lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2781 of 2870

5MT-68

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Case

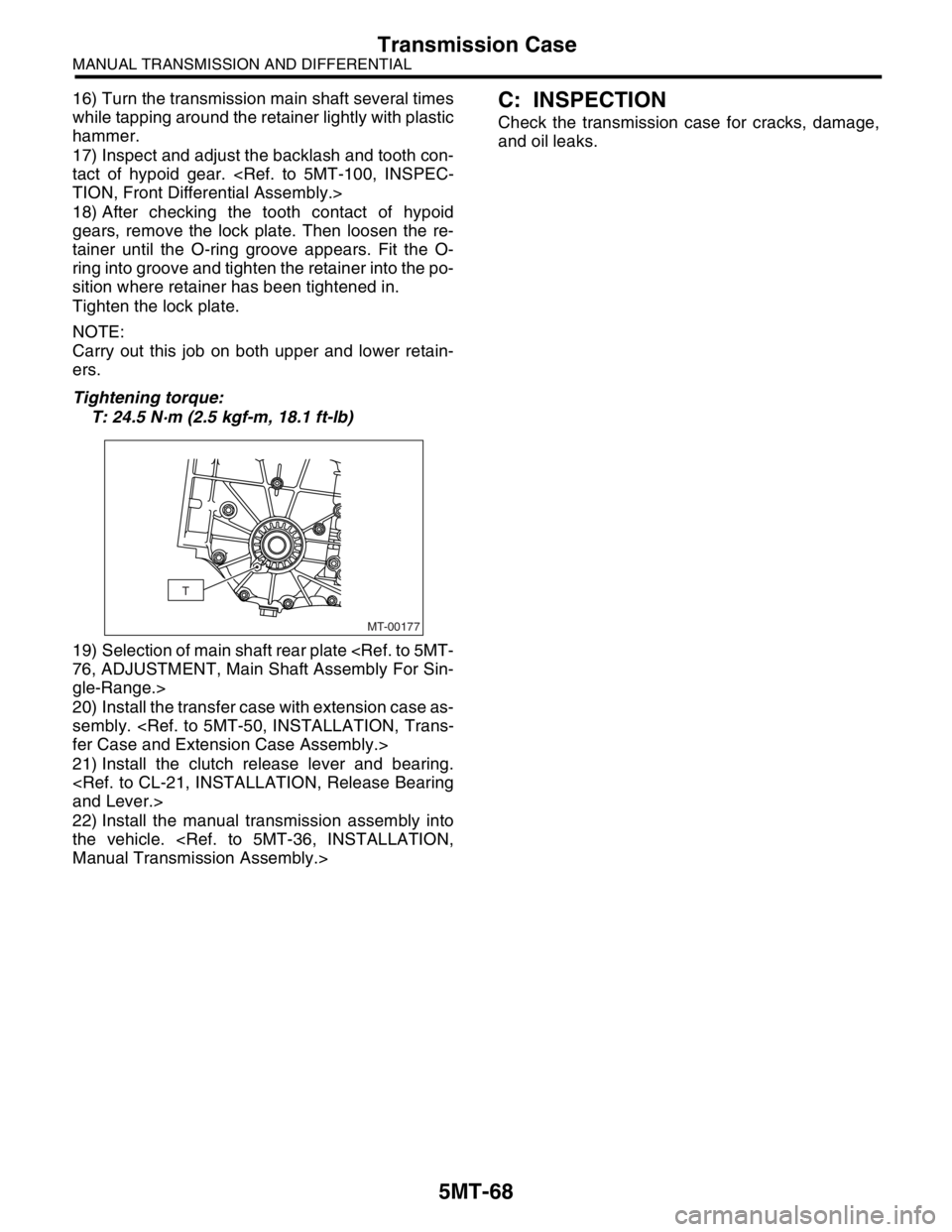

16) Turn the transmission main shaft several times

while tapping around the retainer lightly with plastic

hammer.

17) Inspect and adjust the backlash and tooth con-

tact of hypoid gear.

18) After checking the tooth contact of hypoid

gears, remove the lock plate. Then loosen the re-

tainer until the O-ring groove appears. Fit the O-

ring into groove and tighten the retainer into the po-

sition where retainer has been tightened in.

Tighten the lock plate.

NOTE:

Carry out this job on both upper and lower retain-

ers.

Tightening torque:

T: 24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

19) Selection of main shaft rear plate

gle-Range.>

20) Install the transfer case with extension case as-

sembly.

21) Install the clutch release lever and bearing.

22) Install the manual transmission assembly into

the vehicle.

Check the transmission case for cracks, damage,

and oil leaks.

MT-00177

T

Page 2782 of 2870

5MT-69

MANUAL TRANSMISSION AND DIFFERENTIAL

Main Shaft Assembly For Single-Range

17.Main Shaft Assembly For Sin-

gle-Range

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the transfer case with extension case

assembly.

3) Remove the transmission case.

Assembly.>

4) Remove the drive pinion shaft assembly.

bly.>

5) Remove the main shaft assembly.

B: INSTALLATION

1) Wrap the clutch splined section with vinyl tape to

prevent damage to oil seal.

2) Apply grease Unilube #2 (or equivalent) to the

sealing lip of oil seal.

3) Install the needle bearing and new oil seal onto

the front of transmission main shaft assembly.

4) Install the needle bearing outer race knock pin

hole into transmission case knock pin.

NOTE:

Align the end face of seal with surface (A) when in-

stalling oil seal.

5) Install the drive pinion assembly.

bly.>

6) Install the transmission case.

7) Install the transfer case with extension case as-

sembly.

8) Install the manual transmission assembly to ve-

hicle.

