lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2664 of 2870

4AT(H4DOTC)-88

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

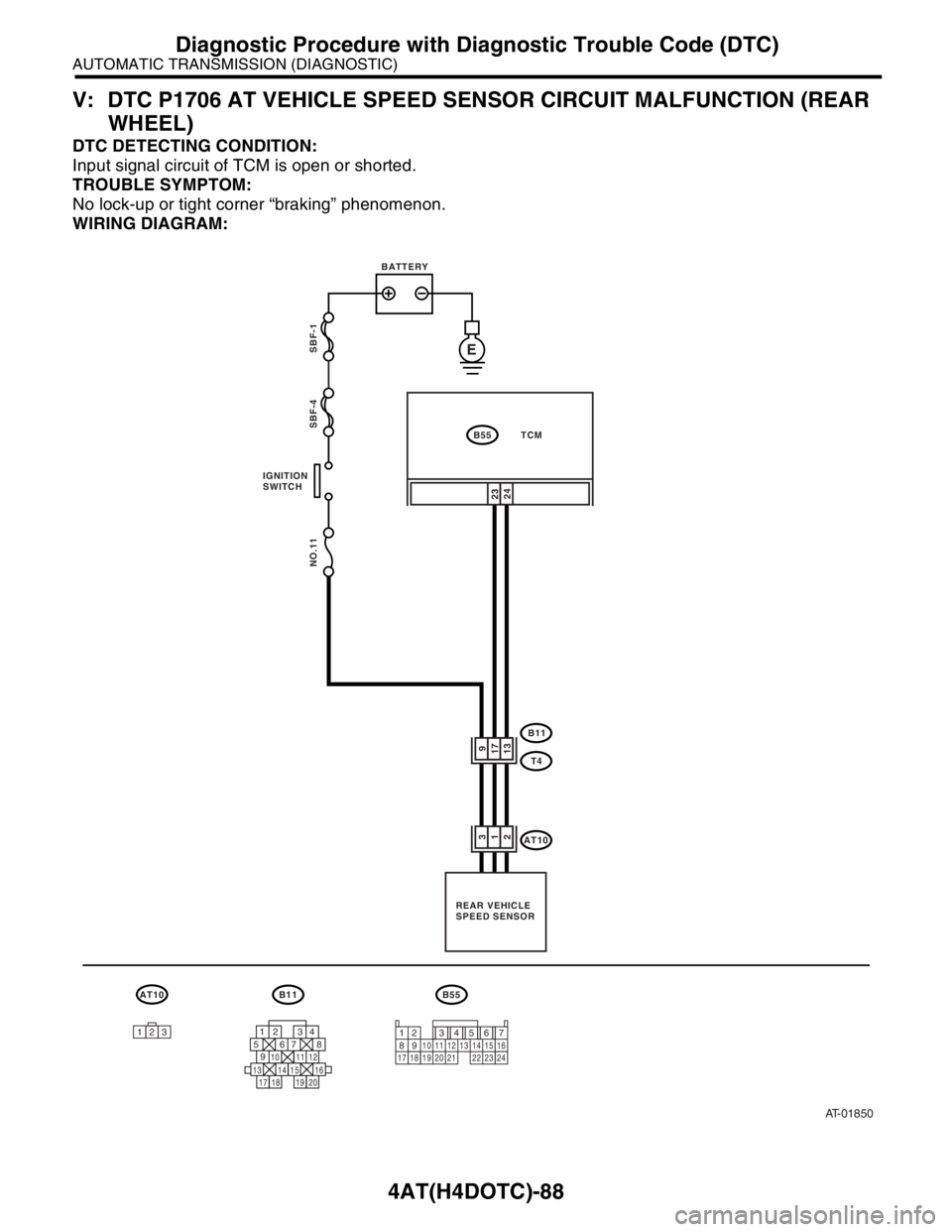

V: DTC P1706 AT VEHICLE SPEED SENSOR CIRCUIT MALFUNCTION (REAR

WHEEL)

DTC DETECTING CONDITION:

Input signal circuit of TCM is open or shorted.

TROUBLE SYMPTOM:

No lock-up or tight corner “braking” phenomenon.

WIRING DIAGRAM:

