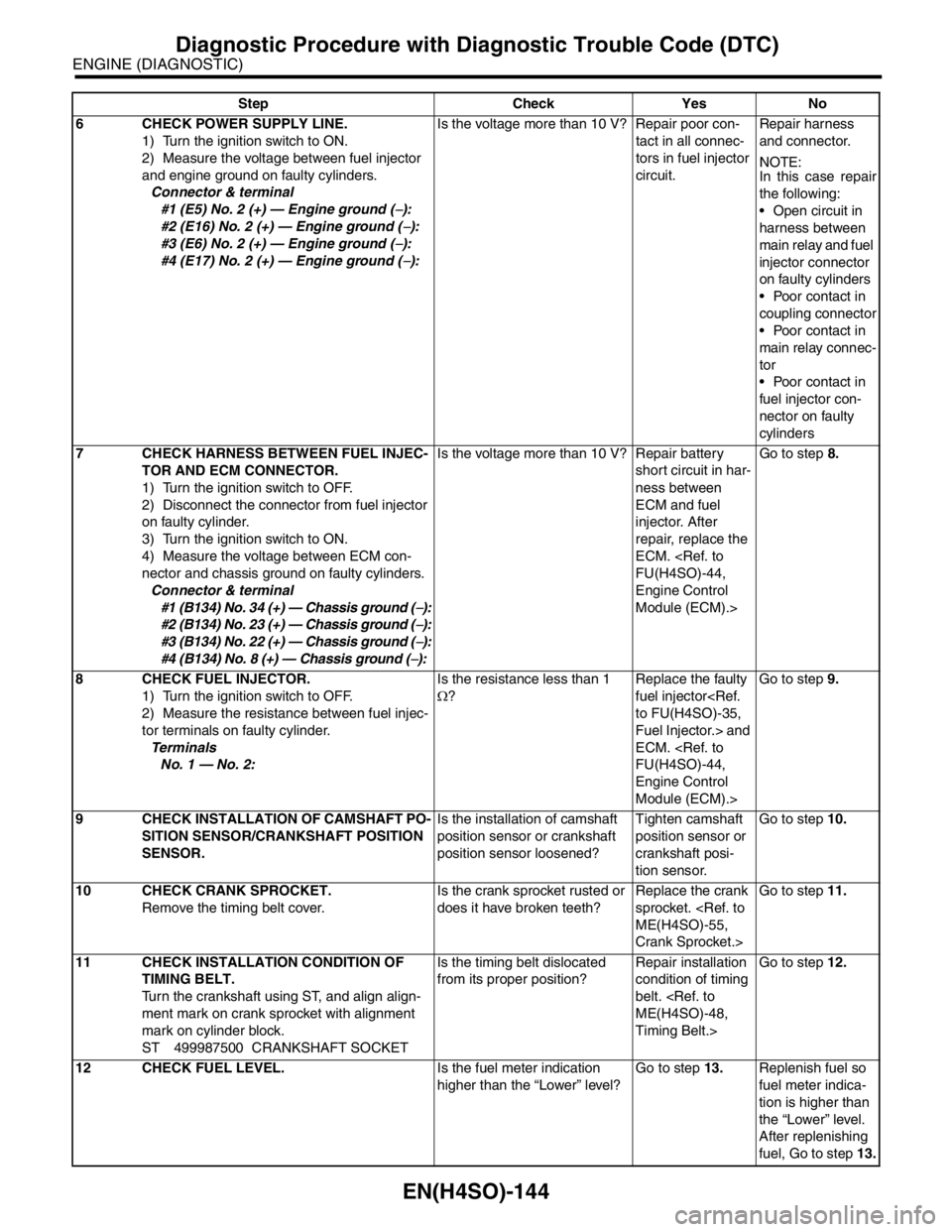

5) Insert the cartridge to Subaru Select Monitor.

