torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 915 of 2870

ME(H4SO)-46

MECHANICAL

Crank Pulley

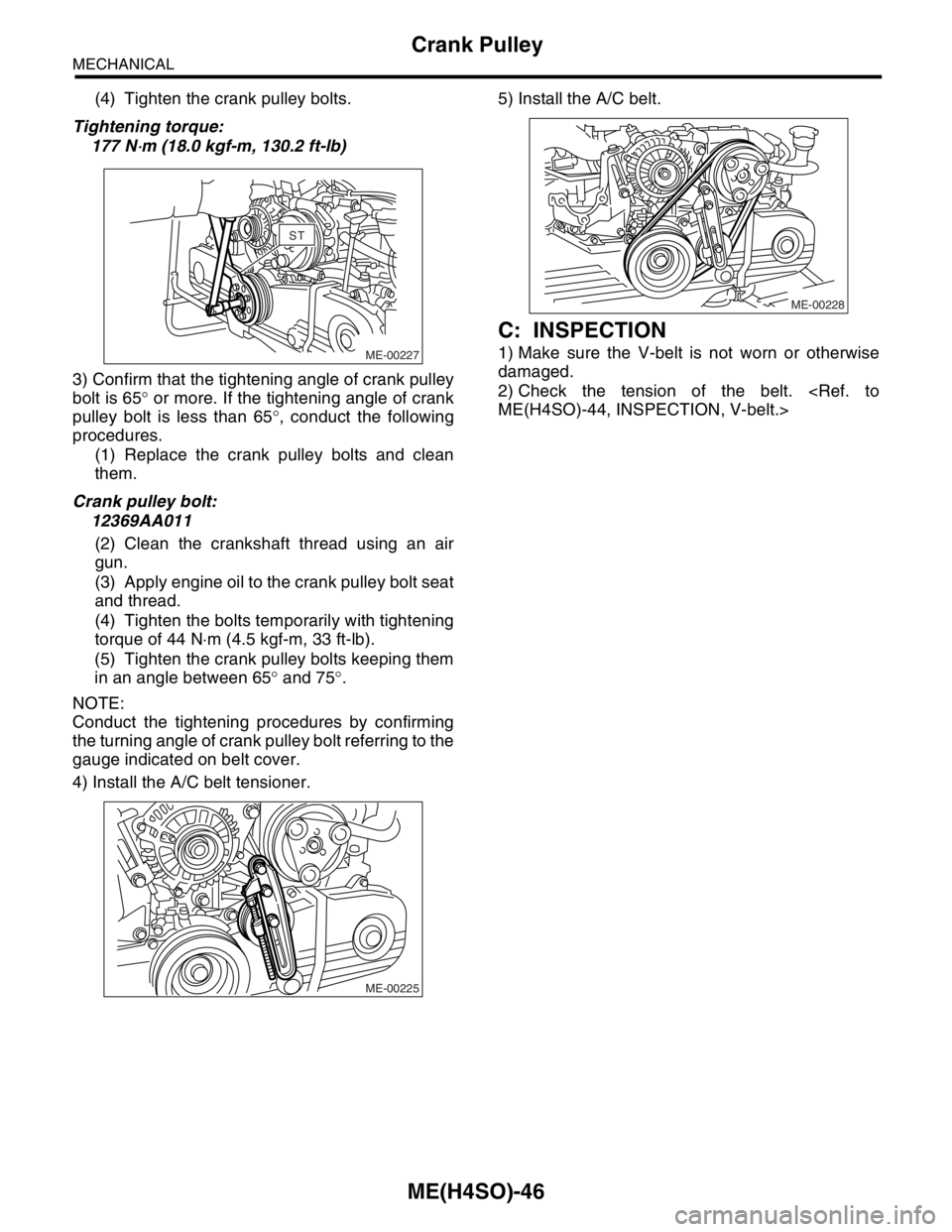

(4) Tighten the crank pulley bolts.

Tightening torque:

177 N

⋅m (18.0 kgf-m, 130.2 ft-lb)

3) Confirm that the tightening angle of crank pulley

bolt is 65° or more. If the tightening angle of crank

pulley bolt is less than 65°, conduct the following

procedures.

(1) Replace the crank pulley bolts and clean

them.

Crank pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Apply engine oil to the crank pulley bolt seat

and thread.

(4) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(5) Tighten the crank pulley bolts keeping them

in an angle between 65° and 75°.

NOTE:

Conduct the tightening procedures by confirming

the turning angle of crank pulley bolt referring to the

gauge indicated on belt cover.

4) Install the A/C belt tensioner.5) Install the A/C belt.

C: INSPECTION

1) Make sure the V-belt is not worn or otherwise

damaged.

2) Check the tension of the belt.