AT-01850

2324

B11

AT10

T491713

312

B55 TCM BATTERY

IGNITION

SWITCH

REAR VEHICLE

SPEED SENSOR

ESBF-1

SBF-4 NO.11

123

AT10B11

12 34

5678

9

13 14 15

20 19 1716 10 11 1218

B55

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

Page 2702 of 2870

4AT(H4DOTC)-126

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

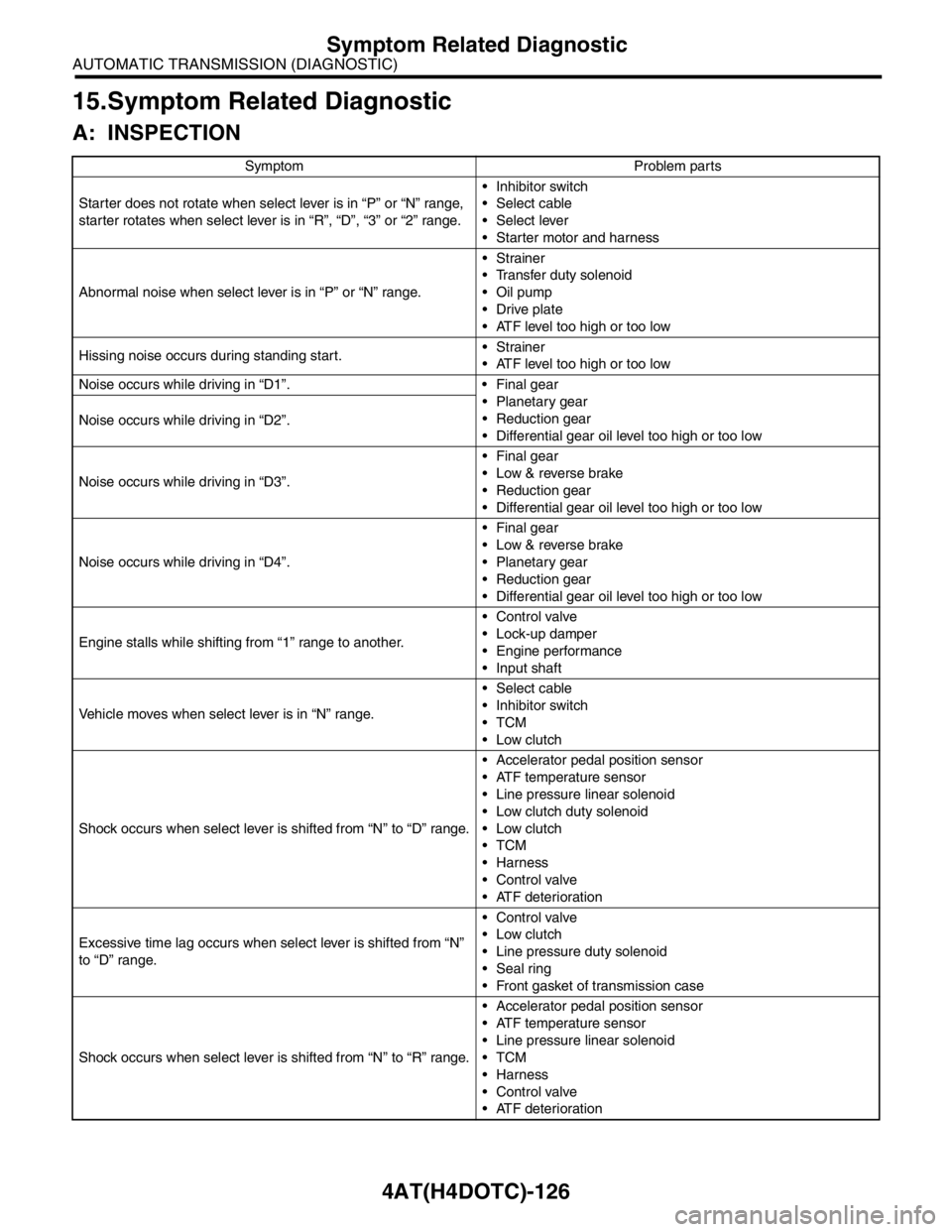

15.Symptom Related Diagnostic

A: INSPECTION

Symptom Problem parts

Starter does not rotate when select lever is in “P” or “N” range,

starter rotates when select lever is in “R”, “D”, “3” or “2” range. Inhibitor switch

Select cable

Select lever

Starter motor and harness

Abnormal noise when select lever is in “P” or “N” range. Strainer

Transfer duty solenoid

Oil pump

Drive plate

ATF level too high or too low

Hissing noise occurs during standing start. Strainer

ATF level too high or too low

Noise occurs while driving in “D1”. Final gear

Planetary gear

Reduction gear

Differential gear oil level too high or too low Noise occurs while driving in “D2”.

Noise occurs while driving in “D3”. Final gear

Low & reverse brake

Reduction gear

Differential gear oil level too high or too low

Noise occurs while driving in “D4”. Final gear

Low & reverse brake

Planetary gear

Reduction gear

Differential gear oil level too high or too low

Engine stalls while shifting from “1” range to another. Control valve

Lock-up damper

Engine performance

Input shaft

Vehicle moves when select lever is in “N” range. Select cable

Inhibitor switch

TCM

Low clutch

Shock occurs when select lever is shifted from “N” to “D” range. Accelerator pedal position sensor

ATF temperature sensor

Line pressure linear solenoid

Low clutch duty solenoid

Low clutch

TCM

Harness

Control valve

ATF deterioration

Excessive time lag occurs when select lever is shifted from “N”

to “D” range. Control valve

Low clutch

Line pressure duty solenoid

Seal ring

Front gasket of transmission case

Shock occurs when select lever is shifted from “N” to “R” range. Accelerator pedal position sensor

