lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2731 of 2870

5MT-19

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

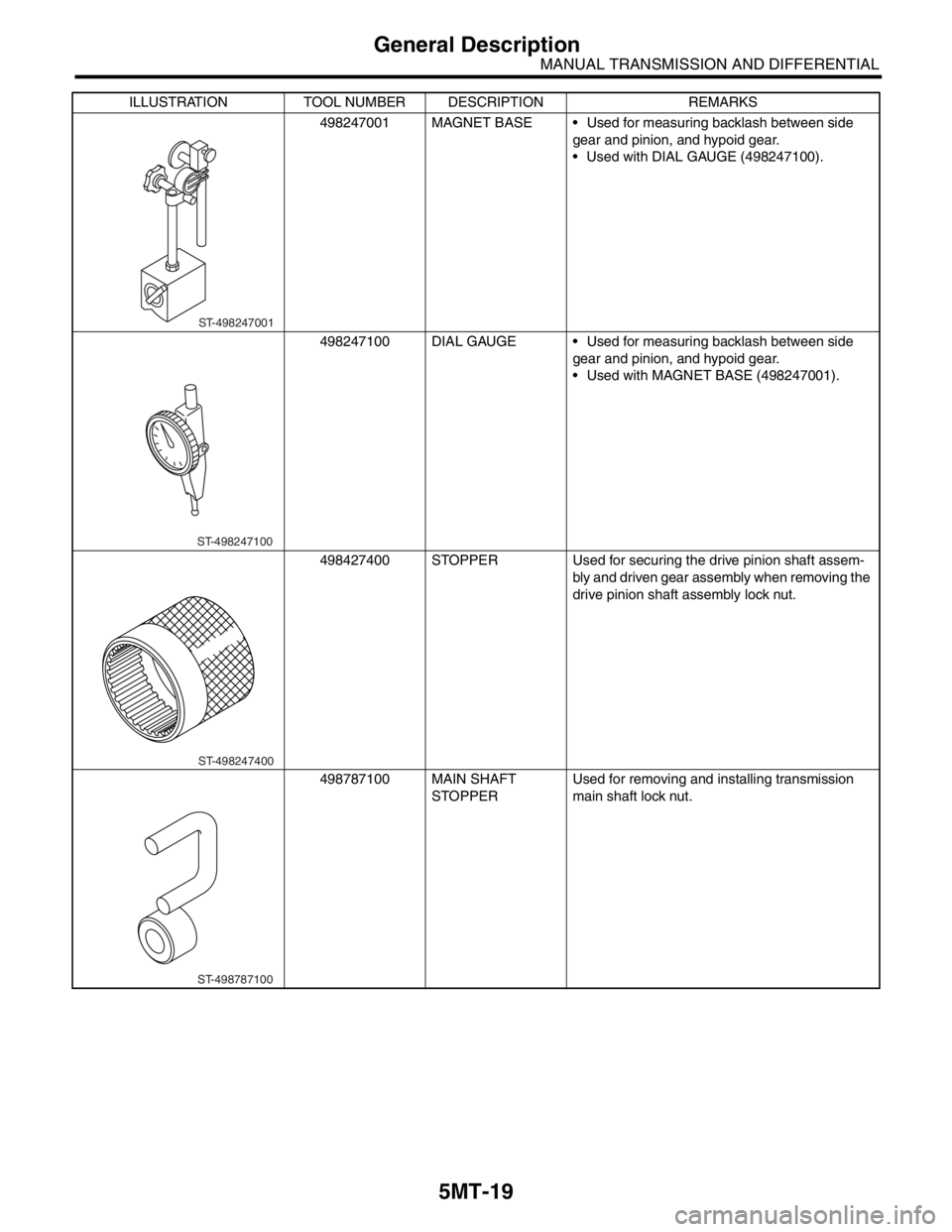

498247001 MAGNET BASE Used for measuring backlash between side

gear and pinion, and hypoid gear.

Used with DIAL GAUGE (498247100).

498247100 DIAL GAUGE Used for measuring backlash between side

gear and pinion, and hypoid gear.

Used with MAGNET BASE (498247001).

498427400 STOPPER Used for securing the drive pinion shaft assem-

bly and driven gear assembly when removing the

drive pinion shaft assembly lock nut.

498787100 MAIN SHAFT

STOPPERUsed for removing and installing transmission

main shaft lock nut. ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-498247001