STST

ME-00225

ME-00228

Page 916 of 2870

ME(H4SO)-47

MECHANICAL

Timing Belt Cover

14.Timing Belt Cover

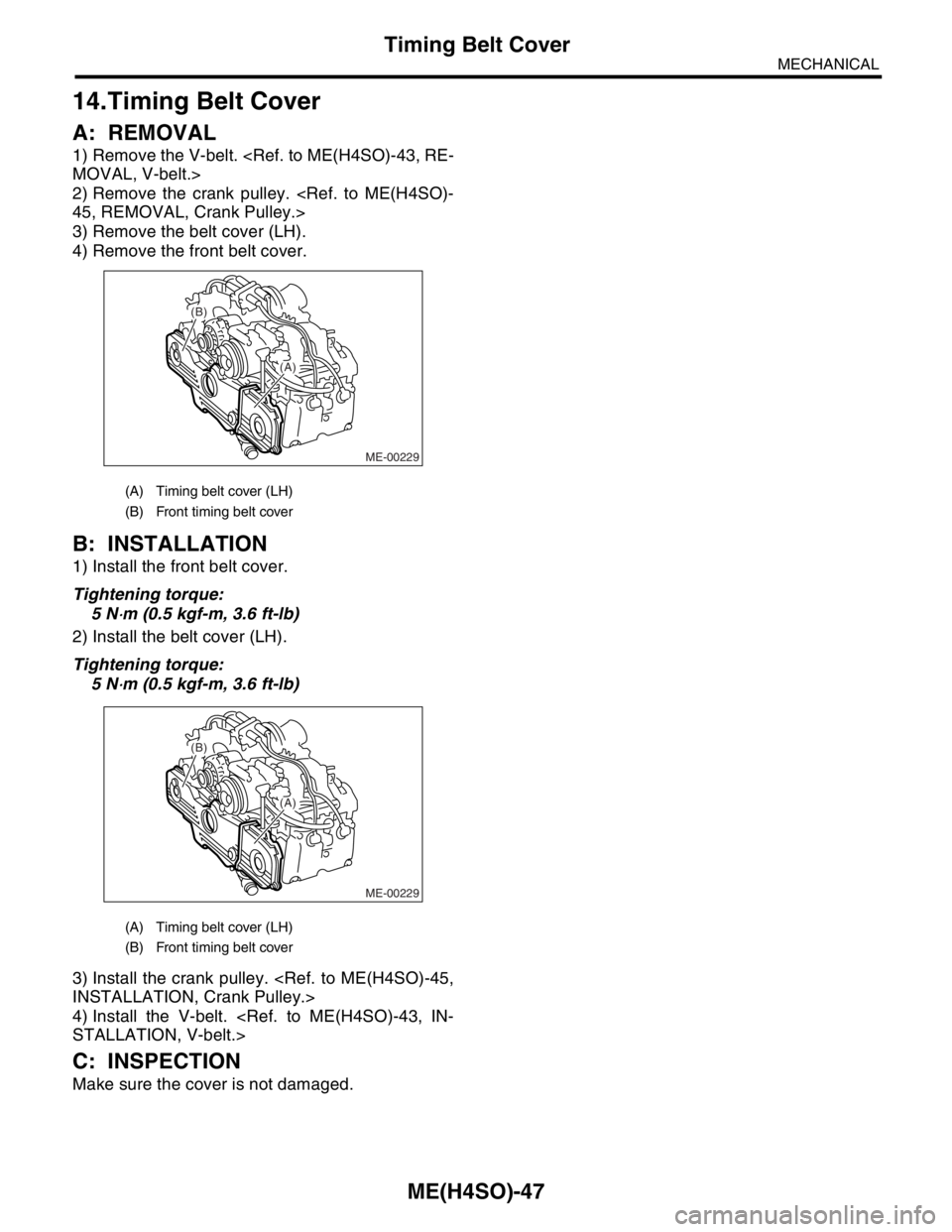

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the belt cover (LH).

4) Remove the front belt cover.

B: INSTALLATION

1) Install the front belt cover.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

2) Install the belt cover (LH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

3) Install the crank pulley.

4) Install the V-belt.

C: INSPECTION

Make sure the cover is not damaged.

(A) Timing belt cover (LH)

(B) Front timing belt cover

(A) Timing belt cover (LH)

(B) Front timing belt cover

ME-00229

(A)

(B)

ME-00229

(A)

(B)

Page 919 of 2870

ME(H4SO)-50

MECHANICAL

Timing Belt

2) Install the automatic belt tension adjuster as-

sembly.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

3) Install the belt idler (No. 1).

