torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 945 of 2870

ME(H4SO)-74

MECHANICAL

Cylinder Block

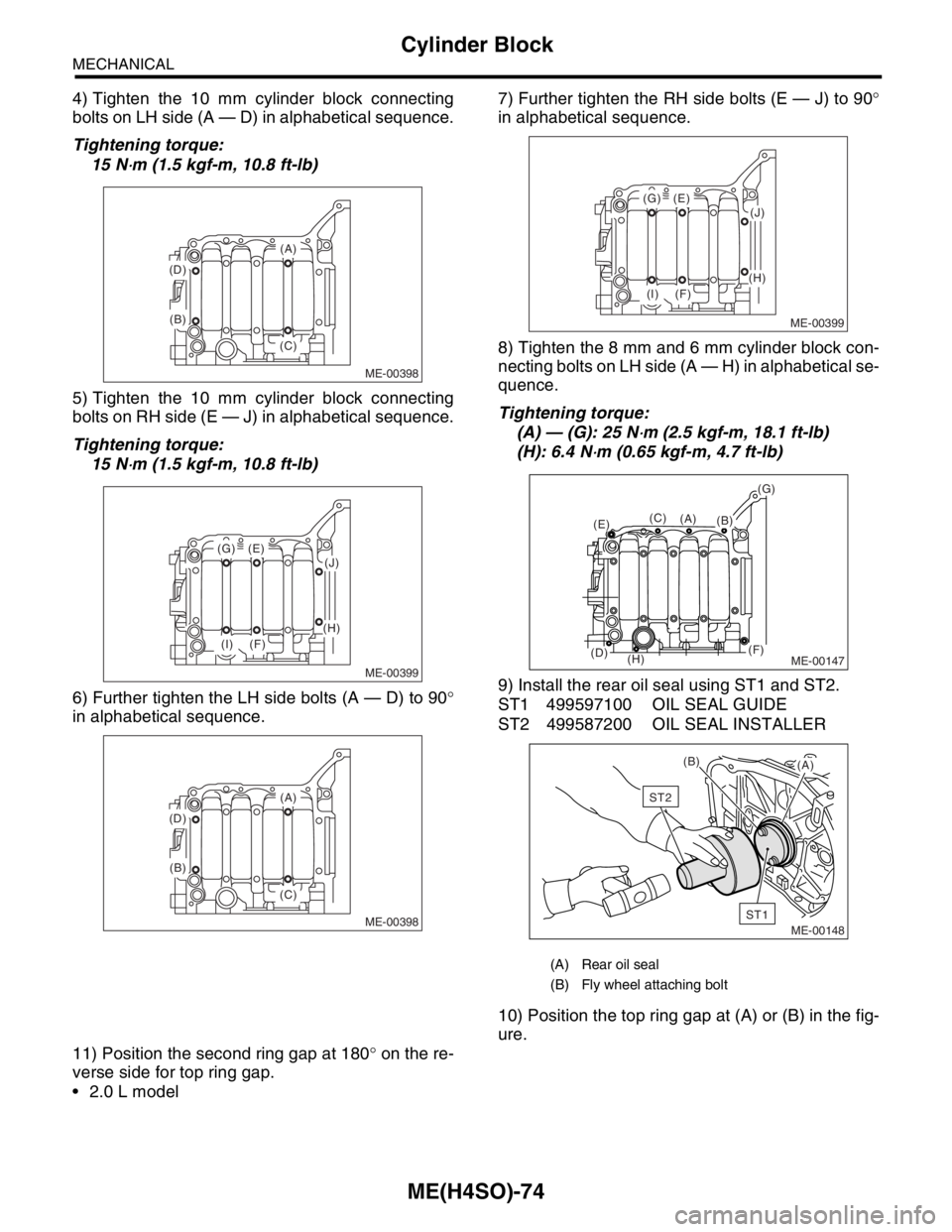

4) Tighten the 10 mm cylinder block connecting

bolts on LH side (A — D) in alphabetical sequence.

Tightening torque:

15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

5) Tighten the 10 mm cylinder block connecting

bolts on RH side (E — J) in alphabetical sequence.

Tightening torque:

15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

6) Further tighten the LH side bolts (A — D) to 90°

in alphabetical sequence.7) Further tighten the RH side bolts (E — J) to 90°

in alphabetical sequence.

8) Tighten the 8 mm and 6 mm cylinder block con-

necting bolts on LH side (A — H) in alphabetical se-

quence.

Tightening torque:

(A) — (G): 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(H): 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

9) Install the rear oil seal using ST1 and ST2.

ST1 499597100 OIL SEAL GUIDE

ST2 499587200 OIL SEAL INSTALLER

10) Position the top ring gap at (A) or (B) in the fig-

ure.

11) Position the second ring gap at 180° on the re-

verse side for top ring gap.

2.0 L model

ME-00398

(A)

(B)

(C) (D)

ME-00399

(E)(G)

(F)(I)

(J)

(H)

ME-00398

(A)

(B)

(C) (D)

(A) Rear oil seal

(B) Fly wheel attaching bolt

ME-00399

(E)(G)

(F)(I)

(J)

(H)

ME-00147

(B)(C)

(D)

(E)

(F)

(G)

(H)

(A)

ME-00148

ST1

ST2

(B)

(A)

