lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1472 of 2870

ME(H4DOTC)-16

MECHANICAL

General Description

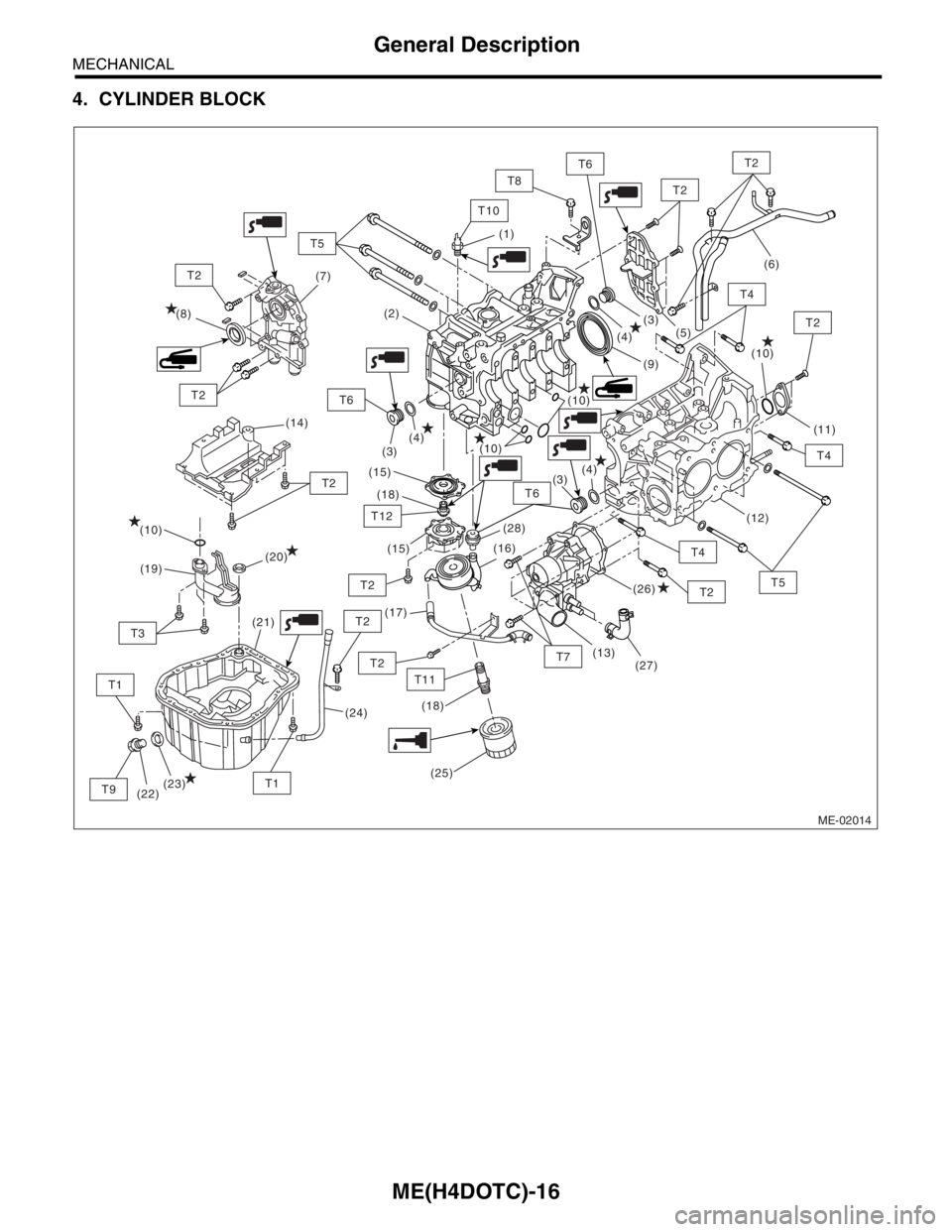

4. CYLINDER BLOCK

ME-02014

(14)

T2

T6

T7

T2

T2

T2

T2

T8

T5

T4

T5

T4

T2

T6

T6

T2

T11

T12

T10

T1

T1

T3

T9

T2

T2

T2

(9) (8)(7)(6)

(15)(10)

(10)

(10)(11)

(12)

(13) (18)

(15)

(17)(28)

(22)(21)

(23)(20)

(19)

(26)

(18)

(25) (10)

(27)

(5)

(4)

(4)

(4)(3)

(3)

(3) (2)(1)

(24)

(16)T4

Page 1473 of 2870

ME(H4DOTC)-17

MECHANICAL

General Description

(1) Oil pressure switch (15) AdapterTightening torque: N⋅m (kgf-m, ft-lb)

(2) Cylinder block (RH) (16) Oil coolerT1: 5 (0.5, 3.6)

(3) Service hole plug (17) Waster by-pass pipe T2: 6.4 (0.65, 4.7)

(4) Gasket (18) ConnectorT3: 10 (1.0, 7.2)

(5) Oil separator cover (19) Oil strainerT4: 25 (2.5, 18.1)

(6) Water by-pass pipe (20) GasketT5:

BLOCK.> (7) Oil pump (21) Oil pan

(8) Front oil seal (22) Drain plug

(9) Rear oil seal (23) Metal gasketT6: 70 (7.1, 50.6)

(10) O-ring (24) Oil level gauge guideT7: First 12 (1.2, 8.7)

Second 12 (1.2, 8.7)

(11) Service hole cover (25) Oil filter

(12) Cylinder block (LH) (26) GasketT8: 16 (1.6, 11.6)

(13) Water pump (27) Water pump hoseT9: 44 (4.5, 33)

(14) Baffle plate (28) PlugT10: 25 (2.5, 18.1)

T11: 54 (5.3, 39)

T12: 45 (4.6, 33)

Page 1491 of 2870

ME(H4DOTC)-35

MECHANICAL

Engine Oil Pressure

6. Engine Oil Pressure

A: INSPECTION

1) Remove the oil pressure switch from engine cyl-

inder block.