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

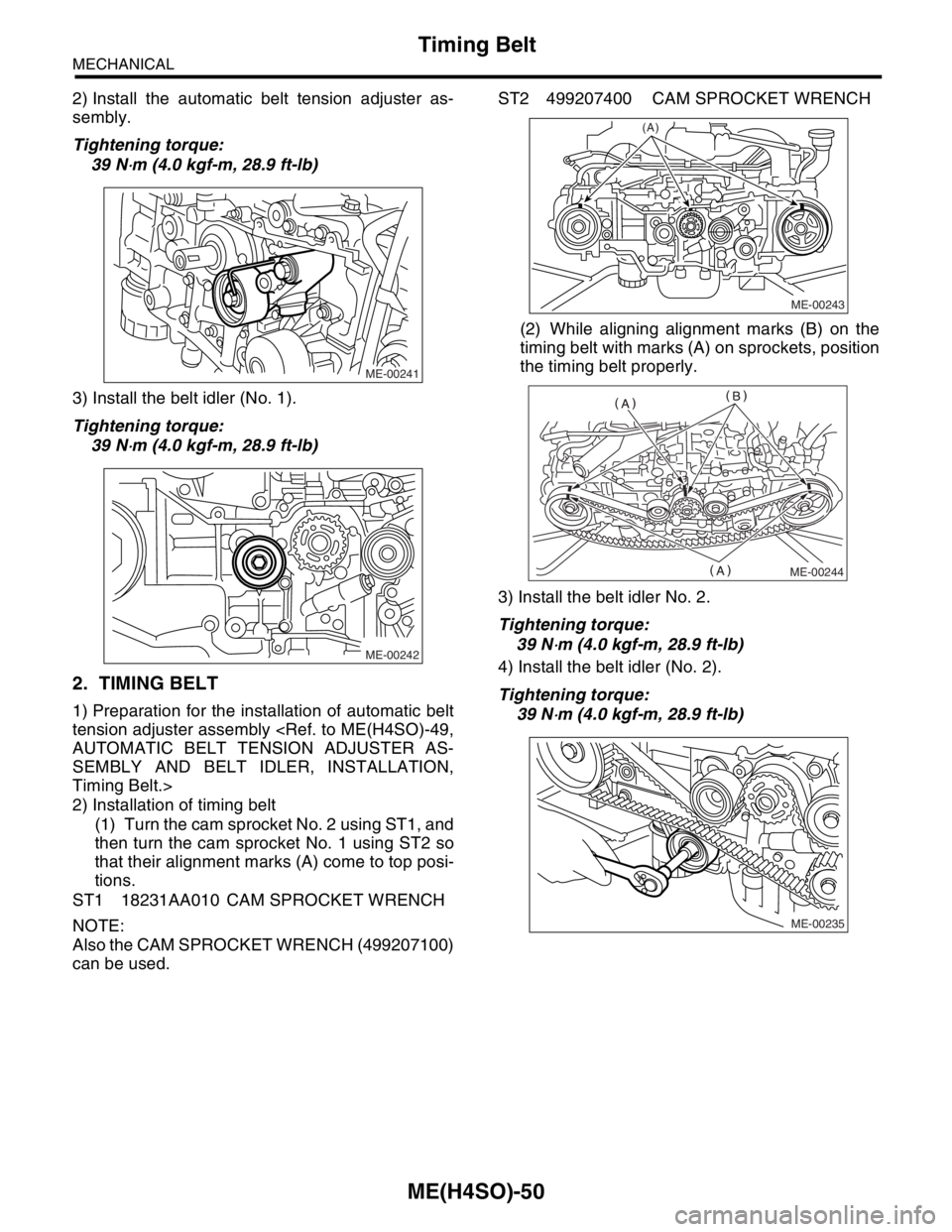

2. TIMING BELT

1) Preparation for the installation of automatic belt

tension adjuster assembly

SEMBLY AND BELT IDLER, INSTALLATION,

Timing Belt.>

2) Installation of timing belt

(1) Turn the cam sprocket No. 2 using ST1, and

then turn the cam sprocket No. 1 using ST2 so

that their alignment marks (A) come to top posi-

tions.

ST1 18231AA010 CAM SPROCKET WRENCH

NOTE:

Also the CAM SPROCKET WRENCH (499207100)

can be used.ST2 499207400 CAM SPROCKET WRENCH

(2) While aligning alignment marks (B) on the

timing belt with marks (A) on sprockets, position

the timing belt properly.

3) Install the belt idler No. 2.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

4) Install the belt idler (No. 2).

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

ME-00241

ME-00242

ME-00243

(A)

ME-00244

ME-00235

Page 920 of 2870

ME(H4SO)-51

MECHANICAL

Timing Belt

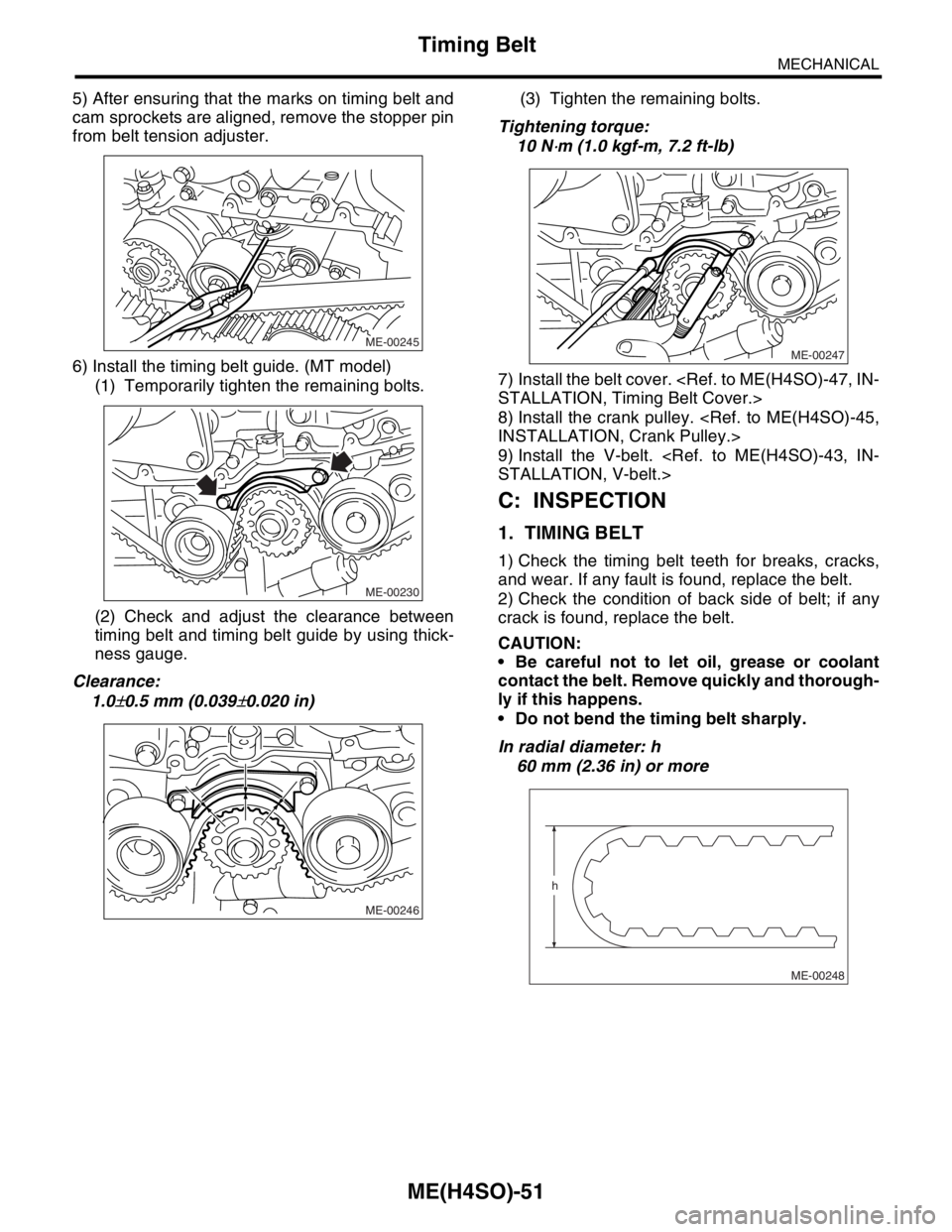

5) After ensuring that the marks on timing belt and

cam sprockets are aligned, remove the stopper pin

from belt tension adjuster.

