lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2807 of 2870

5MT-94

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

F: ADJUSTMENT

1. THRUST BEARING PRELOAD

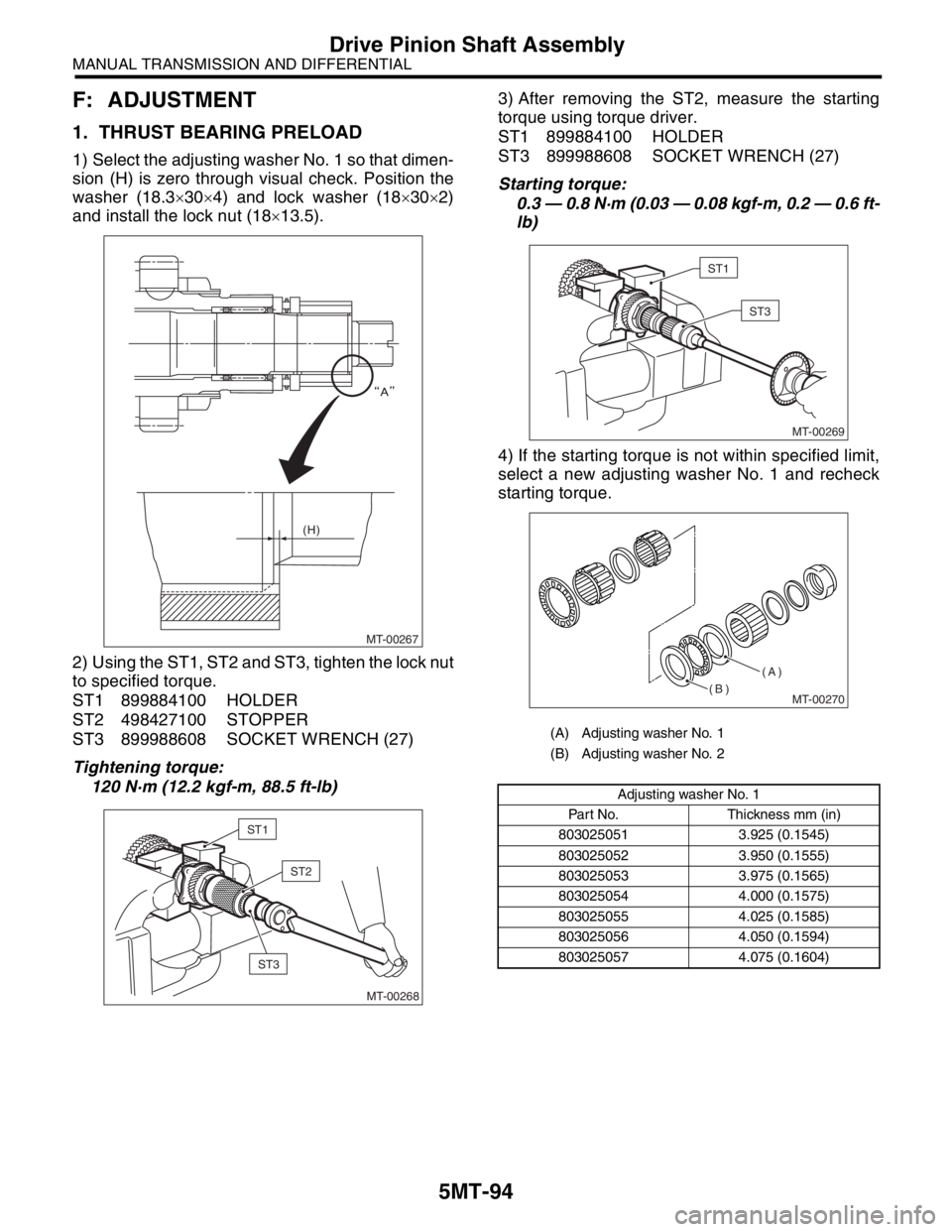

1) Select the adjusting washer No. 1 so that dimen-

sion (H) is zero through visual check. Position the

washer (18.3×30×4) and lock washer (18×30×2)

and install the lock nut (18×13.5).

2) Using the ST1, ST2 and ST3, tighten the lock nut

to specified torque.

ST1 899884100 HOLDER

ST2 498427100 STOPPER

ST3 899988608 SOCKET WRENCH (27)

Tightening torque:

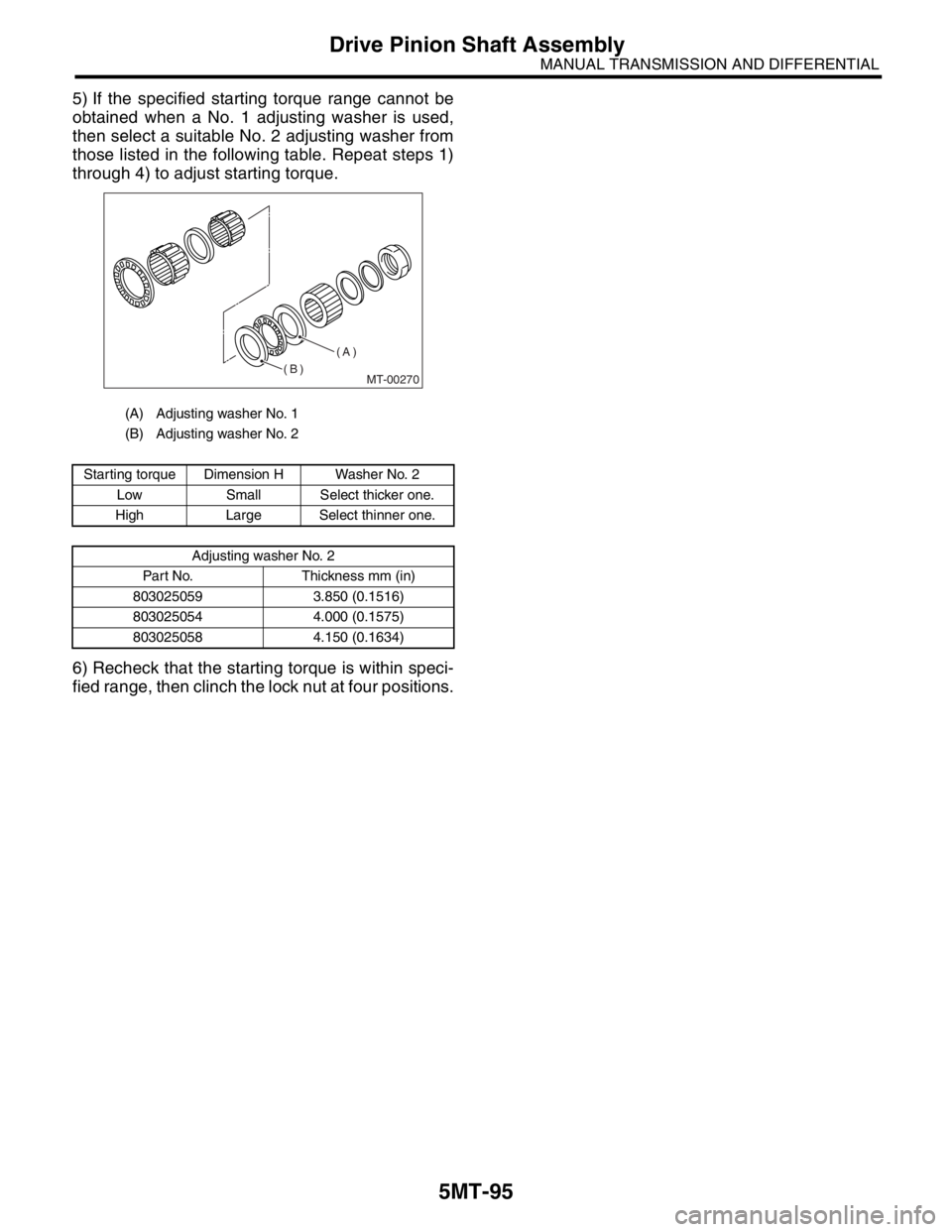

120 N·m (12.2 kgf-m, 88.5 ft-lb) 3) After removing the ST2, measure the starting

torque using torque driver.

ST1 899884100 HOLDER

ST3 899988608 SOCKET WRENCH (27)

Starting torque:

0.3 — 0.8 N·m (0.03 — 0.08 kgf-m, 0.2 — 0.6 ft-

lb)

4) If the starting torque is not within specified limit,

select a new adjusting washer No. 1 and recheck

starting torque.

MT-00267 (H)

MT-00268

ST1

ST2

ST3

(A) Adjusting washer No. 1

(B) Adjusting washer No. 2

Adjusting washer No. 1

Part No. Thickness mm (in)

803025051 3.925 (0.1545)

803025052 3.950 (0.1555)

803025053 3.975 (0.1565)

803025054 4.000 (0.1575)

803025055 4.025 (0.1585)

803025056 4.050 (0.1594)

803025057 4.075 (0.1604)

MT-00269

ST1

ST3

MT-00270

(A)

(B)

Page 2808 of 2870

5MT-95

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

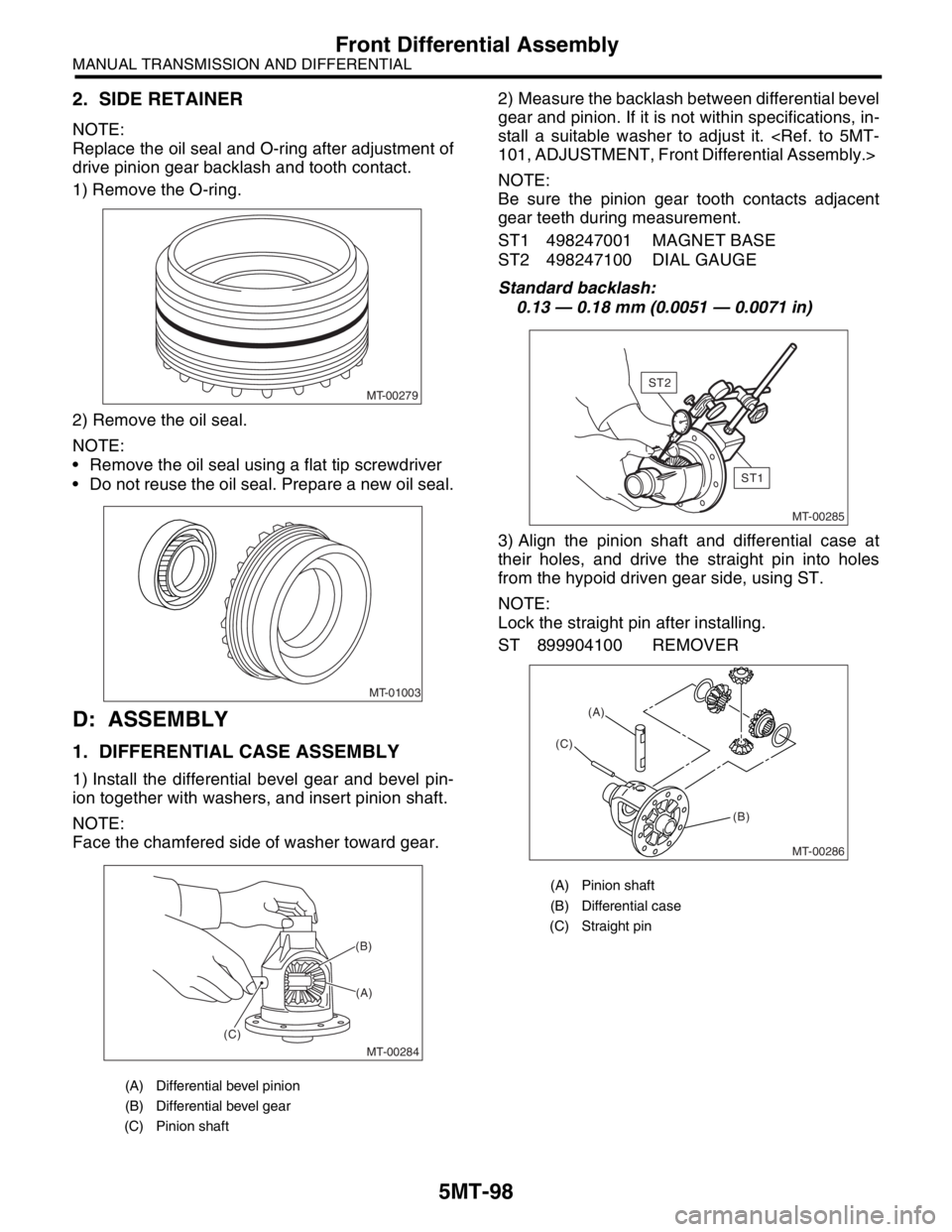

5) If the specified starting torque range cannot be

obtained when a No. 1 adjusting washer is used,

then select a suitable No. 2 adjusting washer from

those listed in the following table. Repeat steps 1)

through 4) to adjust starting torque.