2) Connect the oil pressure gauge hose to cylinder

block.

3) Connect the battery ground cable to battery.

4) Start the engine, and then measure the oil pres-

sure.

Oil pressure:

98 kPa (1.0 kg/cm

2, 14 psi) or more at 800 rpm

294 kPa (3.0 kg/cm2, 43 psi) or more at 5,000

rpm

If the oil pressure is out of specification, check oil

pump, oil filter and lubrication line.

System Trouble in General.>

If the oil pressure warning light is turned ON and

oil pressure is in specification, replace the oil pres-

sure switch.

NOTE:

The specified data is based on an engine oil tem-

perature of 80°C (176°F).

5) After measuring the oil pressure, install the oil

pressure switch.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

FU-00009

ME-00009

Page 1494 of 2870

ME(H4DOTC)-38

MECHANICAL

Valve Clearance

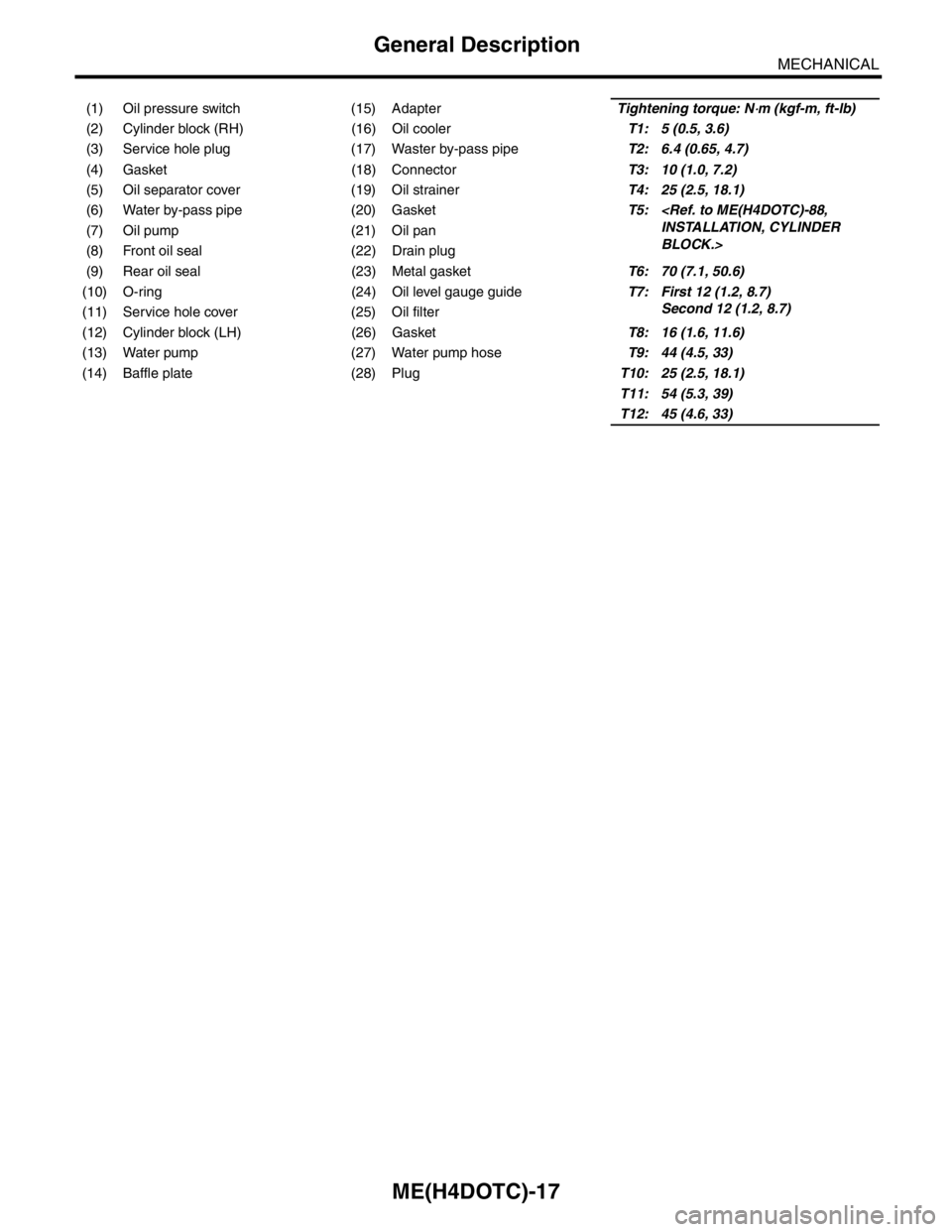

(5) Move the washer tank upward.

(6) Disconnect the ignition coil connector.

(7) Remove the ignition coil.

(8) Place a suitable container under the vehicle.

(9) Disconnect the PCV hose from rocker cover

(LH).

(10)Remove the bolts, and then remove the

rocker cover (LH).