6) Install the timing belt guide. (MT model)

(1) Temporarily tighten the remaining bolts.

(2) Check and adjust the clearance between

timing belt and timing belt guide by using thick-

ness gauge.

Clearance:

1.0

±0.5 mm (0.039±0.020 in)(3) Tighten the remaining bolts.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

7) Install the belt cover.

8) Install the crank pulley.

9) Install the V-belt.

C: INSPECTION

1. TIMING BELT

1) Check the timing belt teeth for breaks, cracks,

and wear. If any fault is found, replace the belt.

2) Check the condition of back side of belt; if any

crack is found, replace the belt.

CAUTION:

Be careful not to let oil, grease or coolant

contact the belt. Remove quickly and thorough-

ly if this happens.

Do not bend the timing belt sharply.

In radial diameter: h

60 mm (2.36 in) or more

ME-00245

ME-00230

ME-00246

ME-00247

ME-00248

h

Page 924 of 2870

ME(H4SO)-53

MECHANICAL

Cam Sprocket

16.Cam Sprocket

A: REMOVAL

1. REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the belt cover.

4) Remove the timing belt assembly.

5) Remove the camshaft position sensor.

Sensor.>

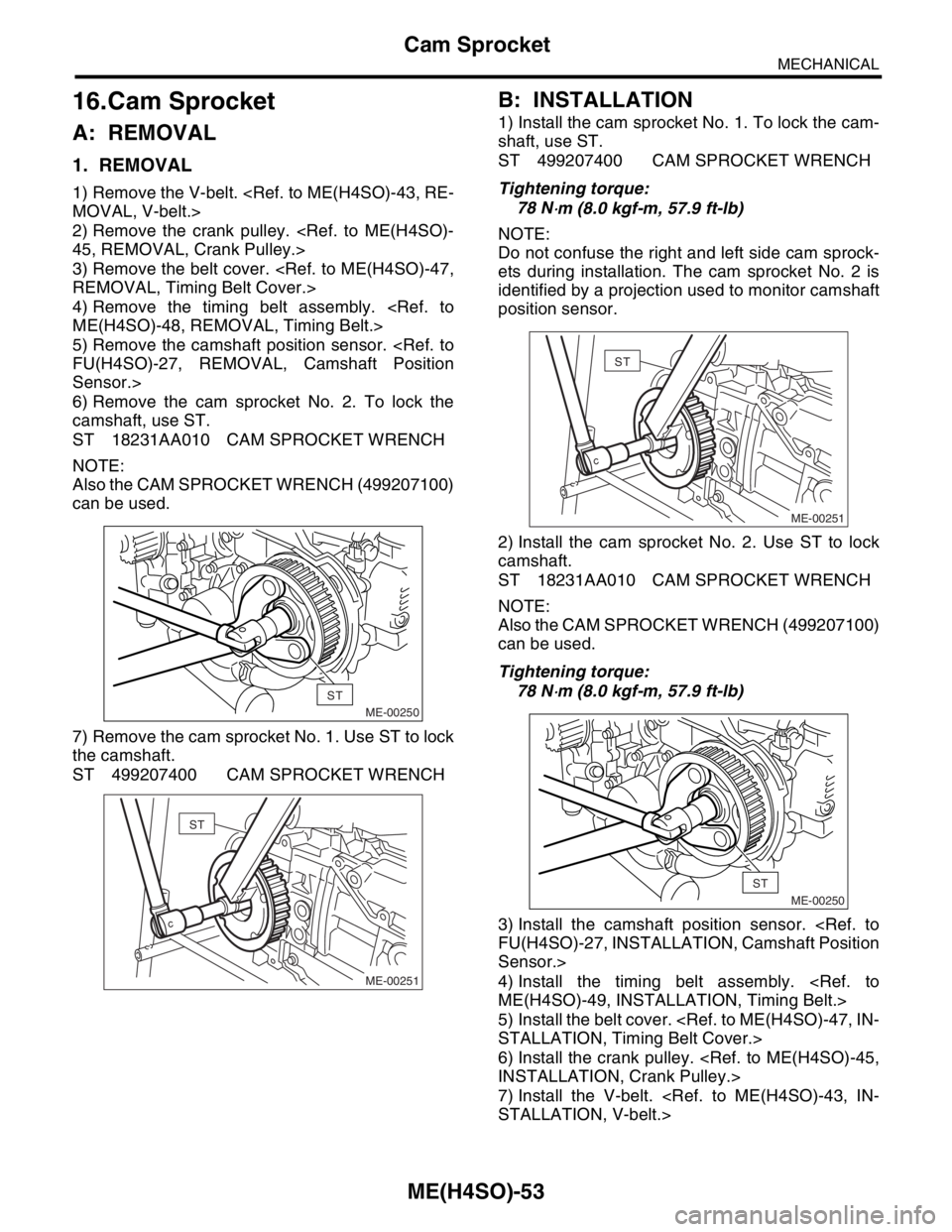

6) Remove the cam sprocket No. 2. To lock the

camshaft, use ST.

ST 18231AA010 CAM SPROCKET WRENCH

NOTE:

Also the CAM SPROCKET WRENCH (499207100)

can be used.

7) Remove the cam sprocket No. 1. Use ST to lock

the camshaft.