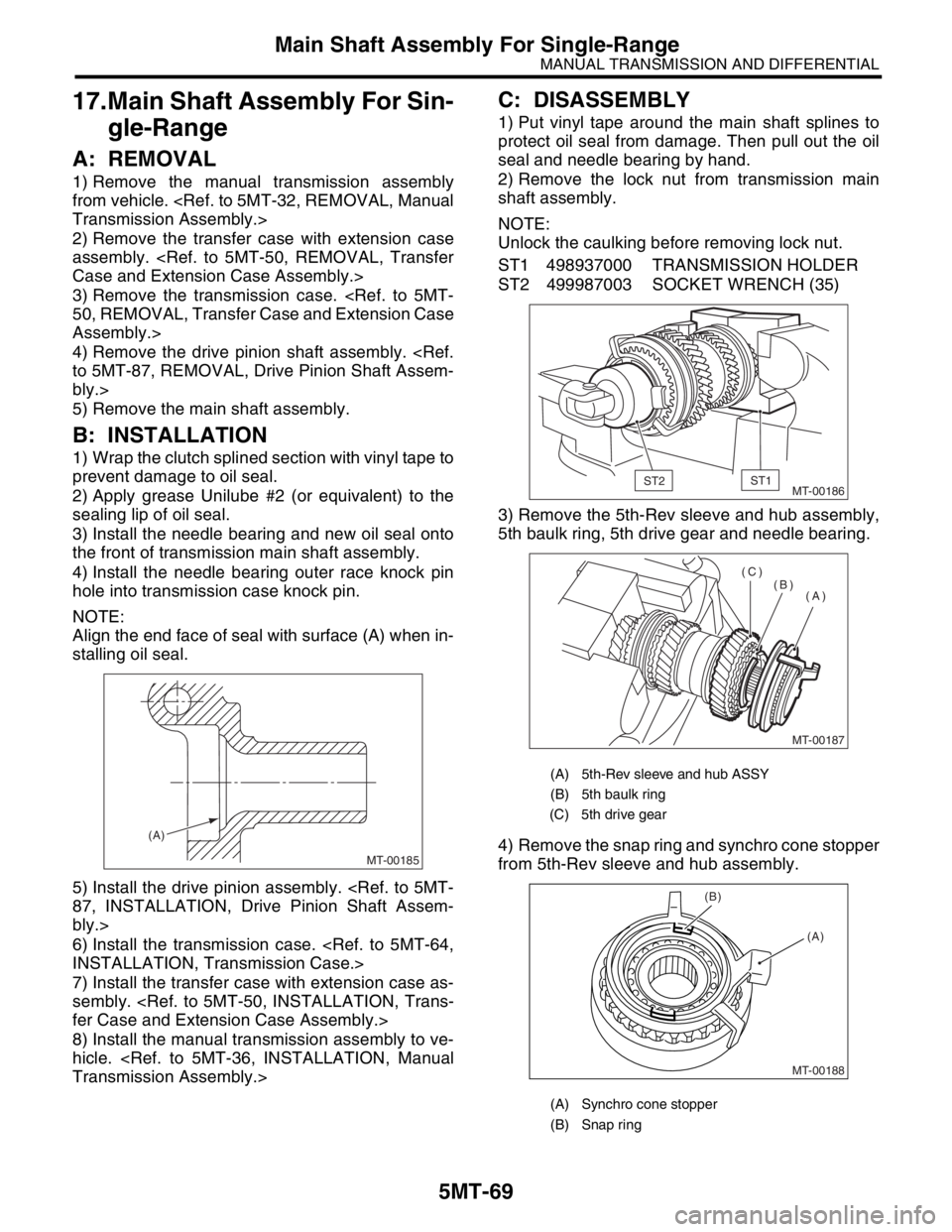

C: DISASSEMBLY

1) Put vinyl tape around the main shaft splines to

protect oil seal from damage. Then pull out the oil

seal and needle bearing by hand.

2) Remove the lock nut from transmission main

shaft assembly.

NOTE:

Unlock the caulking before removing lock nut.

ST1 498937000 TRANSMISSION HOLDER

ST2 499987003 SOCKET WRENCH (35)

3) Remove the 5th-Rev sleeve and hub assembly,

5th baulk ring, 5th drive gear and needle bearing.

4) Remove the snap ring and synchro cone stopper

from 5th-Rev sleeve and hub assembly.

MT-00185

(A)

(A) 5th-Rev sleeve and hub ASSY

(B) 5th baulk ring

(C) 5th drive gear

(A) Synchro cone stopper

(B) Snap ring

MT-00186ST2ST1

MT-00187

(A) (B) (C)

MT-00188

(A) (B)