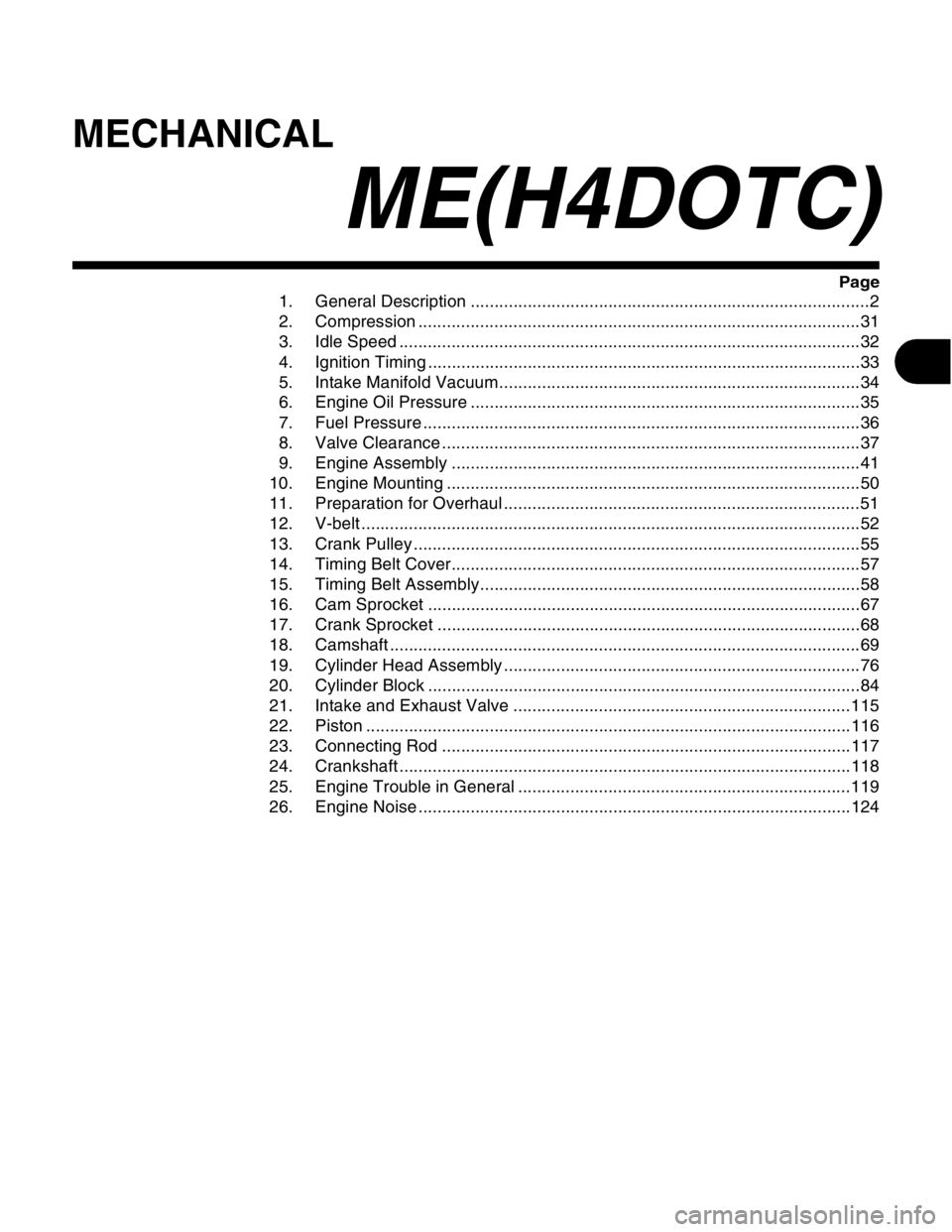

11) Turn the crankshaft pulley clockwise until arrow

mark on the camshaft sprocket is set to position

shown in the figure.

NOTE:

Turn the crankshaft using socket wrench.

12) Measure the #1 cylinder intake valve and #3

cylinder exhaust valve clearance by using thick-

ness gauge (A).

NOTE:

Insert the thickness gauge in as horizontal a di-

rection as possible with respect to the shim.

Measure the exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.35

±0.02 mm (0.0138±0.0008 in)NOTE:

If the measured value is not within specification,

take notes of the value in order to adjust the valve

clearance later on.

13) If necessary, adjust the valve clearance.

ance.>

14) Further turn the crankshaft pulley clockwise.

Using the same procedures described previously,

and then measure the valve clearances again.

(1) Set the arrow mark on camshaft sprocket to

position shown in the figure, and then measure

the #2 cylinder exhaust valve and #3 cylinder in-

take valve clearances.

(2) Set the arrow mark on camshaft sprocket to

position shown in the figure, and then measure

the #2 cylinder intake valve and #4 cylinder ex-

haust valve clearances.

ME-00017

ME-00733

ME-00019

(A)