Page 948 of 2870

ME(H4SO)-77

MECHANICAL

Cylinder Block

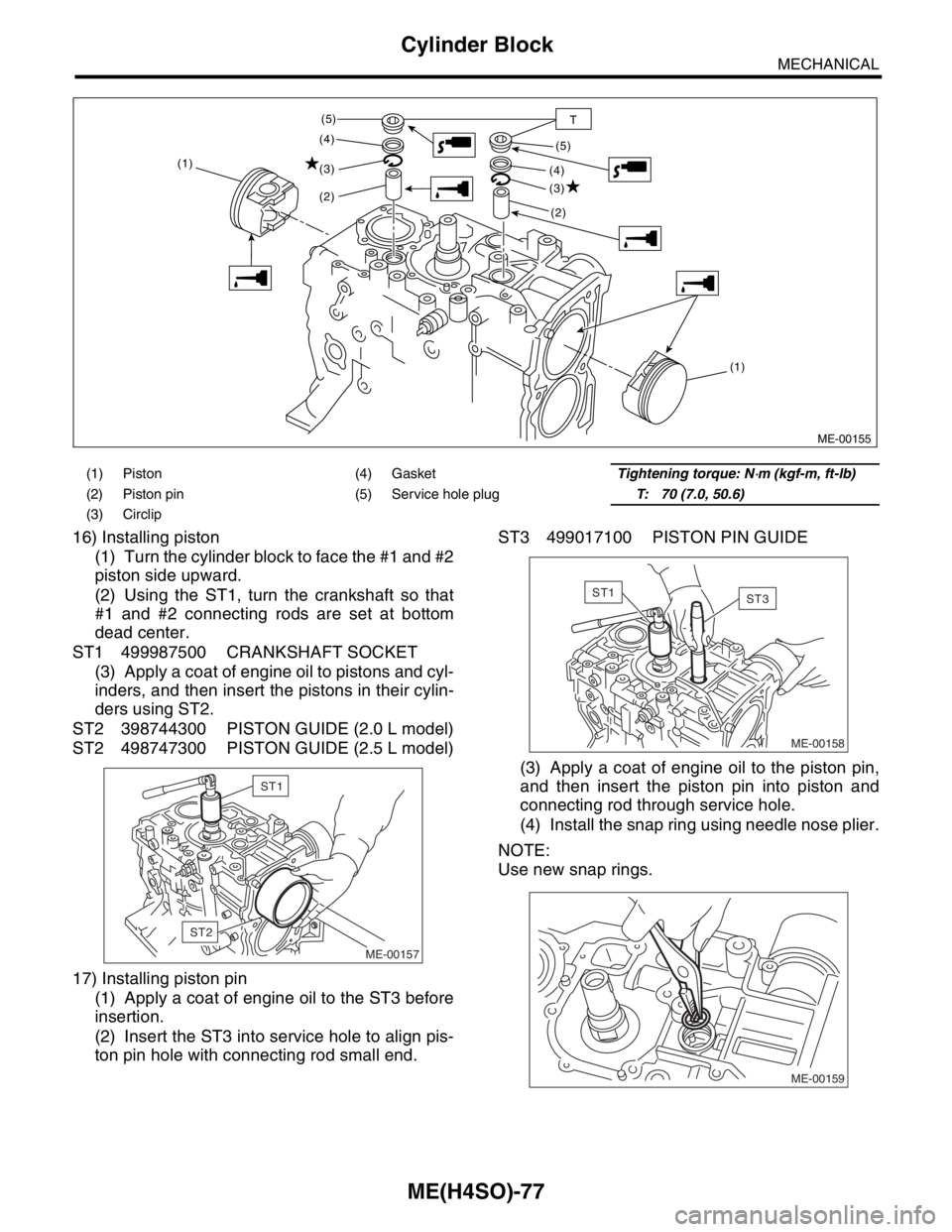

16) Installing piston

(1) Turn the cylinder block to face the #1 and #2

piston side upward.

(2) Using the ST1, turn the crankshaft so that

#1 and #2 connecting rods are set at bottom

dead center.

ST1 499987500 CRANKSHAFT SOCKET

(3) Apply a coat of engine oil to pistons and cyl-

inders, and then insert the pistons in their cylin-

ders using ST2.

ST2 398744300 PISTON GUIDE (2.0 L model)

ST2 498747300 PISTON GUIDE (2.5 L model)

17) Installing piston pin

(1) Apply a coat of engine oil to the ST3 before

insertion.

(2) Insert the ST3 into service hole to align pis-

ton pin hole with connecting rod small end.ST3 499017100 PISTON PIN GUIDE

(3) Apply a coat of engine oil to the piston pin,

and then insert the piston pin into piston and

connecting rod through service hole.

(4) Install the snap ring using needle nose plier.

NOTE:

Use new snap rings.

(1) Piston (4) GasketTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (5) Service hole plugT: 70 (7.0, 50.6)

(3) Circlip

ME-00155

(1) (1)

(2)

(2) (3)

(3) (4)

(4) (5)

(5)