ATF temperature sensor

Line pressure linear solenoid

TCM

Harness

Control valve

ATF deterioration

Page 2704 of 2870

4AT(H4DOTC)-128

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

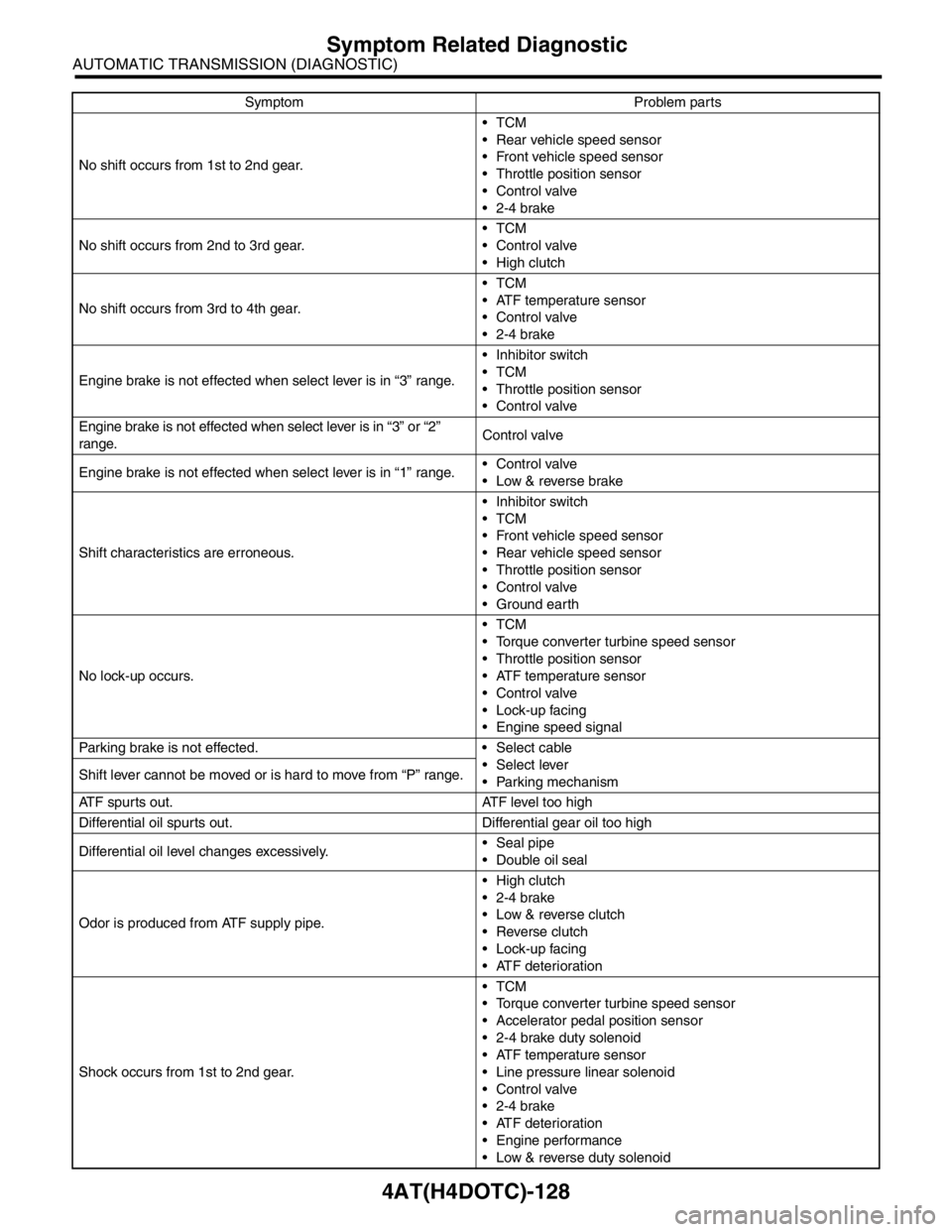

No shift occurs from 1st to 2nd gear.TCM

Rear vehicle speed sensor

Front vehicle speed sensor

Throttle position sensor

Control valve

2-4 brake

No shift occurs from 2nd to 3rd gear.TCM

Control valve

High clutch

No shift occurs from 3rd to 4th gear.TCM

ATF temperature sensor

Control valve

2-4 brake

Engine brake is not effected when select lever is in “3” range. Inhibitor switch

TCM

Throttle position sensor

Control valve

Engine brake is not effected when select lever is in “3” or “2”

range.Control valve

Engine brake is not effected when select lever is in “1” range. Control valve

Low & reverse brake

Shift characteristics are erroneous. Inhibitor switch

TCM

Front vehicle speed sensor

Rear vehicle speed sensor

Throttle position sensor

Control valve

Ground earth

No lock-up occurs.TCM

Torque converter turbine speed sensor

Throttle position sensor

ATF temperature sensor

Control valve

Lock-up facing

Engine speed signal

Parking brake is not effected. Select cable

Select lever

Parking mechanism Shift lever cannot be moved or is hard to move from “P” range.