ST-498247100

ST-498247400

ST-498787100

Page 2732 of 2870

5MT-20

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

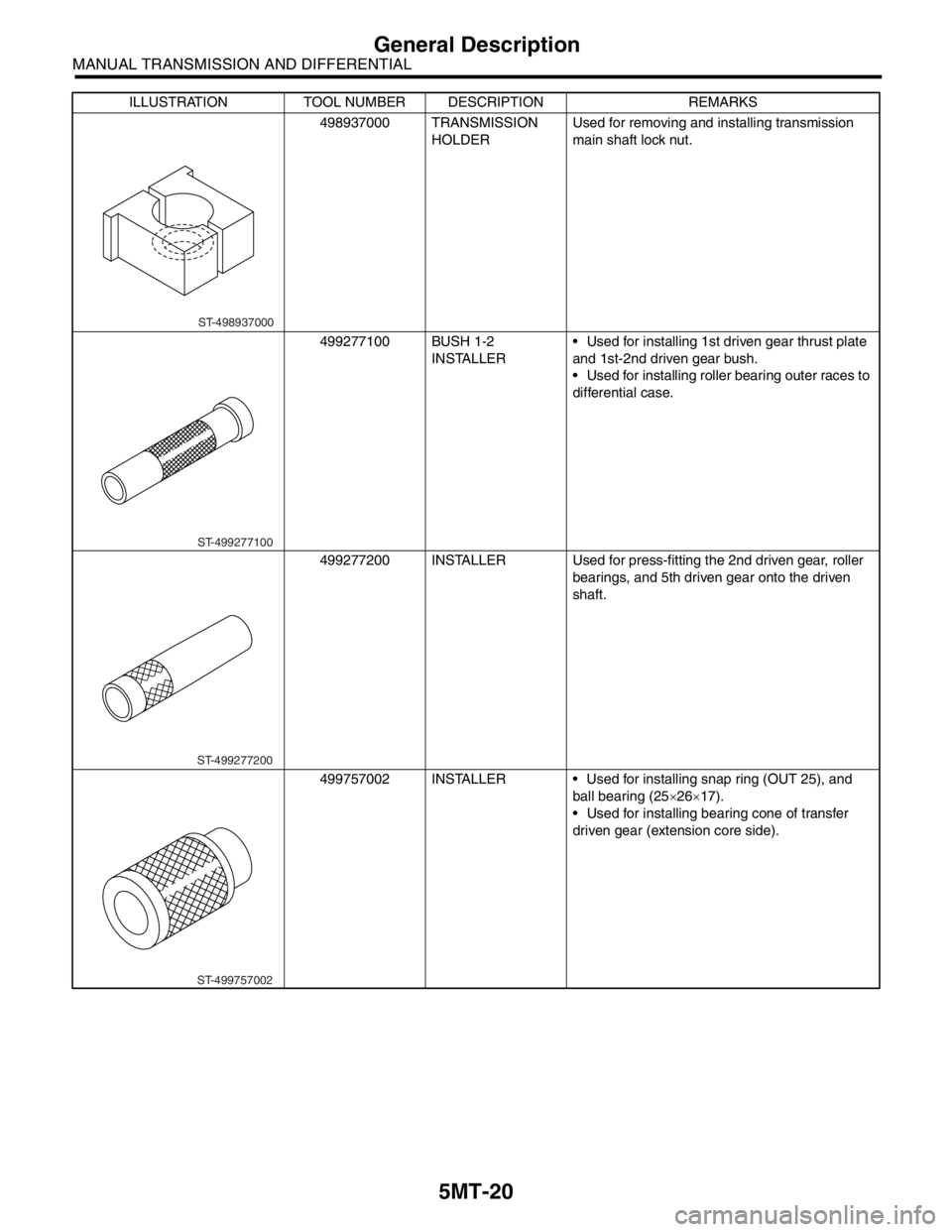

498937000 TRANSMISSION

HOLDERUsed for removing and installing transmission

main shaft lock nut.

499277100 BUSH 1-2

INSTALLER Used for installing 1st driven gear thrust plate

and 1st-2nd driven gear bush.

Used for installing roller bearing outer races to

differential case.

499277200 INSTALLER Used for press-fitting the 2nd driven gear, roller

bearings, and 5th driven gear onto the driven

shaft.

499757002 INSTALLER Used for installing snap ring (OUT 25), and

ball bearing (25×26×17).

Used for installing bearing cone of transfer

driven gear (extension core side). ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-498937000

ST-499277100

ST-499277200

ST-499757002

Page 2734 of 2870

5MT-22

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

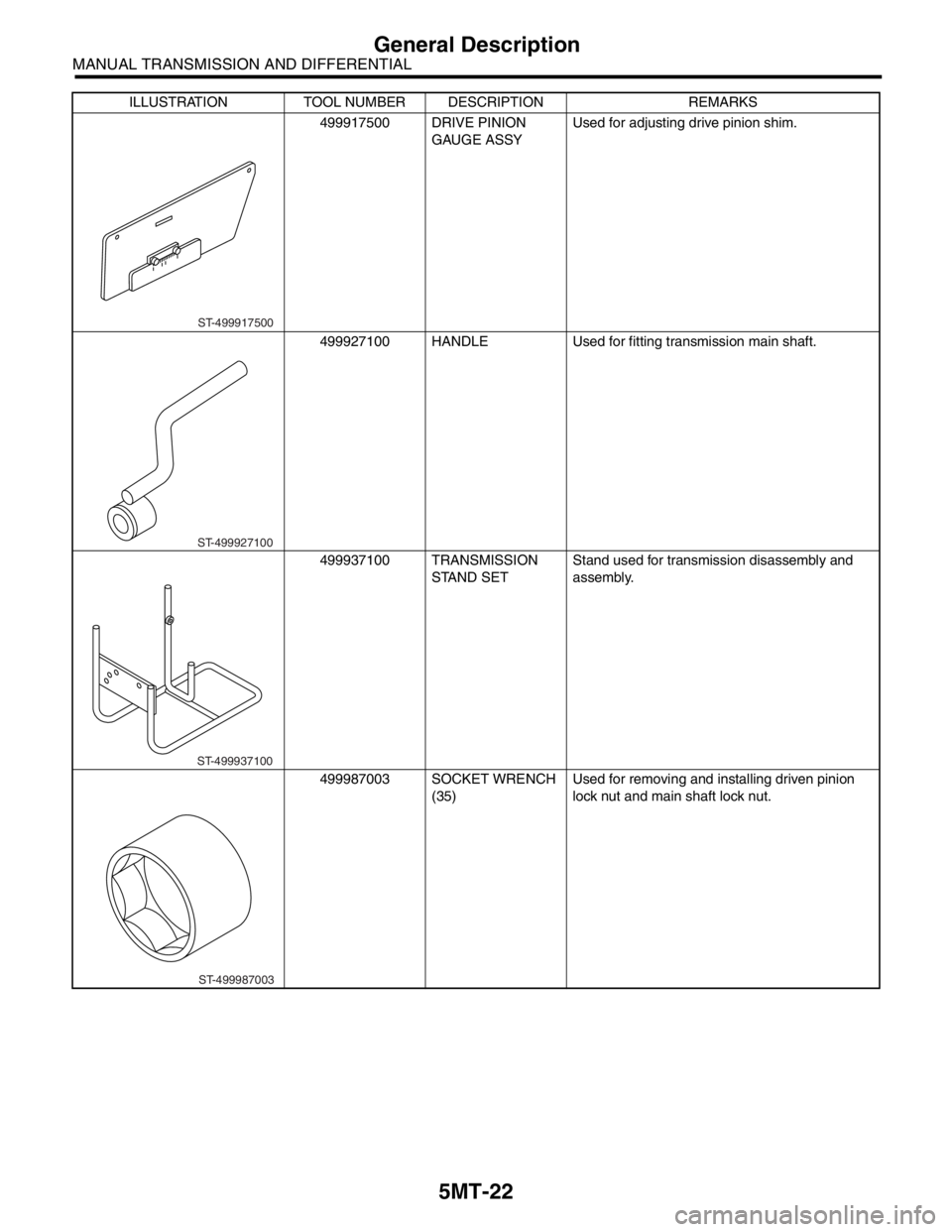

499917500 DRIVE PINION

GAUGE ASSYUsed for adjusting drive pinion shim.

