SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 481 of 1456

1. General

A: PRECAUTIONS

1) Clean oil, grease, dirt and dust from transmis-

sion.

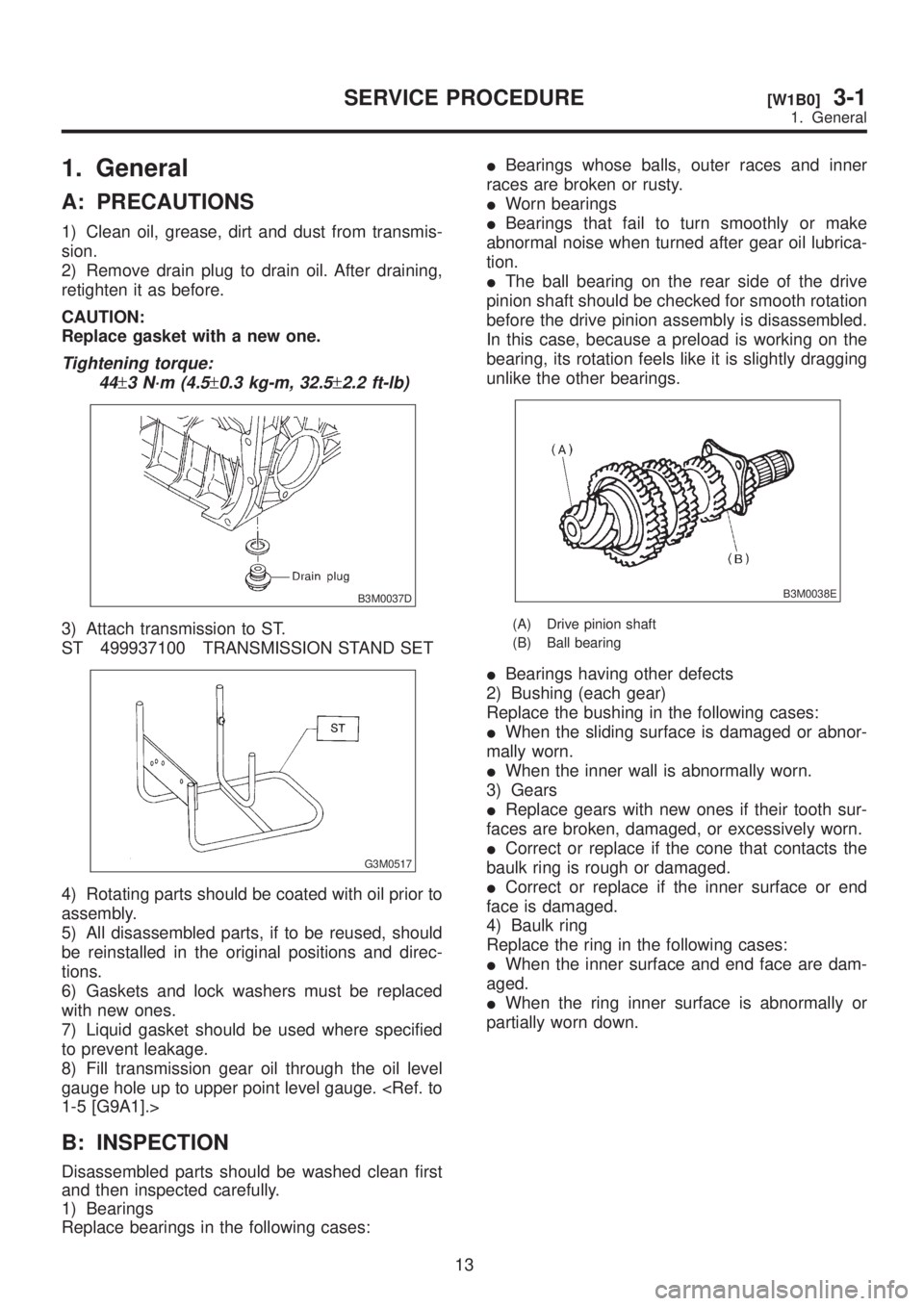

2) Remove drain plug to drain oil. After draining,

retighten it as before.

CAUTION:

Replace gasket with a new one.