Page 2786 of 2870

5MT-73

MANUAL TRANSMISSION AND DIFFERENTIAL

Main Shaft Assembly For Single-Range

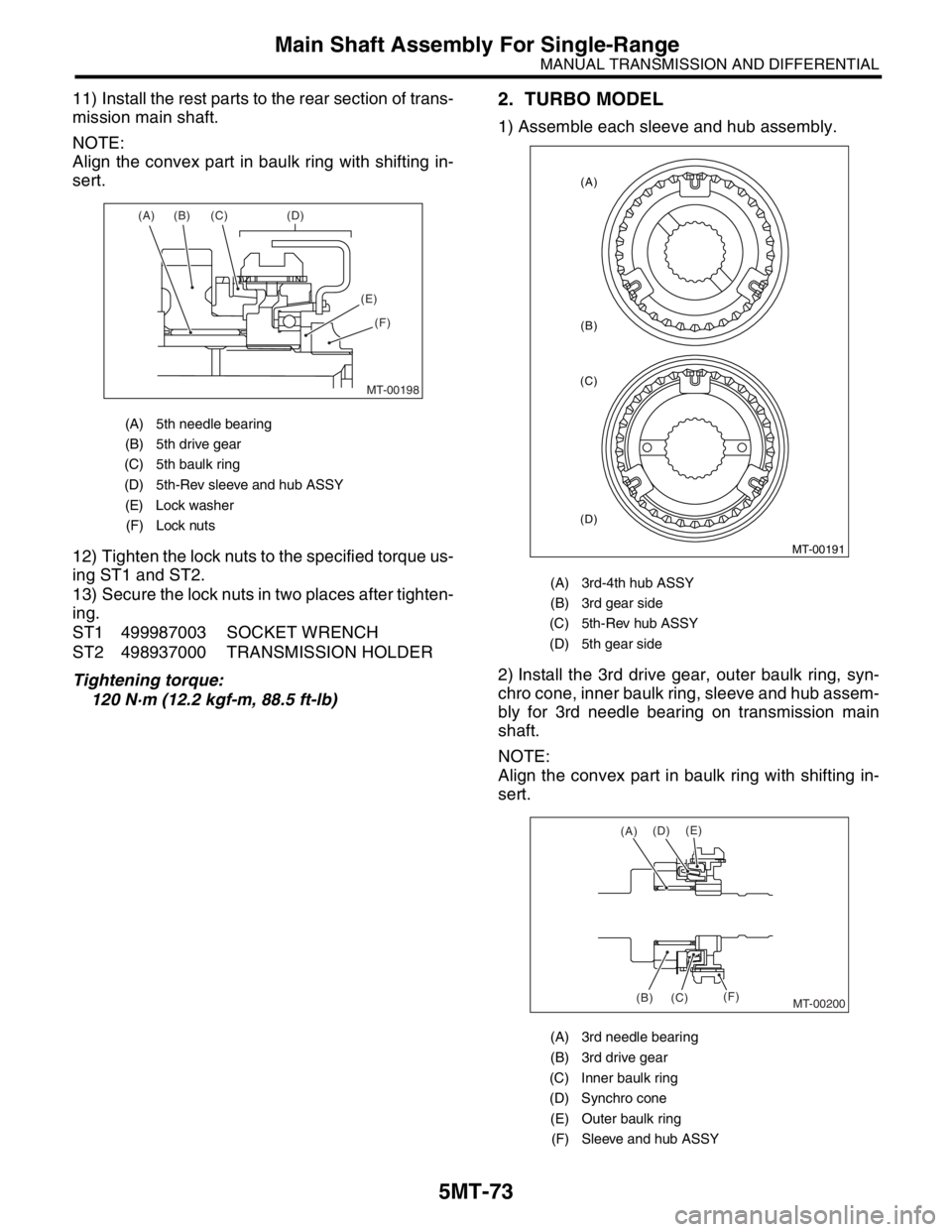

11) Install the rest parts to the rear section of trans-

mission main shaft.

NOTE:

Align the convex part in baulk ring with shifting in-

sert.

12) Tighten the lock nuts to the specified torque us-

ing ST1 and ST2.

13) Secure the lock nuts in two places after tighten-

ing.

ST1 499987003 SOCKET WRENCH

ST2 498937000 TRANSMISSION HOLDER

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb) 2. TURBO MODEL

1) Assemble each sleeve and hub assembly.

2) Install the 3rd drive gear, outer baulk ring, syn-

chro cone, inner baulk ring, sleeve and hub assem-

bly for 3rd needle bearing on transmission main

shaft.

NOTE:

Align the convex part in baulk ring with shifting in-

sert.

(A) 5th needle bearing

(B) 5th drive gear

(C) 5th baulk ring

(D) 5th-Rev sleeve and hub ASSY

(E) Lock washer

(F) Lock nuts

MT-00198

(A) (B) (C) (D)

(E)

(F)

(A) 3rd-4th hub ASSY

(B) 3rd gear side

(C) 5th-Rev hub ASSY

(D) 5th gear side

(A) 3rd needle bearing

(B) 3rd drive gear

(C) Inner baulk ring

(D) Synchro cone

(E) Outer baulk ring

(F) Sleeve and hub ASSY

MT-00191 (D) (C)(B) (A)

MT-00200

(A)

(B)

(C) (D)(E)

(F)

Page 2788 of 2870

5MT-75

MANUAL TRANSMISSION AND DIFFERENTIAL

Main Shaft Assembly For Single-Range

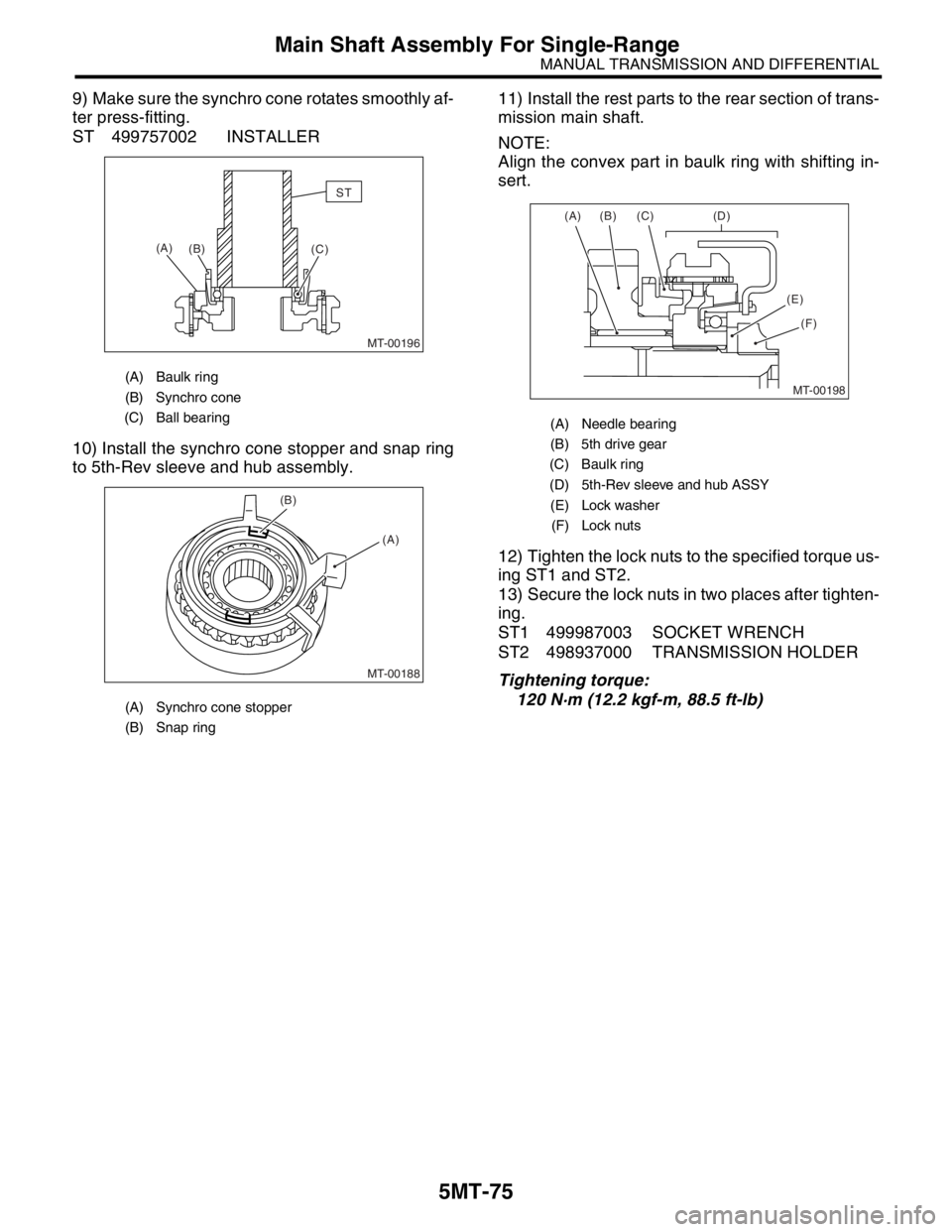

9) Make sure the synchro cone rotates smoothly af-

ter press-fitting.

ST 499757002 INSTALLER

10) Install the synchro cone stopper and snap ring

to 5th-Rev sleeve and hub assembly.11) Install the rest parts to the rear section of trans-

mission main shaft.

