lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2535 of 2870

4AT(H4SO)-76

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

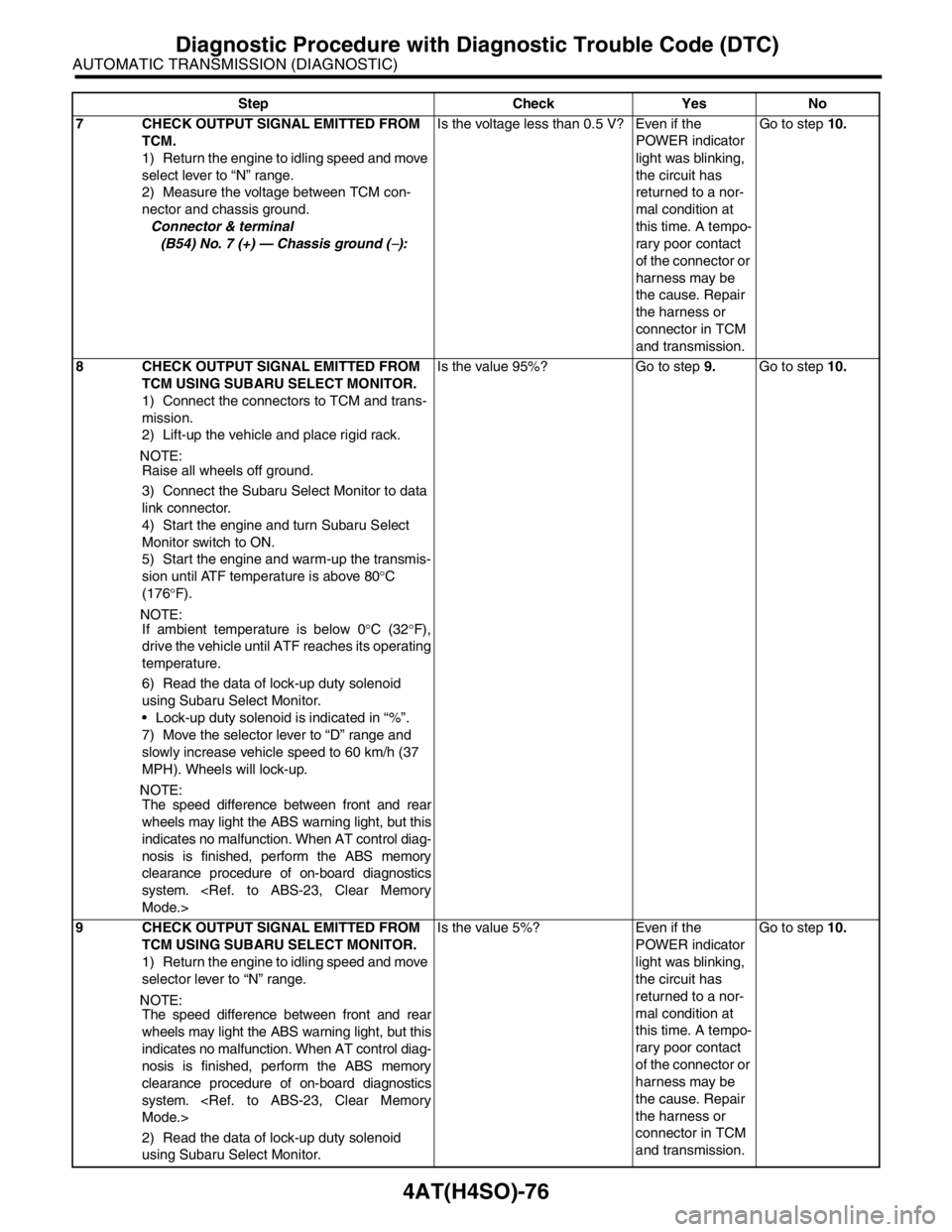

7 CHECK OUTPUT SIGNAL EMITTED FROM

TCM.

1) Return the engine to idling speed and move

select lever to “N” range.

2) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B54) No. 7 (+) — Chassis ground (

−):Is the voltage less than 0.5 V? Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in TCM

and transmission.Go to step 10.

8 CHECK OUTPUT SIGNAL EMITTED FROM

TCM USING SUBARU SELECT MONITOR.

1) Connect the connectors to TCM and trans-

mission.

2) Lift-up the vehicle and place rigid rack.

N

OTE:

Raise all wheels off ground.

3) Connect the Subaru Select Monitor to data

link connector.

4) Start the engine and turn Subaru Select

Monitor switch to ON.

5) Start the engine and warm-up the transmis-

sion until ATF temperature is above 80°C

(176°F).

N

OTE:

If ambient temperature is below 0°C (32°F),

drive the vehicle until ATF reaches its operating

temperature.

6) Read the data of lock-up duty solenoid

using Subaru Select Monitor.

Lock-up duty solenoid is indicated in “%”.

7) Move the selector lever to “D” range and

slowly increase vehicle speed to 60 km/h (37

MPH). Wheels will lock-up.

N

OTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control diag-

nosis is finished, perform the ABS memory

clearance procedure of on-board diagnostics

system.

9 CHECK OUTPUT SIGNAL EMITTED FROM

TCM USING SUBARU SELECT MONITOR.

1) Return the engine to idling speed and move

selector lever to “N” range.

N

OTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control diag-

nosis is finished, perform the ABS memory

clearance procedure of on-board diagnostics

system.

2) Read the data of lock-up duty solenoid

using Subaru Select Monitor.Is the value 5%? Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in TCM