ST 499207400 CAM SPROCKET WRENCH

B: INSTALLATION

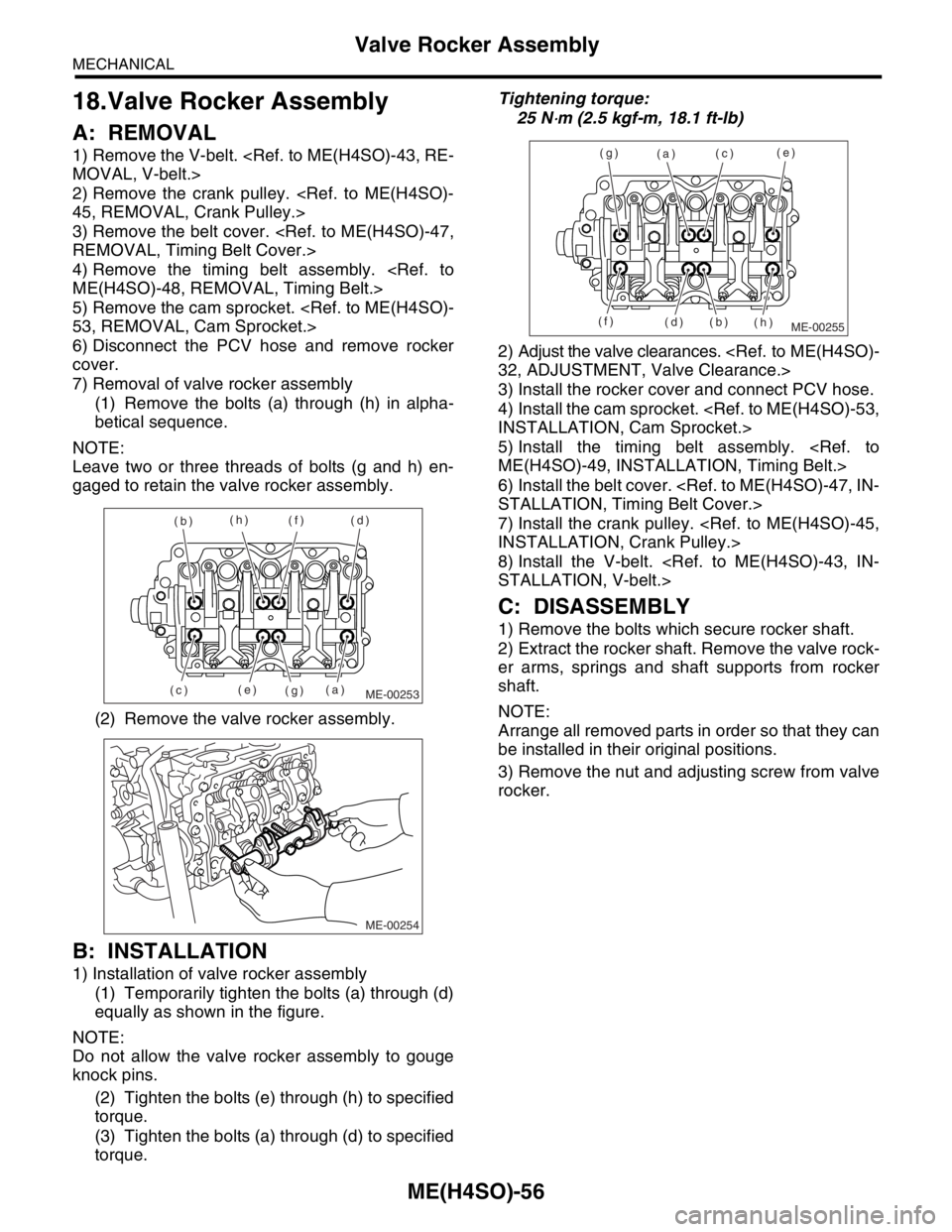

1) Install the cam sprocket No. 1. To lock the cam-

shaft, use ST.

ST 499207400 CAM SPROCKET WRENCH

Tightening torque:

78 N

⋅m (8.0 kgf-m, 57.9 ft-lb)

NOTE:

Do not confuse the right and left side cam sprock-

ets during installation. The cam sprocket No. 2 is

identified by a projection used to monitor camshaft

position sensor.

2) Install the cam sprocket No. 2. Use ST to lock

camshaft.

ST 18231AA010 CAM SPROCKET WRENCH

NOTE:

Also the CAM SPROCKET WRENCH (499207100)

can be used.

Tightening torque:

78 N

⋅m (8.0 kgf-m, 57.9 ft-lb)

3) Install the camshaft position sensor.

Sensor.>

4) Install the timing belt assembly.

5) Install the belt cover.

6) Install the crank pulley.

7) Install the V-belt.

ME-00250

ST

ME-00251

ST

ME-00251

ST

ME-00250

ST

Page 927 of 2870

ME(H4SO)-56

MECHANICAL

Valve Rocker Assembly

18.Valve Rocker Assembly

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the belt cover.

4) Remove the timing belt assembly.

5) Remove the cam sprocket.

6) Disconnect the PCV hose and remove rocker

cover.