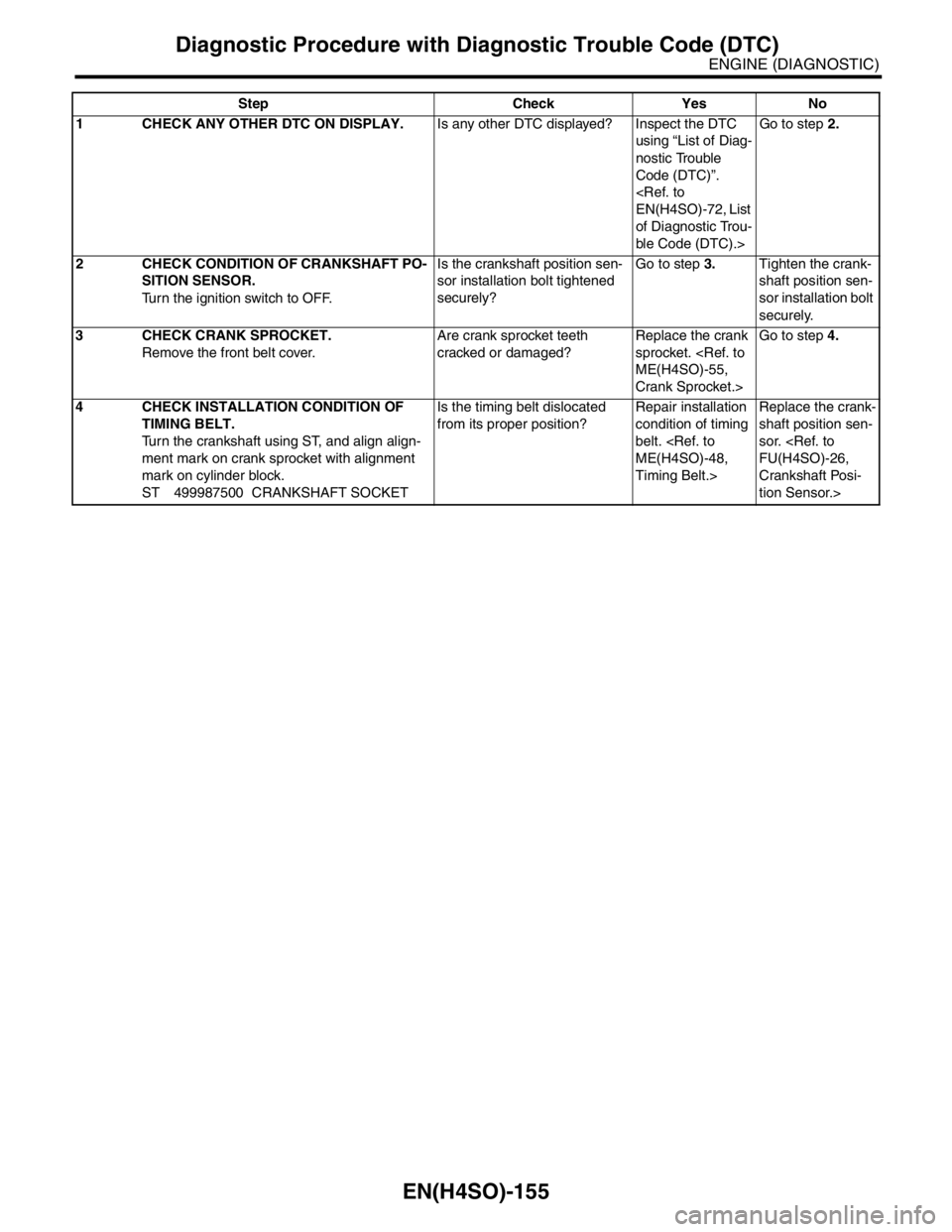

6) Connect the test mode connector (A) located at

the lower portion of instrument panel (on the driv-

er’s side).

(A) Rigid rack

(B) Free rollers

EN-00041

(A)

(B)

EN-00038

EN-00039

EN-00238

(A)

Page 1173 of 2870

EN(H4SO)-75

ENGINE (DIAGNOSTIC)

List of Diagnostic Trouble Code (DTC)

P0720 AT Vehicle Speed Sensor Circuit

Malfunction

P0726 Engine Speed Input Circuit Malfunc-

tion

P0731 Gear 1 Incorrect Ratio

P0732 Gear 2 Incorrect Ratio

P0733 Gear 3 Incorrect Ratio

P0734 Gear 4 Incorrect Ratio

P0741 Torque Converter Clutch Circuit Per-

formance or Stuck Off

Diagnostic Trouble Code (DTC).>

P0743 Torque Converter Clutch Circuit Elec-

trical

P0748 Pressure Control Solenoid “A” Elec-

trical

P0753 Shift Solenoid “A” Electrical

P0758 Shift Solenoid “B” Electrical

P0771 Low clutch timing solenoid

P0778 Pressure Control Solenoid “B” Elec-

trical

P0785 Shift/Timing Solenoid

P0851 Neutral Switch Input Circuit Low

(MT MODEL), Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

P0852 Neutral Switch Input Circuit High

P0864 TCM Communication Circuit Range/

Pe r fo r ma nc e

Code (DTC).>

P0865 TCM Communication Circuit Low

P0866 TCM Communication Circuit Low

P1110 Atmospheric Pressure Sensor Circuit

Malfunction (Low Input)

Diagnostic Trouble Code (DTC).>

P1111 Atmospheric Pressure Sensor Circuit

Malfunction (High Input)

Diagnostic Trouble Code (DTC).>

P1134 A/F Sensor Micro-Computer Problem

P1137 O

2 Sensor Circuit (Lambda= 1)

(Bank 1 Sensor 1)

(DTC).>

P1492 EGR Valve Signal #1 Circuit Malfunc-

tion (Low Input)

ble Code (DTC).> DTC Item NOTE

Page 1242 of 2870

EN(H4SO)-144

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

6 CHECK POWER SUPPLY LINE.

1) Turn the ignition switch to ON.

2) Measure the voltage between fuel injector

and engine ground on faulty cylinders.

Connector & terminal

#1 (E5) No. 2 (+) — Engine ground (

−):

#2 (E16) No. 2 (+) — Engine ground (

−):

#3 (E6) No. 2 (+) — Engine ground (

−):

#4 (E17) No. 2 (+) — Engine ground (

−):Is the voltage more than 10 V? Repair poor con-

tact in all connec-

tors in fuel injector

circuit.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

main relay and fuel

injector connector

on faulty cylinders

Poor contact in

coupling connector

Poor contact in

main relay connec-

tor

Poor contact in

fuel injector con-

nector on faulty

cylinders

7 CHECK HARNESS BETWEEN FUEL INJEC-

TOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel injector

on faulty cylinder.

3) Turn the ignition switch to ON.

4) Measure the voltage between ECM con-

nector and chassis ground on faulty cylinders.

Connector & terminal

#1 (B134) No. 34 (+) — Chassis ground (

−):

#2 (B134) No. 23 (+) — Chassis ground (

−):

#3 (B134) No. 22 (+) — Chassis ground (

−):

#4 (B134) No. 8 (+) — Chassis ground (

−):Is the voltage more than 10 V? Repair battery

short circuit in har-

ness between

ECM and fuel

injector. After

repair, replace the

ECM.

Engine Control

Module (ECM).>Go to step 8.

8 CHECK FUEL INJECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between fuel injec-

tor terminals on faulty cylinder.

Te r m i n a l s

No. 1 — No. 2:Is the resistance less than 1

Ω?Replace the faulty

fuel injector

Fuel Injector.> and

ECM.

Engine Control

Module (ECM).>Go to step 9.

9 CHECK INSTALLATION OF CAMSHAFT PO-

SITION SENSOR/CRANKSHAFT POSITION

SENSOR.Is the installation of camshaft

position sensor or crankshaft

position sensor loosened?Tighten camshaft

position sensor or

crankshaft posi-

tion sensor.Go to step 10.

10 CHECK CRANK SPROCKET.

Remove the timing belt cover.Is the crank sprocket rusted or

does it have broken teeth?Replace the crank

sprocket.