and transmission.Go to step 10. Step Check Yes No

Page 2536 of 2870

4AT(H4SO)-77

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

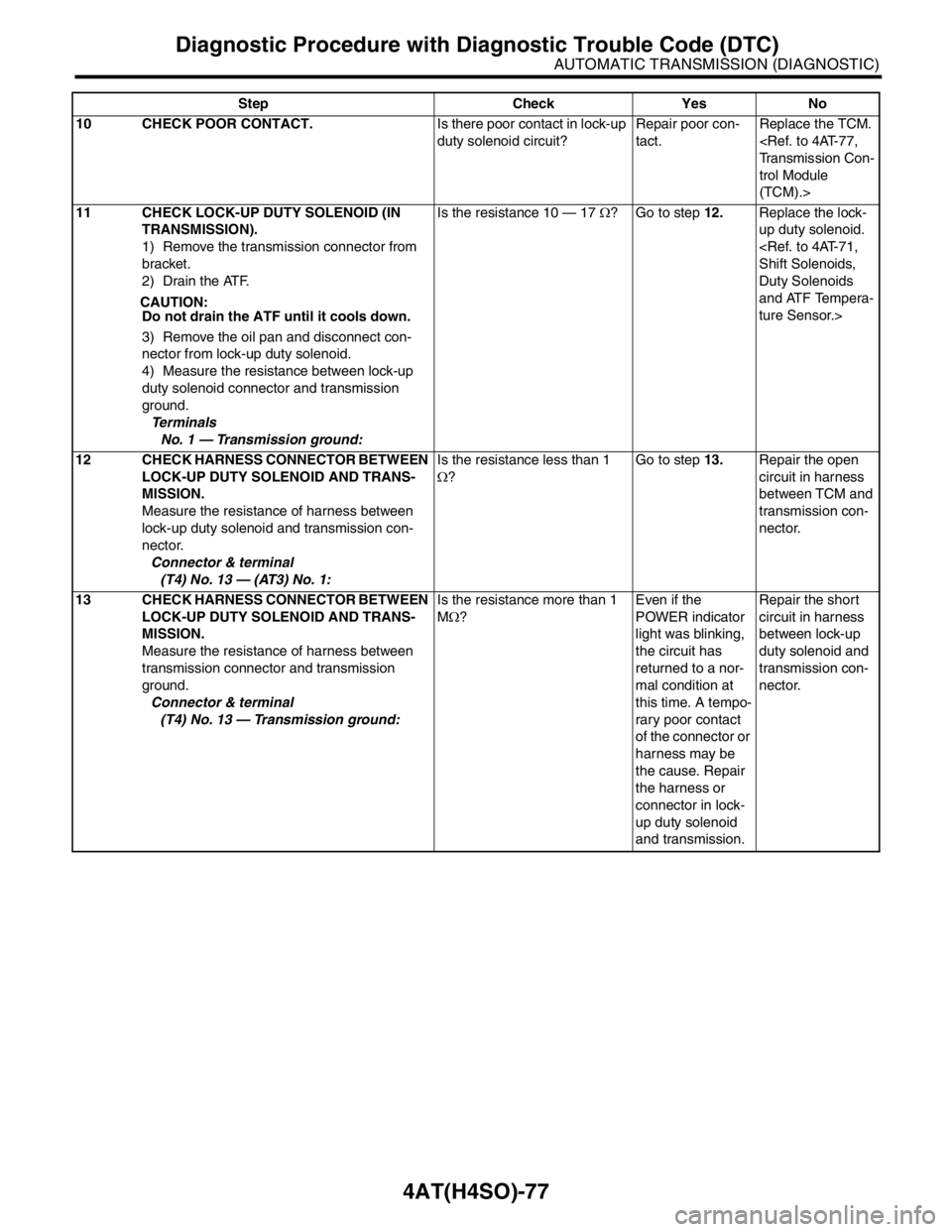

10 CHECK POOR CONTACT.Is there poor contact in lock-up

duty solenoid circuit?Repair poor con-

tact.Replace the TCM.

trol Module

(TCM).>

11 CHECK LOCK-UP DUTY SOLENOID (IN

TRANSMISSION).

1) Remove the transmission connector from

bracket.

2) Drain the ATF.

CAUTION:

Do not drain the ATF until it cools down.

3) Remove the oil pan and disconnect con-

nector from lock-up duty solenoid.

4) Measure the resistance between lock-up

duty solenoid connector and transmission

ground.

Te r m i n a l s

No. 1 — Transmission ground:Is the resistance 10 — 17 Ω? Go to step 12.Replace the lock-

up duty solenoid.

Duty Solenoids

and ATF Tempera-

ture Sensor.>

12 CHECK HARNESS CONNECTOR BETWEEN

LOCK-UP DUTY SOLENOID AND TRANS-

MISSION.

Measure the resistance of harness between

lock-up duty solenoid and transmission con-

nector.

Connector & terminal

(T4) No. 13 — (AT3) No. 1:Is the resistance less than 1

Ω?Go to step 13.Repair the open

circuit in harness

between TCM and

transmission con-

nector.

13 CHECK HARNESS CONNECTOR BETWEEN

LOCK-UP DUTY SOLENOID AND TRANS-

MISSION.

Measure the resistance of harness between

transmission connector and transmission

ground.