Tightening torque:

44

±3 N´m (4.5±0.3 kg-m, 32.5±2.2 ft-lb)

B3M0037D

3) Attach transmission to ST.

ST 499937100 TRANSMISSION STAND SET

G3M0517

4) Rotating parts should be coated with oil prior to

assembly.

5) All disassembled parts, if to be reused, should

be reinstalled in the original positions and direc-

tions.

6) Gaskets and lock washers must be replaced

with new ones.

7) Liquid gasket should be used where specified

to prevent leakage.

8) Fill transmission gear oil through the oil level

gauge hole up to upper point level gauge.

B: INSPECTION

Disassembled parts should be washed clean first

and then inspected carefully.

1) Bearings

Replace bearings in the following cases:IBearings whose balls, outer races and inner

races are broken or rusty.

IWorn bearings

IBearings that fail to turn smoothly or make

abnormal noise when turned after gear oil lubrica-

tion.

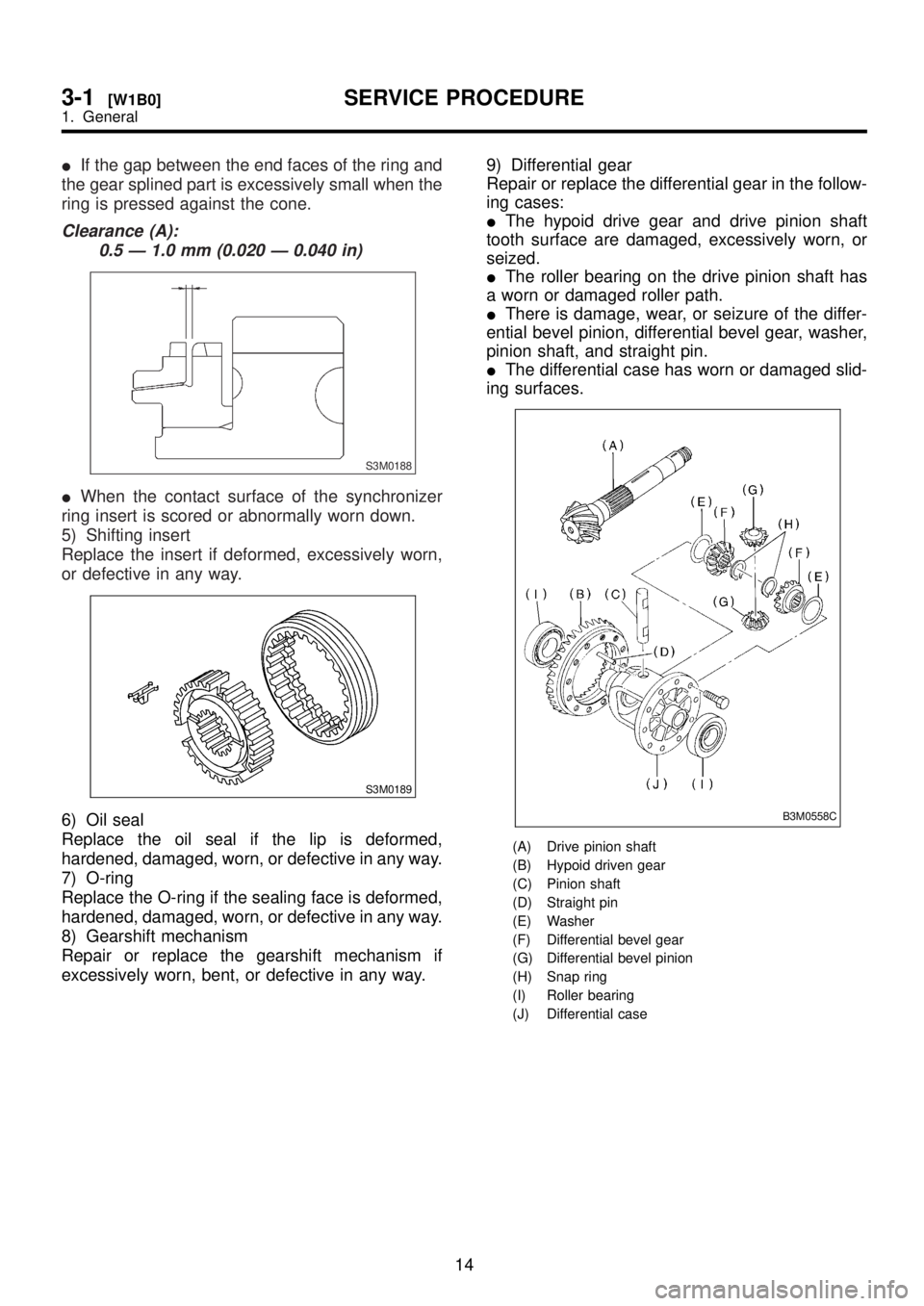

IThe ball bearing on the rear side of the drive

pinion shaft should be checked for smooth rotation

before the drive pinion assembly is disassembled.

In this case, because a preload is working on the

bearing, its rotation feels like it is slightly dragging

unlike the other bearings.

B3M0038E

(A) Drive pinion shaft

(B) Ball bearing

IBearings having other defects

2) Bushing (each gear)

Replace the bushing in the following cases:

IWhen the sliding surface is damaged or abnor-

mally worn.

IWhen the inner wall is abnormally worn.

3) Gears

IReplace gears with new ones if their tooth sur-

faces are broken, damaged, or excessively worn.