6) Recheck that the starting torque is within speci-

fied range, then clinch the lock nut at four positions.

(A) Adjusting washer No. 1

(B) Adjusting washer No. 2

Starting torque Dimension H Washer No. 2

Low Small Select thicker one.

High Large Select thinner one.

Adjusting washer No. 2

Part No. Thickness mm (in)

803025059 3.850 (0.1516)

803025054 4.000 (0.1575)

803025058 4.150 (0.1634)

MT-00270

(A)

(B)

Page 2811 of 2870

5MT-98

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

2. SIDE RETAINER

NOTE:

Replace the oil seal and O-ring after adjustment of

drive pinion gear backlash and tooth contact.

1) Remove the O-ring.

2) Remove the oil seal.

NOTE:

Remove the oil seal using a flat tip screwdriver

Do not reuse the oil seal. Prepare a new oil seal.

D: ASSEMBLY

1. DIFFERENTIAL CASE ASSEMBLY

1) Install the differential bevel gear and bevel pin-

ion together with washers, and insert pinion shaft.

NOTE:

Face the chamfered side of washer toward gear.2) Measure the backlash between differential bevel

gear and pinion. If it is not within specifications, in-

stall a suitable washer to adjust it.

NOTE:

Be sure the pinion gear tooth contacts adjacent

gear teeth during measurement.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

3) Align the pinion shaft and differential case at

their holes, and drive the straight pin into holes

from the hypoid driven gear side, using ST.

NOTE:

Lock the straight pin after installing.

ST 899904100 REMOVER

(A) Differential bevel pinion

(B) Differential bevel gear

(C) Pinion shaft

MT-00279

MT-01003

MT-00284

(A) (B)

(C)

(A) Pinion shaft

(B) Differential case

(C) Straight pin

MT-00285

ST1

ST2

MT-00286

(A)

(C)

(B)

Page 2813 of 2870

5MT-100

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

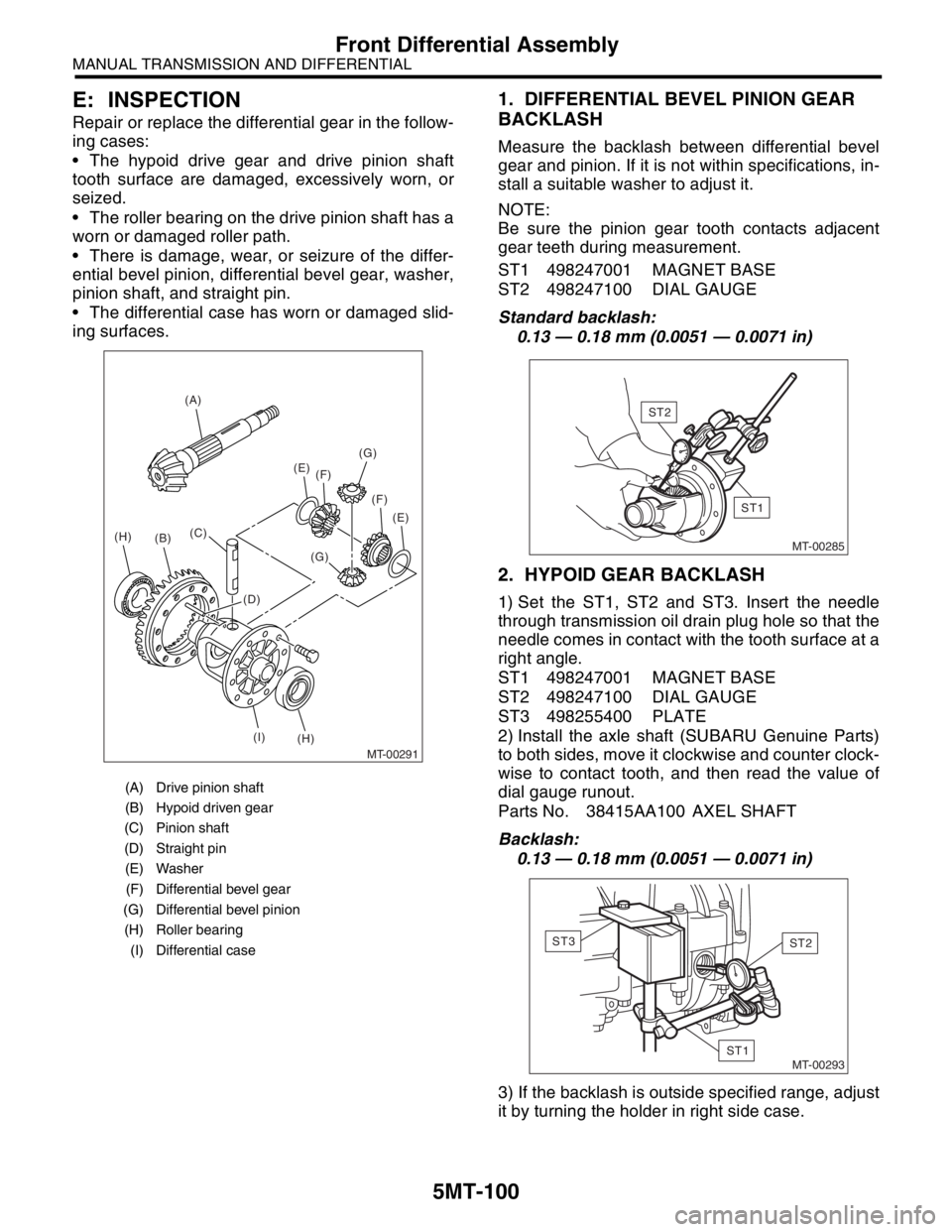

E: INSPECTION

Repair or replace the differential gear in the follow-

ing cases:

The hypoid drive gear and drive pinion shaft

tooth surface are damaged, excessively worn, or

seized.