Connector & terminal

(T4) No. 13 — Transmission ground:Is the resistance more than 1

MΩ?Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in lock-

up duty solenoid

and transmission.Repair the short

circuit in harness

between lock-up

duty solenoid and

transmission con-

nector. Step Check Yes No

Page 2540 of 2870

4AT(H4SO)-81

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

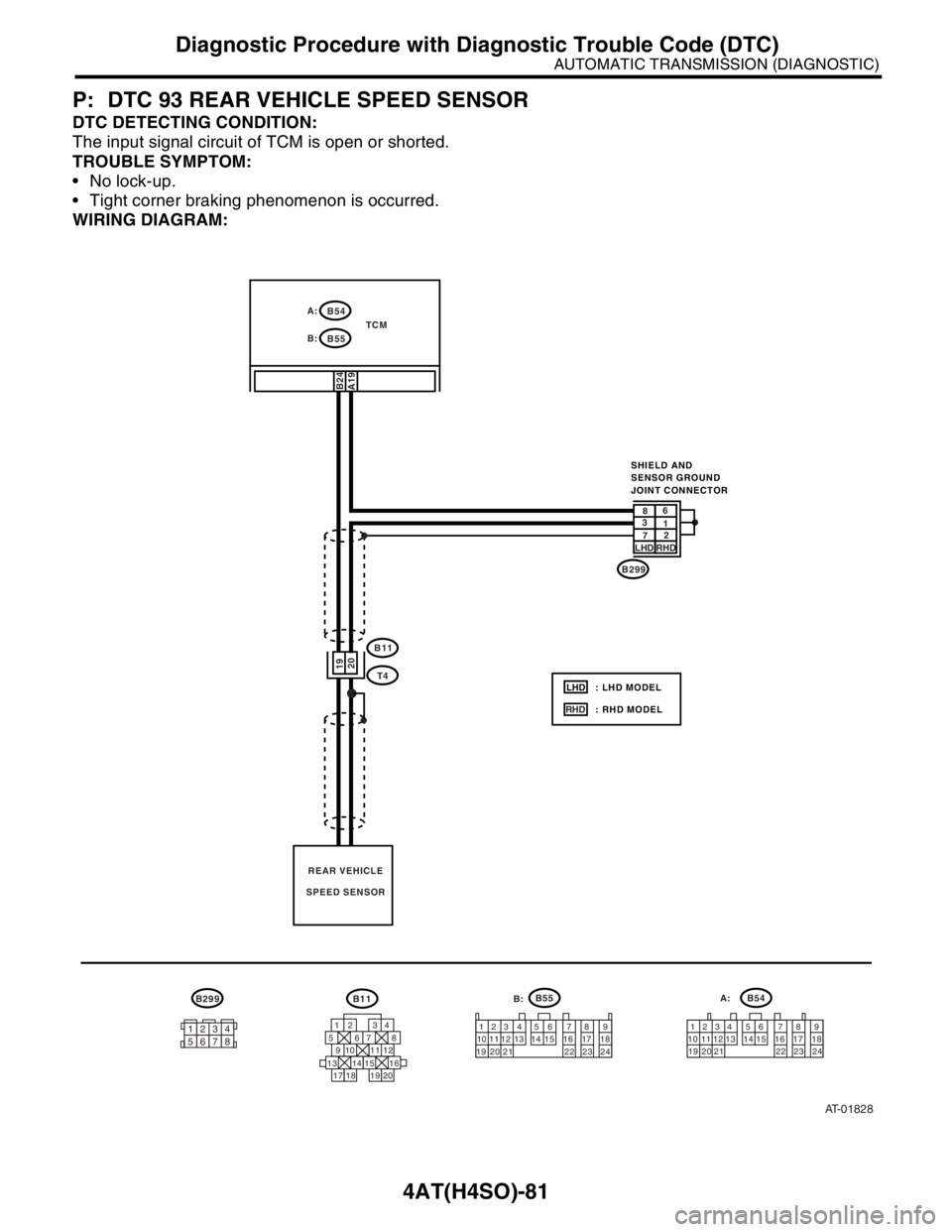

P: DTC 93 REAR VEHICLE SPEED SENSOR

DTC DETECTING CONDITION:

The input signal circuit of TCM is open or shorted.

TROUBLE SYMPTOM:

No lock-up.

Tight corner braking phenomenon is occurred.

WIRING DIAGRAM:

AT-01828

19

20

B11

B299

T4

TCMB55 B:

B24

A19

SHIELD AND

SENSOR GROUND

JOINT CONNECTOR

LHD: LHD MODEL

: RHD MODEL

REAR VEHICLE

B55

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

19 20 21 22 23 24

B11

12 34

5678

9

13 14 15

20 19 1716 10 11 12

18

SPEED SENSOR

B54

1234 5 6 7 8 9

10 11 12 13 14 15 16 17 18

19 20 21 22 23 24

B299

12345678

B54 A:

RHD

61

2

RHD 8

LHD3

7

A:

B:

Page 2569 of 2870

4AT(H4SO)-110

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

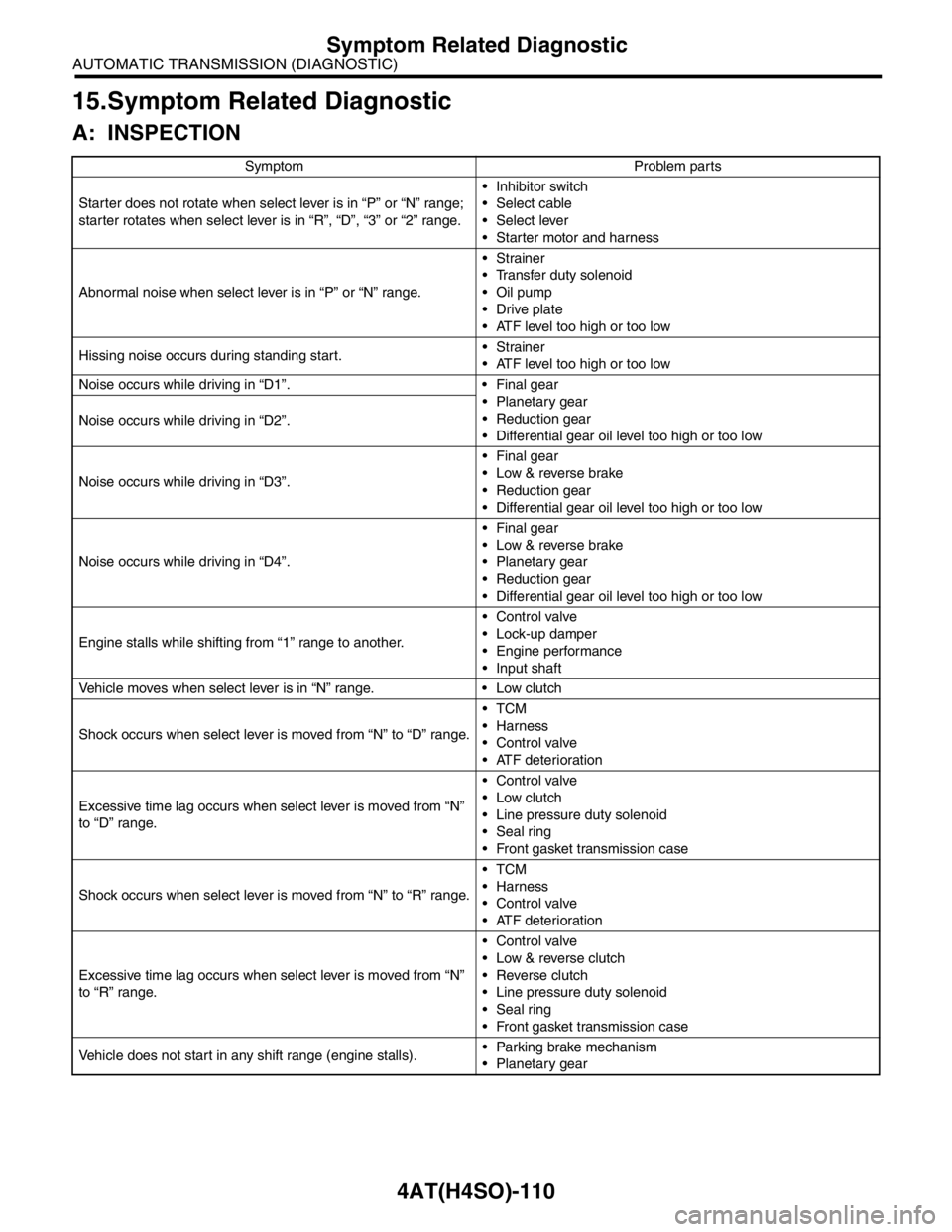

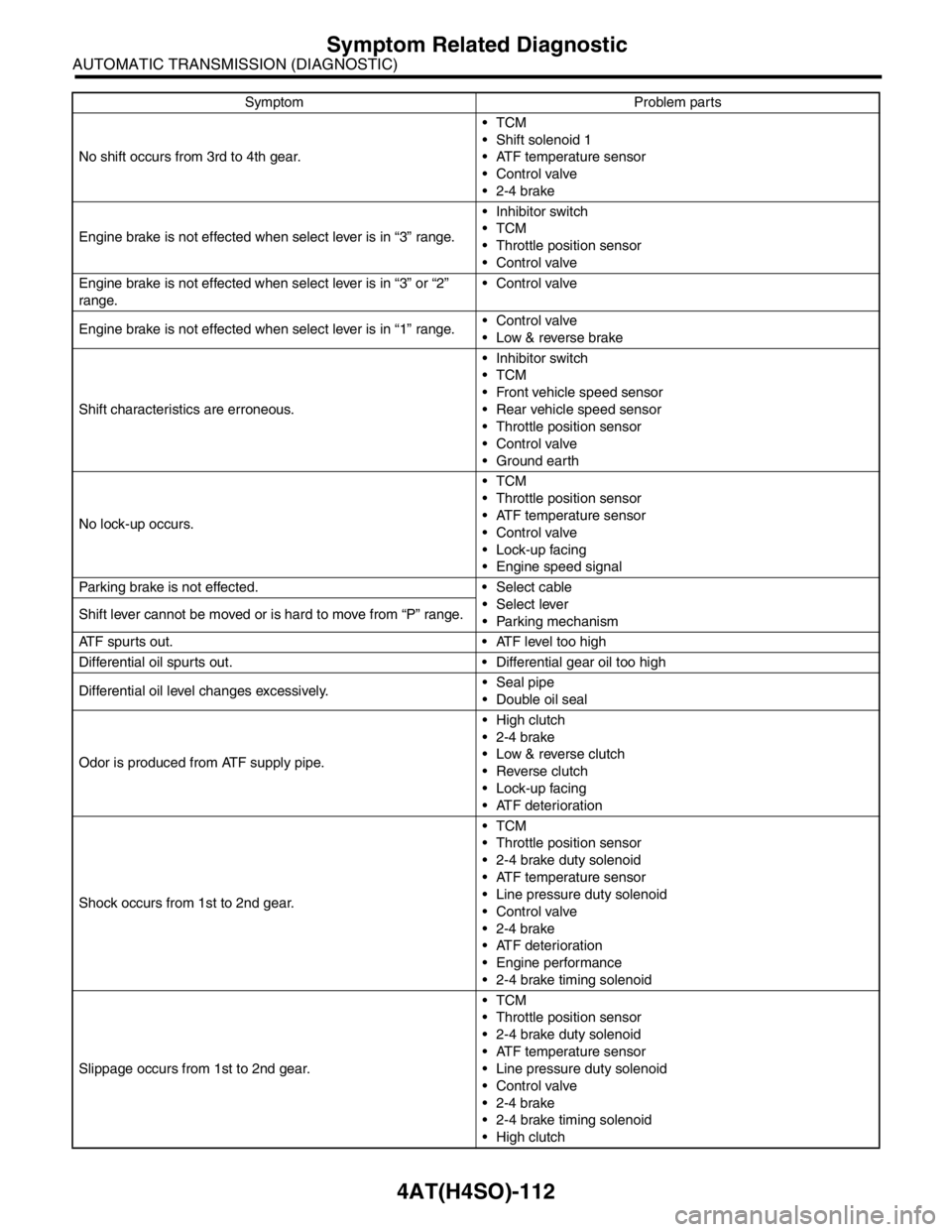

15.Symptom Related Diagnostic

A: INSPECTION

Symptom Problem parts

Starter does not rotate when select lever is in “P” or “N” range;

starter rotates when select lever is in “R”, “D”, “3” or “2” range. Inhibitor switch

Select cable

Select lever

Starter motor and harness

Abnormal noise when select lever is in “P” or “N” range. Strainer

Transfer duty solenoid

Oil pump

Drive plate

ATF level too high or too low

Hissing noise occurs during standing start. Strainer

ATF level too high or too low

Noise occurs while driving in “D1”. Final gear

Planetary gear

Reduction gear

Differential gear oil level too high or too low Noise occurs while driving in “D2”.

Noise occurs while driving in “D3”. Final gear

Low & reverse brake

Reduction gear

Differential gear oil level too high or too low

Noise occurs while driving in “D4”. Final gear

Low & reverse brake

Planetary gear

Reduction gear

Differential gear oil level too high or too low

Engine stalls while shifting from “1” range to another. Control valve

Lock-up damper

Engine performance

Input shaft

Vehicle moves when select lever is in “N” range. Low clutch

Shock occurs when select lever is moved from “N” to “D” range.TCM

Harness

Control valve

ATF deterioration

Excessive time lag occurs when select lever is moved from “N”

to “D” range. Control valve

Low clutch

Line pressure duty solenoid

Seal ring

Front gasket transmission case

Shock occurs when select lever is moved from “N” to “R” range.TCM

Harness

Control valve

ATF deterioration

Excessive time lag occurs when select lever is moved from “N”

to “R” range. Control valve

Low & reverse clutch

Reverse clutch

Line pressure duty solenoid

Seal ring

Front gasket transmission case

Vehicle does not start in any shift range (engine stalls). Parking brake mechanism

Planetary gear

Page 2571 of 2870

4AT(H4SO)-112

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

No shift occurs from 3rd to 4th gear.TCM

Shift solenoid 1

ATF temperature sensor

Control valve

2-4 brake

Engine brake is not effected when select lever is in “3” range. Inhibitor switch

TCM

Throttle position sensor

Control valve

Engine brake is not effected when select lever is in “3” or “2”

range. Control valve

Engine brake is not effected when select lever is in “1” range. Control valve

Low & reverse brake

Shift characteristics are erroneous. Inhibitor switch

TCM

Front vehicle speed sensor

Rear vehicle speed sensor

Throttle position sensor

Control valve

Ground earth

No lock-up occurs.TCM

Throttle position sensor

ATF temperature sensor

Control valve

Lock-up facing

Engine speed signal

Parking brake is not effected. Select cable

Select lever

Parking mechanism Shift lever cannot be moved or is hard to move from “P” range.