499927100 HANDLE Used for fitting transmission main shaft.

499937100 TRANSMISSION

STAND SETStand used for transmission disassembly and

assembly.

499987003 SOCKET WRENCH

(35)Used for removing and installing driven pinion

lock nut and main shaft lock nut. ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-499917500

ST-499927100

ST-499937100

ST-499987003

Page 2735 of 2870

5MT-23

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

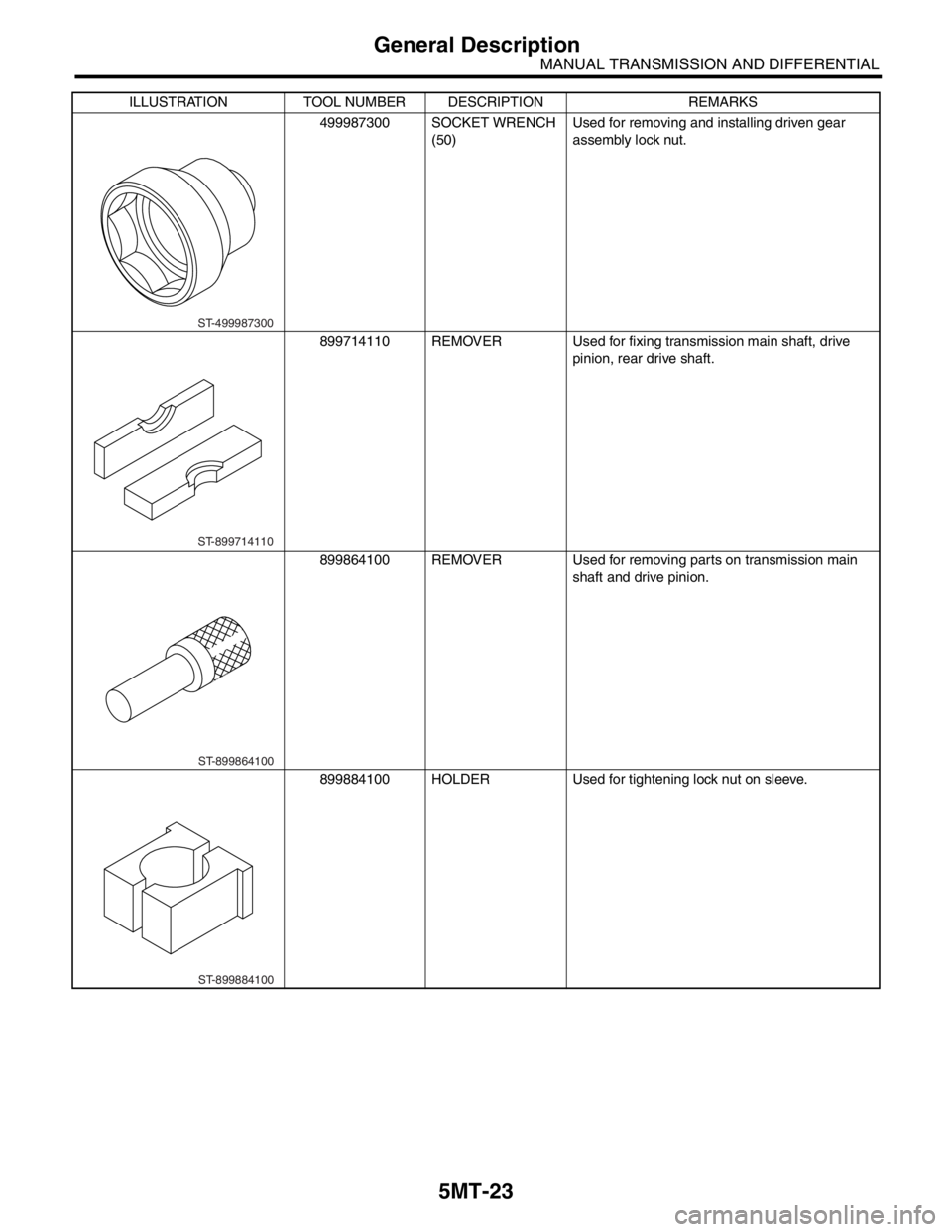

499987300 SOCKET WRENCH

(50)Used for removing and installing driven gear

assembly lock nut.

899714110 REMOVER Used for fixing transmission main shaft, drive

pinion, rear drive shaft.

899864100 REMOVER Used for removing parts on transmission main

shaft and drive pinion.