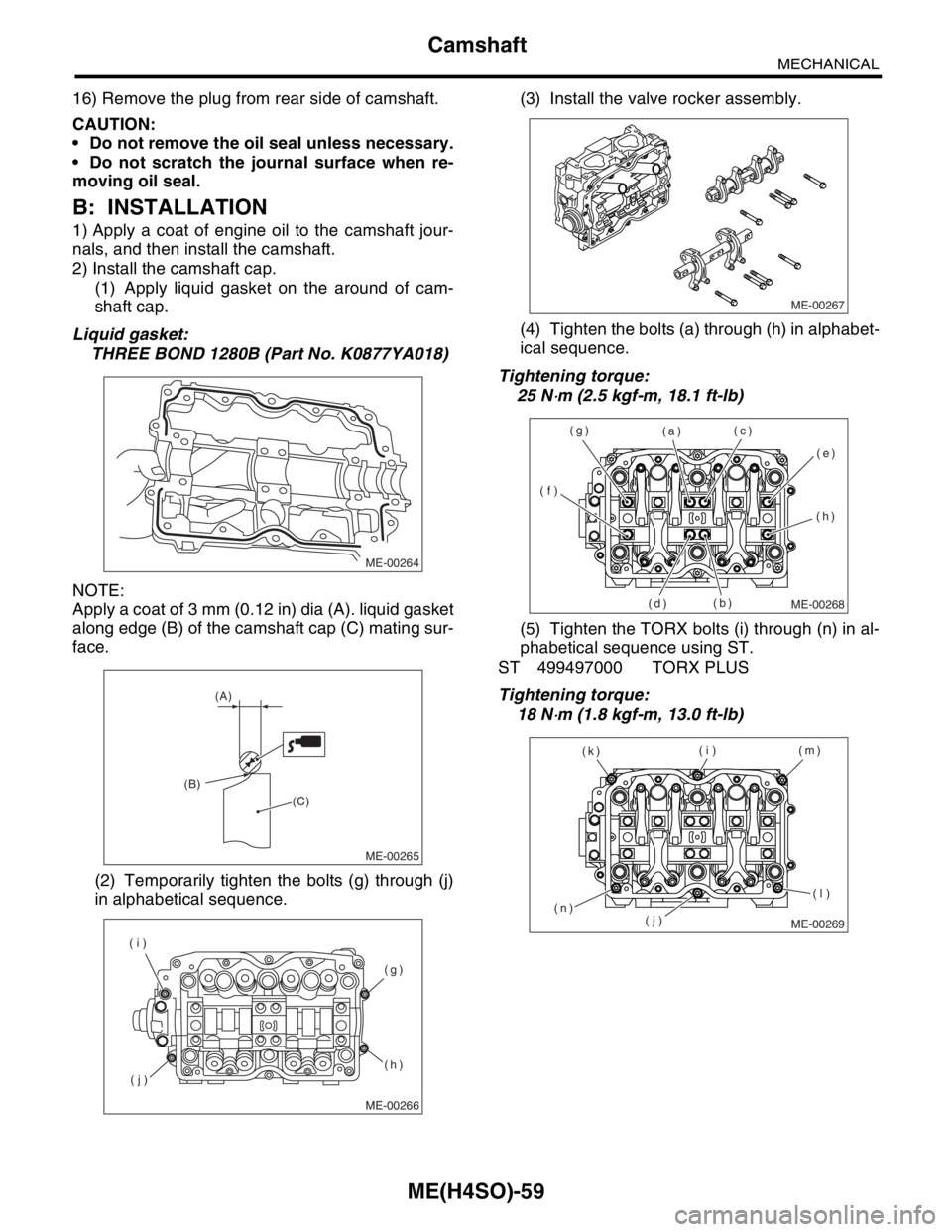

7) Removal of valve rocker assembly

(1) Remove the bolts (a) through (h) in alpha-

betical sequence.

NOTE:

Leave two or three threads of bolts (g and h) en-

gaged to retain the valve rocker assembly.

(2) Remove the valve rocker assembly.

B: INSTALLATION

1) Installation of valve rocker assembly

(1) Temporarily tighten the bolts (a) through (d)

equally as shown in the figure.

NOTE:

Do not allow the valve rocker assembly to gouge

knock pins.

(2) Tighten the bolts (e) through (h) to specified

torque.

(3) Tighten the bolts (a) through (d) to specified

torque.Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

2) Adjust the valve clearances.

3) Install the rocker cover and connect PCV hose.

4) Install the cam sprocket.

5) Install the timing belt assembly.

6) Install the belt cover.

7) Install the crank pulley.

8) Install the V-belt.

C: DISASSEMBLY

1) Remove the bolts which secure rocker shaft.

2) Extract the rocker shaft. Remove the valve rock-

er arms, springs and shaft supports from rocker

shaft.

NOTE:

Arrange all removed parts in order so that they can

be installed in their original positions.

3) Remove the nut and adjusting screw from valve

rocker.

ME-00253(a) (b)

(c)(d)

(e)(f)

(g) (h)

ME-00254

ME-00255

(a)

(b)(c)

(d)(e)

(f)(g)

(h)

Page 928 of 2870

ME(H4SO)-57

MECHANICAL

Valve Rocker Assembly

D: ASSEMBLY

1) Install the adjusting screw and nut to valve rock-

er.

2) Arrange the valve rocker arms, springs and shaft

supports in assembly order and insert valve rocker

shaft.

Tightening torque (Shaft supports installing

bolts):

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

NOTE:

Valve rocker arms, rocker shaft and shaft supports

have identification marks. Ensure the parts with

same markings are properly assembled.

3) Install the valve rocker shaft securing bolts.

E: INSPECTION

1. VALVE ROCKER ARM AND ROCKER

SHAFT

1) Measure the inside diameter of valve rocker arm

and outside diameter of valve rocker shaft, and de-

termine the difference between the two (= oil clear-

ance).

Clearance between arm and shaft:

Standard

0.020 — 0.054 mm (0.0008 — 0.0021 in)

Limit

0.10 mm (0.0039 in)2) If oil clearance exceeds the limit, replace the

valve rocker arm or shaft, whichever shows greater

amount of wear.

Rocker arm inside diameter:

22.020 — 22.041 mm (0.8669 — 0.8678 in)

Rocker shaft diameter:

21.987 — 22.000 mm (0.8656 — 0.8661 in)

3) If cam or valve contact surface of valve rocker

arm is worn or dented excessively, replace the

valve rocker arm.

4) Check that the valve rocker arm roller rotates

smoothly. If not, replace the valve rocker arm.

ME-00256

ME-00257

Page 930 of 2870

ME(H4SO)-59

MECHANICAL

Camshaft

16) Remove the plug from rear side of camshaft.

CAUTION:

Do not remove the oil seal unless necessary.

Do not scratch the journal surface when re-

moving oil seal.

B: INSTALLATION

1) Apply a coat of engine oil to the camshaft jour-

nals, and then install the camshaft.