Crank Sprocket.>Go to step 11.

11 CHECK INSTALLATION CONDITION OF

TIMING BELT.

Turn the crankshaft using ST, and align align-

ment mark on crank sprocket with alignment

mark on cylinder block.

ST 499987500 CRANKSHAFT SOCKETIs the timing belt dislocated

from its proper position?Repair installation

condition of timing

belt.

Timing Belt.>Go to step 12.

12 CHECK FUEL LEVEL.Is the fuel meter indication

higher than the “Lower” level?Go to step 13.Replenish fuel so

fuel meter indica-

tion is higher than

the “Lower” level.

After replenishing

fuel, Go to step 13. Step Check Yes No

Page 1253 of 2870

EN(H4SO)-155

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the DTC

using “List of Diag-

nostic Trouble

Code (DTC)”.

of Diagnostic Trou-

ble Code (DTC).>Go to step 2.

2 CHECK CONDITION OF CRANKSHAFT PO-

SITION SENSOR.

Turn the ignition switch to OFF.Is the crankshaft position sen-

sor installation bolt tightened

securely?Go to step 3.Tighten the crank-

shaft position sen-

sor installation bolt

securely.

3 CHECK CRANK SPROCKET.

Remove the front belt cover.Are crank sprocket teeth

cracked or damaged?Replace the crank

sprocket.

Crank Sprocket.>Go to step 4.

4 CHECK INSTALLATION CONDITION OF

TIMING BELT.

Turn the crankshaft using ST, and align align-

ment mark on crank sprocket with alignment

mark on cylinder block.

ST 499987500 CRANKSHAFT SOCKETIs the timing belt dislocated

from its proper position?Repair installation

condition of timing

belt.

Timing Belt.>Replace the crank-

shaft position sen-

sor.

Crankshaft Posi-

tion Sensor.>

Page 1308 of 2870

EN(H4SO)-210

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

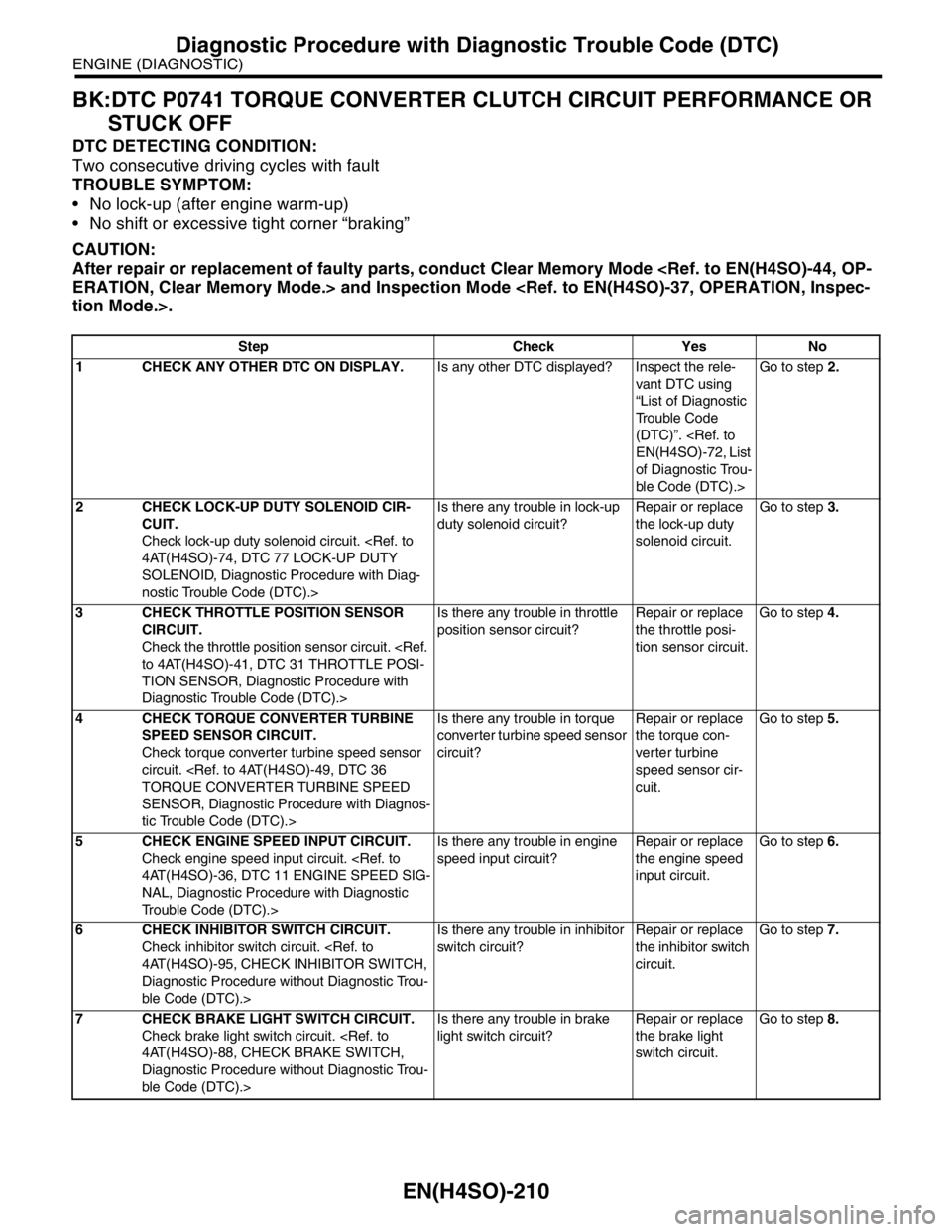

BK:DTC P0741 TORQUE CONVERTER CLUTCH CIRCUIT PERFORMANCE OR

STUCK OFF

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

No lock-up (after engine warm-up)

No shift or excessive tight corner “braking”

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

of Diagnostic Trou-

ble Code (DTC).>Go to step 2.