NOTE:

Align the convex part in baulk ring with shifting in-

sert.

12) Tighten the lock nuts to the specified torque us-

ing ST1 and ST2.

13) Secure the lock nuts in two places after tighten-

ing.

ST1 499987003 SOCKET WRENCH

ST2 498937000 TRANSMISSION HOLDER

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

(A) Baulk ring

(B) Synchro cone

(C) Ball bearing

(A) Synchro cone stopper

(B) Snap ring

MT-00196

(B) (A)

(C)

ST

MT-00188

(A) (B)

(A) Needle bearing

(B) 5th drive gear

(C) Baulk ring

(D) 5th-Rev sleeve and hub ASSY

(E) Lock washer

(F) Lock nuts

MT-00198

(A) (B) (C) (D)

(E)

(F)

Page 2790 of 2870

5MT-77

MANUAL TRANSMISSION AND DIFFERENTIAL

Main Shaft Assembly For Dual-Range

18.Main Shaft Assembly For

Dual-Range

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the transfer case with extension case

assembly.

3) Remove the transmission case.

4) Remove the drive pinion shaft assembly.

bly.>

5) Remove the main shaft assembly and input shaft

assembly.

B: INSTALLATION

1) Install the needle bearing onto the front of trans-

mission main shaft assembly.

2) Select the input shaft adjusting shim and install it

to the input shaft assembly.

3) Connect the main shaft assembly and input shaft

assembly.

4) Install the needle bearing outer race knock pin

hole into transmission case knock pin.

5) Install the drive pinion assembly.

bly.>

6) Install the transmission case.

7) Install the transfer case with extension case as-

sembly.

8) Install the manual transmission assembly to ve-

hicle.

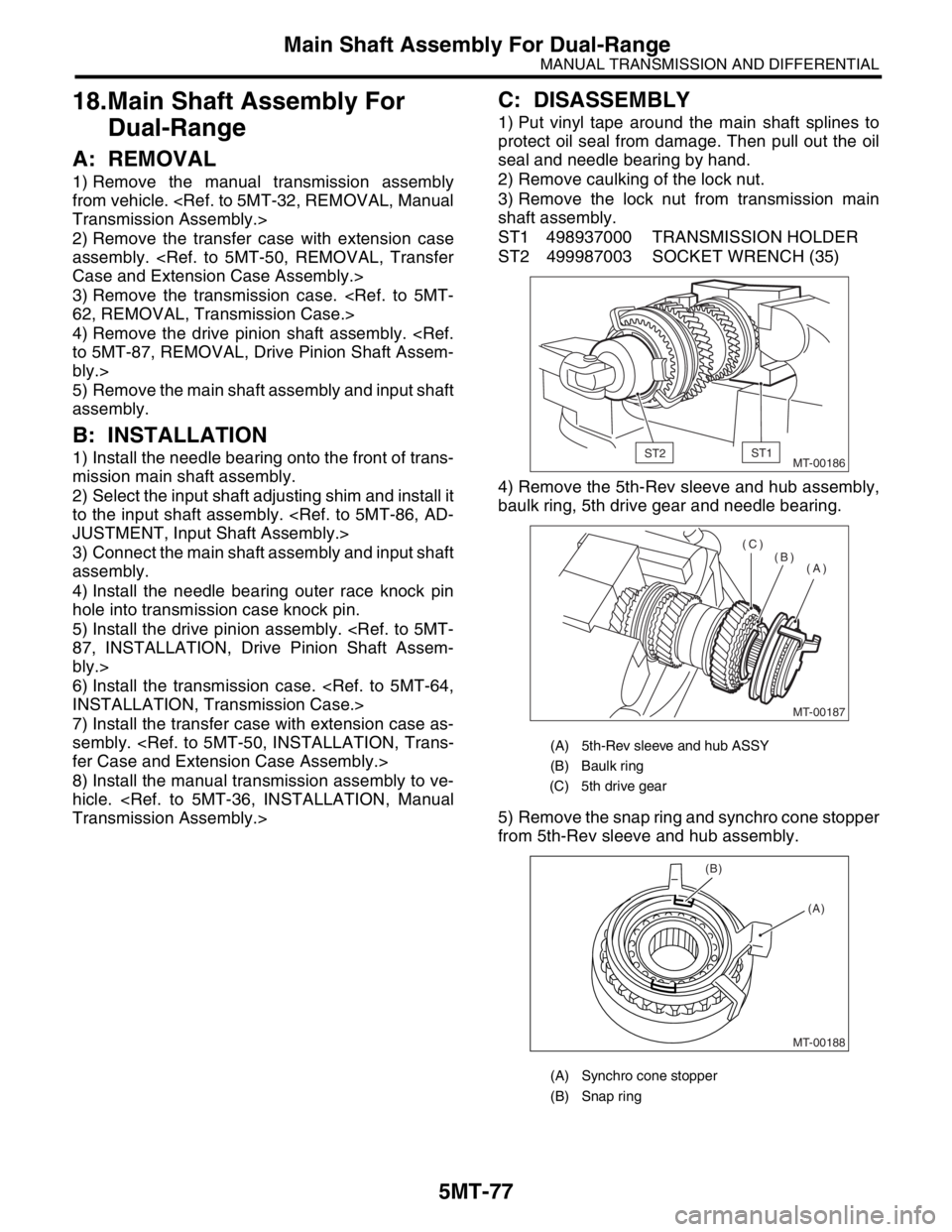

C: DISASSEMBLY

1) Put vinyl tape around the main shaft splines to

protect oil seal from damage. Then pull out the oil

seal and needle bearing by hand.

2) Remove caulking of the lock nut.

3) Remove the lock nut from transmission main

shaft assembly.

ST1 498937000 TRANSMISSION HOLDER

ST2 499987003 SOCKET WRENCH (35)

4) Remove the 5th-Rev sleeve and hub assembly,

baulk ring, 5th drive gear and needle bearing.

5) Remove the snap ring and synchro cone stopper

from 5th-Rev sleeve and hub assembly.