899884100 HOLDER Used for tightening lock nut on sleeve. ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-499987300

ST-899714110

ST-899864100

ST-899884100

Page 2736 of 2870

5MT-24

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

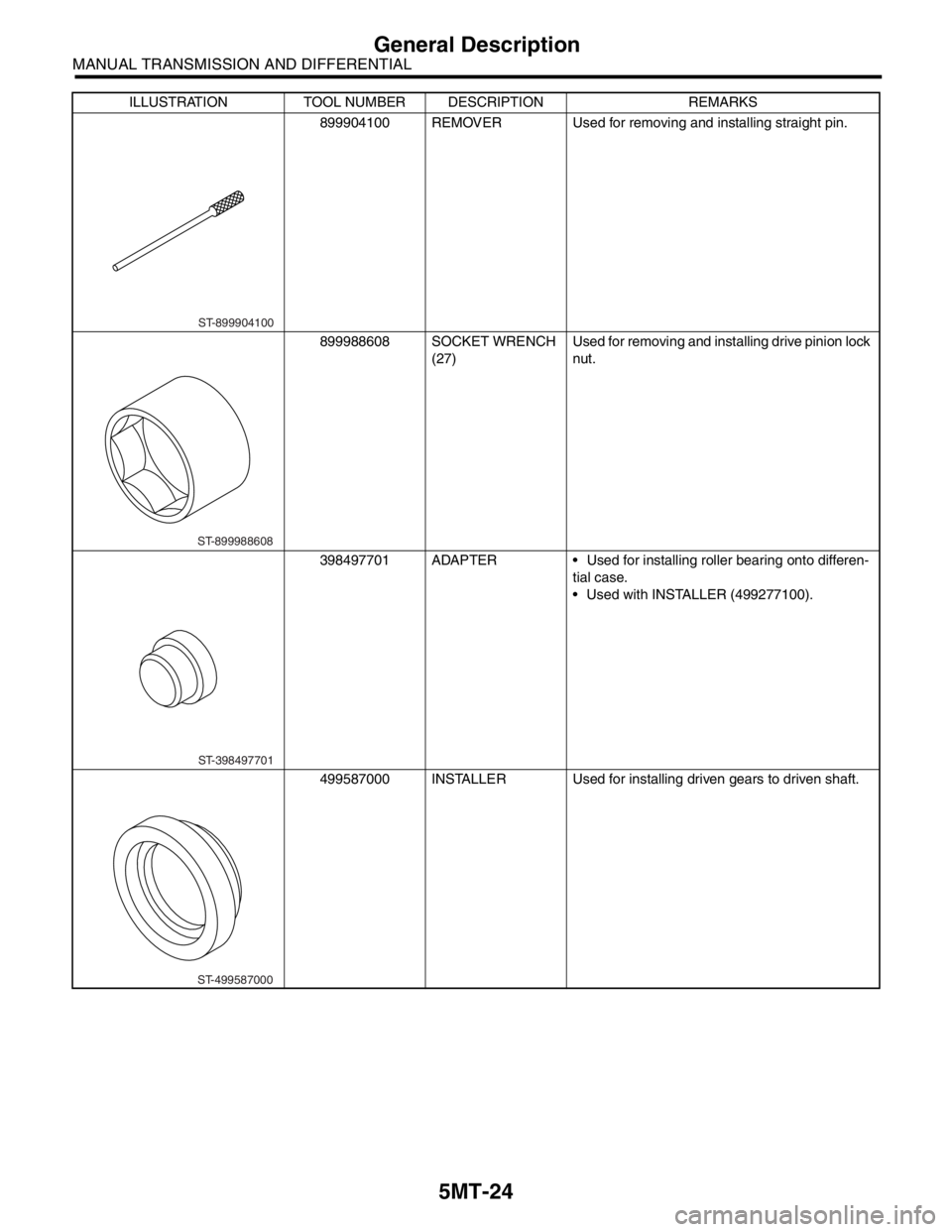

899904100 REMOVER Used for removing and installing straight pin.

899988608 SOCKET WRENCH

(27)Used for removing and installing drive pinion lock

nut.

398497701 ADAPTER Used for installing roller bearing onto differen-

tial case.

Used with INSTALLER (499277100).

499587000 INSTALLER Used for installing driven gears to driven shaft. ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-899904100