2 CHECK LOCK-UP DUTY SOLENOID CIR-

CUIT.

Check lock-up duty solenoid circuit.

SOLENOID, Diagnostic Procedure with Diag-

nostic Trouble Code (DTC).>Is there any trouble in lock-up

duty solenoid circuit?Repair or replace

the lock-up duty

solenoid circuit.Go to step 3.

3 CHECK THROTTLE POSITION SENSOR

CIRCUIT.

Check the throttle position sensor circuit.

TION SENSOR, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>Is there any trouble in throttle

position sensor circuit?Repair or replace

the throttle posi-

tion sensor circuit.Go to step 4.

4 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR CIRCUIT.

Check torque converter turbine speed sensor

circuit.

SENSOR, Diagnostic Procedure with Diagnos-

tic Trouble Code (DTC).>Is there any trouble in torque

converter turbine speed sensor

circuit?Repair or replace

the torque con-

ver ter turbine

speed sensor cir-

cuit.Go to step 5.

5 CHECK ENGINE SPEED INPUT CIRCUIT.

Check engine speed input circuit.

NAL, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>Is there any trouble in engine

speed input circuit?Repair or replace

the engine speed

input circuit.Go to step 6.

6 CHECK INHIBITOR SWITCH CIRCUIT.

Check inhibitor switch circuit.

Diagnostic Procedure without Diagnostic Trou-

ble Code (DTC).>Is there any trouble in inhibitor

switch circuit?Repair or replace

the inhibitor switch

circuit.Go to step 7.

7 CHECK BRAKE LIGHT SWITCH CIRCUIT.

Check brake light switch circuit.

Diagnostic Procedure without Diagnostic Trou-

ble Code (DTC).>Is there any trouble in brake

light switch circuit?Repair or replace

the brake light

switch circuit.Go to step 8.

Page 1385 of 2870

FU(H4DOTC)-30

FUEL INJECTION (FUEL SYSTEM)

Crankshaft Position Sensor

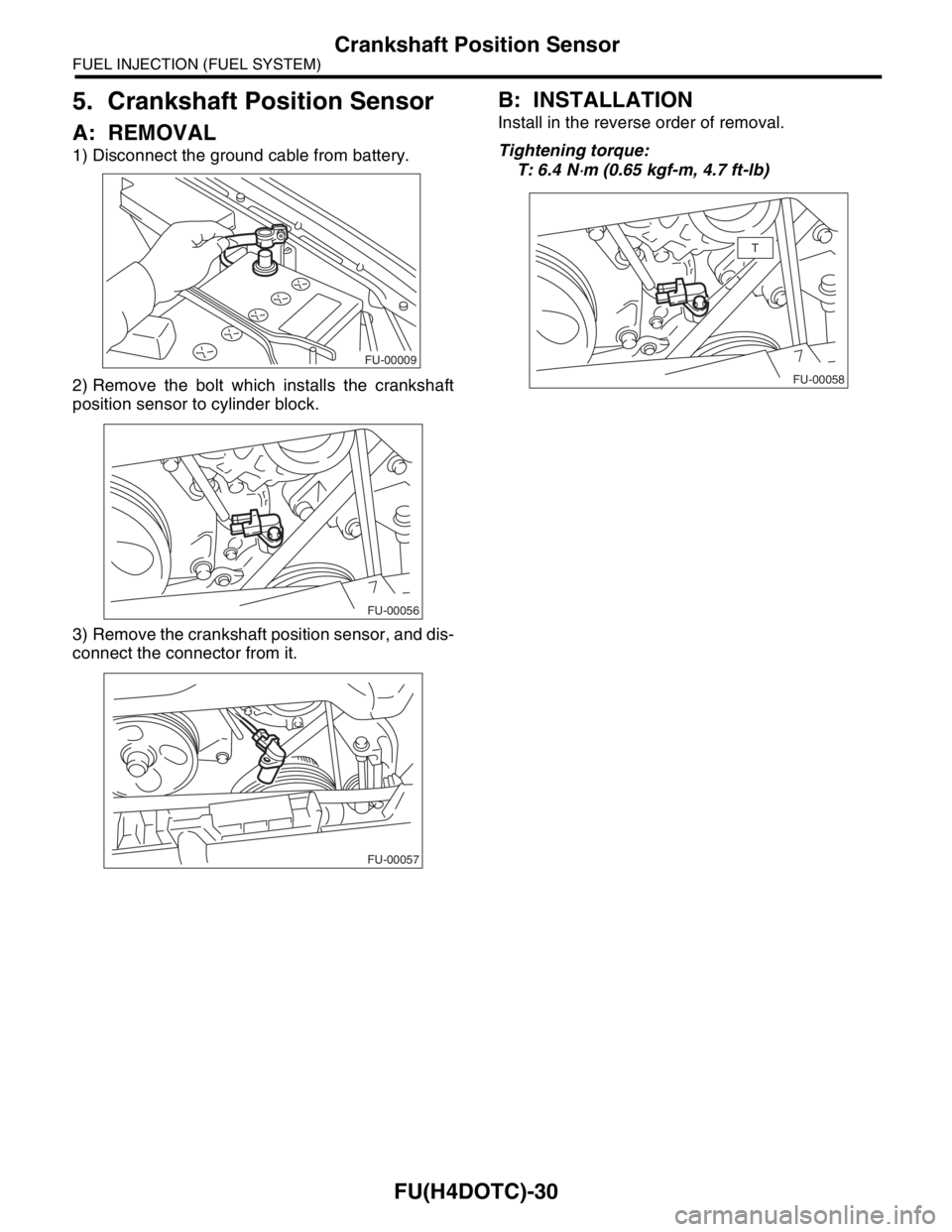

5. Crankshaft Position Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the bolt which installs the crankshaft

position sensor to cylinder block.