T

ME-00157

ST2

ST1

ME-00158

ST1ST3

ME-00159

Page 949 of 2870

ME(H4SO)-78

MECHANICAL

Cylinder Block

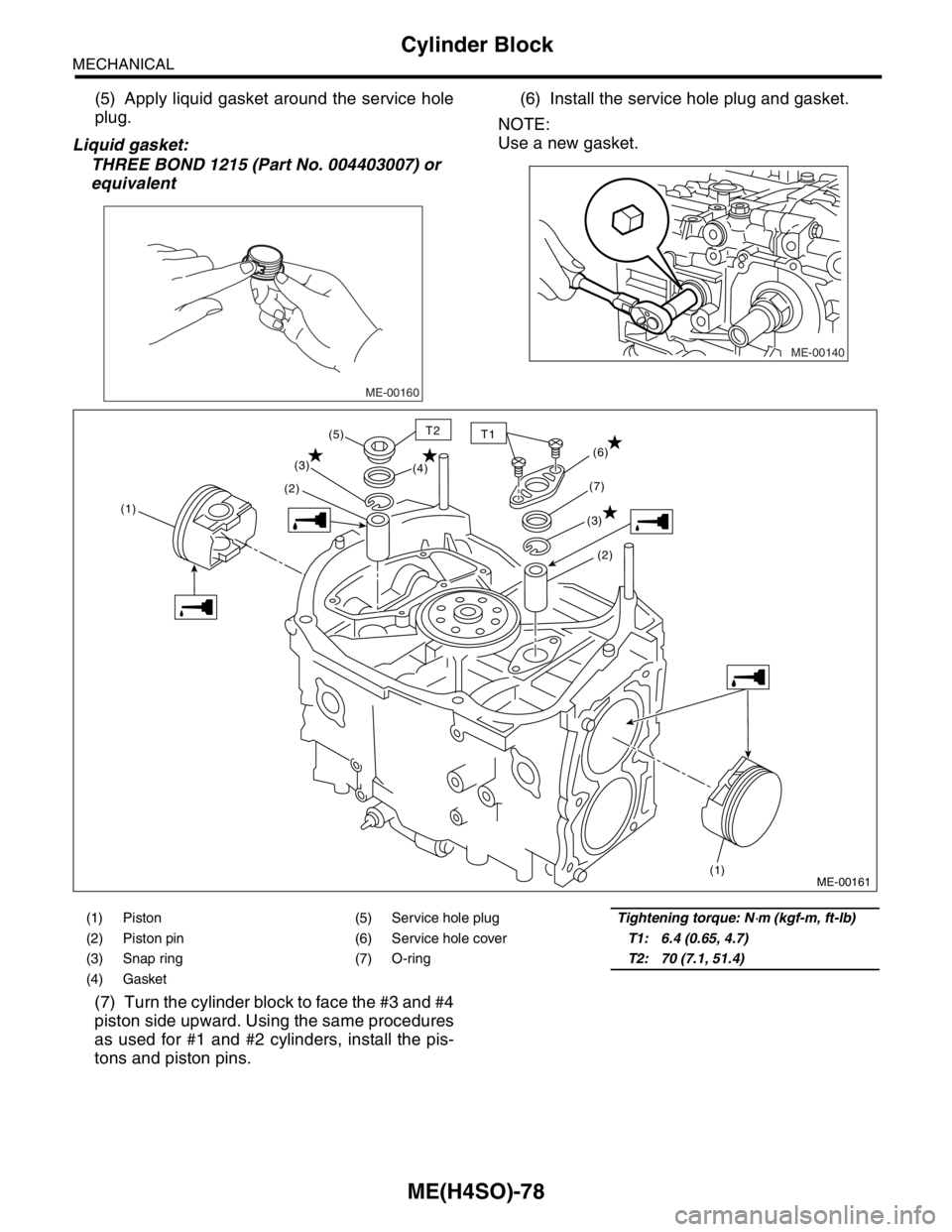

(5) Apply liquid gasket around the service hole

plug.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007) or

equivalent(6) Install the service hole plug and gasket.

NOTE:

Use a new gasket.

(7) Turn the cylinder block to face the #3 and #4

piston side upward. Using the same procedures

as used for #1 and #2 cylinders, install the pis-

tons and piston pins.

ME-00160

ME-00140

(1) Piston (5) Service hole plugTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (6) Service hole coverT1: 6.4 (0.65, 4.7)

(3) Snap ring (7) O-ringT2: 70 (7.1, 51.4)

(4) Gasket

(1)(2)(3)

(1)

(2) (6)

(3)(7) (4) (5)