ICorrect or replace if the cone that contacts the

baulk ring is rough or damaged.

ICorrect or replace if the inner surface or end

face is damaged.

4) Baulk ring

Replace the ring in the following cases:

IWhen the inner surface and end face are dam-

aged.

IWhen the ring inner surface is abnormally or

partially worn down.

13

[W1B0]3-1SERVICE PROCEDURE

1. General

Page 482 of 1456

IIf the gap between the end faces of the ring and

the gear splined part is excessively small when the

ring is pressed against the cone.

Clearance (A):

0.5 Ð 1.0 mm (0.020 Ð 0.040 in)

S3M0188

IWhen the contact surface of the synchronizer

ring insert is scored or abnormally worn down.

5) Shifting insert

Replace the insert if deformed, excessively worn,

or defective in any way.

S3M0189

6) Oil seal

Replace the oil seal if the lip is deformed,

hardened, damaged, worn, or defective in any way.

7) O-ring

Replace the O-ring if the sealing face is deformed,

hardened, damaged, worn, or defective in any way.

8) Gearshift mechanism

Repair or replace the gearshift mechanism if

excessively worn, bent, or defective in any way.9) Differential gear

Repair or replace the differential gear in the follow-

ing cases:

IThe hypoid drive gear and drive pinion shaft

tooth surface are damaged, excessively worn, or

seized.

IThe roller bearing on the drive pinion shaft has

a worn or damaged roller path.

IThere is damage, wear, or seizure of the differ-

ential bevel pinion, differential bevel gear, washer,

pinion shaft, and straight pin.