3) Remove the crankshaft position sensor, and dis-

connect the connector from it.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

T: 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

FU-00009

FU-00056

FU-00057

FU-00058

T

Page 1388 of 2870

FU(H4DOTC)-33

FUEL INJECTION (FUEL SYSTEM)

Knock Sensor

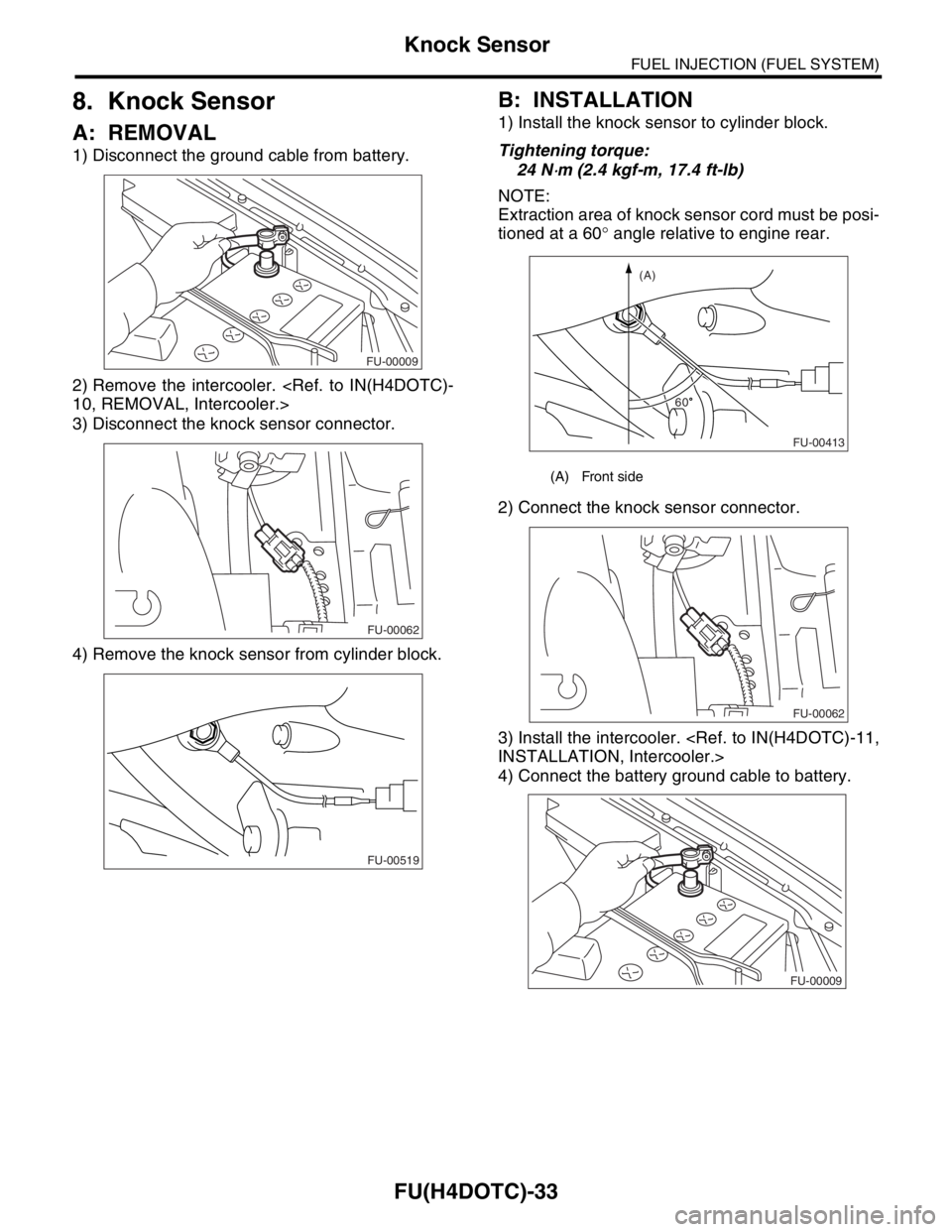

8. Knock Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the intercooler.

3) Disconnect the knock sensor connector.

4) Remove the knock sensor from cylinder block.

B: INSTALLATION

1) Install the knock sensor to cylinder block.

Tightening torque:

24 N

⋅m (2.4 kgf-m, 17.4 ft-lb)

NOTE:

Extraction area of knock sensor cord must be posi-

tioned at a 60° angle relative to engine rear.

2) Connect the knock sensor connector.

3) Install the intercooler.

4) Connect the battery ground cable to battery.

FU-00009

FU-00062

FU-00519

(A) Front side

FU-00413

(A)