ST-899988608

ST-398497701

ST-499587000

Page 2737 of 2870

5MT-25

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

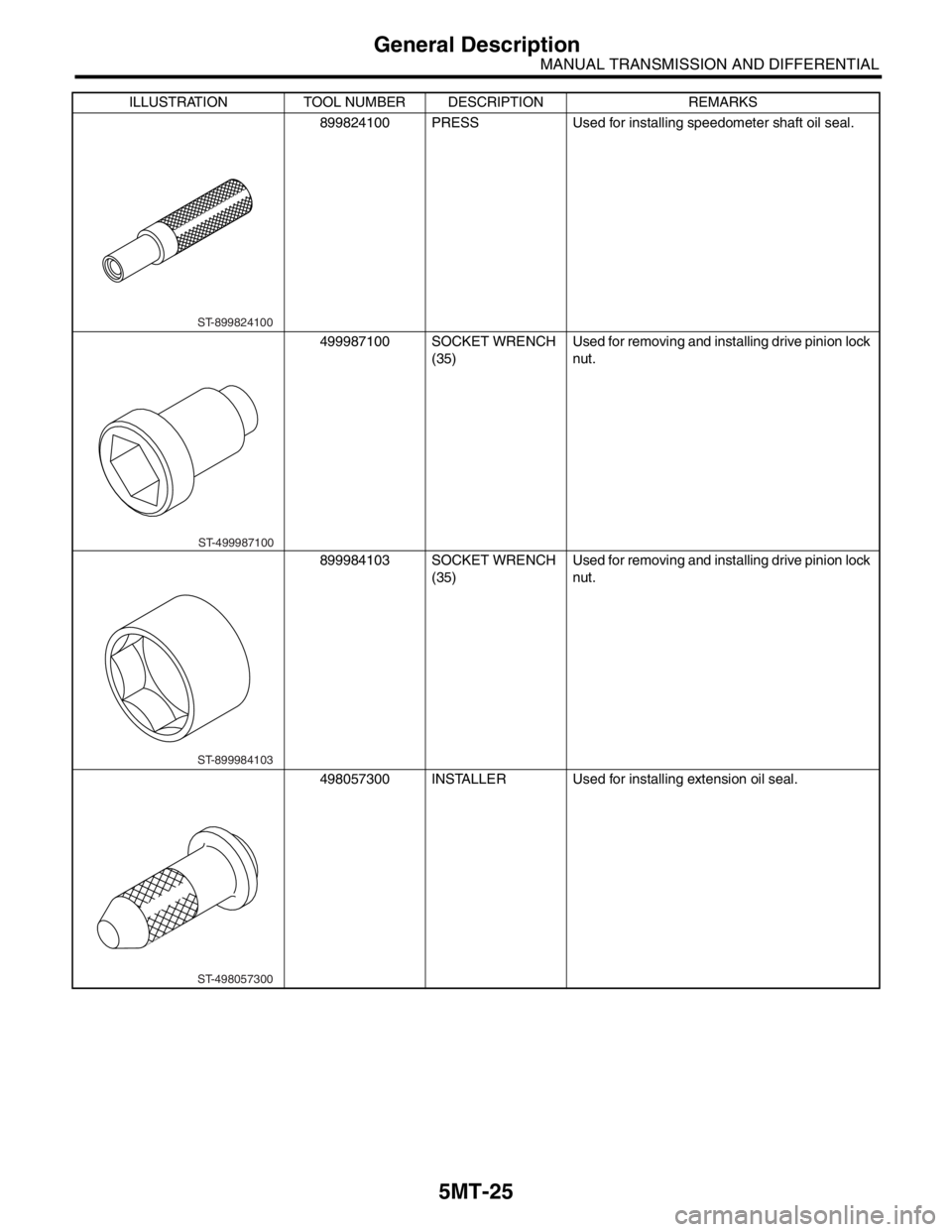

899824100 PRESS Used for installing speedometer shaft oil seal.

499987100 SOCKET WRENCH

(35)Used for removing and installing drive pinion lock

nut.

899984103 SOCKET WRENCH

(35)Used for removing and installing drive pinion lock

nut.

498057300 INSTALLER Used for installing extension oil seal. ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-899824100

ST-499987100

ST-899984103

ST-498057300

Page 2759 of 2870

5MT-47

MANUAL TRANSMISSION AND DIFFERENTIAL

Preparation for Overhaul

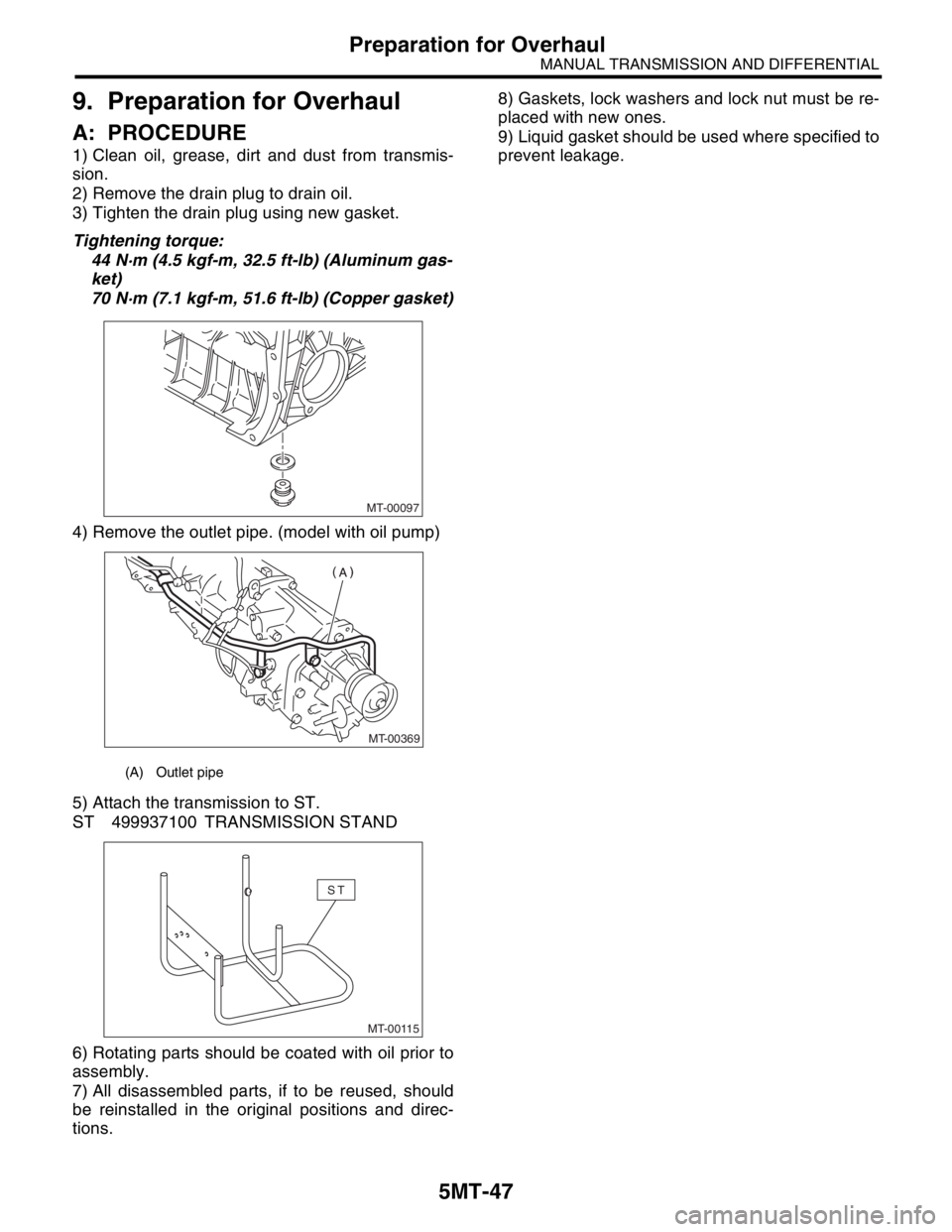

9. Preparation for Overhaul

A: PROCEDURE

1) Clean oil, grease, dirt and dust from transmis-

sion.