ME-00734

ME-00735

Page 1498 of 2870

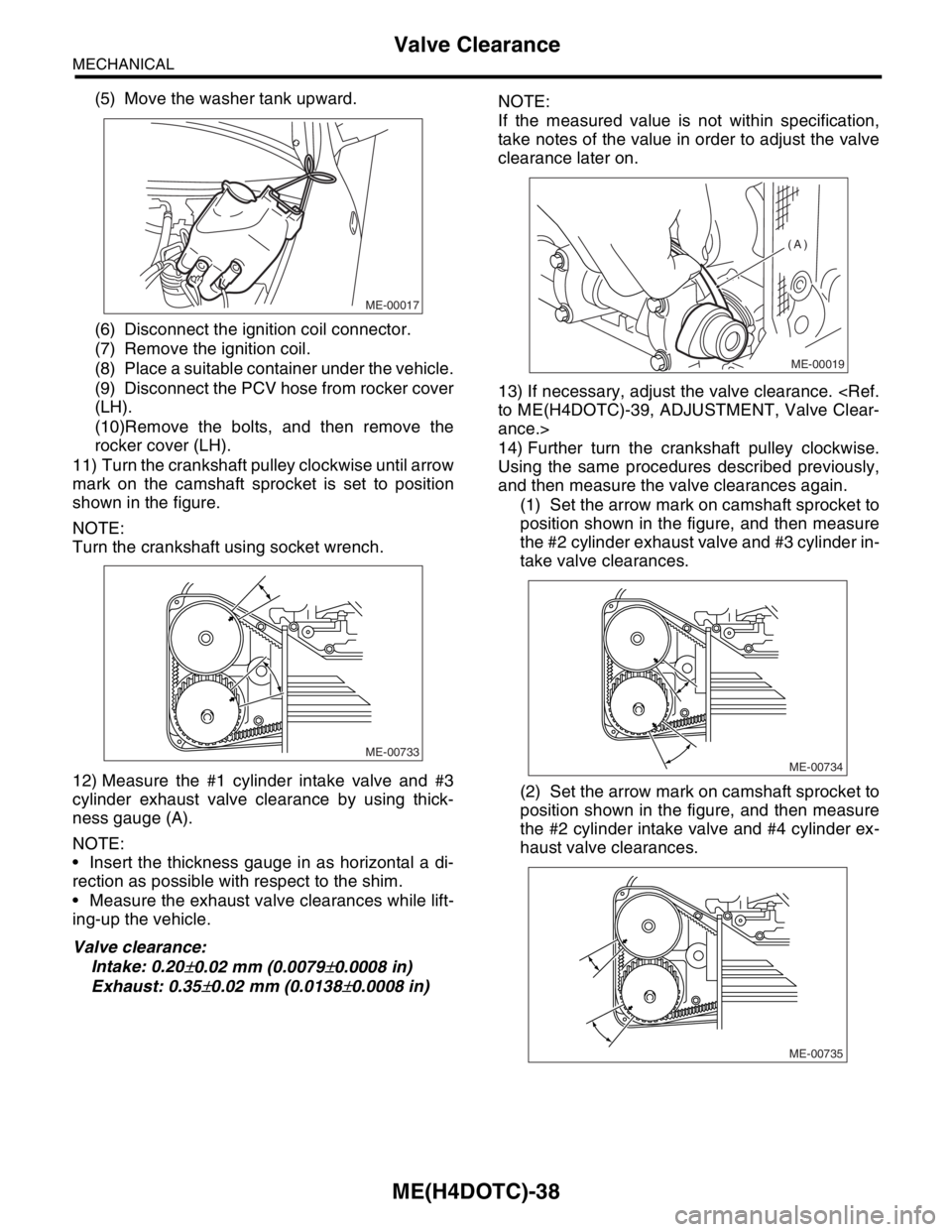

MECHANICAL

ME(H4DOTC)