60

FU-00062

FU-00009

Page 1457 of 2870

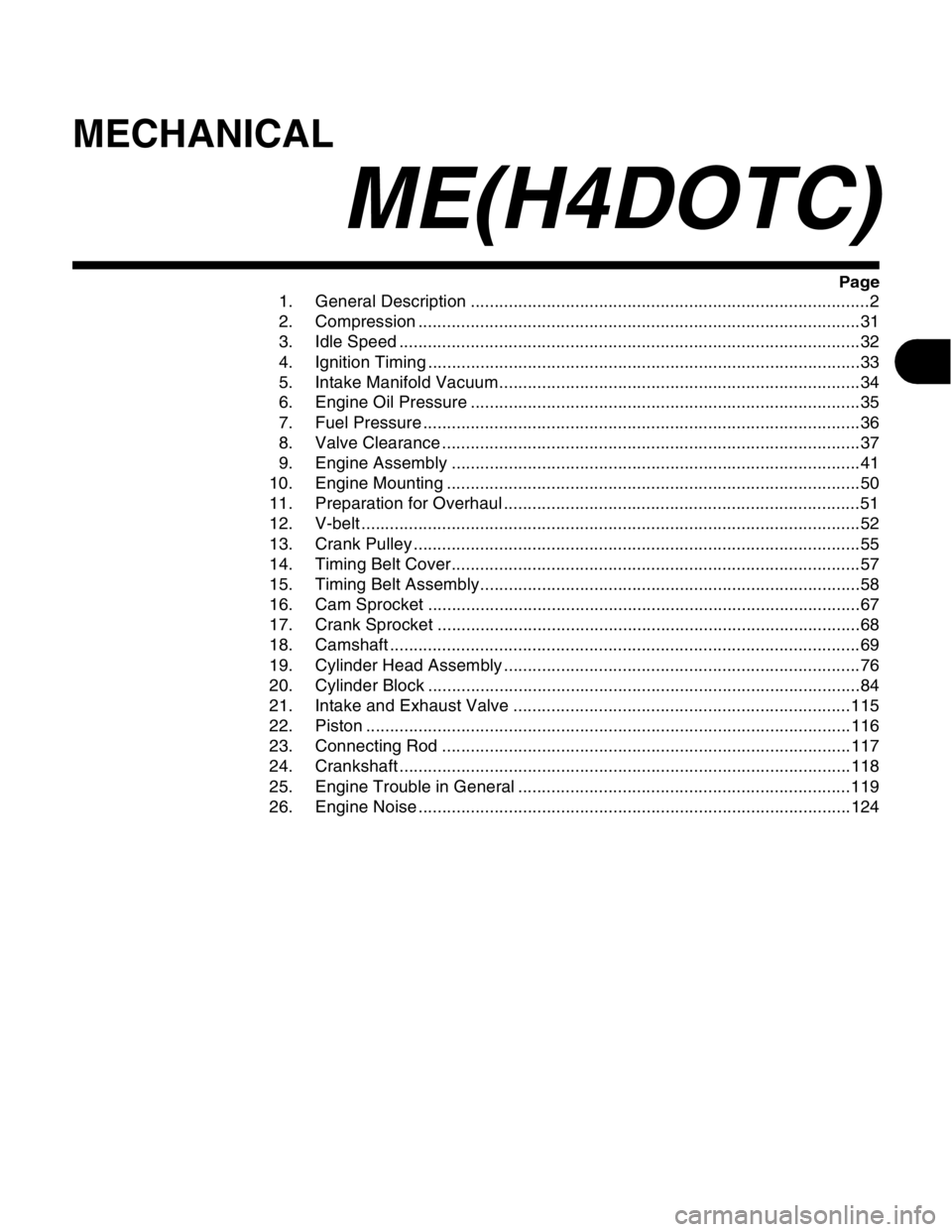

MECHANICAL

ME(H4DOTC)