ATF spurts out. ATF level too high

Differential oil spurts out. Differential gear oil too high

Differential oil level changes excessively. Seal pipe

Double oil seal

Odor is produced from ATF supply pipe.High clutch

2-4 brake

Low & reverse clutch

Reverse clutch

Lock-up facing

ATF deterioration

Shock occurs from 1st to 2nd gear.TCM

Throttle position sensor

2-4 brake duty solenoid

ATF temperature sensor

Line pressure duty solenoid

Control valve

2-4 brake

ATF deterioration

Engine performance

2-4 brake timing solenoid

Slippage occurs from 1st to 2nd gear.TCM

Throttle position sensor

2-4 brake duty solenoid

ATF temperature sensor

Line pressure duty solenoid

Control valve

2-4 brake

2-4 brake timing solenoid

High clutch Symptom Problem parts

Page 2573 of 2870

4AT(H4SO)-114

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

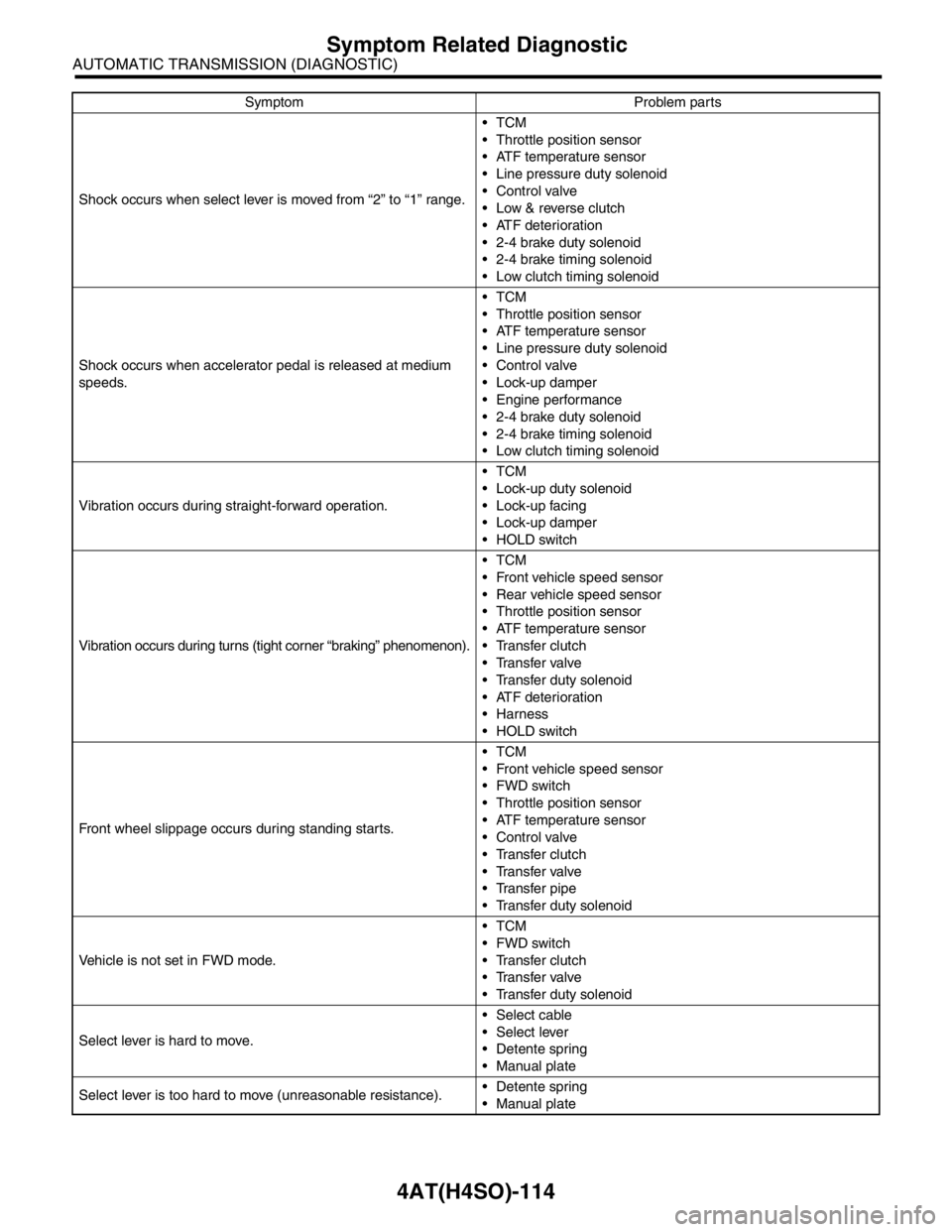

Symptom Related Diagnostic

Shock occurs when select lever is moved from “2” to “1” range.TCM

Throttle position sensor

ATF temperature sensor

Line pressure duty solenoid

Control valve

Low & reverse clutch

ATF deterioration

2-4 brake duty solenoid

2-4 brake timing solenoid

Low clutch timing solenoid

Shock occurs when accelerator pedal is released at medium

speeds.TCM

Throttle position sensor

ATF temperature sensor

Line pressure duty solenoid

Control valve

Lock-up damper

Engine performance

2-4 brake duty solenoid

2-4 brake timing solenoid

Low clutch timing solenoid

Vibration occurs during straight-forward operation.TCM

Lock-up duty solenoid

Lock-up facing

Lock-up damper

HOLD switch

Vibration occurs during turns (tight corner “braking” phenomenon).TCM

Front vehicle speed sensor

Rear vehicle speed sensor

Throttle position sensor

ATF temperature sensor

Transfer clutch

Transfer valve

Transfer duty solenoid