Page

1. General Description ....................................................................................2

2. Compression .............................................................................................31

3. Idle Speed .................................................................................................32

4. Ignition Timing ...........................................................................................33

5. Intake Manifold Vacuum............................................................................34

6. Engine Oil Pressure ..................................................................................35

7. Fuel Pressure ............................................................................................36

8. Valve Clearance ........................................................................................37

9. Engine Assembly ......................................................................................41

10. Engine Mounting .......................................................................................50

11. Preparation for Overhaul ...........................................................................51

12. V-belt .........................................................................................................52

13. Crank Pulley ..............................................................................................55

14. Timing Belt Cover......................................................................................57

15. Timing Belt Assembly................................................................................58

16. Cam Sprocket ...........................................................................................67

17. Crank Sprocket .........................................................................................68

18. Camshaft ...................................................................................................69

19. Cylinder Head Assembly ...........................................................................76

20. Cylinder Block ...........................................................................................84

21. Intake and Exhaust Valve .......................................................................115

22. Piston ......................................................................................................116

23. Connecting Rod ......................................................................................117

24. Crankshaft ...............................................................................................118

25. Engine Trouble in General ......................................................................119

26. Engine Noise ...........................................................................................124

Page 1500 of 2870

ME(H4DOTC)-42

MECHANICAL

Engine Assembly

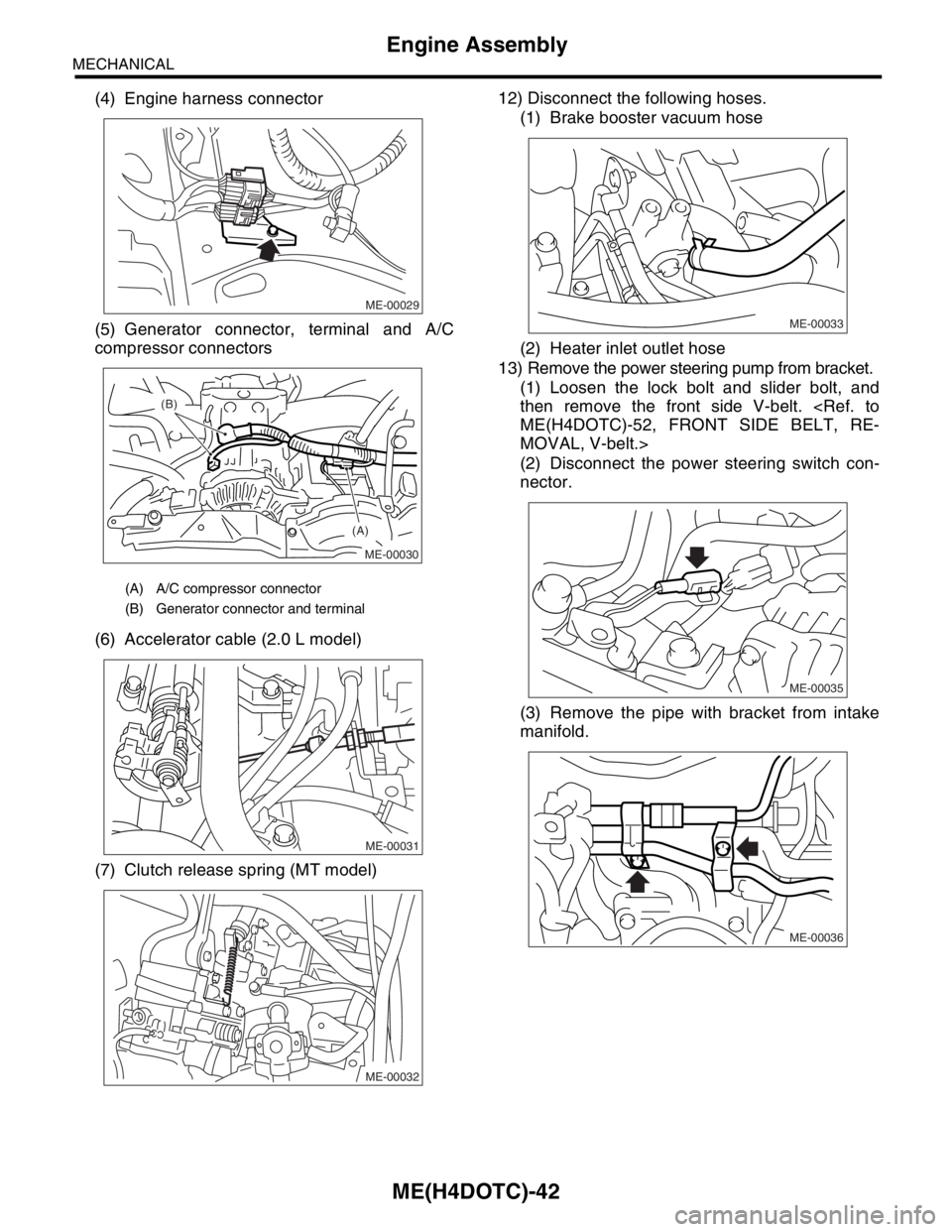

(4) Engine harness connector

(5) Generator connector, terminal and A/C

compressor connectors

(6) Accelerator cable (2.0 L model)

(7) Clutch release spring (MT model)12) Disconnect the following hoses.

(1) Brake booster vacuum hose

(2) Heater inlet outlet hose

13) Remove the power steering pump from bracket.

(1) Loosen the lock bolt and slider bolt, and

then remove the front side V-belt.

MOVAL, V-belt.>

(2) Disconnect the power steering switch con-

nector.

(3) Remove the pipe with bracket from intake

manifold.

(A) A/C compressor connector

(B) Generator connector and terminal

ME-00029

ME-00030

(A) (B)

ME-00031

ME-00032

ME-00033

ME-00035

ME-00036

Page 1510 of 2870

ME(H4DOTC)-52

MECHANICAL

V-belt

12.V-belt

A: REMOVAL

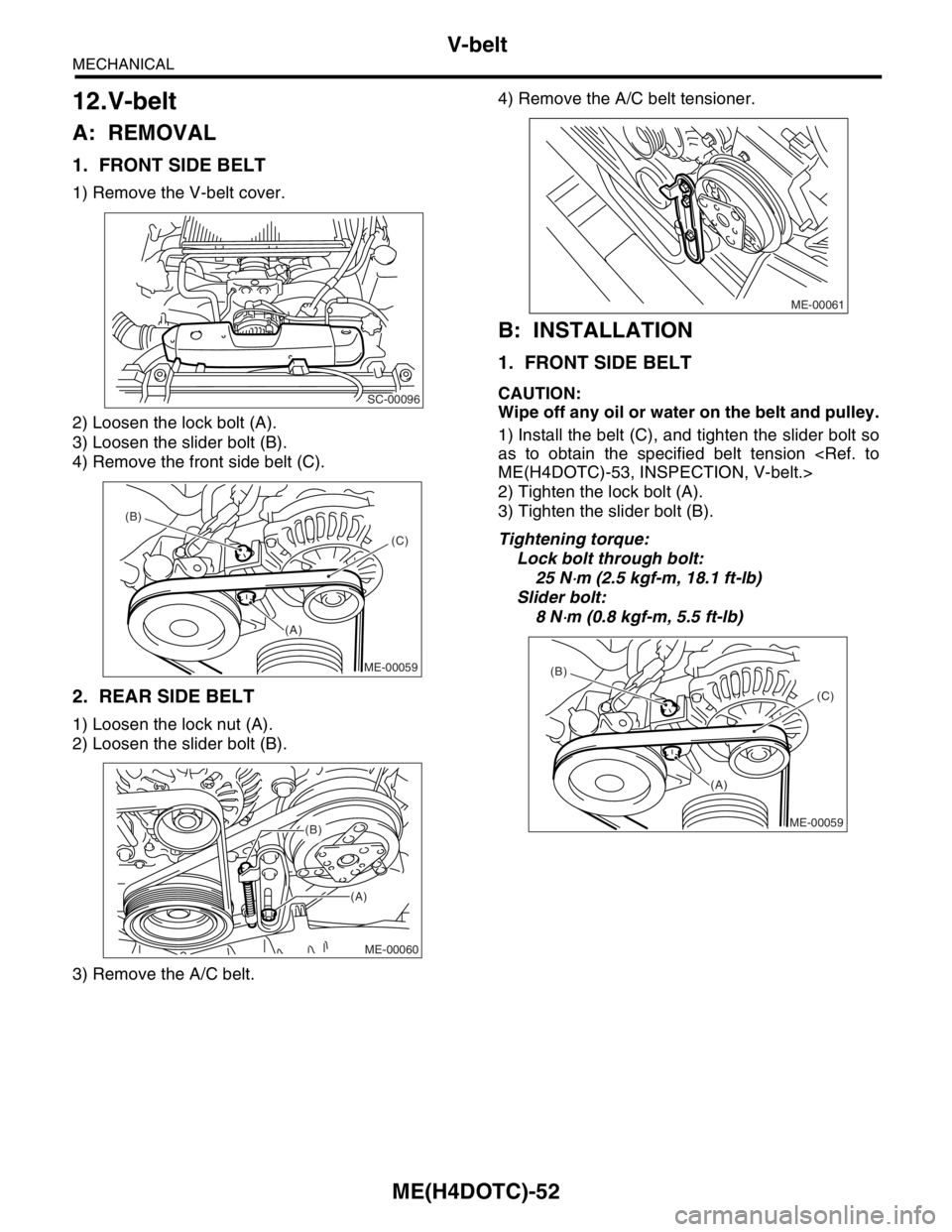

1. FRONT SIDE BELT

1) Remove the V-belt cover.