Page

1. General Description ....................................................................................2

2. Compression .............................................................................................31

3. Idle Speed .................................................................................................32

4. Ignition Timing ...........................................................................................33

5. Intake Manifold Vacuum............................................................................34

6. Engine Oil Pressure ..................................................................................35

7. Fuel Pressure ............................................................................................36

8. Valve Clearance ........................................................................................37

9. Engine Assembly ......................................................................................41

10. Engine Mounting .......................................................................................50

11. Preparation for Overhaul ...........................................................................51

12. V-belt .........................................................................................................52

13. Crank Pulley ..............................................................................................55

14. Timing Belt Cover......................................................................................57

15. Timing Belt Assembly................................................................................58

16. Cam Sprocket ...........................................................................................67

17. Crank Sprocket .........................................................................................68

18. Camshaft ...................................................................................................69

19. Cylinder Head Assembly ...........................................................................76

20. Cylinder Block ...........................................................................................84

21. Intake and Exhaust Valve .......................................................................115

22. Piston ......................................................................................................116

23. Connecting Rod ......................................................................................117

24. Crankshaft ...............................................................................................118

25. Engine Trouble in General ......................................................................119

26. Engine Noise ...........................................................................................124

Page 1459 of 2870

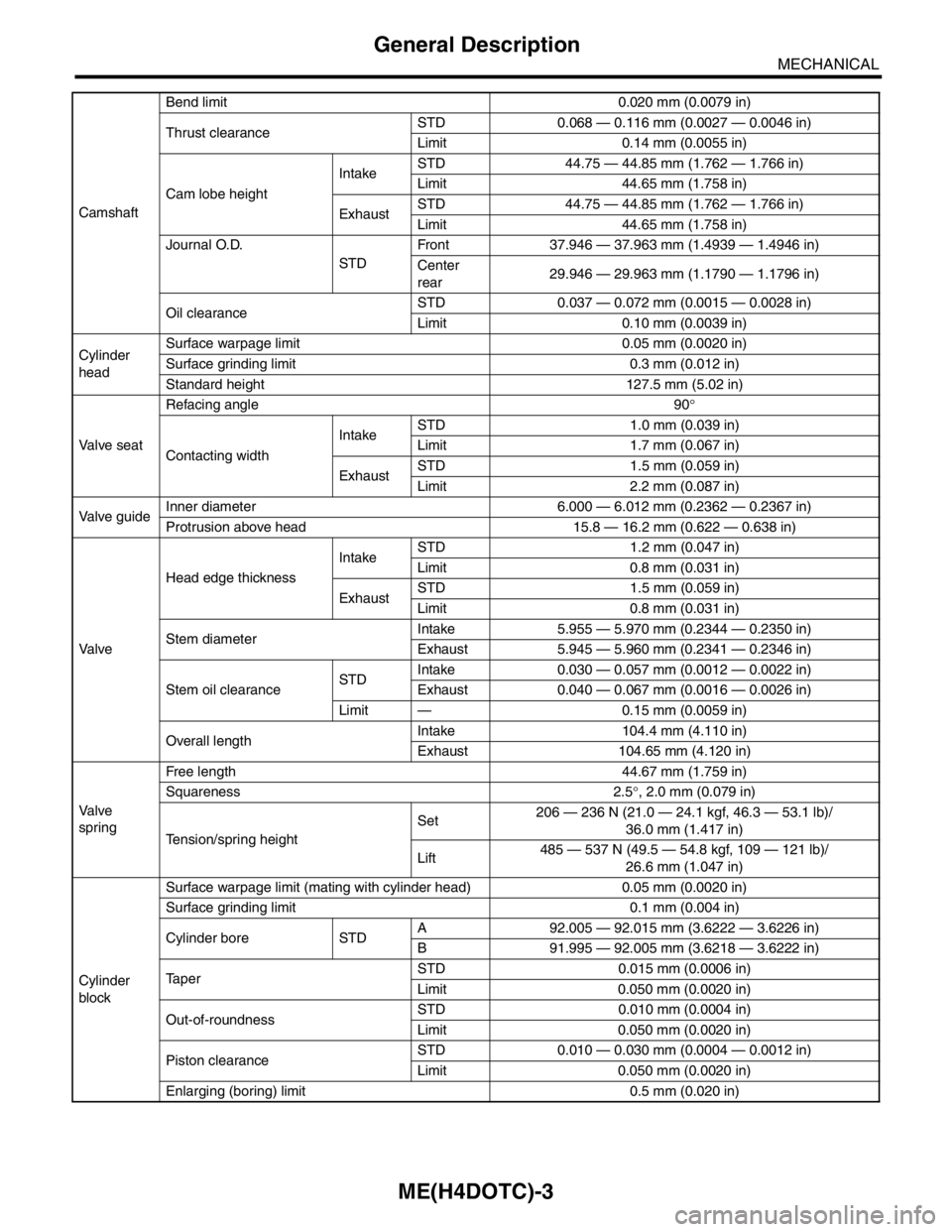

ME(H4DOTC)-3

MECHANICAL

General Description

CamshaftBend limit 0.020 mm (0.0079 in)

Thrust clearanceSTD 0.068 — 0.116 mm (0.0027 — 0.0046 in)

Limit 0.14 mm (0.0055 in)

Cam lobe heightIntakeSTD 44.75 — 44.85 mm (1.762 — 1.766 in)

Limit 44.65 mm (1.758 in)

ExhaustSTD 44.75 — 44.85 mm (1.762 — 1.766 in)

Limit 44.65 mm (1.758 in)

Journal O.D.

STDFront 37.946 — 37.963 mm (1.4939 — 1.4946 in)

Center

rear29.946 — 29.963 mm (1.1790 — 1.1796 in)

Oil clearanceSTD 0.037 — 0.072 mm (0.0015 — 0.0028 in)

Limit 0.10 mm (0.0039 in)

Cylinder

headSurface warpage limit 0.05 mm (0.0020 in)

Surface grinding limit 0.3 mm (0.012 in)

Standard height 127.5 mm (5.02 in)

Va l ve s e a tRefacing angle 90°

Contacting widthIntakeSTD 1.0 mm (0.039 in)

Limit 1.7 mm (0.067 in)

ExhaustSTD 1.5 mm (0.059 in)

Limit 2.2 mm (0.087 in)

Valve guideInner diameter 6.000 — 6.012 mm (0.2362 — 0.2367 in)

Protrusion above head 15.8 — 16.2 mm (0.622 — 0.638 in)

Va l veHead edge thicknessIntakeSTD 1.2 mm (0.047 in)

Limit 0.8 mm (0.031 in)

ExhaustSTD 1.5 mm (0.059 in)

Limit 0.8 mm (0.031 in)

Stem diameterIntake 5.955 — 5.970 mm (0.2344 — 0.2350 in)

Exhaust 5.945 — 5.960 mm (0.2341 — 0.2346 in)

Stem oil clearanceSTDIntake 0.030 — 0.057 mm (0.0012 — 0.0022 in)

Exhaust 0.040 — 0.067 mm (0.0016 — 0.0026 in)

Limit — 0.15 mm (0.0059 in)

Overall lengthIntake 104.4 mm (4.110 in)

Exhaust 104.65 mm (4.120 in)

Va l ve

springFree length 44.67 mm (1.759 in)

Squareness 2.5°, 2.0 mm (0.079 in)

Tension/spring heightSet206 — 236 N (21.0 — 24.1 kgf, 46.3 — 53.1 lb)/

36.0 mm (1.417 in)

Lift485 — 537 N (49.5 — 54.8 kgf, 109 — 121 lb)/

26.6 mm (1.047 in)

Cylinder

blockSurface warpage limit (mating with cylinder head) 0.05 mm (0.0020 in)

Surface grinding limit 0.1 mm (0.004 in)

Cylinder bore STDA 92.005 — 92.015 mm (3.6222 — 3.6226 in)

B 91.995 — 92.005 mm (3.6218 — 3.6222 in)

TaperSTD 0.015 mm (0.0006 in)

Limit 0.050 mm (0.0020 in)

Out-of-roundnessSTD 0.010 mm (0.0004 in)

Limit 0.050 mm (0.0020 in)

Piston clearanceSTD 0.010 — 0.030 mm (0.0004 — 0.0012 in)

Limit 0.050 mm (0.0020 in)

Enlarging (boring) limit 0.5 mm (0.020 in)