ATF spurts out. ATF level too high

Differential oil spurts out. Differential gear oil too high

Differential oil level changes excessively. Seal pipe

Double oil seal

Odor is produced from ATF supply pipe.High clutch

2-4 brake

Low & reverse clutch

Reverse clutch

Lock-up facing

ATF deterioration

Shock occurs from 1st to 2nd gear.TCM

Torque converter turbine speed sensor

Accelerator pedal position sensor

2-4 brake duty solenoid

ATF temperature sensor

Line pressure linear solenoid

Control valve

2-4 brake

ATF deterioration

Engine performance

Low & reverse duty solenoid Symptom Problem parts

Page 2706 of 2870

4AT(H4DOTC)-130

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

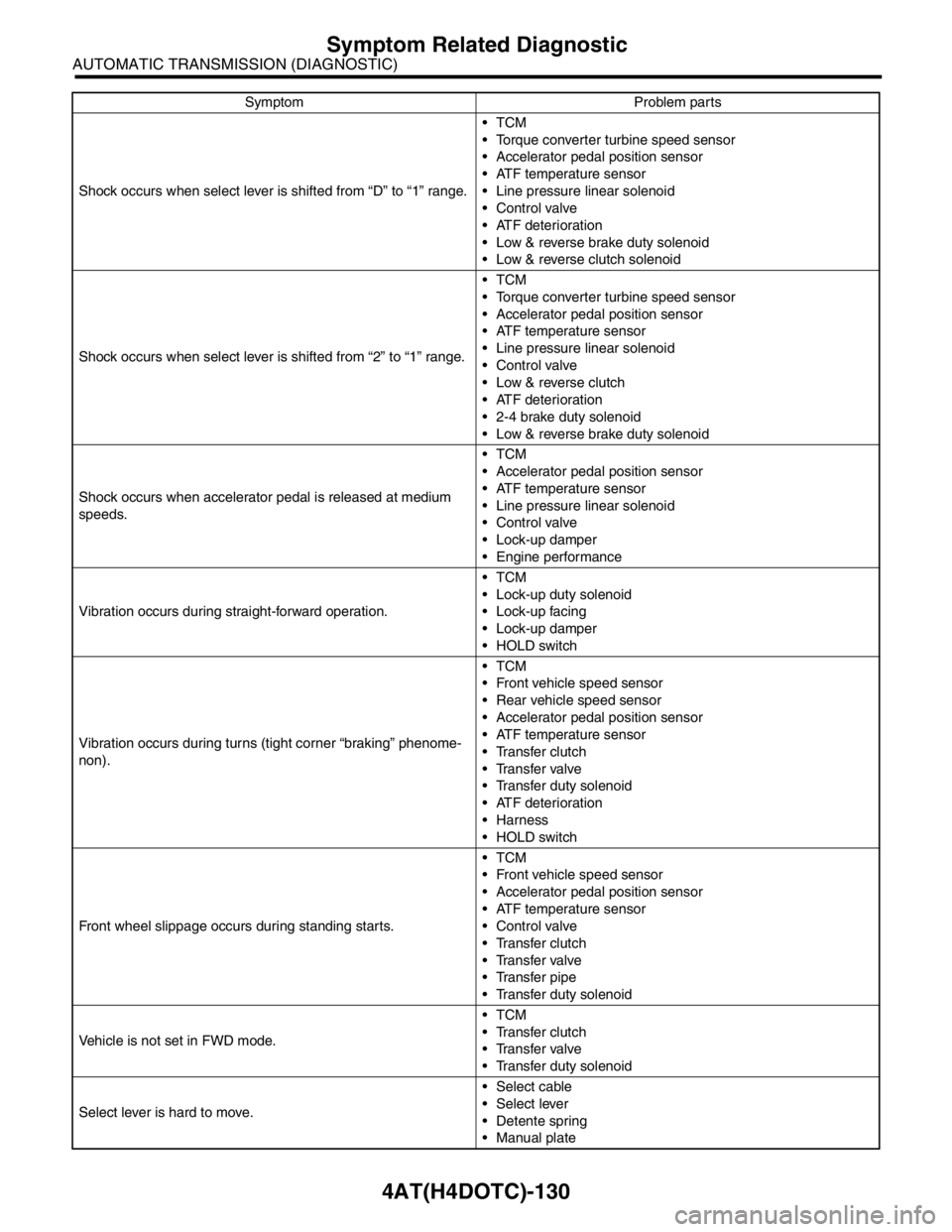

Shock occurs when select lever is shifted from “D” to “1” range.TCM

Torque converter turbine speed sensor

Accelerator pedal position sensor

ATF temperature sensor

Line pressure linear solenoid

Control valve

ATF deterioration

Low & reverse brake duty solenoid

Low & reverse clutch solenoid

Shock occurs when select lever is shifted from “2” to “1” range.TCM

Torque converter turbine speed sensor

Accelerator pedal position sensor

ATF temperature sensor

Line pressure linear solenoid

Control valve

Low & reverse clutch

ATF deterioration

2-4 brake duty solenoid

Low & reverse brake duty solenoid

Shock occurs when accelerator pedal is released at medium

speeds.TCM

Accelerator pedal position sensor

ATF temperature sensor

Line pressure linear solenoid

Control valve

Lock-up damper

Engine performance

Vibration occurs during straight-forward operation.TCM

Lock-up duty solenoid

Lock-up facing

Lock-up damper

HOLD switch

Vibration occurs during turns (tight corner “braking” phenome-

non).TCM

Front vehicle speed sensor

Rear vehicle speed sensor

Accelerator pedal position sensor

ATF temperature sensor

Transfer clutch

Transfer valve

Transfer duty solenoid

ATF deterioration

Harness

HOLD switch