2) Install the camshaft cap.

(1) Apply liquid gasket on the around of cam-

shaft cap.

Liquid gasket:

THREE BOND 1280B (Part No. K0877YA018)

NOTE:

Apply a coat of 3 mm (0.12 in) dia (A). liquid gasket

along edge (B) of the camshaft cap (C) mating sur-

face.

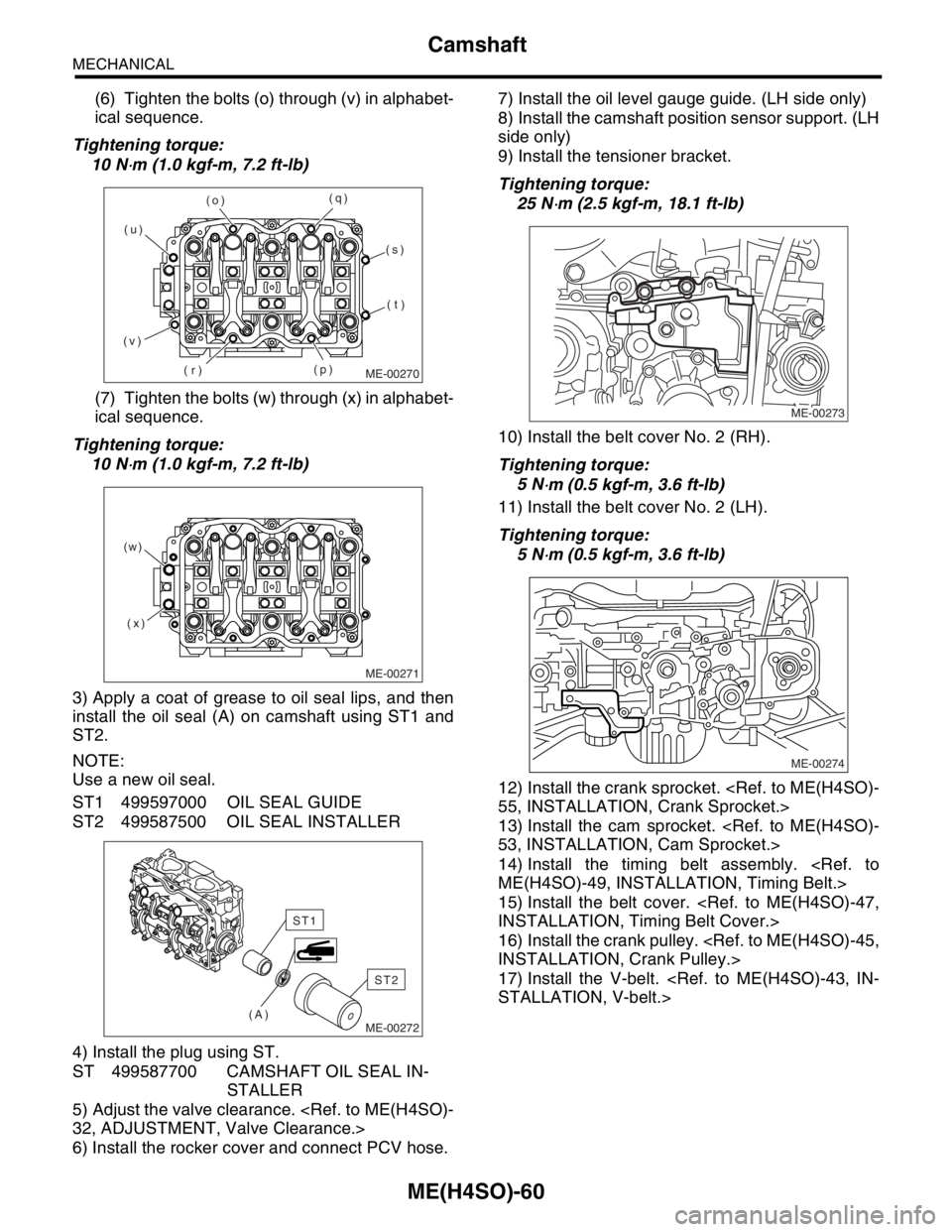

(2) Temporarily tighten the bolts (g) through (j)

in alphabetical sequence.(3) Install the valve rocker assembly.

(4) Tighten the bolts (a) through (h) in alphabet-

ical sequence.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(5) Tighten the TORX bolts (i) through (n) in al-

phabetical sequence using ST.

ST 499497000 TORX PLUS

Tightening torque:

18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

ME-00264

ME-00265

(A)

(B)

(C)

ME-00266

(g)

(h)

(j) (i)

ME-00267

ME-00268

(a)

(b)(c)

(d)(e)

(f)(g)

(h)

ME-00269

(i)

(j)(m)

(n)(k)

(l)

Page 931 of 2870

ME(H4SO)-60

MECHANICAL

Camshaft

(6) Tighten the bolts (o) through (v) in alphabet-

ical sequence.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

(7) Tighten the bolts (w) through (x) in alphabet-

ical sequence.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

3) Apply a coat of grease to oil seal lips, and then

install the oil seal (A) on camshaft using ST1 and

ST2.

NOTE:

Use a new oil seal.

ST1 499597000 OIL SEAL GUIDE

ST2 499587500 OIL SEAL INSTALLER

4) Install the plug using ST.

ST 499587700 CAMSHAFT OIL SEAL IN-

STALLER

5) Adjust the valve clearance.

6) Install the rocker cover and connect PCV hose.7) Install the oil level gauge guide. (LH side only)

8) Install the camshaft position sensor support. (LH

side only)

9) Install the tensioner bracket.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

10) Install the belt cover No. 2 (RH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

11) Install the belt cover No. 2 (LH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

12) Install the crank sprocket.

13) Install the cam sprocket.

14) Install the timing belt assembly.

15) Install the belt cover.

16) Install the crank pulley.

17) Install the V-belt.