(A) 5th-Rev sleeve and hub ASSY

(B) Baulk ring

(C) 5th drive gear

(A) Synchro cone stopper

(B) Snap ring

MT-00186ST2ST1

MT-00187

(A) (B) (C)

MT-00188

(A) (B)

Page 2794 of 2870

5MT-81

MANUAL TRANSMISSION AND DIFFERENTIAL

Main Shaft Assembly For Dual-Range

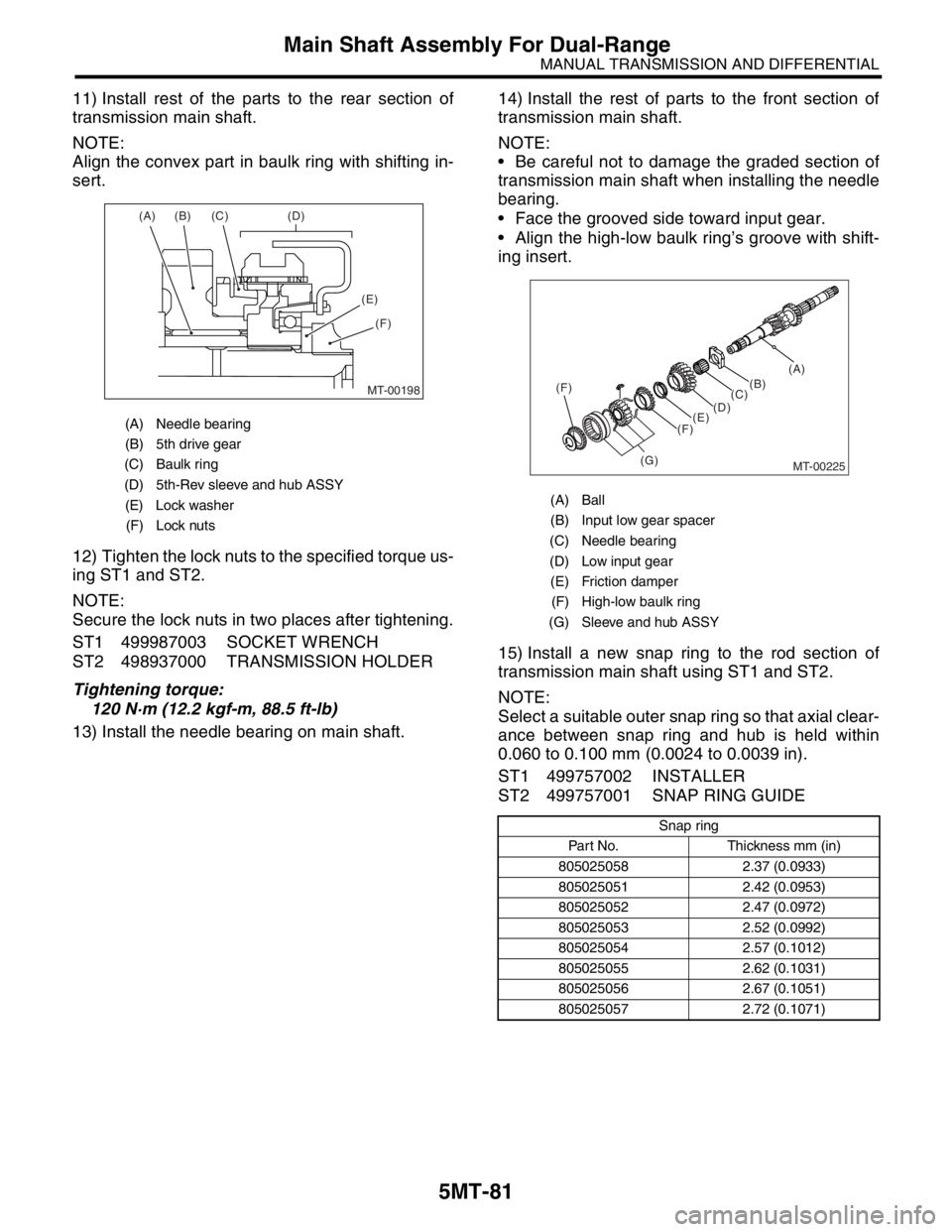

11) Install rest of the parts to the rear section of

transmission main shaft.

NOTE:

Align the convex part in baulk ring with shifting in-

sert.

12) Tighten the lock nuts to the specified torque us-

ing ST1 and ST2.

NOTE:

Secure the lock nuts in two places after tightening.

ST1 499987003 SOCKET WRENCH

ST2 498937000 TRANSMISSION HOLDER

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

13) Install the needle bearing on main shaft.14) Install the rest of parts to the front section of

transmission main shaft.

NOTE:

Be careful not to damage the graded section of

transmission main shaft when installing the needle

bearing.

Face the grooved side toward input gear.

Align the high-low baulk ring’s groove with shift-

ing insert.

15) Install a new snap ring to the rod section of

transmission main shaft using ST1 and ST2.

NOTE:

Select a suitable outer snap ring so that axial clear-

ance between snap ring and hub is held within

0.060 to 0.100 mm (0.0024 to 0.0039 in).

ST1 499757002 INSTALLER

ST2 499757001 SNAP RING GUIDE

(A) Needle bearing

(B) 5th drive gear

(C) Baulk ring

(D) 5th-Rev sleeve and hub ASSY

(E) Lock washer

(F) Lock nuts

MT-00198

(A) (B) (C) (D)

(E)

(F)

(A) Ball

(B) Input low gear spacer

(C) Needle bearing

(D) Low input gear

(E) Friction damper

(F) High-low baulk ring

(G) Sleeve and hub ASSY

Snap ring

Part No. Thickness mm (in)

805025058 2.37 (0.0933)

805025051 2.42 (0.0953)

805025052 2.47 (0.0972)

805025053 2.52 (0.0992)

805025054 2.57 (0.1012)

805025055 2.62 (0.1031)

805025056 2.67 (0.1051)

805025057 2.72 (0.1071)

MT-00225

(F)

(G)(C)(B)(A)

(D)

(E)

(F)

Page 2801 of 2870

5MT-88

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

8) Select one to three shims from the next table for

the value determined as described above and take

a shim thickness which is closest to the indicated

value.

9) Install the differential assembly.

10) Set the transmission main shaft assembly and

drive pinion assembly in position. (So there is no

clearance between the two when moved all the way

to the front). Inspect the suitable 1st-2nd, 3rd-4th

and 5th shifter fork so that coupling sleeve and re-

verse driven gear are positioned in the center of

their synchronizing mechanisms.

11) Install the transmission case.

12) Install the transfer case with extension case as-

sembly.

13) Install the manual transmission assembly to ve-

hicle.