2) Loosen the lock bolt (A).

3) Loosen the slider bolt (B).

4) Remove the front side belt (C).

2. REAR SIDE BELT

1) Loosen the lock nut (A).

2) Loosen the slider bolt (B).

3) Remove the A/C belt.4) Remove the A/C belt tensioner.

B: INSTALLATION

1. FRONT SIDE BELT

CAUTION:

Wipe off any oil or water on the belt and pulley.

1) Install the belt (C), and tighten the slider bolt so

as to obtain the specified belt tension

2) Tighten the lock bolt (A).

3) Tighten the slider bolt (B).

Tightening torque:

Lock bolt through bolt:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

Slider bolt:

8 N

⋅m (0.8 kgf-m, 5.5 ft-lb)

SC-00096

(A)

(C) (B)

ME-00059

(A)

(B)

ME-00060

ME-00061

(A)

(C) (B)

ME-00059

Page 1511 of 2870

ME(H4DOTC)-53

MECHANICAL

V-belt

2. REAR SIDE BELT

1) Install the belt, and tighten the slider bolt (B) so

as to obtain the specified belt tension.

2) Tighten the lock nut (A).

Tightening torque:

Lock nut (A);

22.6 N

⋅m (2.3 kgf-m, 16.6 ft-lb)

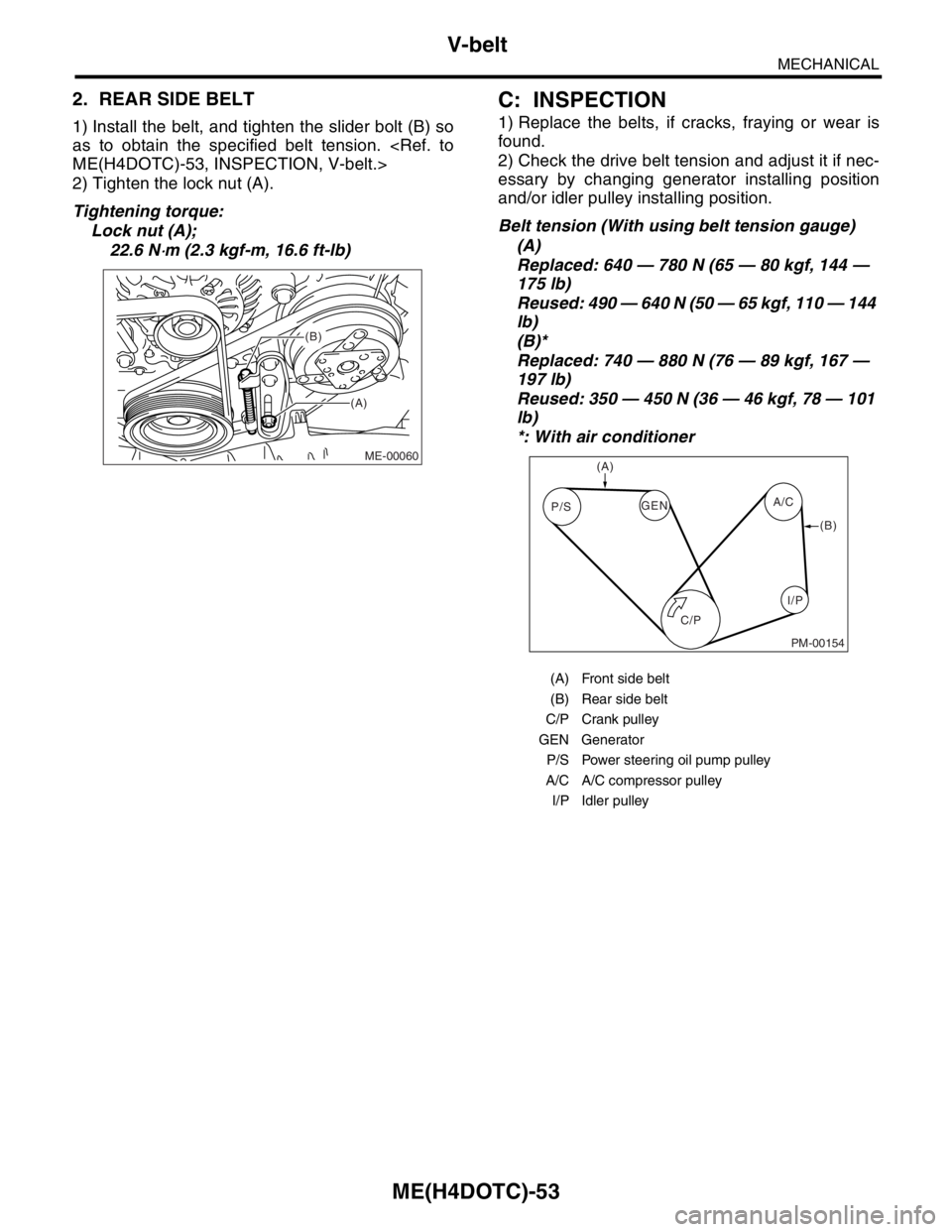

C: INSPECTION

1) Replace the belts, if cracks, fraying or wear is

found.