The roller bearing on the drive pinion shaft has a

worn or damaged roller path.

There is damage, wear, or seizure of the differ-

ential bevel pinion, differential bevel gear, washer,

pinion shaft, and straight pin.

The differential case has worn or damaged slid-

ing surfaces.

1. DIFFERENTIAL BEVEL PINION GEAR

BACKLASH

Measure the backlash between differential bevel

gear and pinion. If it is not within specifications, in-

stall a suitable washer to adjust it.

NOTE:

Be sure the pinion gear tooth contacts adjacent

gear teeth during measurement.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

2. HYPOID GEAR BACKLASH

1) Set the ST1, ST2 and ST3. Insert the needle

through transmission oil drain plug hole so that the

needle comes in contact with the tooth surface at a

right angle.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

ST3 498255400 PLATE

2) Install the axle shaft (SUBARU Genuine Parts)

to both sides, move it clockwise and counter clock-

wise to contact tooth, and then read the value of

dial gauge runout.

Parts No. 38415AA100 AXEL SHAFT

Backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

3) If the backlash is outside specified range, adjust

it by turning the holder in right side case.

(A) Drive pinion shaft

(B) Hypoid driven gear

(C) Pinion shaft

(D) Straight pin

(E) Washer

(F) Differential bevel gear

(G) Differential bevel pinion

(H) Roller bearing

(I) Differential case

MT-00291

(A)

(B)(C)

(E)

(E)

(F)

(F)

(G)

(G)

(D)

(H) (I)

(H)MT-00285

ST1

ST2

MT-00293ST1

ST2ST3

Page 2819 of 2870

5MT-106

MANUAL TRANSMISSION AND DIFFERENTIAL

Shifter Fork and Rod

24.Shifter Fork and Rod

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the back-up light switch and neutral po-

sition switch.

3) Remove the transfer case with extension case

assembly.

4) Remove the transmission case.

5) Remove the drive pinion shaft assembly.

bly.>

6) Remove the main shaft assembly.

Single-Range model

Dual-Range model

7) Remove the differential assembly.

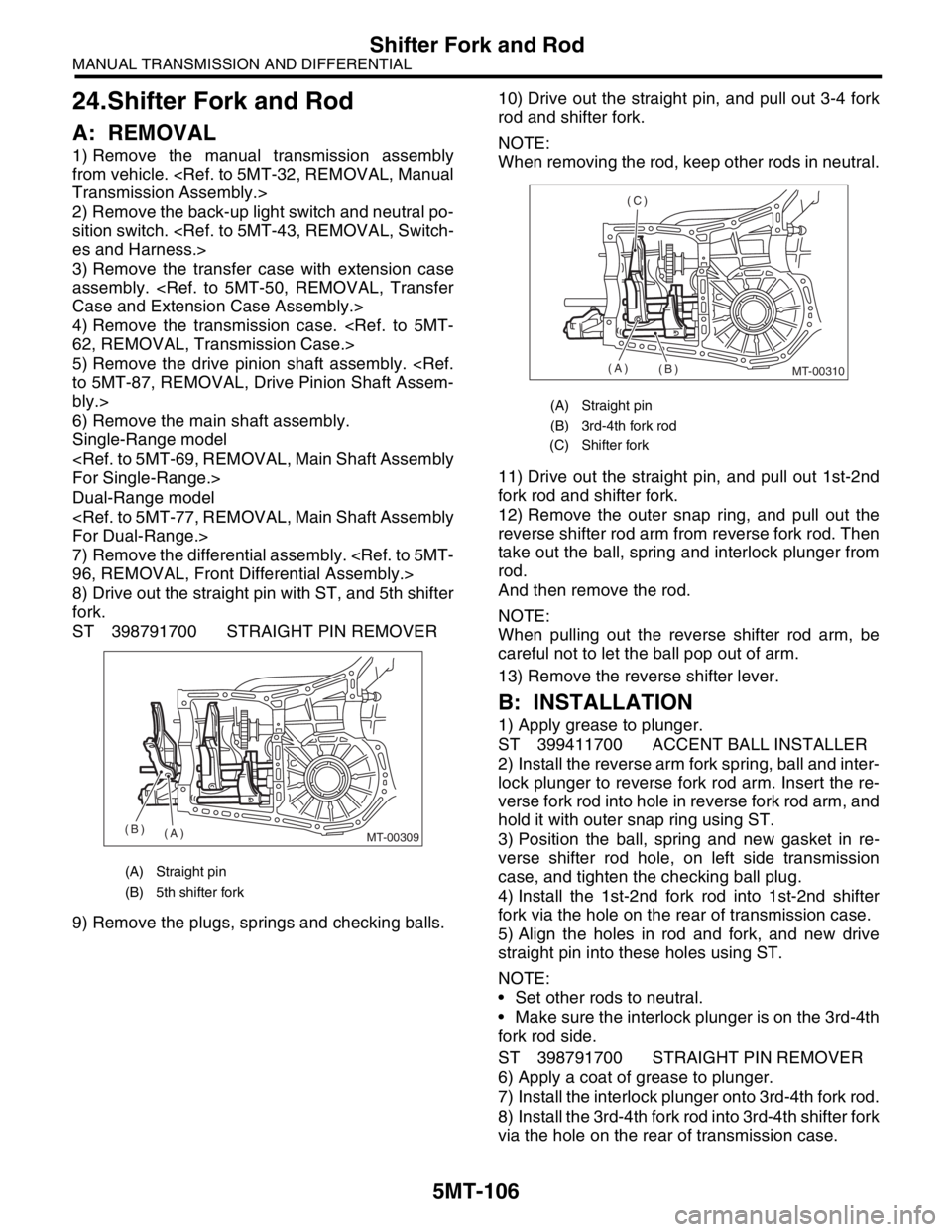

8) Drive out the straight pin with ST, and 5th shifter

fork.