ME-00161

T2T1

Page 950 of 2870

ME(H4SO)-79

MECHANICAL

Cylinder Block

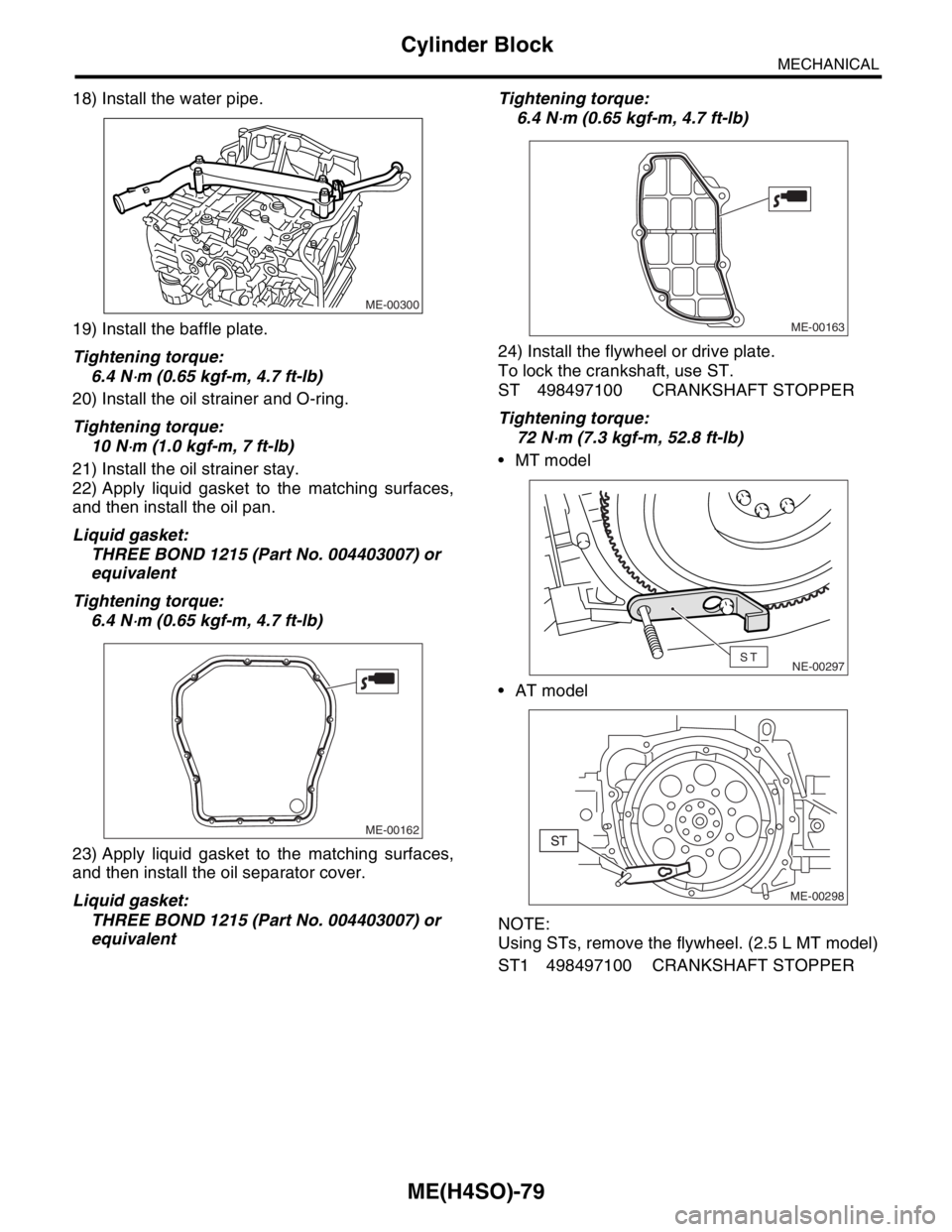

18) Install the water pipe.

19) Install the baffle plate.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

20) Install the oil strainer and O-ring.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7 ft-lb)

21) Install the oil strainer stay.

22) Apply liquid gasket to the matching surfaces,

and then install the oil pan.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007) or

equivalent

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

23) Apply liquid gasket to the matching surfaces,

and then install the oil separator cover.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007) or

equivalentTightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

24) Install the flywheel or drive plate.

To lock the crankshaft, use ST.

ST 498497100 CRANKSHAFT STOPPER

Tightening torque:

72 N

⋅m (7.3 kgf-m, 52.8 ft-lb)

MT model

AT model

NOTE:

Using STs, remove the flywheel. (2.5 L MT model)