Page 1464 of 2870

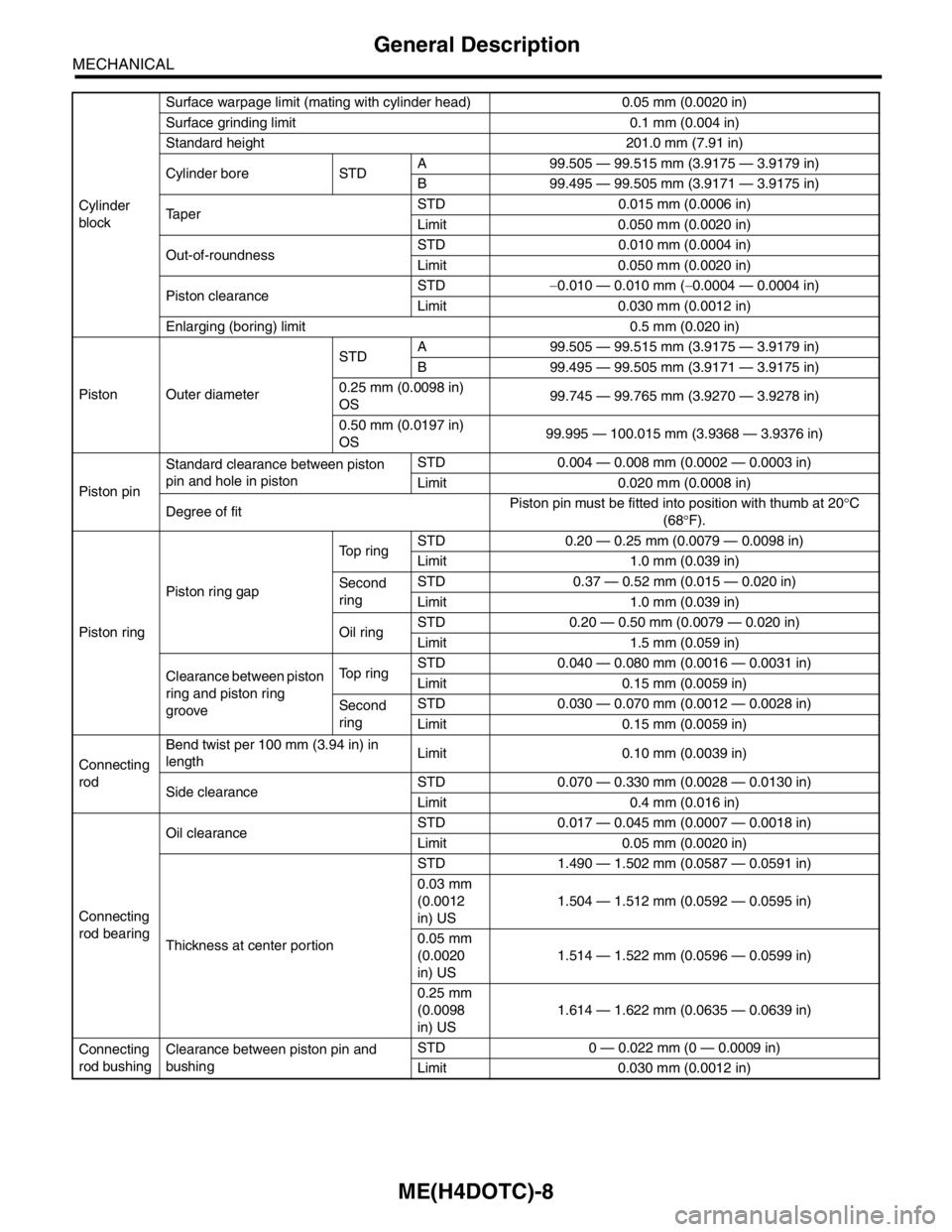

ME(H4DOTC)-8

MECHANICAL

General Description

Cylinder

blockSurface warpage limit (mating with cylinder head) 0.05 mm (0.0020 in)

Surface grinding limit 0.1 mm (0.004 in)

Standard height 201.0 mm (7.91 in)

Cylinder bore STDA 99.505 — 99.515 mm (3.9175 — 3.9179 in)

B 99.495 — 99.505 mm (3.9171 — 3.9175 in)

TaperSTD 0.015 mm (0.0006 in)

Limit 0.050 mm (0.0020 in)

Out-of-roundnessSTD 0.010 mm (0.0004 in)

Limit 0.050 mm (0.0020 in)

Piston clearanceSTD−0.010 — 0.010 mm (−0.0004 — 0.0004 in)

Limit 0.030 mm (0.0012 in)

Enlarging (boring) limit 0.5 mm (0.020 in)

Piston Outer diameterSTDA 99.505 — 99.515 mm (3.9175 — 3.9179 in)

B 99.495 — 99.505 mm (3.9171 — 3.9175 in)

0.25 mm (0.0098 in)

OS99.745 — 99.765 mm (3.9270 — 3.9278 in)

0.50 mm (0.0197 in)

OS99.995 — 100.015 mm (3.9368 — 3.9376 in)

Piston pinStandard clearance between piston

pin and hole in pistonSTD 0.004 — 0.008 mm (0.0002 — 0.0003 in)

Limit 0.020 mm (0.0008 in)

Degree of fitPiston pin must be fitted into position with thumb at 20°C

(68°F).

Piston ringPiston ring gapTop ringSTD 0.20 — 0.25 mm (0.0079 — 0.0098 in)

Limit 1.0 mm (0.039 in)

Second

ringSTD 0.37 — 0.52 mm (0.015 — 0.020 in)

Limit 1.0 mm (0.039 in)

Oil ringSTD 0.20 — 0.50 mm (0.0079 — 0.020 in)

Limit 1.5 mm (0.059 in)

Clearance between piston

ring and piston ring

grooveTop ringSTD 0.040 — 0.080 mm (0.0016 — 0.0031 in)

Limit 0.15 mm (0.0059 in)

Second

ringSTD 0.030 — 0.070 mm (0.0012 — 0.0028 in)

Limit 0.15 mm (0.0059 in)

Connecting

rodBend twist per 100 mm (3.94 in) in

lengthLimit 0.10 mm (0.0039 in)

Side clearanceSTD 0.070 — 0.330 mm (0.0028 — 0.0130 in)

Limit 0.4 mm (0.016 in)

Connecting

rod bearingOil clearanceSTD 0.017 — 0.045 mm (0.0007 — 0.0018 in)

Limit 0.05 mm (0.0020 in)

Thickness at center portionSTD 1.490 — 1.502 mm (0.0587 — 0.0591 in)

0.03 mm

(0.0012

in) US1.504 — 1.512 mm (0.0592 — 0.0595 in)

0.05 mm

(0.0020

in) US1.514 — 1.522 mm (0.0596 — 0.0599 in)

0.25 mm

(0.0098

in) US1.614 — 1.622 mm (0.0635 — 0.0639 in)

Connecting

rod bushingClearance between piston pin and

bushingSTD 0 — 0.022 mm (0 — 0.0009 in)

Limit 0.030 mm (0.0012 in)