Front wheel slippage occurs during standing starts.TCM

Front vehicle speed sensor

Accelerator pedal position sensor

ATF temperature sensor

Control valve

Transfer clutch

Transfer valve

Transfer pipe

Transfer duty solenoid

Vehicle is not set in FWD mode.TCM

Transfer clutch

Transfer valve

Transfer duty solenoid

Select lever is hard to move. Select cable

Select lever

Detente spring

Manual plate Symptom Problem parts

Page 2720 of 2870

5MT-8

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

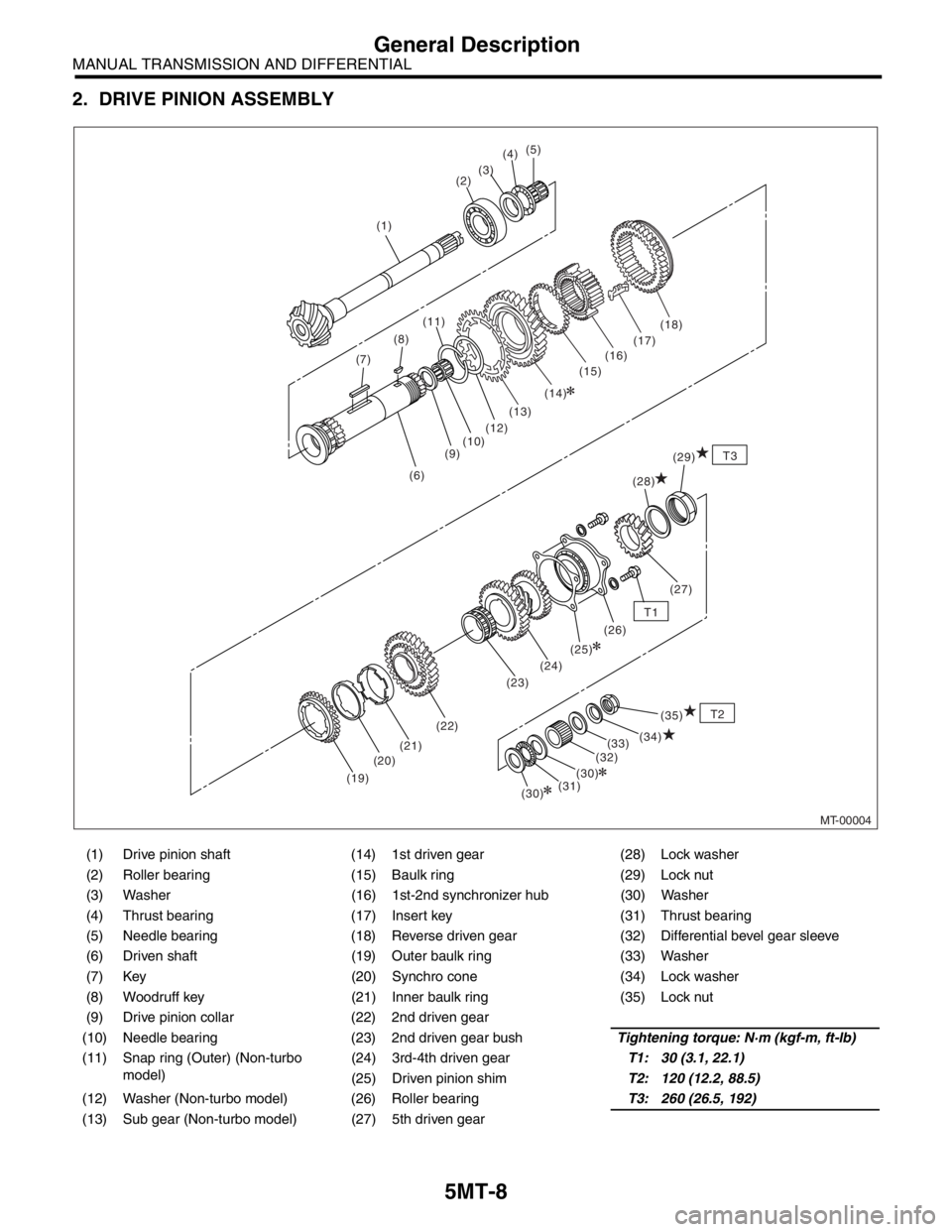

2. DRIVE PINION ASSEMBLY

(1) Drive pinion shaft (14) 1st driven gear (28) Lock washer

(2) Roller bearing (15) Baulk ring (29) Lock nut

(3) Washer (16) 1st-2nd synchronizer hub (30) Washer

(4) Thrust bearing (17) Insert key (31) Thrust bearing

(5) Needle bearing (18) Reverse driven gear (32) Differential bevel gear sleeve

(6) Driven shaft (19) Outer baulk ring (33) Washer

(7) Key (20) Synchro cone (34) Lock washer

(8) Woodruff key (21) Inner baulk ring (35) Lock nut

(9) Drive pinion collar (22) 2nd driven gear

(10) Needle bearing (23) 2nd driven gear bushTightening torque: N·m (kgf-m, ft-lb)

(11) Snap ring (Outer) (Non-turbo

model)(24) 3rd-4th driven gearT1: 30 (3.1, 22.1)

(25) Driven pinion shimT2: 120 (12.2, 88.5)

(12) Washer (Non-turbo model) (26) Roller bearingT3: 260 (26.5, 192)

(13) Sub gear (Non-turbo model) (27) 5th driven gear

MT-00004

(5)

(4)

(1)

(25)(26)(27) (28)(29)

(21)(22)(23)

(31)(30)(32)(33)(34) (24)

(20)(18)

(19)(6)(3)

(2)

(12) (11)

(10)

(9) (8)

(7)

(13)(16)(17)

(14)(15)

T1

T3

(35)T2

(30)

Page 2721 of 2870

5MT-9

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

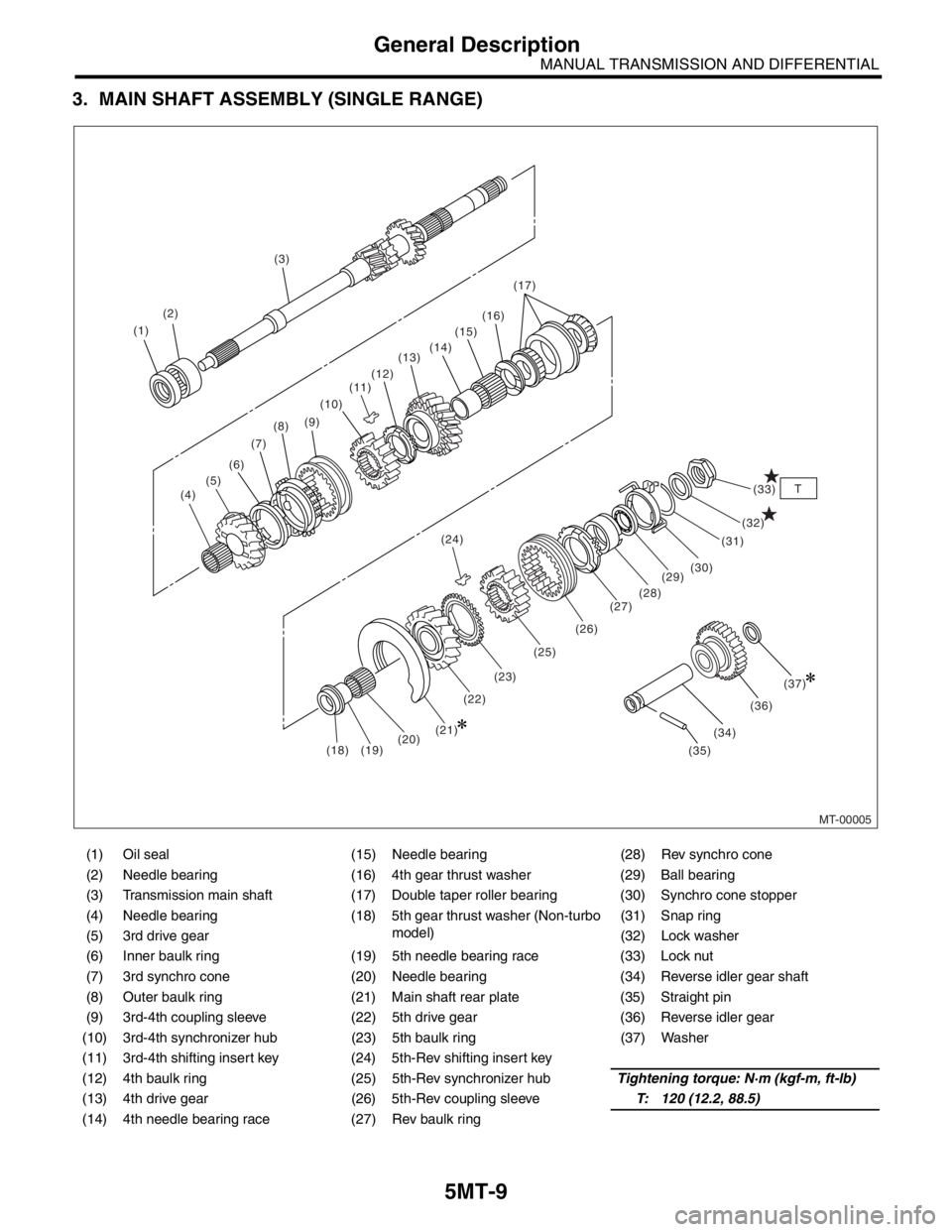

3. MAIN SHAFT ASSEMBLY (SINGLE RANGE)

(1) Oil seal (15) Needle bearing (28) Rev synchro cone

(2) Needle bearing (16) 4th gear thrust washer (29) Ball bearing

(3) Transmission main shaft (17) Double taper roller bearing (30) Synchro cone stopper