2) Check the drive belt tension and adjust it if nec-

essary by changing generator installing position

and/or idler pulley installing position.

Belt tension (With using belt tension gauge)

(A)

Replaced: 640 — 780 N (65 — 80 kgf, 144 —

175 lb)

Reused: 490 — 640 N (50 — 65 kgf, 110 — 144

lb)

(B)*

Replaced: 740 — 880 N (76 — 89 kgf, 167 —

197 lb)

Reused: 350 — 450 N (36 — 46 kgf, 78 — 101

lb)

*: With air conditioner

(A)

(B)

ME-00060

(A) Front side belt

(B) Rear side belt

C/P Crank pulley

GEN Generator

P/S Power steering oil pump pulley

A/C A/C compressor pulley

I/P Idler pulley

C/P P/SA/C

GEN

(A)

(B)

I/P

PM-00154

Page 1513 of 2870

ME(H4DOTC)-55

MECHANICAL

Crank Pulley

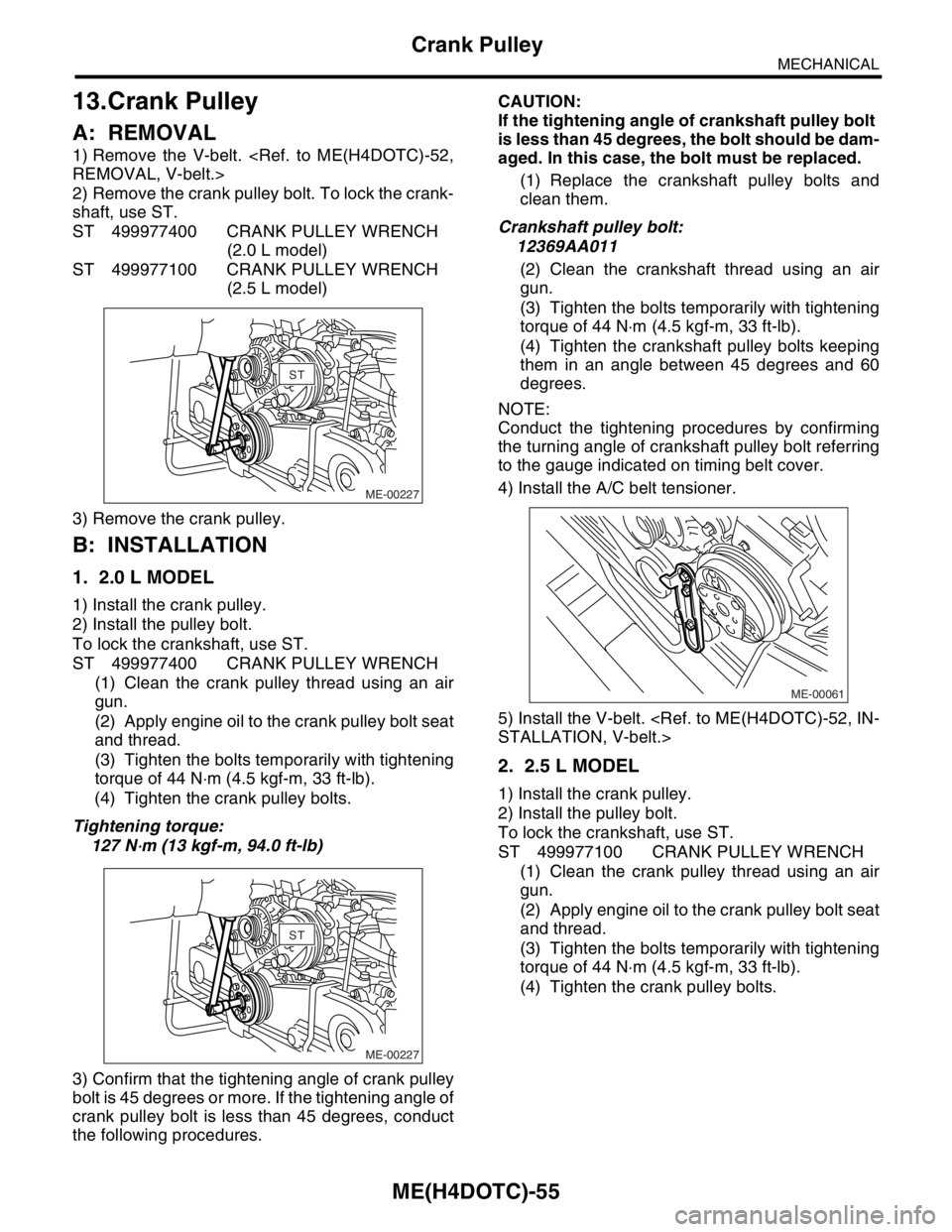

13.Crank Pulley

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley bolt. To lock the crank-

shaft, use ST.

ST 499977400 CRANK PULLEY WRENCH

(2.0 L model)

ST 499977100 CRANK PULLEY WRENCH

(2.5 L model)

3) Remove the crank pulley.

B: INSTALLATION

1. 2.0 L MODEL

1) Install the crank pulley.

2) Install the pulley bolt.

To lock the crankshaft, use ST.

ST 499977400 CRANK PULLEY WRENCH

(1) Clean the crank pulley thread using an air

gun.

(2) Apply engine oil to the crank pulley bolt seat

and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crank pulley bolts.