ST1 498497100 CRANKSHAFT STOPPER

ME-00300

ME-00162

ME-00163

NE-00297ST

ME-00298

Page 951 of 2870

ME(H4SO)-80

MECHANICAL

Cylinder Block

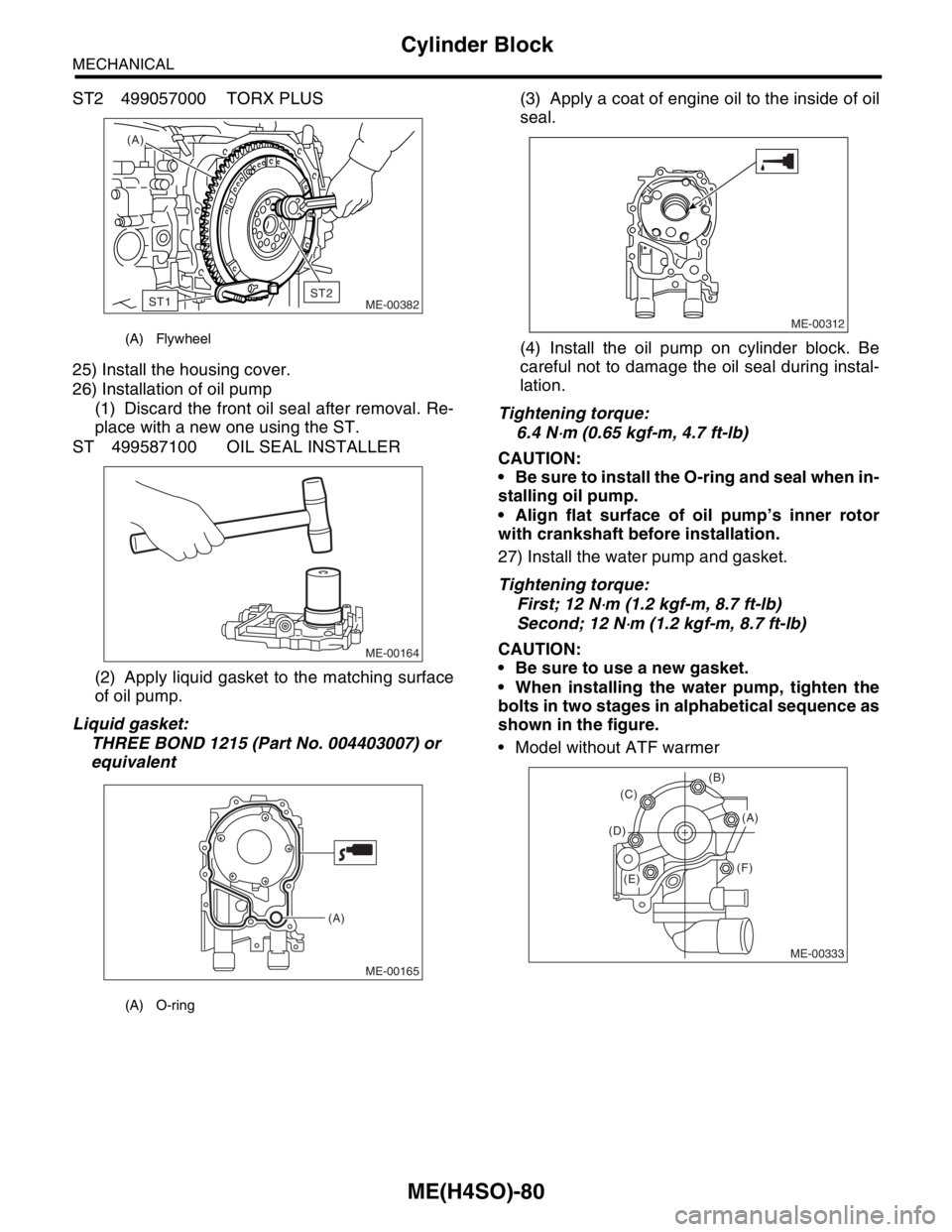

ST2 499057000 TORX PLUS

25) Install the housing cover.

26) Installation of oil pump

(1) Discard the front oil seal after removal. Re-

place with a new one using the ST.

ST 499587100 OIL SEAL INSTALLER

(2) Apply liquid gasket to the matching surface

of oil pump.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007) or

equivalent(3) Apply a coat of engine oil to the inside of oil

seal.

(4) Install the oil pump on cylinder block. Be

careful not to damage the oil seal during instal-

lation.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

CAUTION:

Be sure to install the O-ring and seal when in-

stalling oil pump.

Align flat surface of oil pump’s inner rotor

with crankshaft before installation.

27) Install the water pump and gasket.

Tightening torque:

First; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Second; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

CAUTION:

Be sure to use a new gasket.

When installing the water pump, tighten the

bolts in two stages in alphabetical sequence as

shown in the figure.

Model without ATF warmer

(A) Flywheel

(A) O-ring

(A)

ME-00382

ST1ST2

ME-00164

ME-00165

(A)

ME-00312

ME-00333

(B)

(F) (D)(C)

(A)

(E)

Page 954 of 2870

ME(H4SO)-83

MECHANICAL

Cylinder Block

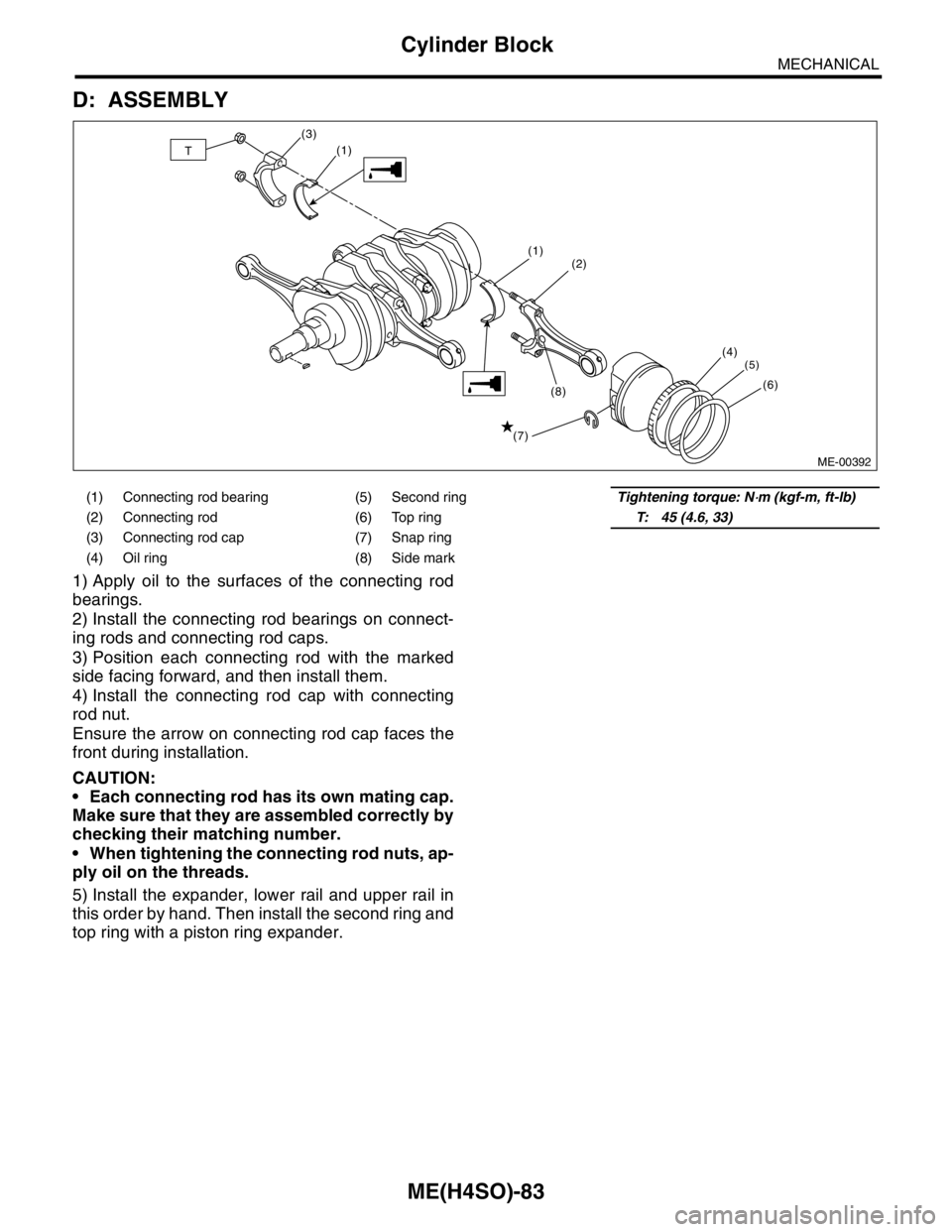

D: ASSEMBLY

1) Apply oil to the surfaces of the connecting rod

bearings.