(4) Needle bearing (18) 5th gear thrust washer (Non-turbo

model)(31) Snap ring

(5) 3rd drive gear (32) Lock washer

(6) Inner baulk ring (19) 5th needle bearing race (33) Lock nut

(7) 3rd synchro cone (20) Needle bearing (34) Reverse idler gear shaft

(8) Outer baulk ring (21) Main shaft rear plate (35) Straight pin

(9) 3rd-4th coupling sleeve (22) 5th drive gear (36) Reverse idler gear

(10) 3rd-4th synchronizer hub (23) 5th baulk ring (37) Washer

(11) 3rd-4th shifting insert key (24) 5th-Rev shifting insert key

(12) 4th baulk ring (25) 5th-Rev synchronizer hubTightening torque: N·m (kgf-m, ft-lb)

(13) 4th drive gear (26) 5th-Rev coupling sleeveT: 120 (12.2, 88.5)

(14) 4th needle bearing race (27) Rev baulk ring

T

(18)

(19)(20)(21)(22)(23) (24)

(25)(26)(27)(28)(29)(30)(31)(32)(33)

(35)(34)(36)

(37)

(3)

(9)(10)

(4)(5) (2)

(1)

(6)(7)(8)(11)(17)

(12)(13)(14)(15)(16)

MT-00005

Page 2723 of 2870

5MT-11

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

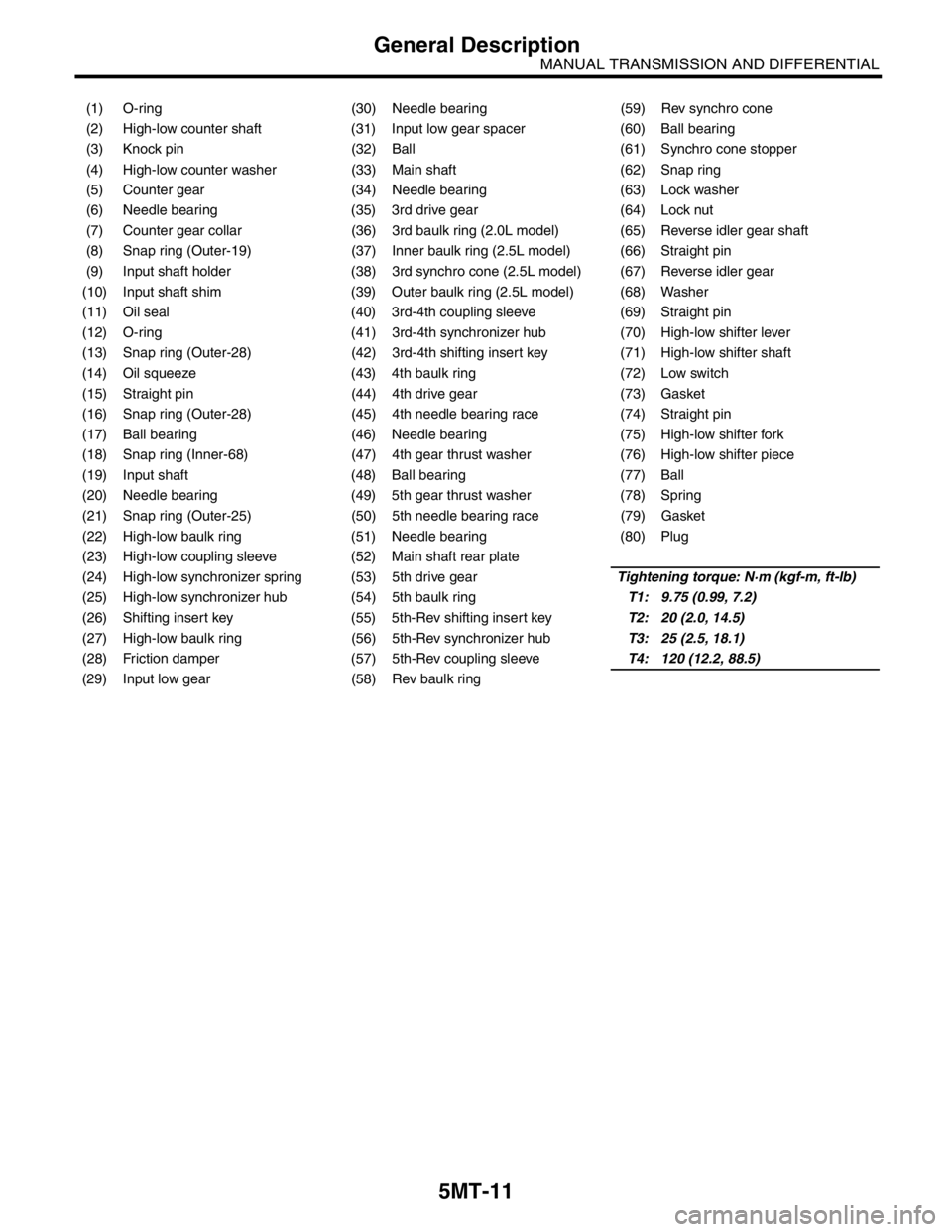

(1) O-ring (30) Needle bearing (59) Rev synchro cone

(2) High-low counter shaft (31) Input low gear spacer (60) Ball bearing

(3) Knock pin (32) Ball (61) Synchro cone stopper

(4) High-low counter washer (33) Main shaft (62) Snap ring

(5) Counter gear (34) Needle bearing (63) Lock washer

(6) Needle bearing (35) 3rd drive gear (64) Lock nut

(7) Counter gear collar (36) 3rd baulk ring (2.0L model) (65) Reverse idler gear shaft

(8) Snap ring (Outer-19) (37) Inner baulk ring (2.5L model) (66) Straight pin

(9) Input shaft holder (38) 3rd synchro cone (2.5L model) (67) Reverse idler gear