ST 398791700 STRAIGHT PIN REMOVER

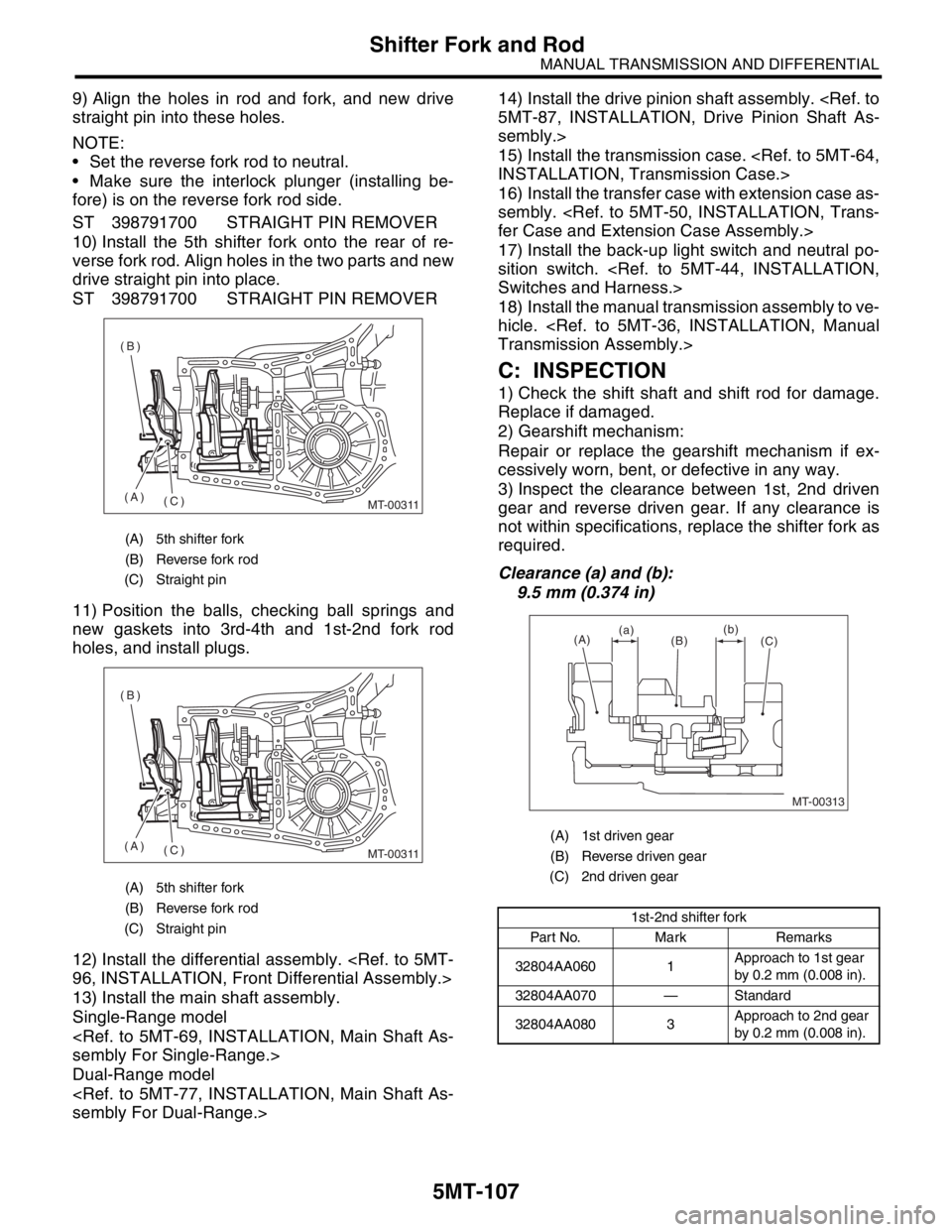

9) Remove the plugs, springs and checking balls.10) Drive out the straight pin, and pull out 3-4 fork

rod and shifter fork.

NOTE:

When removing the rod, keep other rods in neutral.

11) Drive out the straight pin, and pull out 1st-2nd

fork rod and shifter fork.

12) Remove the outer snap ring, and pull out the

reverse shifter rod arm from reverse fork rod. Then

take out the ball, spring and interlock plunger from

rod.

And then remove the rod.

NOTE:

When pulling out the reverse shifter rod arm, be

careful not to let the ball pop out of arm.

13) Remove the reverse shifter lever.

B: INSTALLATION

1) Apply grease to plunger.

ST 399411700 ACCENT BALL INSTALLER

2) Install the reverse arm fork spring, ball and inter-

lock plunger to reverse fork rod arm. Insert the re-

verse fork rod into hole in reverse fork rod arm, and

hold it with outer snap ring using ST.

3) Position the ball, spring and new gasket in re-

verse shifter rod hole, on left side transmission

case, and tighten the checking ball plug.

4) Install the 1st-2nd fork rod into 1st-2nd shifter

fork via the hole on the rear of transmission case.

5) Align the holes in rod and fork, and new drive

straight pin into these holes using ST.

NOTE:

Set other rods to neutral.

Make sure the interlock plunger is on the 3rd-4th

fork rod side.

ST 398791700 STRAIGHT PIN REMOVER

6) Apply a coat of grease to plunger.

7) Install the interlock plunger onto 3rd-4th fork rod.

8) Install the 3rd-4th fork rod into 3rd-4th shifter fork

via the hole on the rear of transmission case.

(A) Straight pin

(B) 5th shifter fork

MT-00309(A) (B)

(A) Straight pin

(B) 3rd-4th fork rod

(C) Shifter fork

MT-00310(A)

(B) (C)

Page 2820 of 2870

5MT-107

MANUAL TRANSMISSION AND DIFFERENTIAL

Shifter Fork and Rod

9) Align the holes in rod and fork, and new drive

straight pin into these holes.