2) Remove the drain plug to drain oil.

3) Tighten the drain plug using new gasket.

Tightening torque:

44 N·m (4.5 kgf-m, 32.5 ft-lb) (Aluminum gas-

ket)

70 N·m (7.1 kgf-m, 51.6 ft-lb) (Copper gasket)

4) Remove the outlet pipe. (model with oil pump)

5) Attach the transmission to ST.

ST 499937100 TRANSMISSION STAND

6) Rotating parts should be coated with oil prior to

assembly.

7) All disassembled parts, if to be reused, should

be reinstalled in the original positions and direc-

tions.8) Gaskets, lock washers and lock nut must be re-

placed with new ones.

9) Liquid gasket should be used where specified to

prevent leakage.

(A) Outlet pipe

MT-00097

MT-00369

MT-00115

ST

Page 2778 of 2870

5MT-65

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Case

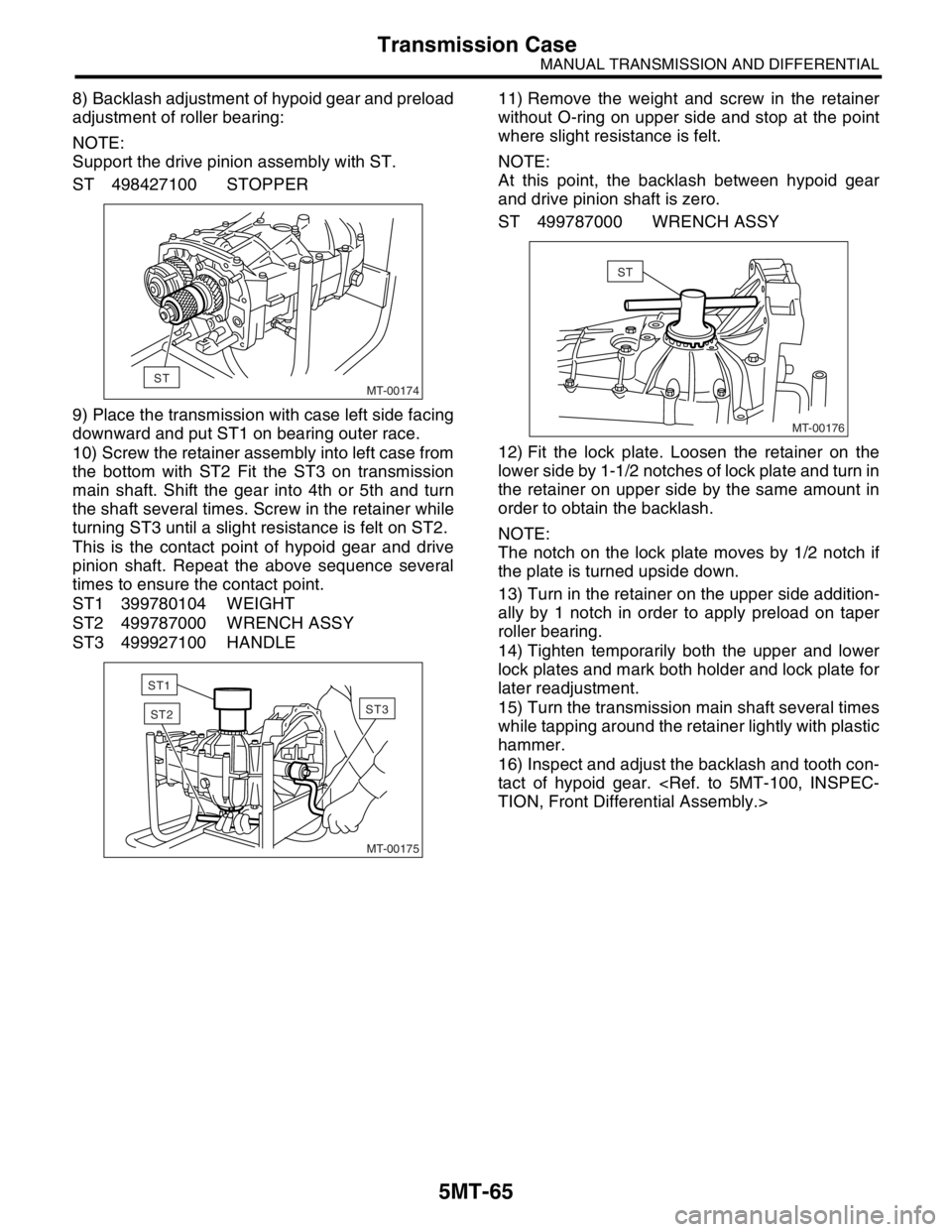

8) Backlash adjustment of hypoid gear and preload

adjustment of roller bearing:

NOTE:

Support the drive pinion assembly with ST.

ST 498427100 STOPPER

9) Place the transmission with case left side facing

downward and put ST1 on bearing outer race.

10) Screw the retainer assembly into left case from

the bottom with ST2 Fit the ST3 on transmission

main shaft. Shift the gear into 4th or 5th and turn

the shaft several times. Screw in the retainer while

turning ST3 until a slight resistance is felt on ST2.

This is the contact point of hypoid gear and drive

pinion shaft. Repeat the above sequence several

times to ensure the contact point.

ST1 399780104 WEIGHT

ST2 499787000 WRENCH ASSY

ST3 499927100 HANDLE11) Remove the weight and screw in the retainer

without O-ring on upper side and stop at the point

where slight resistance is felt.

NOTE:

At this point, the backlash between hypoid gear

and drive pinion shaft is zero.

ST 499787000 WRENCH ASSY

12) Fit the lock plate. Loosen the retainer on the

lower side by 1-1/2 notches of lock plate and turn in

the retainer on upper side by the same amount in

order to obtain the backlash.

NOTE:

The notch on the lock plate moves by 1/2 notch if

the plate is turned upside down.