ATF deterioration

Harness

HOLD switch

Front wheel slippage occurs during standing starts.TCM

Front vehicle speed sensor

FWD switch

Throttle position sensor

ATF temperature sensor

Control valve

Transfer clutch

Transfer valve

Transfer pipe

Transfer duty solenoid

Vehicle is not set in FWD mode.TCM

FWD switch

Transfer clutch

Transfer valve

Transfer duty solenoid

Select lever is hard to move. Select cable

Select lever

Detente spring

Manual plate

Select lever is too hard to move (unreasonable resistance). Detente spring

Manual plate Symptom Problem parts

Page 2580 of 2870

4AT(H4DOTC)-4

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Check List for Interview

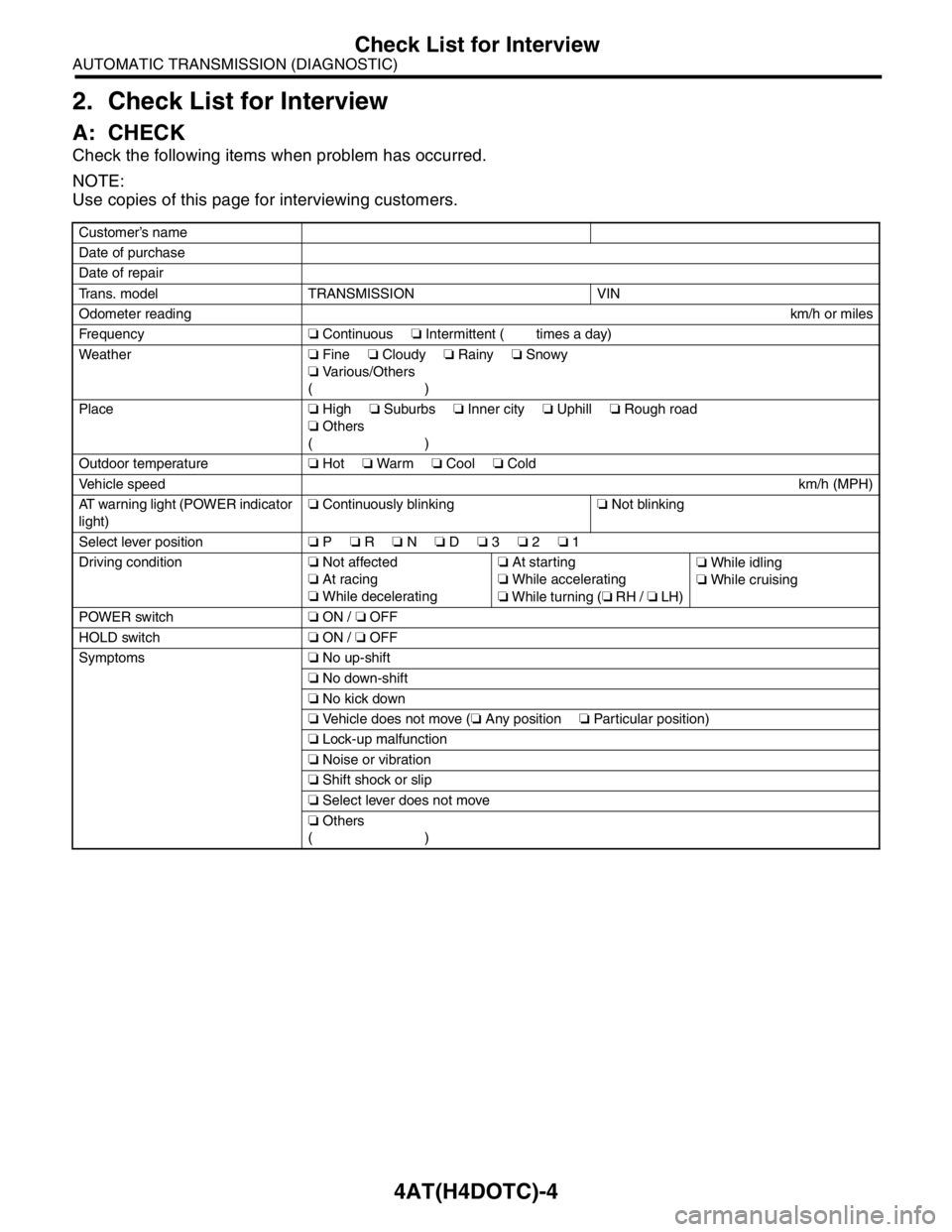

2. Check List for Interview

A: CHECK

Check the following items when problem has occurred.

NOTE:

Use copies of this page for interviewing customers.

Customer’s name

Date of purchase

Date of repair

Trans. model TRANSMISSION VIN

Odometer readingkm/h or miles

Frequency❏ Continuous ❏ Intermittent ( times a day)

Weather❏ Fine ❏ Cloudy ❏ Rainy ❏ Snowy

❏ Va r i o u s / O t h e r s

()

Place❏ High ❏ Suburbs ❏ Inner city ❏ Uphill ❏ Rough road

❏ Others

()

Outdoor temperature❏ Hot ❏ War m ❏ Cool ❏ Cold

Vehicle speedkm/h (MPH)

AT warning light (POWER indicator

light)❏ Continuously blinking❏ Not blinking

Select lever position❏ P ❏ R ❏ N ❏ D ❏ 3 ❏ 2 ❏ 1

Driving condition❏ Not affected

❏ At racing

❏ While decelerating❏ At starting

❏ While accelerating

❏ While turning (❏ RH / ❏ LH)❏ While idling

❏ While cruising

POWER switch❏ ON / ❏ OFF

HOLD switch❏ ON / ❏ OFF

Symptoms❏ No up-shift

❏ No down-shift

❏ No kick down

❏ Vehicle does not move (❏ Any position ❏ Particular position)

❏ Lock-up malfunction

❏ Noise or vibration

❏ Shift shock or slip

❏ Select lever does not move

❏ Others

()