(10) Input shaft shim (39) Outer baulk ring (2.5L model) (68) Washer

(11) Oil seal (40) 3rd-4th coupling sleeve (69) Straight pin

(12) O-ring (41) 3rd-4th synchronizer hub (70) High-low shifter lever

(13) Snap ring (Outer-28) (42) 3rd-4th shifting insert key (71) High-low shifter shaft

(14) Oil squeeze (43) 4th baulk ring (72) Low switch

(15) Straight pin (44) 4th drive gear (73) Gasket

(16) Snap ring (Outer-28) (45) 4th needle bearing race (74) Straight pin

(17) Ball bearing (46) Needle bearing (75) High-low shifter fork

(18) Snap ring (Inner-68) (47) 4th gear thrust washer (76) High-low shifter piece

(19) Input shaft (48) Ball bearing (77) Ball

(20) Needle bearing (49) 5th gear thrust washer (78) Spring

(21) Snap ring (Outer-25) (50) 5th needle bearing race (79) Gasket

(22) High-low baulk ring (51) Needle bearing (80) Plug

(23) High-low coupling sleeve (52) Main shaft rear plate

(24) High-low synchronizer spring (53) 5th drive gearTightening torque: N·m (kgf-m, ft-lb)

(25) High-low synchronizer hub (54) 5th baulk ringT1: 9.75 (0.99, 7.2)

(26) Shifting insert key (55) 5th-Rev shifting insert keyT2: 20 (2.0, 14.5)

(27) High-low baulk ring (56) 5th-Rev synchronizer hubT3: 25 (2.5, 18.1)

(28) Friction damper (57) 5th-Rev coupling sleeveT4: 120 (12.2, 88.5)

(29) Input low gear (58) Rev baulk ring

Page 2724 of 2870

5MT-12

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

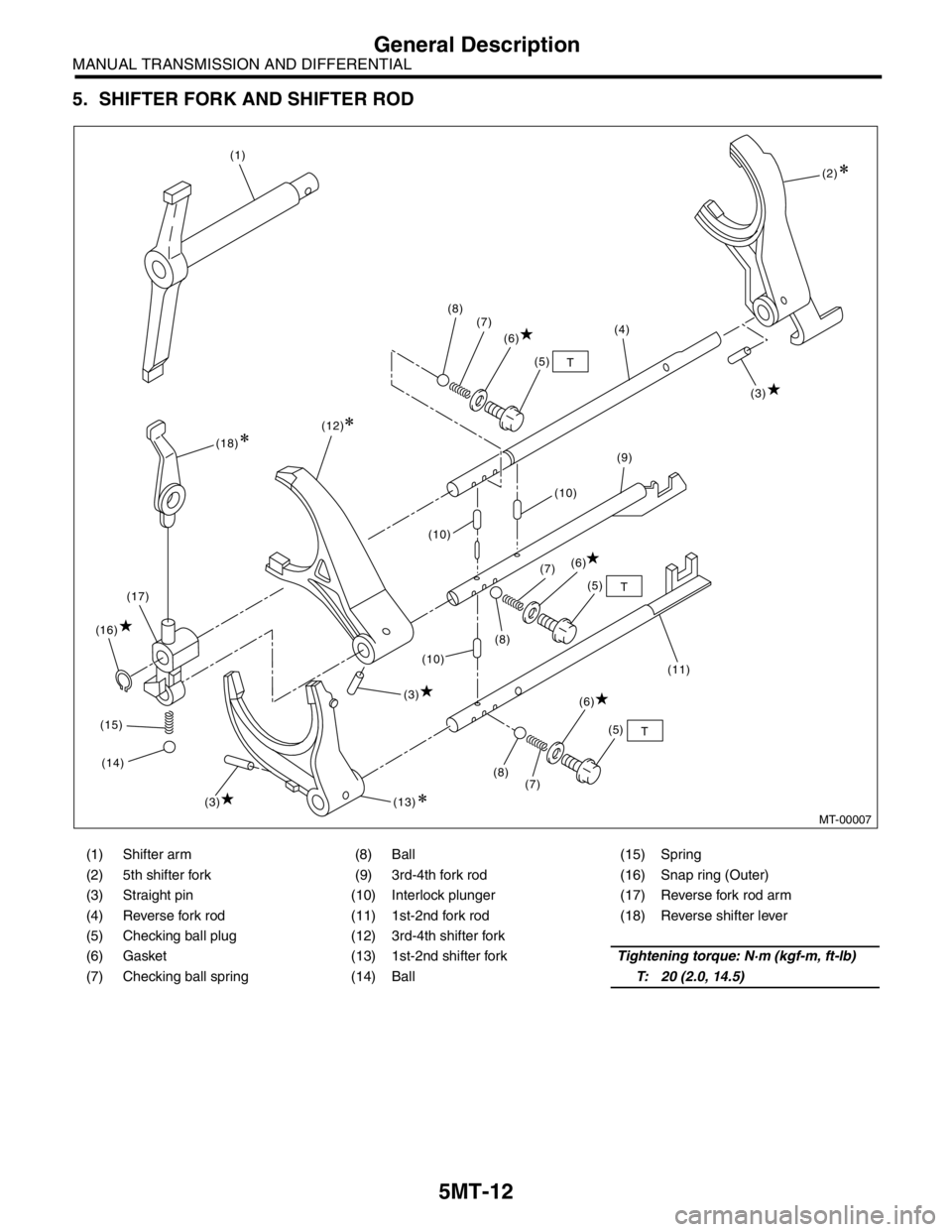

5. SHIFTER FORK AND SHIFTER ROD

(1) Shifter arm (8) Ball (15) Spring

(2) 5th shifter fork (9) 3rd-4th fork rod (16) Snap ring (Outer)

(3) Straight pin (10) Interlock plunger (17) Reverse fork rod arm

(4) Reverse fork rod (11) 1st-2nd fork rod (18) Reverse shifter lever

(5) Checking ball plug (12) 3rd-4th shifter fork

(6) Gasket (13) 1st-2nd shifter forkTightening torque: N·m (kgf-m, ft-lb)

(7) Checking ball spring (14) BallT: 20 (2.0, 14.5)

MT-00007

T

T

T (1)

(2)

(3)

(3)(3) (4)

(5)

(5)