NOTE:

Set the reverse fork rod to neutral.

Make sure the interlock plunger (installing be-

fore) is on the reverse fork rod side.

ST 398791700 STRAIGHT PIN REMOVER

10) Install the 5th shifter fork onto the rear of re-

verse fork rod. Align holes in the two parts and new

drive straight pin into place.

ST 398791700 STRAIGHT PIN REMOVER

11) Position the balls, checking ball springs and

new gaskets into 3rd-4th and 1st-2nd fork rod

holes, and install plugs.

12) Install the differential assembly.

13) Install the main shaft assembly.

Single-Range model

Dual-Range model

sembly.>

15) Install the transmission case.

16) Install the transfer case with extension case as-

sembly.

17) Install the back-up light switch and neutral po-

sition switch.

18) Install the manual transmission assembly to ve-

hicle.

C: INSPECTION

1) Check the shift shaft and shift rod for damage.

Replace if damaged.

2) Gearshift mechanism:

Repair or replace the gearshift mechanism if ex-

cessively worn, bent, or defective in any way.

3) Inspect the clearance between 1st, 2nd driven

gear and reverse driven gear. If any clearance is

not within specifications, replace the shifter fork as

required.

Clearance (a) and (b):

9.5 mm (0.374 in)

(A) 5th shifter fork

(B) Reverse fork rod

(C) Straight pin

(A) 5th shifter fork

(B) Reverse fork rod

(C) Straight pin

MT-00311(C) (A) (B)

MT-00311(C) (A) (B)(A) 1st driven gear

(B) Reverse driven gear

(C) 2nd driven gear

1st-2nd shifter fork

Part No. Mark Remarks

32804AA060 1Approach to 1st gear

by 0.2 mm (0.008 in).

32804AA070 — Standard

32804AA080 3Approach to 2nd gear

by 0.2 mm (0.008 in).

MT-00313

(A)

(B)

(C) (a)(b)

Page 2840 of 2870

CL-14

CLUTCH SYSTEM

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn yourself, because each

part on the vehicle is hot after running.

Use SUBARU genuine fluid, grease etc. or the

equivalent. Do not mix fluid, grease etc. with that of

another grade or from other manufacturers.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Apply grease onto sliding or revolution surfaces

before installation.

Before installing O-rings or snap rings, apply suf-

ficient amount of fluid to avoid damage and defor-

mation.

Before securing a part on a vise, place cushion-

ing material such as wood blocks, aluminum plate,

or shop cloth between the part and the vise.

Keep fluid away from the vehicle body. If any flu-

id contacts the vehicle body, immediately flush the

area with water.

Page 2852 of 2870

CL-26

CLUTCH SYSTEM

Master Cylinder

6. Master Cylinder

A: REMOVAL

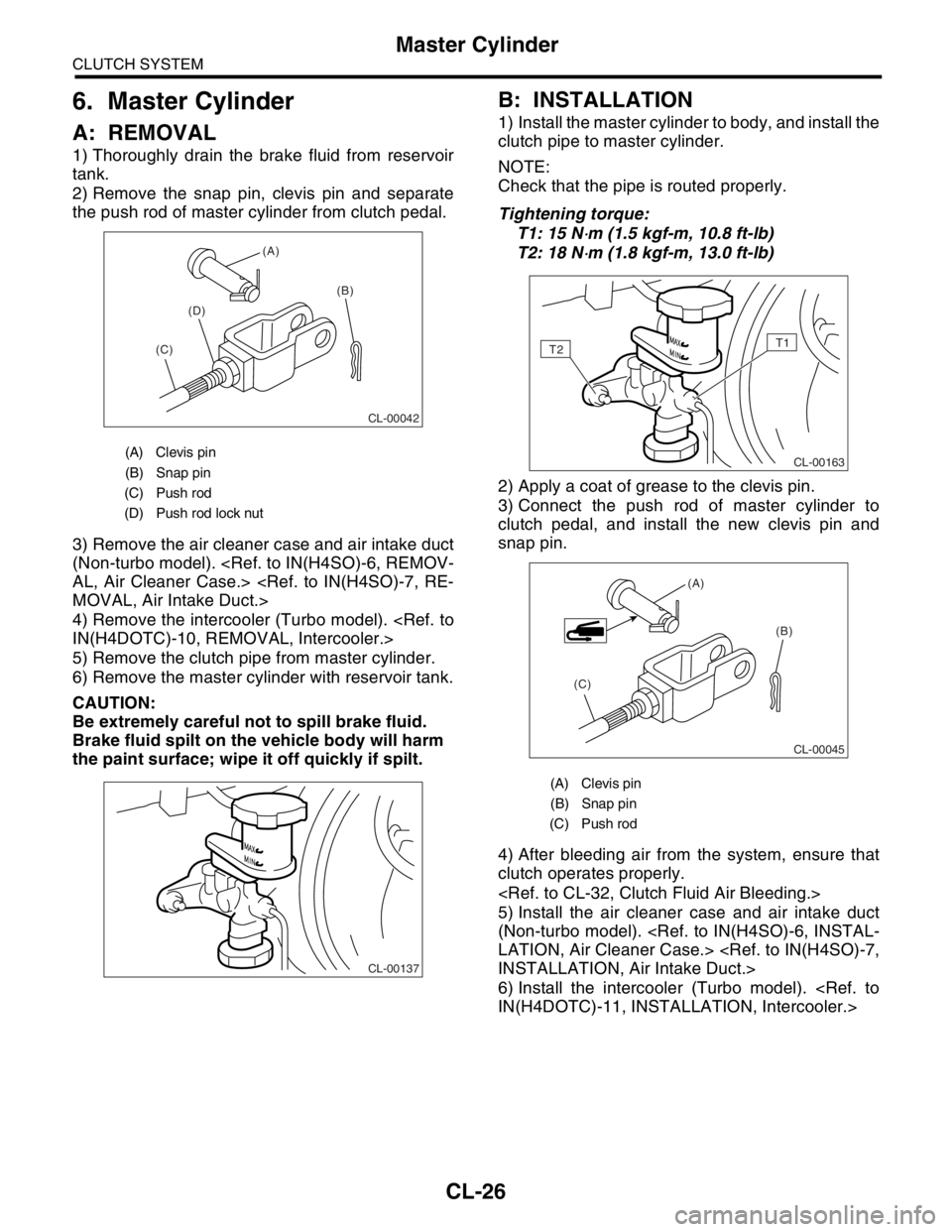

1) Thoroughly drain the brake fluid from reservoir

tank.