ME-00270

(o)

(r)(q)

(v)(u)

(p)(s)

(t)

ME-00271

(x) (w)

ME-00272(A)

ST2

ST1

ME-00273

ME-00274

Page 937 of 2870

ME(H4SO)-66

MECHANICAL

Cylinder Head

NOTE:

Uneven torque for the cylinder head bolts can cause

warping. When reassembling, pay special attention

to the torque so as to tighten evenly.

2. VALVE SEAT

Inspect the intake and exhaust valve seats, and

then correct the contact surfaces with valve seat

cutter if they are defective or when valve guides are

replaced.

Valve seat width: W

Intake (A)

Standard 1.1 mm (0.043 in)

Limit 1.8 mm (0.071 in)

Exhaust (B)

Standard 1.5 mm (0.059 in)

Limit 2.2 mm (0.087 in)

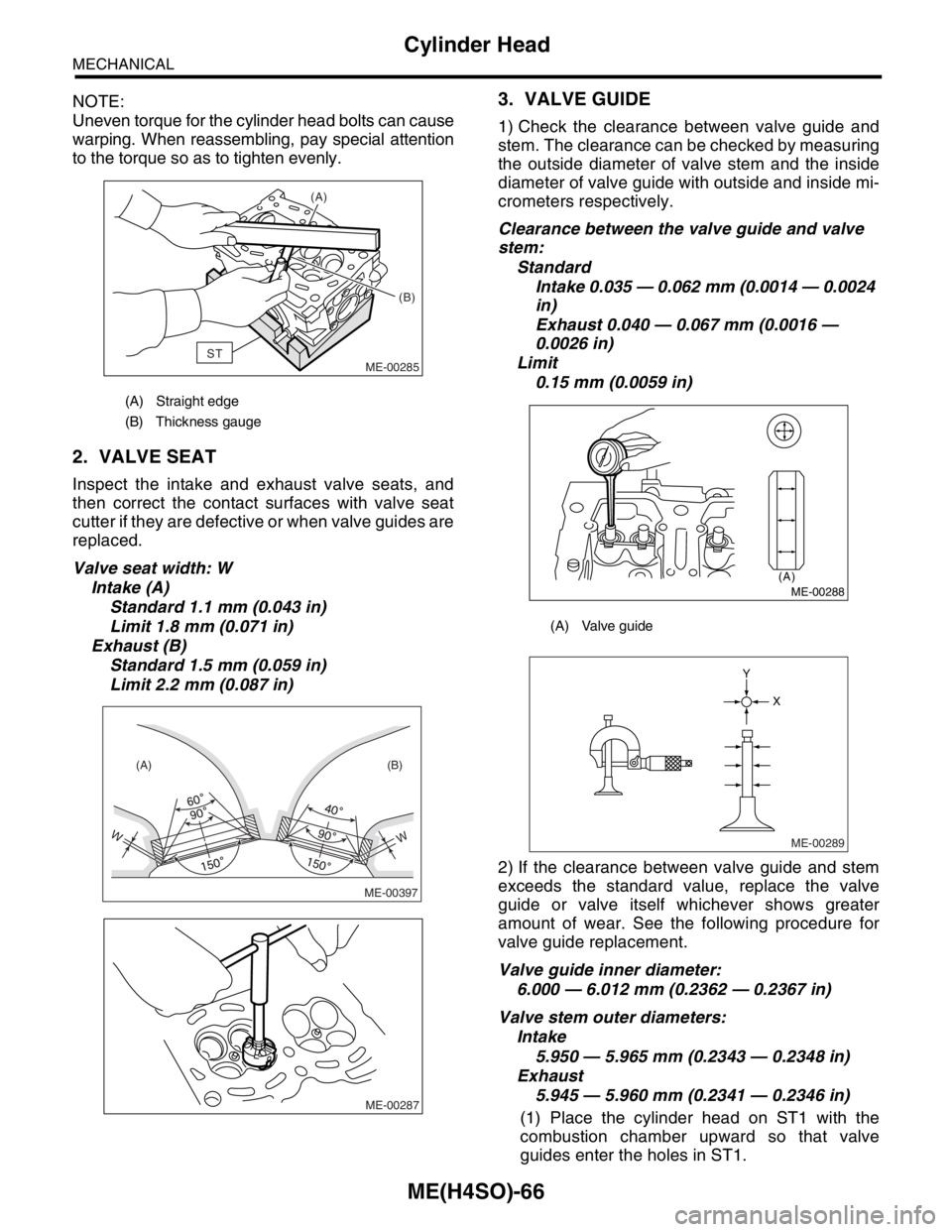

3. VALVE GUIDE

1) Check the clearance between valve guide and

stem. The clearance can be checked by measuring

the outside diameter of valve stem and the inside

diameter of valve guide with outside and inside mi-

crometers respectively.

Clearance between the valve guide and valve

stem:

Standard

Intake 0.035 — 0.062 mm (0.0014 — 0.0024

in)

Exhaust 0.040 — 0.067 mm (0.0016 —

0.0026 in)

Limit

0.15 mm (0.0059 in)

2) If the clearance between valve guide and stem

exceeds the standard value, replace the valve

guide or valve itself whichever shows greater

amount of wear. See the following procedure for

valve guide replacement.

Valve guide inner diameter:

6.000 — 6.012 mm (0.2362 — 0.2367 in)

Valve stem outer diameters:

Intake

5.950 — 5.965 mm (0.2343 — 0.2348 in)

Exhaust

5.945 — 5.960 mm (0.2341 — 0.2346 in)

(1) Place the cylinder head on ST1 with the

combustion chamber upward so that valve

guides enter the holes in ST1.

(A) Straight edge

(B) Thickness gauge

ST(A)

(B)

ME-00285

WW

(A) (B)

ME-00397

ME-00287

(A) Valve guide

(A)

ME-00288

ME-00289

X Y