(5) (6)

(6) (6) (7)

(7)

(7) (8)

(8)(8)(9)

(10)(10)

(10)

(11) (12)

(13) (14) (15) (16)(17)(18)

Page 2727 of 2870

5MT-15

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

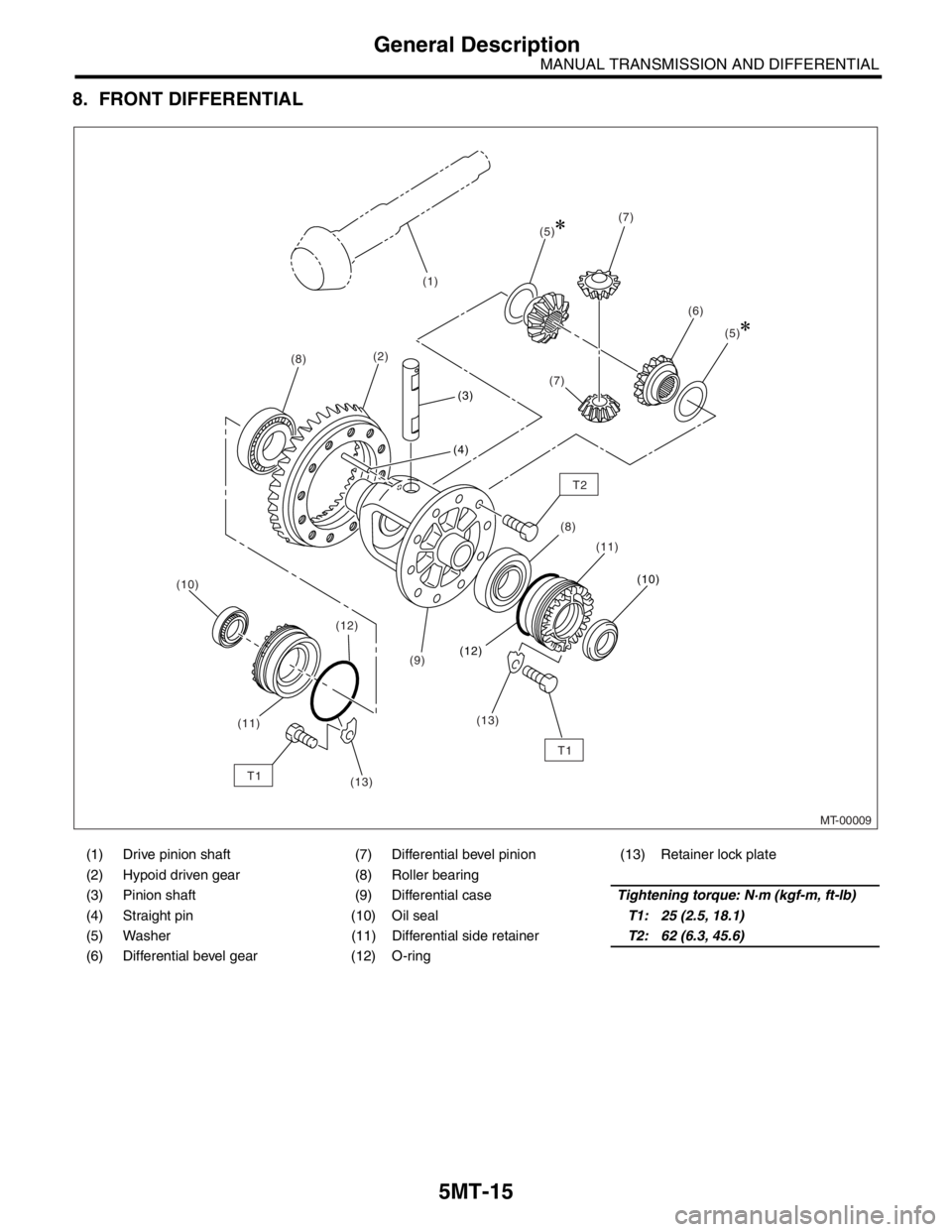

8. FRONT DIFFERENTIAL

(1) Drive pinion shaft (7) Differential bevel pinion (13) Retainer lock plate

(2) Hypoid driven gear (8) Roller bearing

(3) Pinion shaft (9) Differential caseTightening torque: N·m (kgf-m, ft-lb)

(4) Straight pin (10) Oil sealT1: 25 (2.5, 18.1)

(5) Washer (11) Differential side retainerT2: 62 (6.3, 45.6)

(6) Differential bevel gear (12) O-ring

MT-00009

(12)(10)

(1)

(2)

T1

T2

(5)

(5)

(6)

(9)

(7)

(7)

(12) (8)

(8)

(13)

(13)(11)

(11) (10)

T1

(4)(3)

Page 2729 of 2870

5MT-17

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation, and disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Until the oil pan is removed, do not place with the

oil pan side facing up to prevent foreign matter from

entering the valve body.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly and replacement.

When disassembling the case and other light al-

loy parts, use a plastic hammer to force it apart. Do

not pry it apart with a screwdriver or other tool.

Be careful not to burn your hands, because each

part on the vehicle is hot after running. Use SUBARU genuine gear oil, grease etc. or

the equivalent. Do not mix gear oil, grease etc. with

that of another grade or from other manufacturers.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Apply gear oil onto sliding or revolution surfaces

before installation.

Replace deformed or otherwise damaged snap

rings with new ones.

Before installing O-rings or oil seals, apply suffi-

cient amount of gear oil to avoid damage and defor-

mation.

Be careful not to incorrectly install or fail to install

O-rings, snap rings and other such parts.

Before securing a part on a vise, place cushion-

ing material such as wood blocks, aluminum plate,

or shop cloth between the part and the vis e.

Avoid damaging the mating surface of the case.

Before applying sealant, completely remove the

old seal.

D: PREPARATION TOOL

1. SPECIAL TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

399411700 ACCENT BALL

INSTALLERUsed for installing reverse shifter rail arm.

899524100 PULLER SET Used for removing and installing roller bearing

(Differential).

(1) PULLER

(2) CAP

ST-399411700

ST-899524100