IThe differential case has worn or damaged slid-

ing surfaces.B3M0558C

(A) Drive pinion shaft

(B) Hypoid driven gear

(C) Pinion shaft

(D) Straight pin

(E) Washer

(F) Differential bevel gear

(G) Differential bevel pinion

(H) Snap ring

(I) Roller bearing

(J) Differential case

14

3-1[W1B0]SERVICE PROCEDURE

1. General

Page 483 of 1456

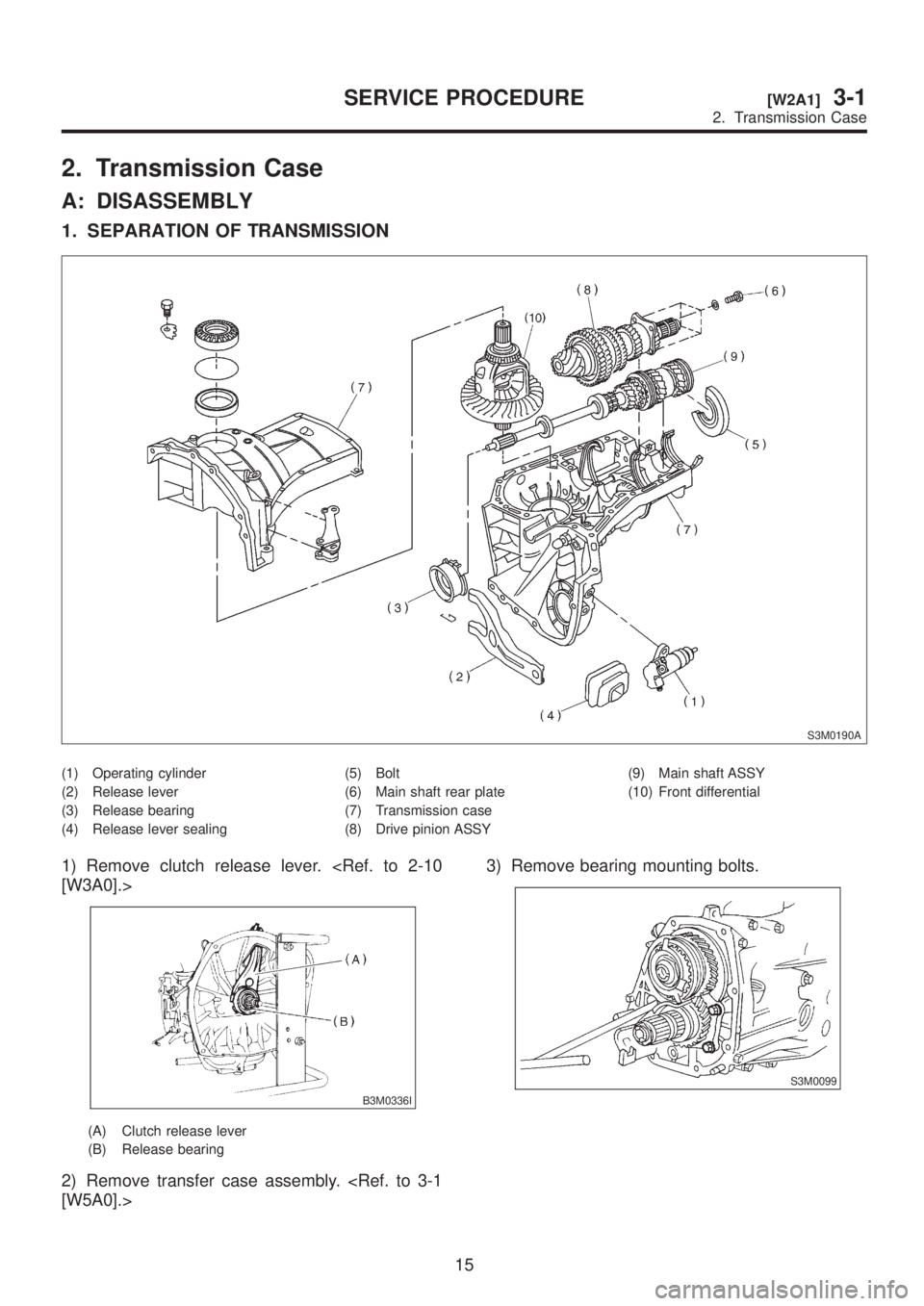

2. Transmission Case

A: DISASSEMBLY

1. SEPARATION OF TRANSMISSION

S3M0190A

(1) Operating cylinder

(2) Release lever

(3) Release bearing

(4) Release lever sealing(5) Bolt

(6) Main shaft rear plate

(7) Transmission case

(8) Drive pinion ASSY(9) Main shaft ASSY

(10) Front differential

1) Remove clutch release lever.

B3M0336I

(A) Clutch release lever

(B) Release bearing

2) Remove transfer case assembly.