13) Turn in the retainer on the upper side addition-

ally by 1 notch in order to apply preload on taper

roller bearing.

14) Tighten temporarily both the upper and lower

lock plates and mark both holder and lock plate for

later readjustment.

15) Turn the transmission main shaft several times

while tapping around the retainer lightly with plastic

hammer.

16) Inspect and adjust the backlash and tooth con-

tact of hypoid gear.

MT-00174ST

MT-00175

ST3ST2

ST1

MT-00176

ST

Page 2779 of 2870

5MT-66

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Case

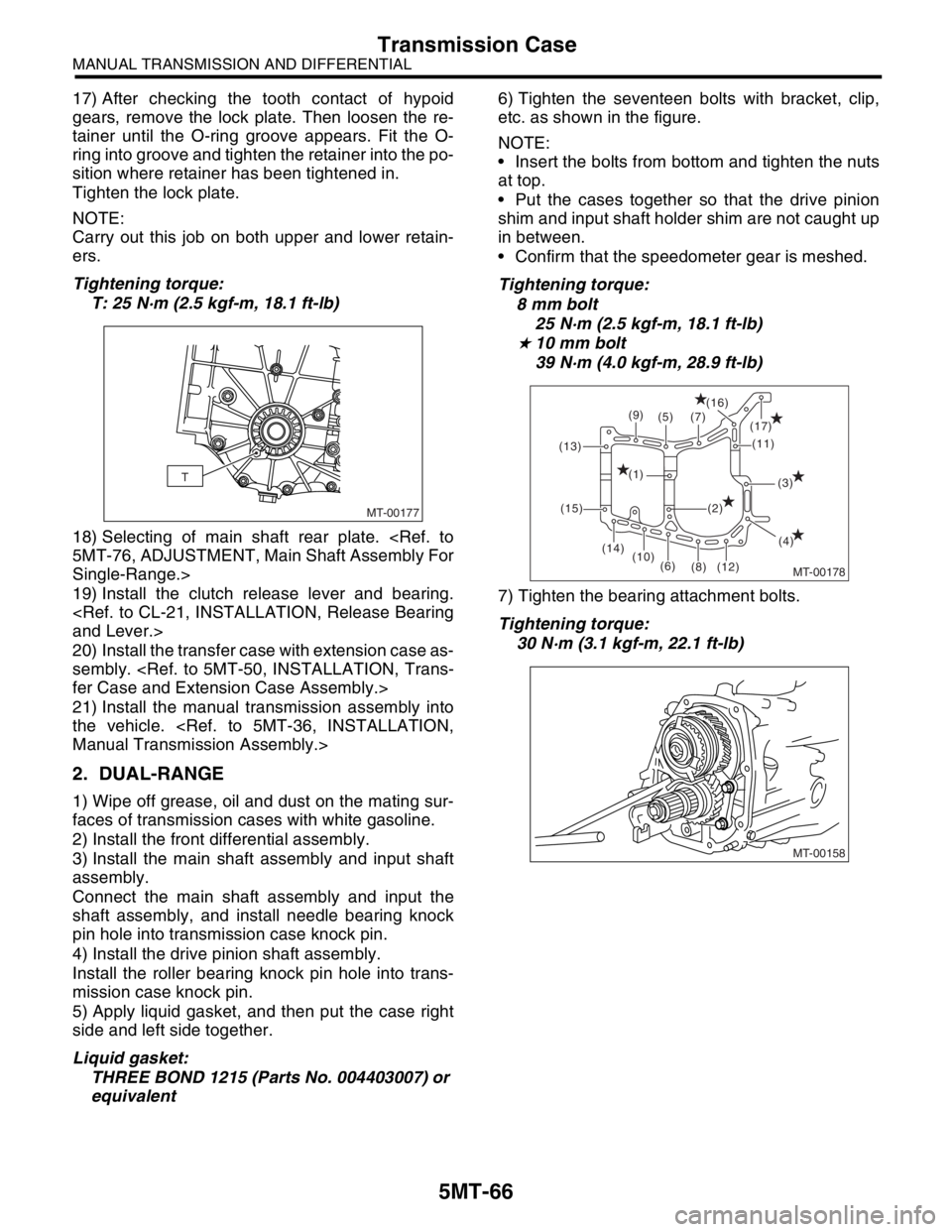

17) After checking the tooth contact of hypoid

gears, remove the lock plate. Then loosen the re-

tainer until the O-ring groove appears. Fit the O-

ring into groove and tighten the retainer into the po-

sition where retainer has been tightened in.

Tighten the lock plate.

NOTE:

Carry out this job on both upper and lower retain-

ers.

Tightening torque:

T: 25 N·m (2.5 kgf-m, 18.1 ft-lb)

18) Selecting of main shaft rear plate.

Single-Range.>

19) Install the clutch release lever and bearing.

20) Install the transfer case with extension case as-

sembly.

21) Install the manual transmission assembly into

the vehicle.

2. DUAL-RANGE

1) Wipe off grease, oil and dust on the mating sur-

faces of transmission cases with white gasoline.

2) Install the front differential assembly.

3) Install the main shaft assembly and input shaft

assembly.

Connect the main shaft assembly and input the

shaft assembly, and install needle bearing knock

pin hole into transmission case knock pin.

4) Install the drive pinion shaft assembly.

Install the roller bearing knock pin hole into trans-

mission case knock pin.

5) Apply liquid gasket, and then put the case right

side and left side together.