2) Install the connecting rod bearings on connect-

ing rods and connecting rod caps.

3) Position each connecting rod with the marked

side facing forward, and then install them.

4) Install the connecting rod cap with connecting

rod nut.

Ensure the arrow on connecting rod cap faces the

front during installation.

CAUTION:

Each connecting rod has its own mating cap.

Make sure that they are assembled correctly by

checking their matching number.

When tightening the connecting rod nuts, ap-

ply oil on the threads.

5) Install the expander, lower rail and upper rail in

this order by hand. Then install the second ring and

top ring with a piston ring expander.

(1) Connecting rod bearing (5) Second ringTightening torque: N⋅m (kgf-m, ft-lb)

(2) Connecting rod (6) Top ringT: 45 (4.6, 33)

(3) Connecting rod cap (7) Snap ring

(4) Oil ring (8) Side mark

ME-00392

(2)

(4)

(5)

(6)

(1)

(1)

(7)(8) (3)T

Page 971 of 2870

EX(H4SO)-3

EXHAUST

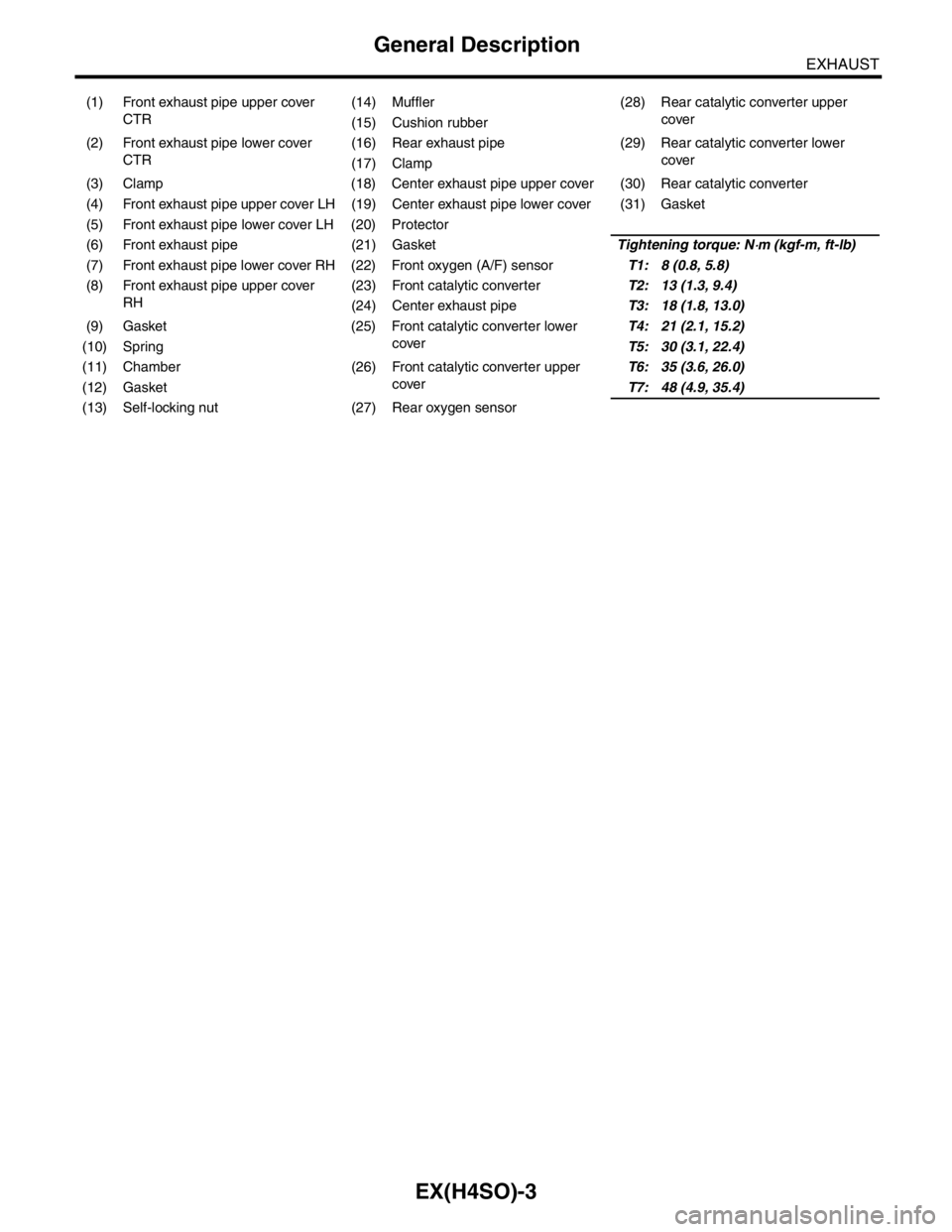

General Description

(1) Front exhaust pipe upper cover

CTR(14) Muffler (28) Rear catalytic converter upper

cover

(15) Cushion rubber

(2) Front exhaust pipe lower cover

CTR(16) Rear exhaust pipe (29) Rear catalytic converter lower

cover

(17) Clamp

(3) Clamp (18) Center exhaust pipe upper cover (30) Rear catalytic converter

(4) Front exhaust pipe upper cover LH (19) Center exhaust pipe lower cover (31) Gasket

(5) Front exhaust pipe lower cover LH (20) Protector

(6) Front exhaust pipe (21) GasketTightening torque: N

⋅m (kgf-m, ft-lb)