Page 2587 of 2870

4AT(H4DOTC)-11

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

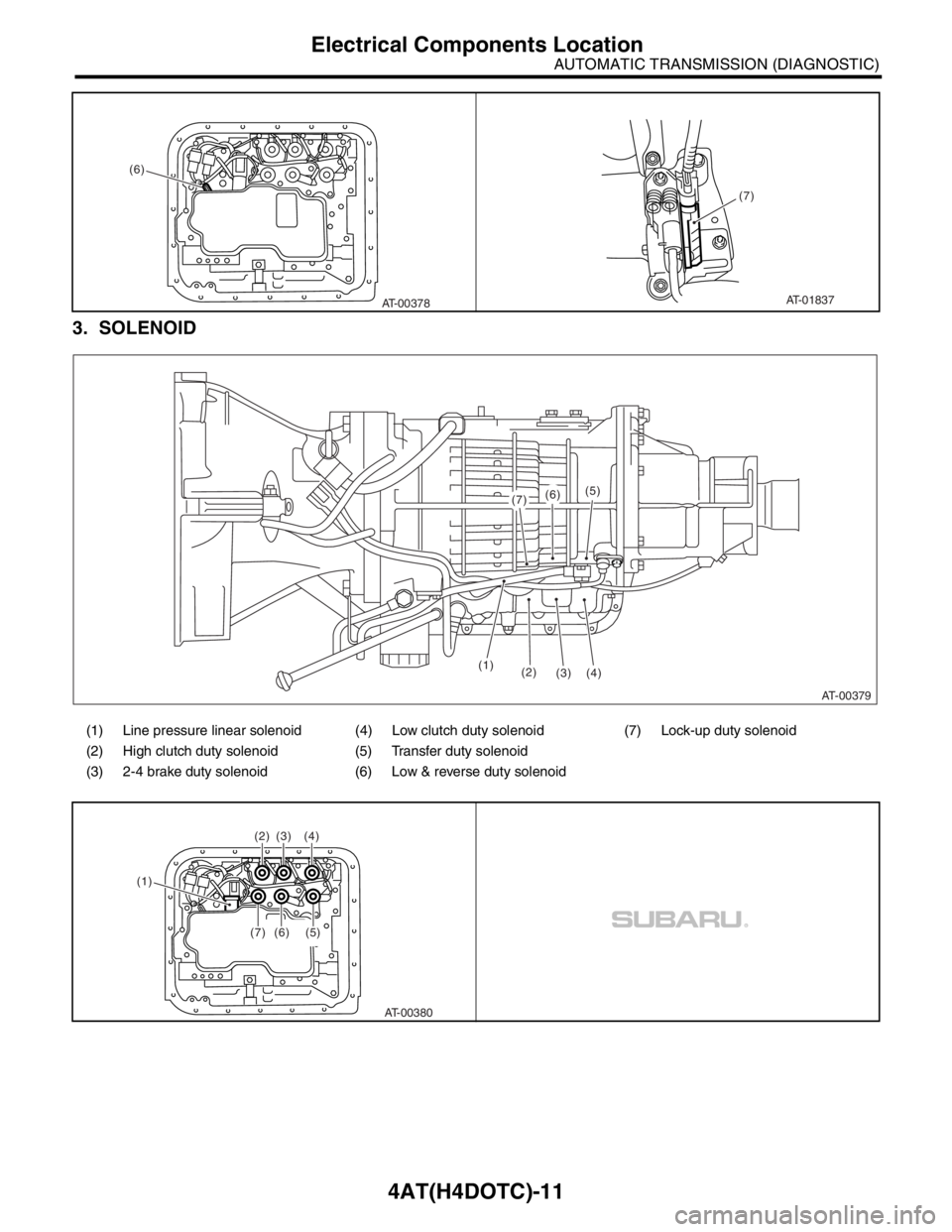

Electrical Components Location

3. SOLENOID

(1) Line pressure linear solenoid (4) Low clutch duty solenoid (7) Lock-up duty solenoid

(2) High clutch duty solenoid (5) Transfer duty solenoid

(3) 2-4 brake duty solenoid (6) Low & reverse duty solenoid

(6)

AT-00378

(7)

AT-01837

AT-00379

(1)(2)(3)(4)

(5)(6)

(7)

(2) (3) (4)

(7) (6) (5)

(1)

AT-00380

Page 2589 of 2870

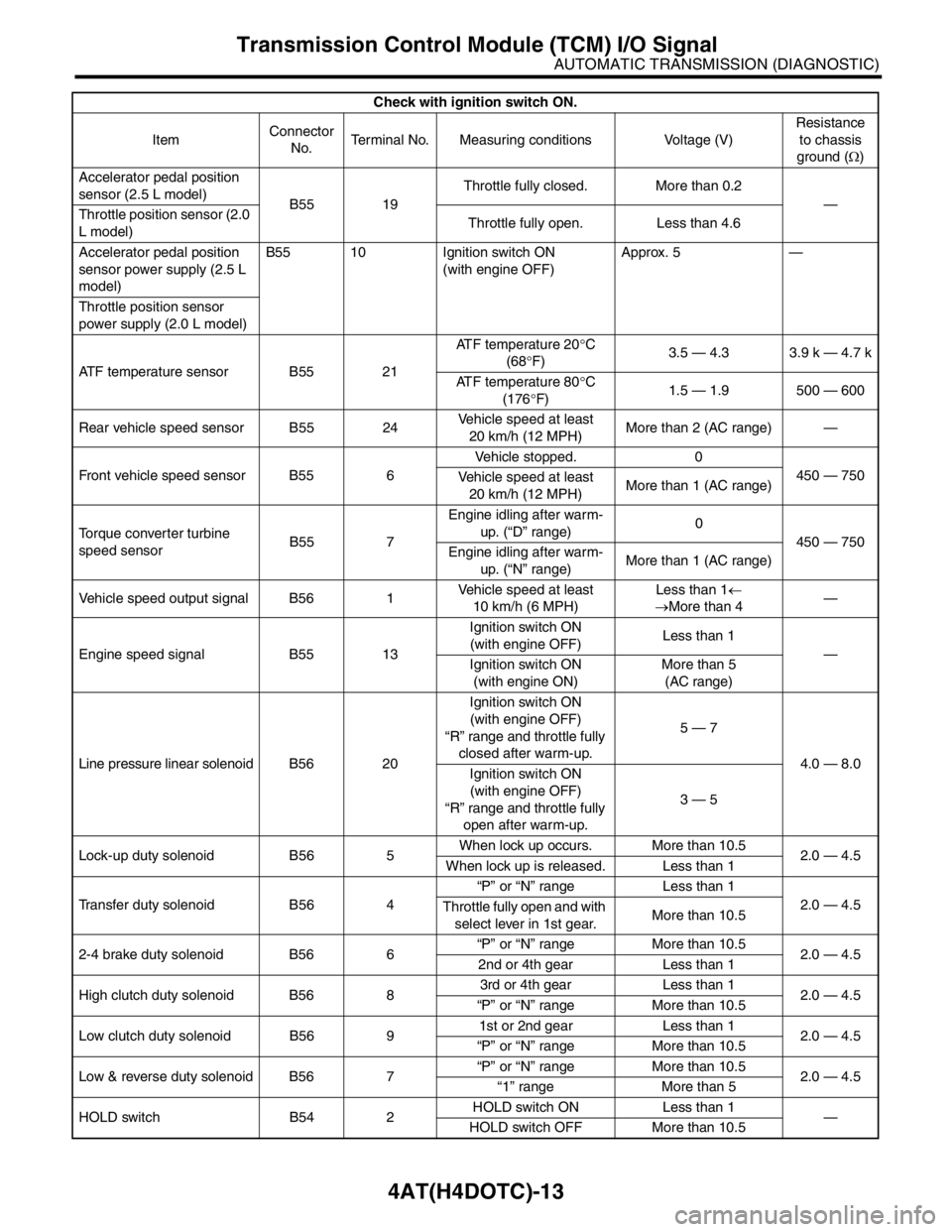

4AT(H4DOTC)-13

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Transmission Control Module (TCM) I/O Signal

Accelerator pedal position

sensor (2.5 L model)

B55 19Throttle fully closed. More than 0.2

—

Throttle position sensor (2.0

L model)Throttle fully open. Less than 4.6

Accelerator pedal position

sensor power supply (2.5 L

model)B55 10 Ignition switch ON

(with engine OFF)Approx. 5 —

Throttle position sensor

power supply (2.0 L model)

ATF temperature sensor B55 21ATF temperature 20°C

(68°F)3.5 — 4.3 3.9 k — 4.7 k

ATF temperature 80°C

(176°F)1.5 — 1.9 500 — 600

Rear vehicle speed sensor B55 24Vehicle speed at least

20 km/h (12 MPH)More than 2 (AC range) —

Front vehicle speed sensor B55 6Vehicle stopped. 0

450 — 750

Vehicle speed at least

20 km/h (12 MPH)More than 1 (AC range)

Torque converter turbine

speed sensorB55 7Engine idling after warm-

up. (“D” range)0

450 — 750

Engine idling after warm-

up. (“N” range)More than 1 (AC range)