Liquid gasket:

THREE BOND 1215 (Parts No. 004403007) or

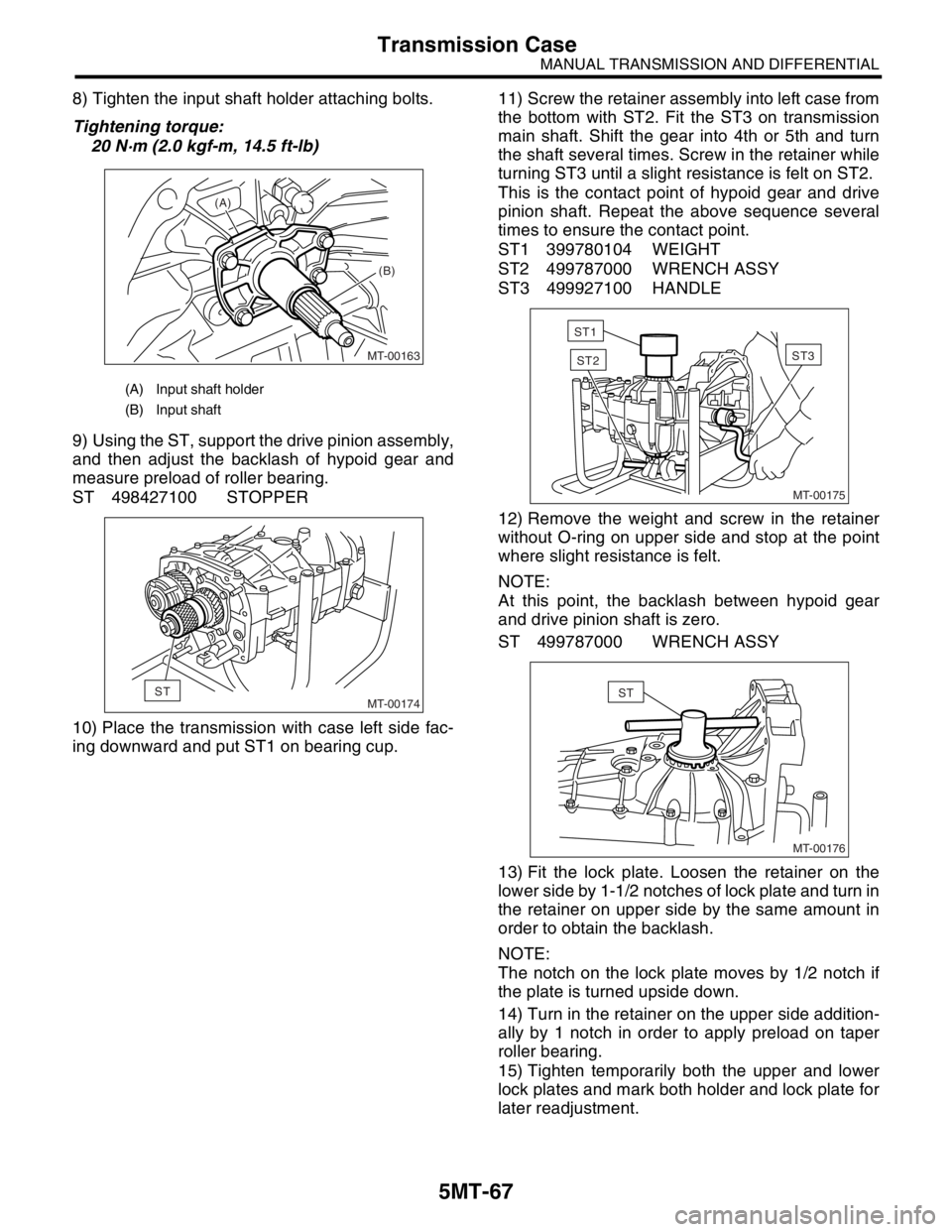

equivalent6) Tighten the seventeen bolts with bracket, clip,

etc. as shown in the figure.

NOTE:

Insert the bolts from bottom and tighten the nuts

at top.

Put the cases together so that the drive pinion

shim and input shaft holder shim are not caught up

in between.

Confirm that the speedometer gear is meshed.

Tightening torque:

8 mm bolt

25 N·m (2.5 kgf-m, 18.1 ft-lb)

★ 10 mm bolt

39 N·m (4.0 kgf-m, 28.9 ft-lb)

7) Tighten the bearing attachment bolts.

Tightening torque:

30 N·m (3.1 kgf-m, 22.1 ft-lb)

MT-00177

T

MT-00178

(9)

(7) (5)(16)

(17)

(11)

(3)

(4) (2) (1)

(12) (8) (6) (10) (14) (15) (13)

MT-00158

Page 2780 of 2870

5MT-67

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Case

8) Tighten the input shaft holder attaching bolts.

Tightening torque:

20 N·m (2.0 kgf-m, 14.5 ft-lb)

9) Using the ST, support the drive pinion assembly,

and then adjust the backlash of hypoid gear and

measure preload of roller bearing.

ST 498427100 STOPPER

10) Place the transmission with case left side fac-

ing downward and put ST1 on bearing cup.11) Screw the retainer assembly into left case from

the bottom with ST2. Fit the ST3 on transmission

main shaft. Shift the gear into 4th or 5th and turn

the shaft several times. Screw in the retainer while

turning ST3 until a slight resistance is felt on ST2.

This is the contact point of hypoid gear and drive

pinion shaft. Repeat the above sequence several

times to ensure the contact point.

ST1 399780104 WEIGHT

ST2 499787000 WRENCH ASSY

ST3 499927100 HANDLE

12) Remove the weight and screw in the retainer

without O-ring on upper side and stop at the point

where slight resistance is felt.

NOTE:

At this point, the backlash between hypoid gear

and drive pinion shaft is zero.

ST 499787000 WRENCH ASSY

13) Fit the lock plate. Loosen the retainer on the

lower side by 1-1/2 notches of lock plate and turn in

the retainer on upper side by the same amount in

order to obtain the backlash.

NOTE:

The notch on the lock plate moves by 1/2 notch if

the plate is turned upside down.

14) Turn in the retainer on the upper side addition-

ally by 1 notch in order to apply preload on taper

roller bearing.

15) Tighten temporarily both the upper and lower

lock plates and mark both holder and lock plate for

later readjustment.

(A) Input shaft holder

(B) Input shaft

MT-00163

(A)

(B)

MT-00174ST

MT-00175

ST3ST2

ST1

MT-00176

ST