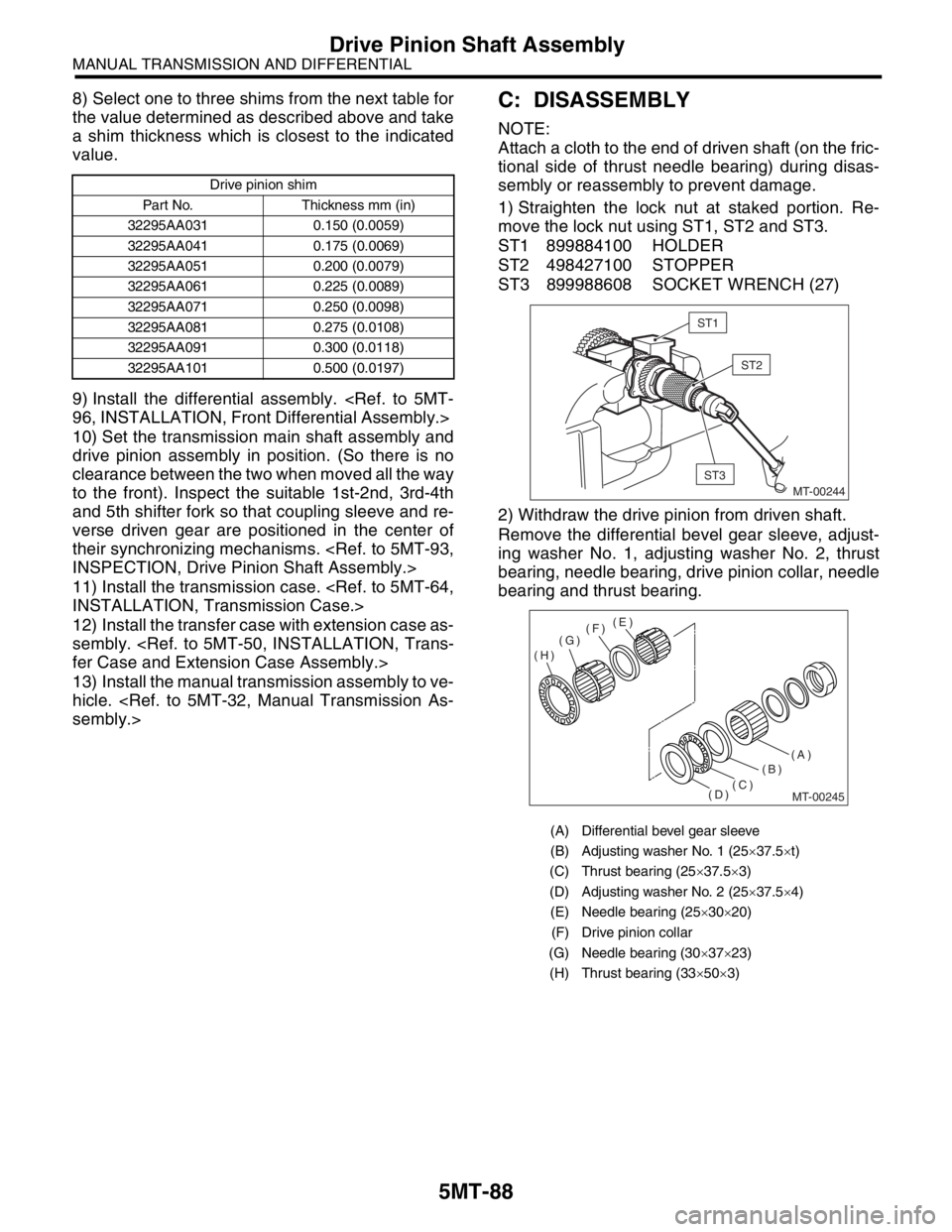

NOTE:

Attach a cloth to the end of driven shaft (on the fric-

tional side of thrust needle bearing) during disas-

sembly or reassembly to prevent damage.

1) Straighten the lock nut at staked portion. Re-

move the lock nut using ST1, ST2 and ST3.

ST1 899884100 HOLDER

ST2 498427100 STOPPER

ST3 899988608 SOCKET WRENCH (27)

2) Withdraw the drive pinion from driven shaft.

Remove the differential bevel gear sleeve, adjust-

ing washer No. 1, adjusting washer No. 2, thrust

bearing, needle bearing, drive pinion collar, needle

bearing and thrust bearing.

Drive pinion shim

Part No. Thickness mm (in)

32295AA031 0.150 (0.0059)

32295AA041 0.175 (0.0069)

32295AA051 0.200 (0.0079)

32295AA061 0.225 (0.0089)

32295AA071 0.250 (0.0098)

32295AA081 0.275 (0.0108)

32295AA091 0.300 (0.0118)

32295AA101 0.500 (0.0197)

(A) Differential bevel gear sleeve

(B) Adjusting washer No. 1 (25×37.5×t)

(C) Thrust bearing (25×37.5×3)

(D) Adjusting washer No. 2 (25×37.5×4)

(E) Needle bearing (25×30×20)

(F) Drive pinion collar

(G) Needle bearing (30×37×23)

(H) Thrust bearing (33×50×3)

ST1

ST2

MT-00244

ST3

MT-00245

(B)

(D)(C)(A) (F)

(H)(G)(E)