Vehicle speed output signal B56 1Vehicle speed at least

10 km/h (6 MPH)Less than 1←

→More than 4—

Engine speed signal B55 13Ignition switch ON

(with engine OFF)Less than 1

—

Ignition switch ON

(with engine ON)More than 5

(AC range)

Line pressure linear solenoid B56 20Ignition switch ON

(with engine OFF)

“R” range and throttle fully

closed after warm-up.5 — 7

4.0 — 8.0

Ignition switch ON

(with engine OFF)

“R” range and throttle fully

open after warm-up.3 — 5

Lock-up duty solenoid B56 5When lock up occurs. More than 10.5

2.0 — 4.5

When lock up is released. Less than 1

Transfer duty solenoid B56 4“P” or “N” range Less than 1

2.0 — 4.5

Throttle fully open and with

select lever in 1st gear.More than 10.5

2-4 brake duty solenoid B56 6“P” or “N” range More than 10.5

2.0 — 4.5

2nd or 4th gear Less than 1

High clutch duty solenoid B56 83rd or 4th gear Less than 1

2.0 — 4.5

“P” or “N” range More than 10.5

Low clutch duty solenoid B56 91st or 2nd gear Less than 1

2.0 — 4.5

“P” or “N” range More than 10.5

Low & reverse duty solenoid B56 7“P” or “N” range More than 10.5

2.0 — 4.5

“1” range More than 5

HOLD switch B54 2HOLD switch ON Less than 1

—

HOLD switch OFF More than 10.5 Check with ignition switch ON.

ItemConnector

No.Terminal No. Measuring conditions Voltage (V)Resistance

to chassis

ground (Ω)

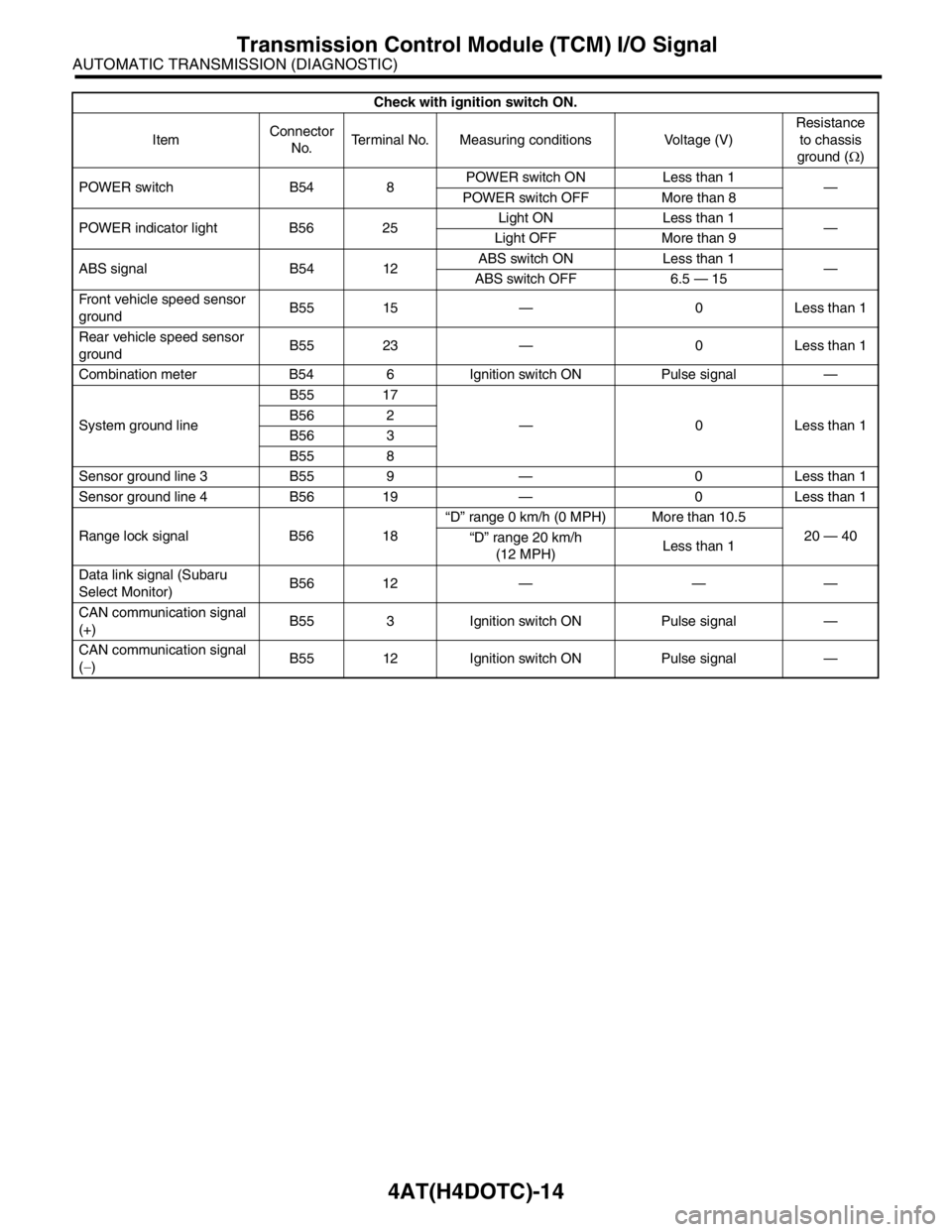

Page 2590 of 2870

4AT(H4DOTC)-14

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Transmission Control Module (TCM) I/O Signal

POWER switch B54 8POWER switch ON Less than 1

—

POWER switch OFF More than 8

POWER indicator light B56 25Light ON Less than 1

—

Light OFF More than 9

ABS signal B54 12ABS switch ON Less than 1

—

ABS switch OFF 6.5 — 15

Front vehicle speed sensor

groundB55 15 — 0 Less than 1

Rear vehicle speed sensor

groundB55 23 — 0 Less than 1

Combination meter B54 6 Ignition switch ON Pulse signal —

System ground lineB55 17

— 0 Less than 1 B56 2

B56 3

B55 8

Sensor ground line 3 B55 9 — 0 Less than 1

Sensor ground line 4 B56 19 — 0 Less than 1

Range lock signal B56 18“D” range 0 km/h (0 MPH) More than 10.5

20 — 40

“D” range 20 km/h

(12 MPH)Less than 1

Data link signal (Subaru

Select Monitor)B56 12 — — —

CAN communication signal

(+)B55 3 Ignition switch ON Pulse signal —

CAN communication signal

(−)B55 12 Ignition switch ON Pulse signal —Check with ignition switch ON.

ItemConnector

No.Terminal No. Measuring conditions Voltage (V)Resistance

to chassis

ground (Ω)