(7) Front exhaust pipe lower cover RH (22) Front oxygen (A/F) sensorT1: 8 (0.8, 5.8)

(8) Front exhaust pipe upper cover

RH(23) Front catalytic converterT2: 13 (1.3, 9.4)

(24) Center exhaust pipeT3: 18 (1.8, 13.0)

(9) Gasket (25) Front catalytic converter lower

coverT4: 21 (2.1, 15.2)

(10) SpringT5: 30 (3.1, 22.4)

(11) Chamber (26) Front catalytic converter upper

coverT6: 35 (3.6, 26.0)

(12) GasketT7: 48 (4.9, 35.4)

(13) Self-locking nut (27) Rear oxygen sensor

Page 973 of 2870

EX(H4SO)-5

EXHAUST

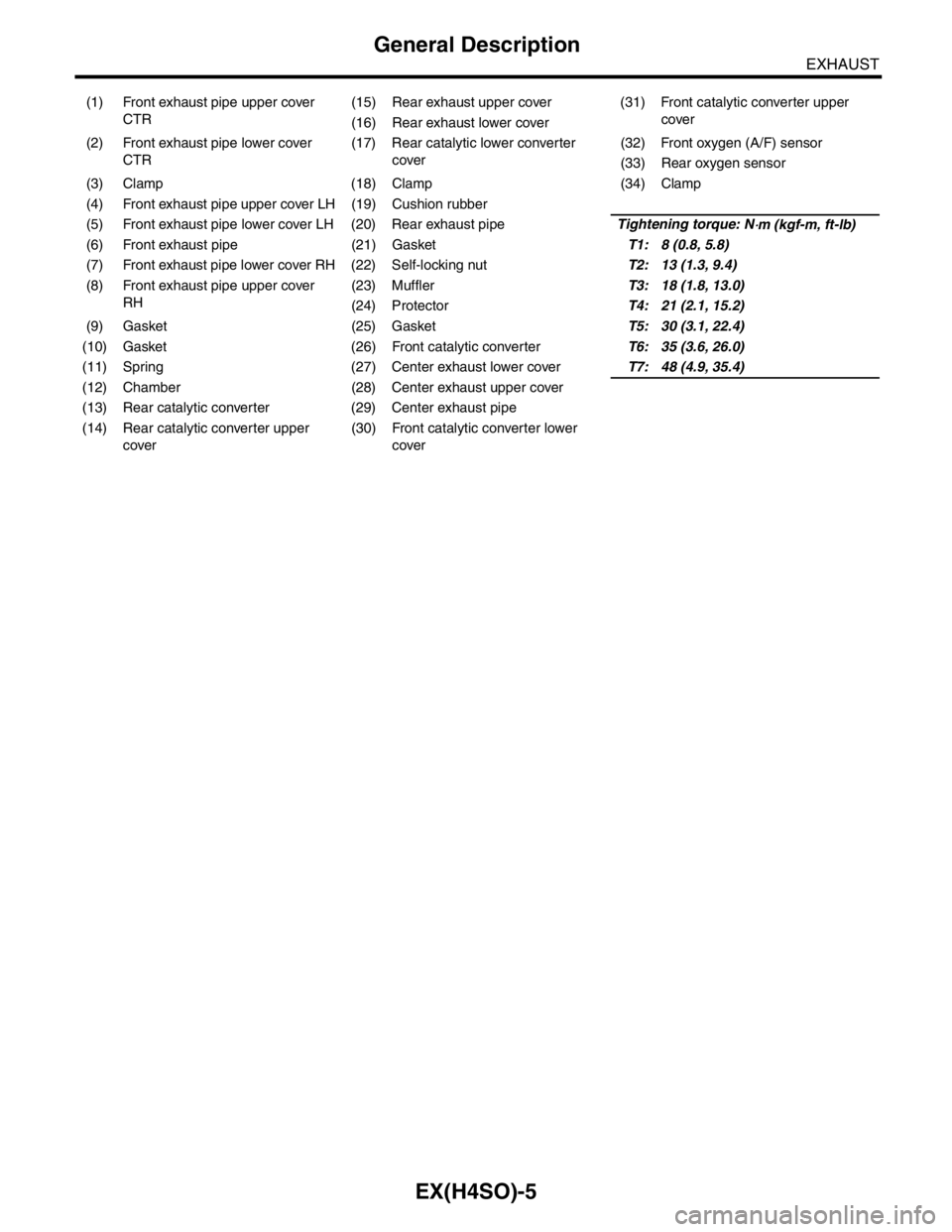

General Description

(1) Front exhaust pipe upper cover

CTR(15) Rear exhaust upper cover (31) Front catalytic converter upper

cover

(16) Rear exhaust lower cover

(2) Front exhaust pipe lower cover

CTR(17) Rear catalytic lower converter

cover(32) Front oxygen (A/F) sensor

(33) Rear oxygen sensor

(3) Clamp (18) Clamp (34) Clamp

(4) Front exhaust pipe upper cover LH (19) Cushion rubber

(5) Front exhaust pipe lower cover LH (20) Rear exhaust pipeTightening torque: N

⋅m (kgf-m, ft-lb)

(6) Front exhaust pipe (21) GasketT1: 8 (0.8, 5.8)

(7) Front exhaust pipe lower cover RH (22) Self-locking nutT2: 13 (1.3, 9.4)

(8) Front exhaust pipe upper cover

RH(23) MufflerT3: 18 (1.8, 13.0)

(24) ProtectorT4: 21 (2.1, 15.2)

(9) Gasket (25) GasketT5: 30 (3.1, 22.4)

(10) Gasket (26) Front catalytic converterT6: 35 (3.6, 26.0)