Page 2802 of 2870

5MT-89

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

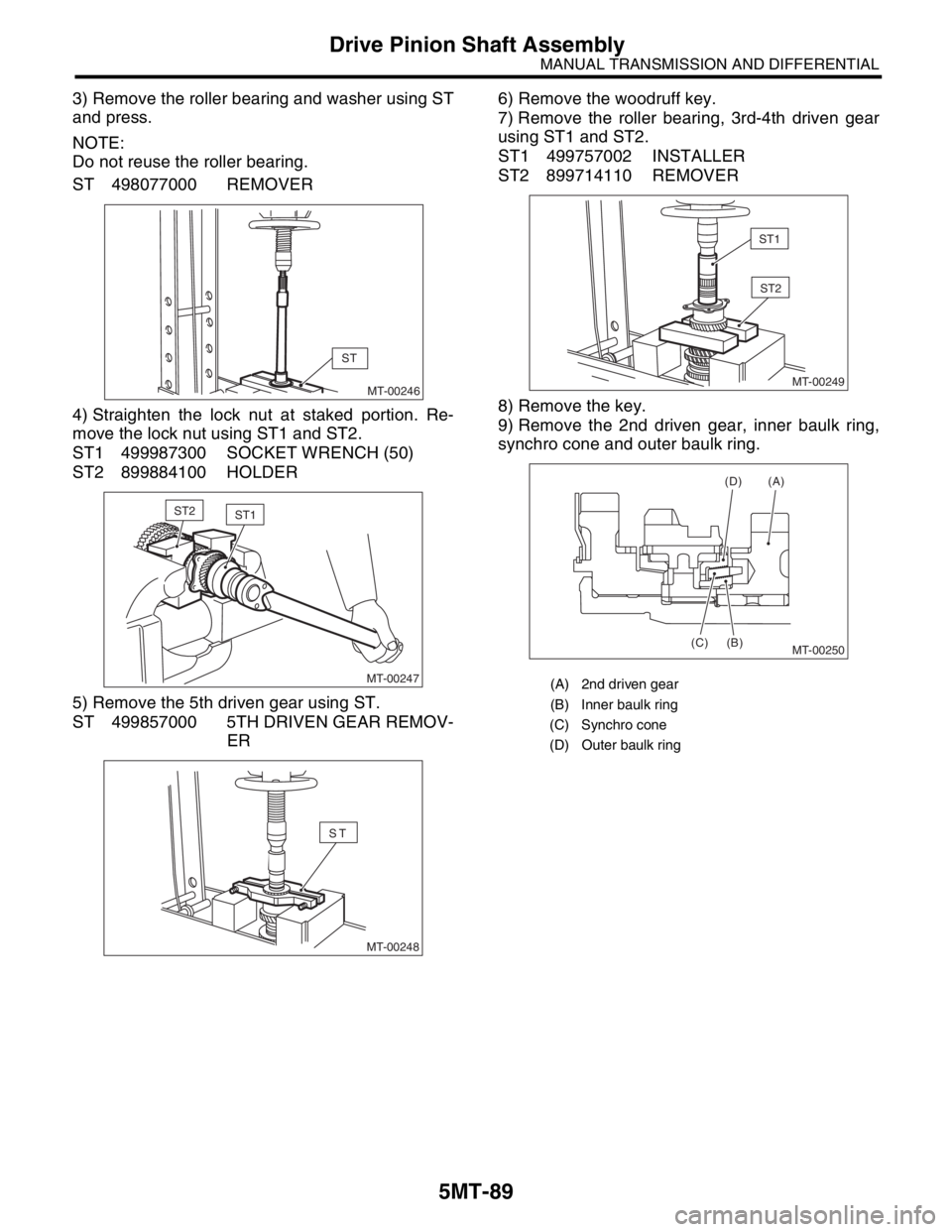

3) Remove the roller bearing and washer using ST

and press.

NOTE:

Do not reuse the roller bearing.

ST 498077000 REMOVER

4) Straighten the lock nut at staked portion. Re-

move the lock nut using ST1 and ST2.

ST1 499987300 SOCKET WRENCH (50)

ST2 899884100 HOLDER

5) Remove the 5th driven gear using ST.

ST 499857000 5TH DRIVEN GEAR REMOV-

ER6) Remove the woodruff key.

7) Remove the roller bearing, 3rd-4th driven gear

using ST1 and ST2.

ST1 499757002 INSTALLER

ST2 899714110 REMOVER

8) Remove the key.

9) Remove the 2nd driven gear, inner baulk ring,

synchro cone and outer baulk ring.

MT-00246

ST

MT-00247

ST1ST2

MT-00248

ST

(A) 2nd driven gear

(B) Inner baulk ring

(C) Synchro cone

(D) Outer baulk ring

MT-00249

ST1

ST2

MT-00250

(A)

(B) (C)(D)

Page 2804 of 2870

5MT-91

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

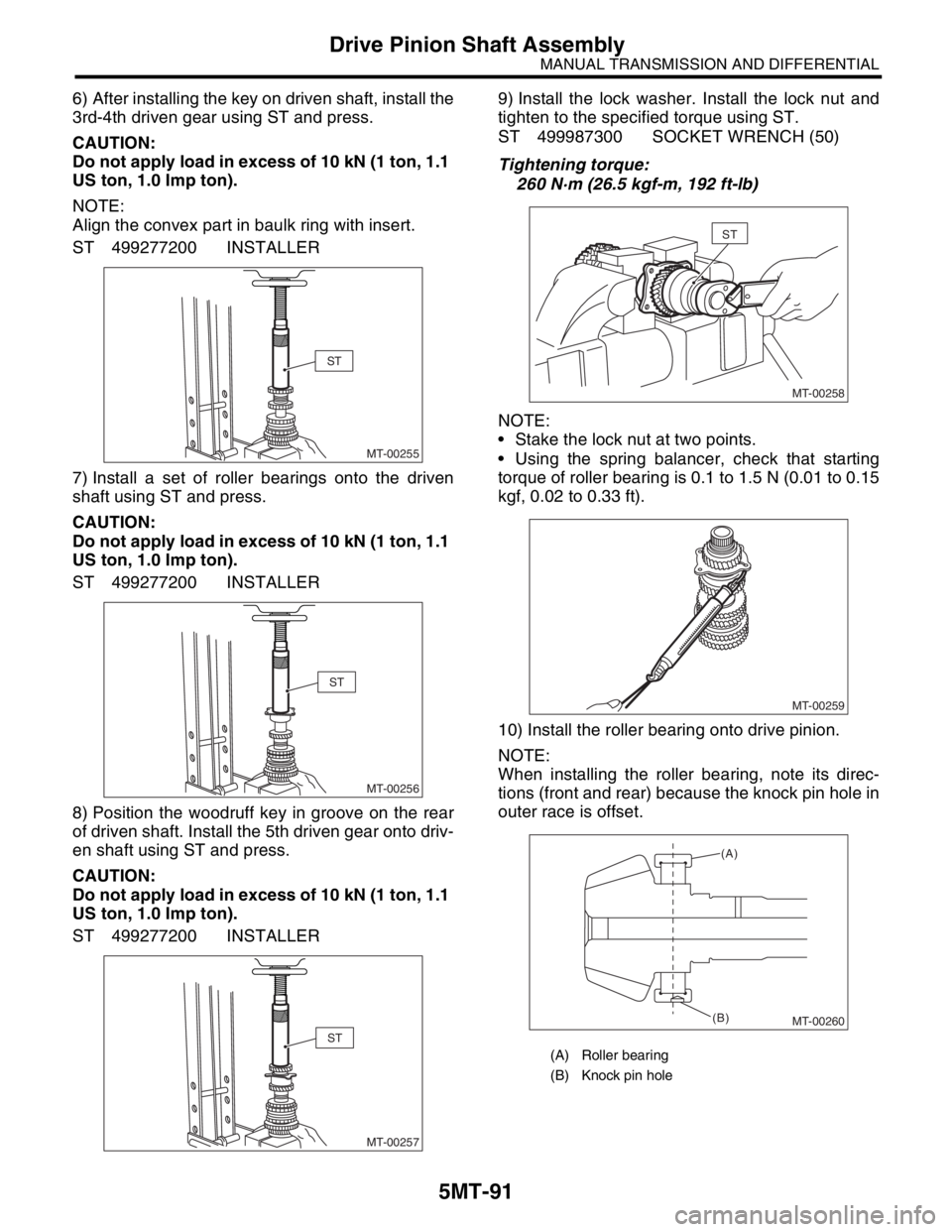

6) After installing the key on driven shaft, install the

3rd-4th driven gear using ST and press.