2) Remove the snap pin, clevis pin and separate

the push rod of master cylinder from clutch pedal.

3) Remove the air cleaner case and air intake duct

(Non-turbo model).

4) Remove the intercooler (Turbo model).

5) Remove the clutch pipe from master cylinder.

6) Remove the master cylinder with reservoir tank.

CAUTION:

Be extremely careful not to spill brake fluid.

Brake fluid spilt on the vehicle body will harm

the paint surface; wipe it off quickly if spilt.

B: INSTALLATION

1) Install the master cylinder to body, and install the

clutch pipe to master cylinder.

NOTE:

Check that the pipe is routed properly.

Tightening torque:

T1: 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

T2: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

2) Apply a coat of grease to the clevis pin.

3) Connect the push rod of master cylinder to

clutch pedal, and install the new clevis pin and

snap pin.

4) After bleeding air from the system, ensure that

clutch operates properly.

5) Install the air cleaner case and air intake duct

(Non-turbo model).

6) Install the intercooler (Turbo model).

(A) Clevis pin

(B) Snap pin

(C) Push rod

(D) Push rod lock nut

CL-00042

(A)

(B)

(C)(D)

CL-00137

(A) Clevis pin

(B) Snap pin

(C) Push rod

CL-00163

T2T1

CL-00045

(A)

(B)

(C)

Page 2860 of 2870

CL-34

CLUTCH SYSTEM

Clutch Pedal

10.Clutch Pedal

A: REMOVAL

1. LHD MODEL

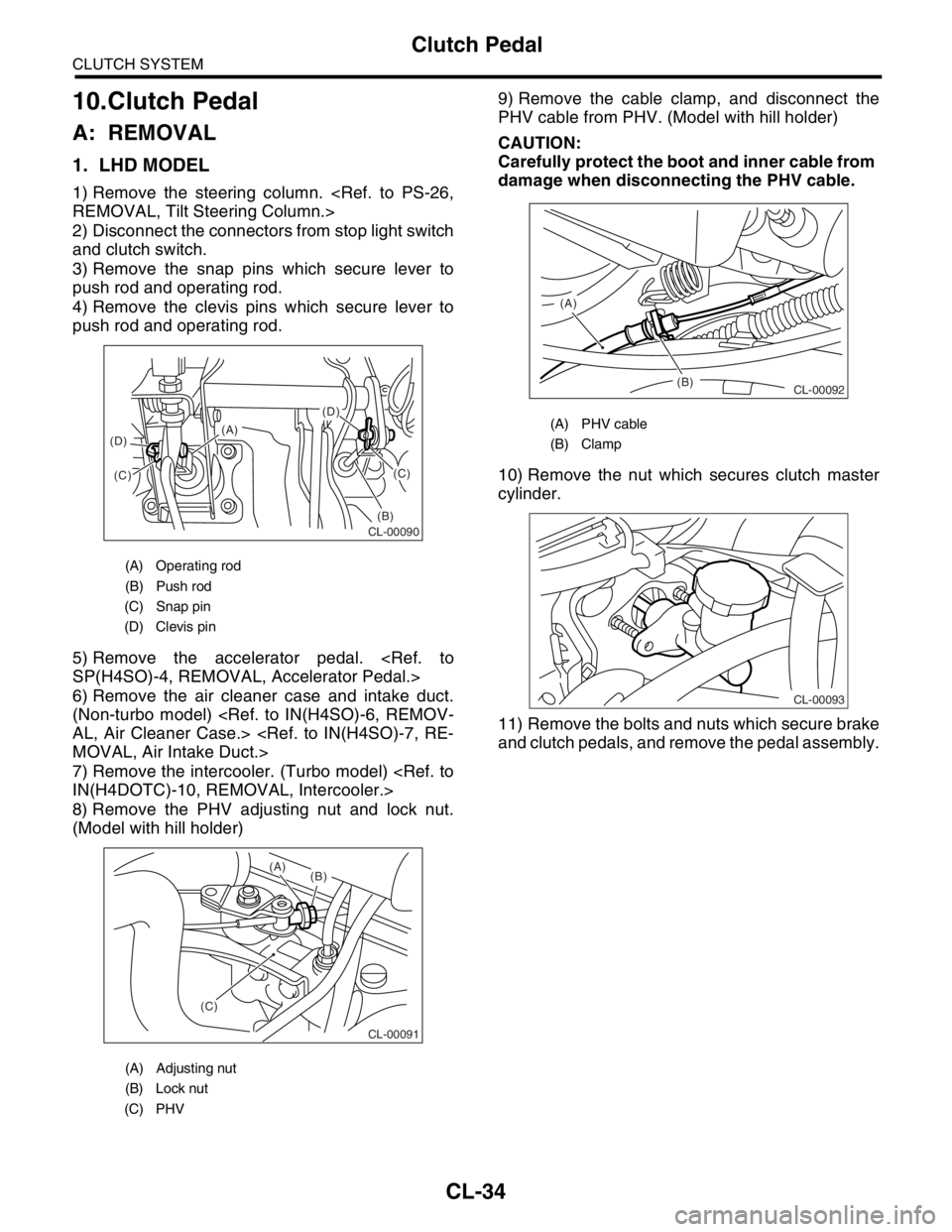

1) Remove the steering column.

2) Disconnect the connectors from stop light switch

and clutch switch.

3) Remove the snap pins which secure lever to

push rod and operating rod.

4) Remove the clevis pins which secure lever to

push rod and operating rod.

5) Remove the accelerator pedal.

6) Remove the air cleaner case and intake duct.

(Non-turbo model)

7) Remove the intercooler. (Turbo model)

8) Remove the PHV adjusting nut and lock nut.