(11) Spring (27) Center exhaust lower coverT7: 48 (4.9, 35.4)

(12) Chamber (28) Center exhaust upper cover

(13) Rear catalytic converter (29) Center exhaust pipe

(14) Rear catalytic converter upper

cover(30) Front catalytic converter lower

cover

Page 974 of 2870

EX(H4SO)-6

EXHAUST

General Description

B: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn your hands, because each

part on the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

Page 976 of 2870

EX(H4SO)-8

EXHAUST

Front Exhaust Pipe

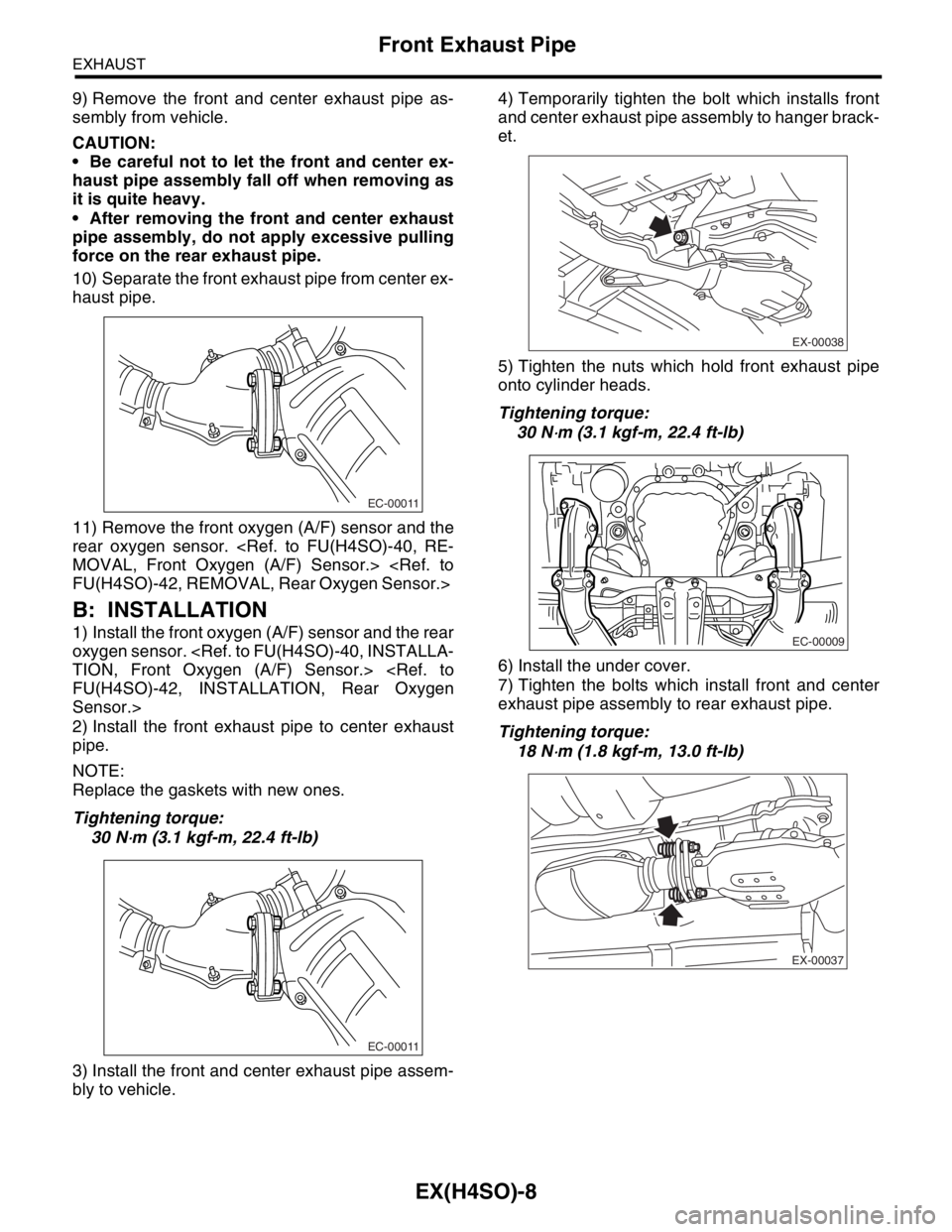

9) Remove the front and center exhaust pipe as-

sembly from vehicle.

CAUTION:

Be careful not to let the front and center ex-

haust pipe assembly fall off when removing as

it is quite heavy.

After removing the front and center exhaust

pipe assembly, do not apply excessive pulling

force on the rear exhaust pipe.

10) Separate the front exhaust pipe from center ex-

haust pipe.

11) Remove the front oxygen (A/F) sensor and the

rear oxygen sensor.

B: INSTALLATION

1) Install the front oxygen (A/F) sensor and the rear

oxygen sensor.

Sensor.>

2) Install the front exhaust pipe to center exhaust

pipe.

NOTE:

Replace the gaskets with new ones.

Tightening torque:

30 N

⋅m (3.1 kgf-m, 22.4 ft-lb)

3) Install the front and center exhaust pipe assem-

bly to vehicle.4) Temporarily tighten the bolt which installs front

and center exhaust pipe assembly to hanger brack-

et.

5) Tighten the nuts which hold front exhaust pipe

onto cylinder heads.

Tightening torque:

30 N

⋅m (3.1 kgf-m, 22.4 ft-lb)

6) Install the under cover.

7) Tighten the bolts which install front and center

exhaust pipe assembly to rear exhaust pipe.

Tightening torque:

18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

EC-00011

EC-00011

EX-00038

EC-00009

EX-00037