CAUTION:

Do not apply load in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton).

NOTE:

Align the convex part in baulk ring with insert.

ST 499277200 INSTALLER

7) Install a set of roller bearings onto the driven

shaft using ST and press.

CAUTION:

Do not apply load in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton).

ST 499277200 INSTALLER

8) Position the woodruff key in groove on the rear

of driven shaft. Install the 5th driven gear onto driv-

en shaft using ST and press.

CAUTION:

Do not apply load in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton).

ST 499277200 INSTALLER9) Install the lock washer. Install the lock nut and

tighten to the specified torque using ST.

ST 499987300 SOCKET WRENCH (50)

Tightening torque:

260 N·m (26.5 kgf-m, 192 ft-lb)

NOTE:

Stake the lock nut at two points.

Using the spring balancer, check that starting

torque of roller bearing is 0.1 to 1.5 N (0.01 to 0.15

kgf, 0.02 to 0.33 ft).

10) Install the roller bearing onto drive pinion.

NOTE:

When installing the roller bearing, note its direc-

tions (front and rear) because the knock pin hole in

outer race is offset.

MT-00255

ST

MT-00256

ST

MT-00257

ST

(A) Roller bearing

(B) Knock pin hole

MT-00258

ST

MT-00259

MT-00260

(A)

(B)

Page 2805 of 2870

5MT-92

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

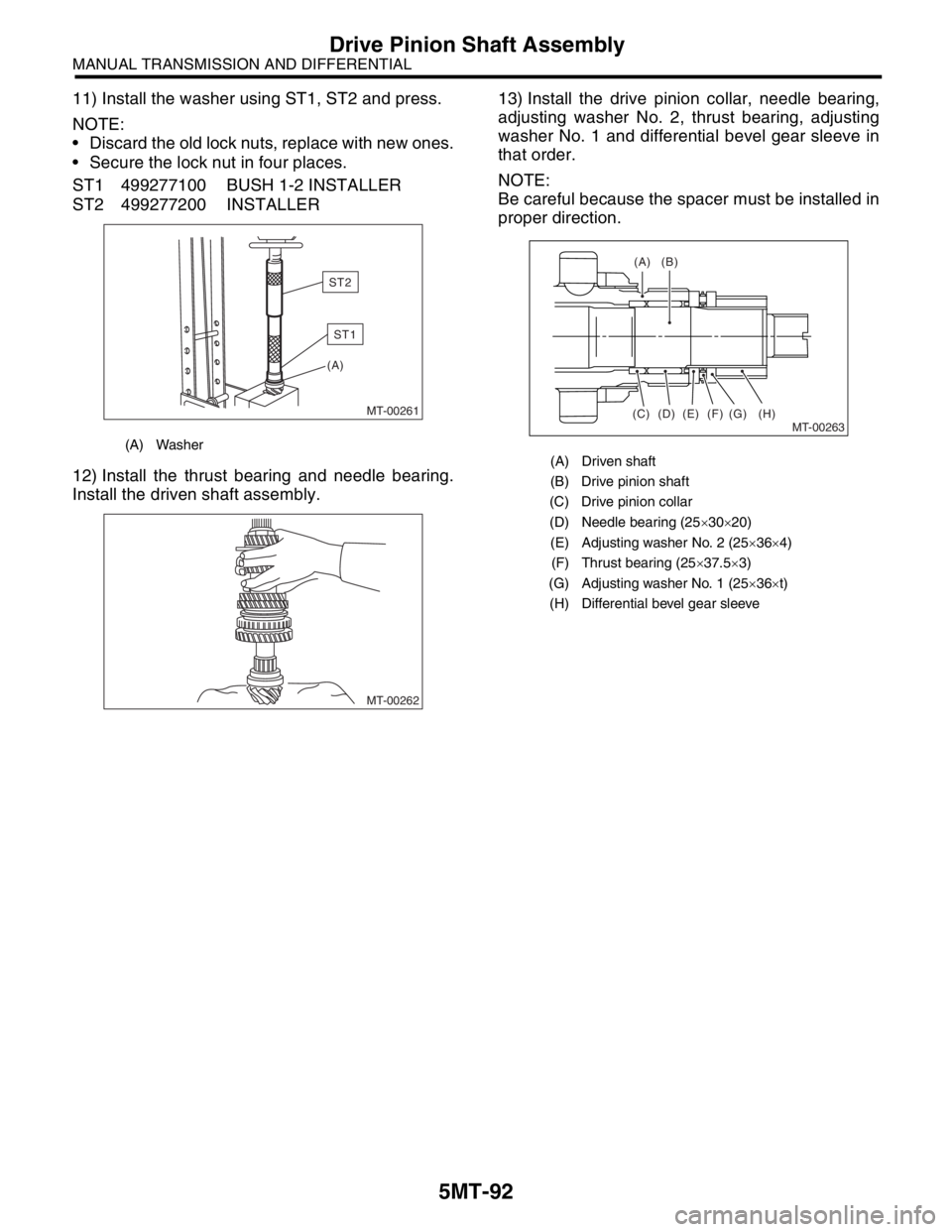

11) Install the washer using ST1, ST2 and press.

NOTE:

Discard the old lock nuts, replace with new ones.

Secure the lock nut in four places.

ST1 499277100 BUSH 1-2 INSTALLER

ST2 499277200 INSTALLER

12) Install the thrust bearing and needle bearing.

Install the driven shaft assembly.13) Install the drive pinion collar, needle bearing,

adjusting washer No. 2, thrust bearing, adjusting

washer No. 1 and differential bevel gear sleeve in

that order.

NOTE:

Be careful because the spacer must be installed in

proper direction.

(A) Washer

MT-00261

(A)

ST1

ST2

MT-00262

(A) Driven shaft

(B) Drive pinion shaft

(C) Drive pinion collar

(D) Needle bearing (25×30×20)

(E) Adjusting washer No. 2 (25×36×4)

(F) Thrust bearing (25×37.5×3)

(G) Adjusting washer No. 1 (25×36×t)

(H) Differential bevel gear sleeve

MT-00263

(A) (B)

(C) (D) (E) (F) (G) (H)