(Model with hill holder)9) Remove the cable clamp, and disconnect the

PHV cable from PHV. (Model with hill holder)

CAUTION:

Carefully protect the boot and inner cable from

damage when disconnecting the PHV cable.

10) Remove the nut which secures clutch master

cylinder.

11) Remove the bolts and nuts which secure brake

and clutch pedals, and remove the pedal assembly.

(A) Operating rod

(B) Push rod

(C) Snap pin

(D) Clevis pin

(A) Adjusting nut

(B) Lock nut

(C) PHV

(D)

(B)(C)

(C) (D)(A)

CL-00090

CL-00091

(C)(B) (A)

(A) PHV cable

(B) Clamp

(B) (A)

CL-00092

CL-00093

Page 2861 of 2870

CL-35

CLUTCH SYSTEM

Clutch Pedal

2. RHD MODEL

1) Disconnect the ground cable from battery.

2) Loosen the screws and clips, and then remove

the lower cover.

3) Disconnect the clutch switch connector. (Model

with cruise control system)

4) Remove the snap pin connecting clutch pedal

and clutch master cylinder rod, and then pull the

clevis pin out.

5) Remove the clutch master cylinder mounting

nut.

6) Remove the PHV adjusting nut and the lock nut.

(Model with hill holder)

7) Remove the cable clamp, and disconnect the

PHV cable from PHV. (Model with hill holder)CAUTION:

Carefully protect the boot and inner cable from

damage when disconnecting the PHV cable.

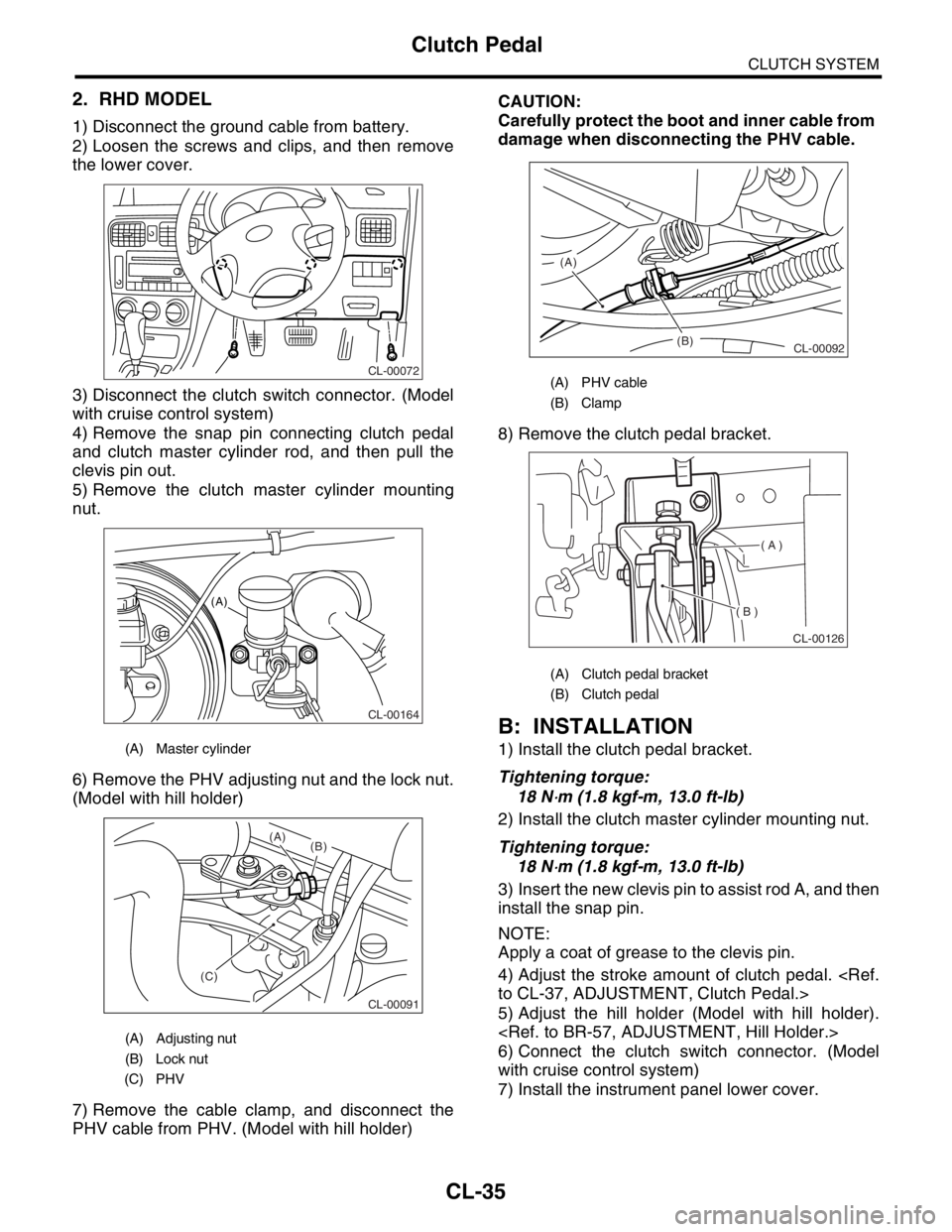

8) Remove the clutch pedal bracket.

B: INSTALLATION

1) Install the clutch pedal bracket.

Tightening torque:

18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

2) Install the clutch master cylinder mounting nut.

Tightening torque:

18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

3) Insert the new clevis pin to assist rod A, and then

install the snap pin.

NOTE:

Apply a coat of grease to the clevis pin.

4) Adjust the stroke amount of clutch pedal.

5) Adjust the hill holder (Model with hill holder).

6) Connect the clutch switch connector. (Model

with cruise control system)

7) Install the instrument panel lower cover.

(A) Master cylinder

(A) Adjusting nut

(B) Lock nut

(C) PHV

CL-00072

CL-00164

(A)

CL-00091

(C)(B) (A)

(A) PHV cable

(B) Clamp

(A) Clutch pedal bracket

(B) Clutch pedal

(B) (A)

CL-00092

( A )

( B )

CL-00126