Tightening torque:

127 N

⋅m (13 kgf-m, 94.0 ft-lb)

3) Confirm that the tightening angle of crank pulley

bolt is 45 degrees or more. If the tightening angle of

crank pulley bolt is less than 45 degrees, conduct

the following procedures.CAUTION:

If the tightening angle of crankshaft pulley bolt

is less than 45 degrees, the bolt should be dam-

aged. In this case, the bolt must be replaced.

(1) Replace the crankshaft pulley bolts and

clean them.

Crankshaft pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crankshaft pulley bolts keeping

them in an angle between 45 degrees and 60

degrees.

NOTE:

Conduct the tightening procedures by confirming

the turning angle of crankshaft pulley bolt referring

to the gauge indicated on timing belt cover.

4) Install the A/C belt tensioner.

5) Install the V-belt.

2. 2.5 L MODEL

1) Install the crank pulley.

2) Install the pulley bolt.

To lock the crankshaft, use ST.

ST 499977100 CRANK PULLEY WRENCH

(1) Clean the crank pulley thread using an air

gun.

(2) Apply engine oil to the crank pulley bolt seat

and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crank pulley bolts.

ME-00227

STST

ME-00227

STST

ME-00061

Page 1516 of 2870

ME(H4DOTC)-58

MECHANICAL

Timing Belt Assembly

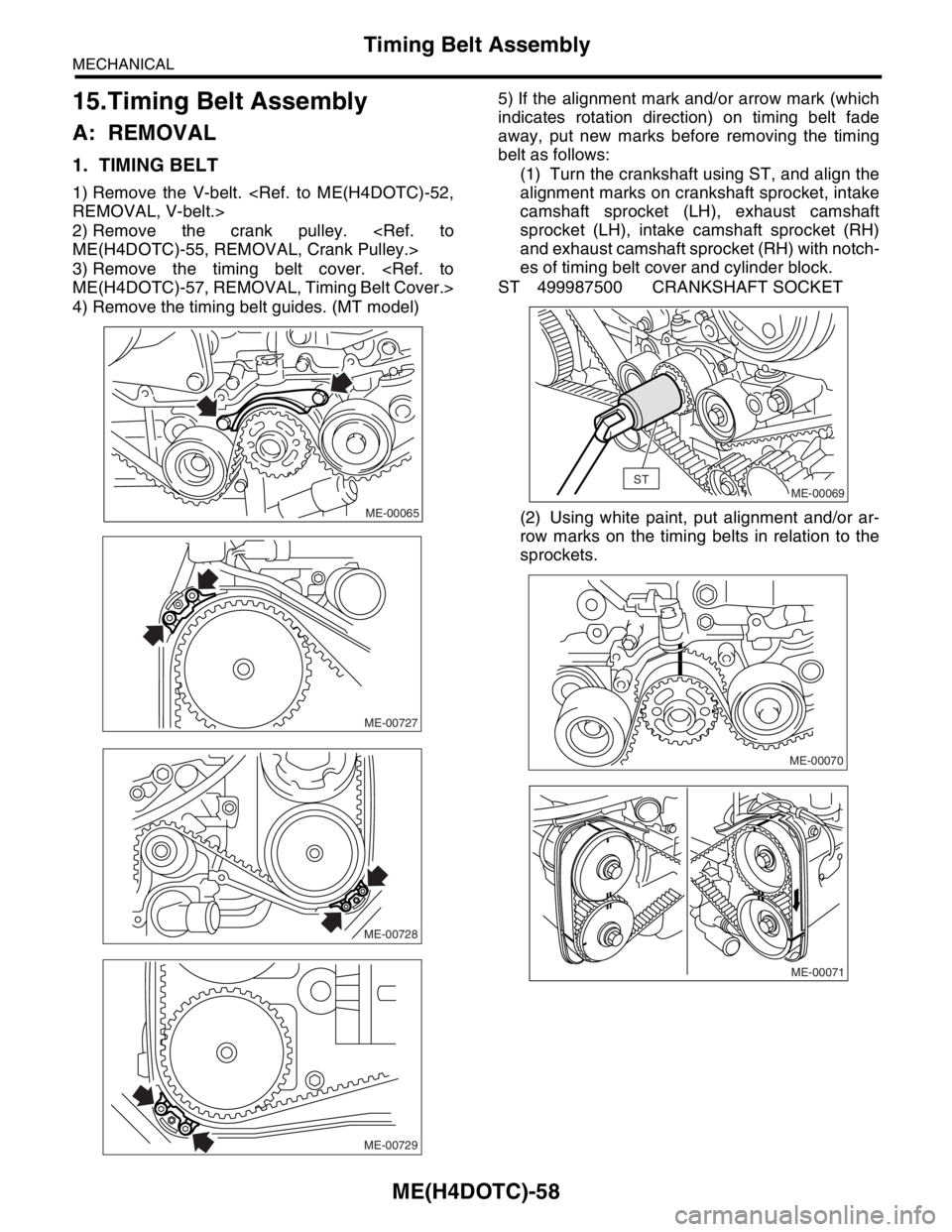

15.Timing Belt Assembly

A: REMOVAL

1. TIMING BELT

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt guides. (MT model)5) If the alignment mark and/or arrow mark (which

indicates rotation direction) on timing belt fade

away, put new marks before removing the timing

belt as follows:

(1) Turn the crankshaft using ST, and align the

alignment marks on crankshaft sprocket, intake

camshaft sprocket (LH), exhaust camshaft

sprocket (LH), intake camshaft sprocket (RH)

and exhaust camshaft sprocket (RH) with notch-

es of timing belt cover and cylinder block.

ST 499987500 CRANKSHAFT SOCKET

(2) Using white paint, put alignment and/or ar-

row marks on the timing belts in relation to the

sprockets.

ME-00065

ME-00727

ME-00728

ME-00729

ME-00069ST

ME-00070

ME-00071