S3M0099

15

[W2A1]3-1SERVICE PROCEDURE

2. Transmission Case

Page 484 of 1456

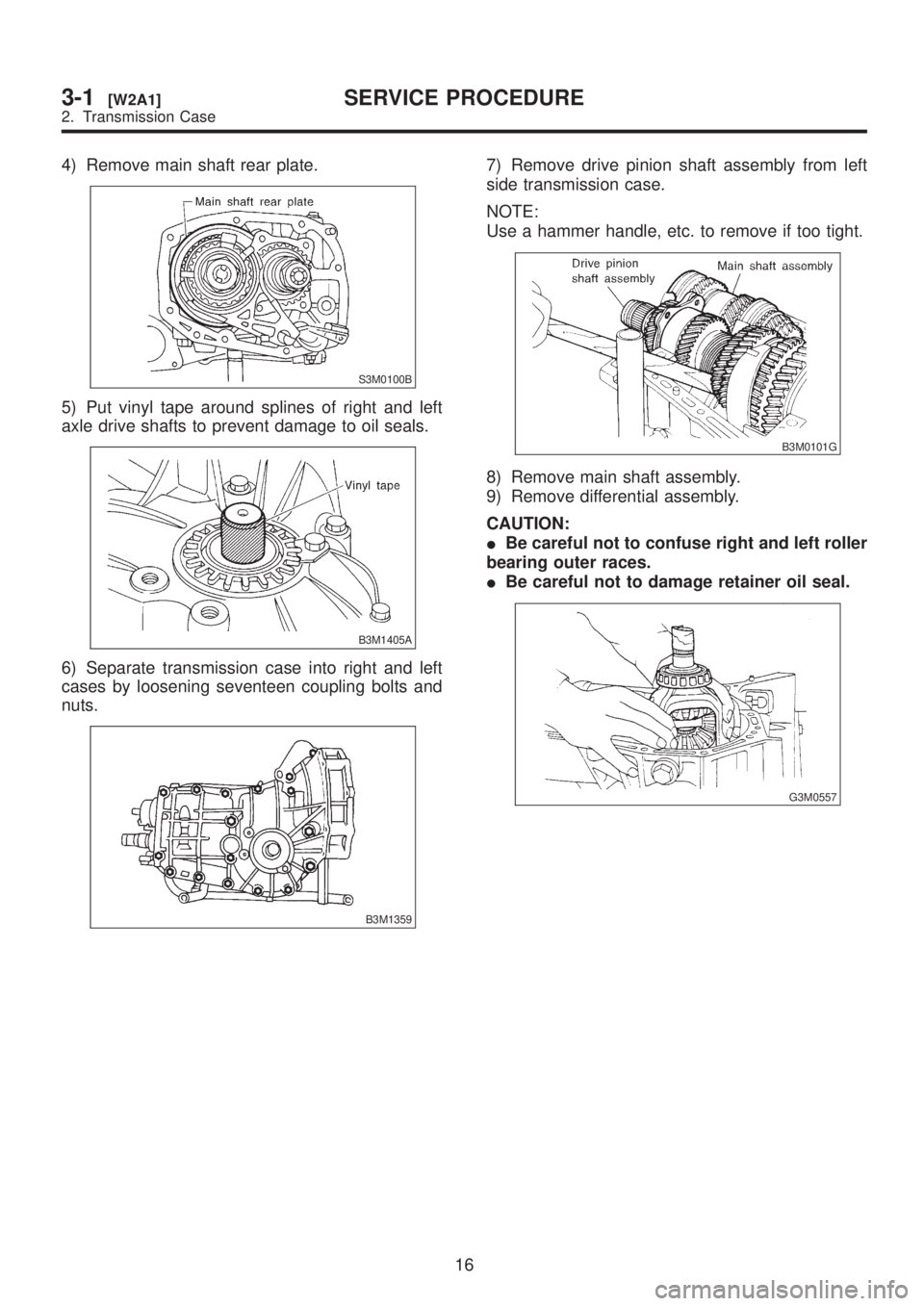

4) Remove main shaft rear plate.

S3M0100B

5) Put vinyl tape around splines of right and left

axle drive shafts to prevent damage to oil seals.

B3M1405A

6) Separate transmission case into right and left

cases by loosening seventeen coupling bolts and

nuts.

B3M1359

7) Remove drive pinion shaft assembly from left

side transmission case.

NOTE:

Use a hammer handle, etc. to remove if too tight.

B3M0101G

8) Remove main shaft assembly.

9) Remove differential assembly.

CAUTION:

IBe careful not to confuse right and left roller

bearing outer races.

IBe careful not to damage retainer oil seal.

G3M0557

16

3-1[W2A1]SERVICE PROCEDURE

2. Transmission Case

Page 485 of 1456

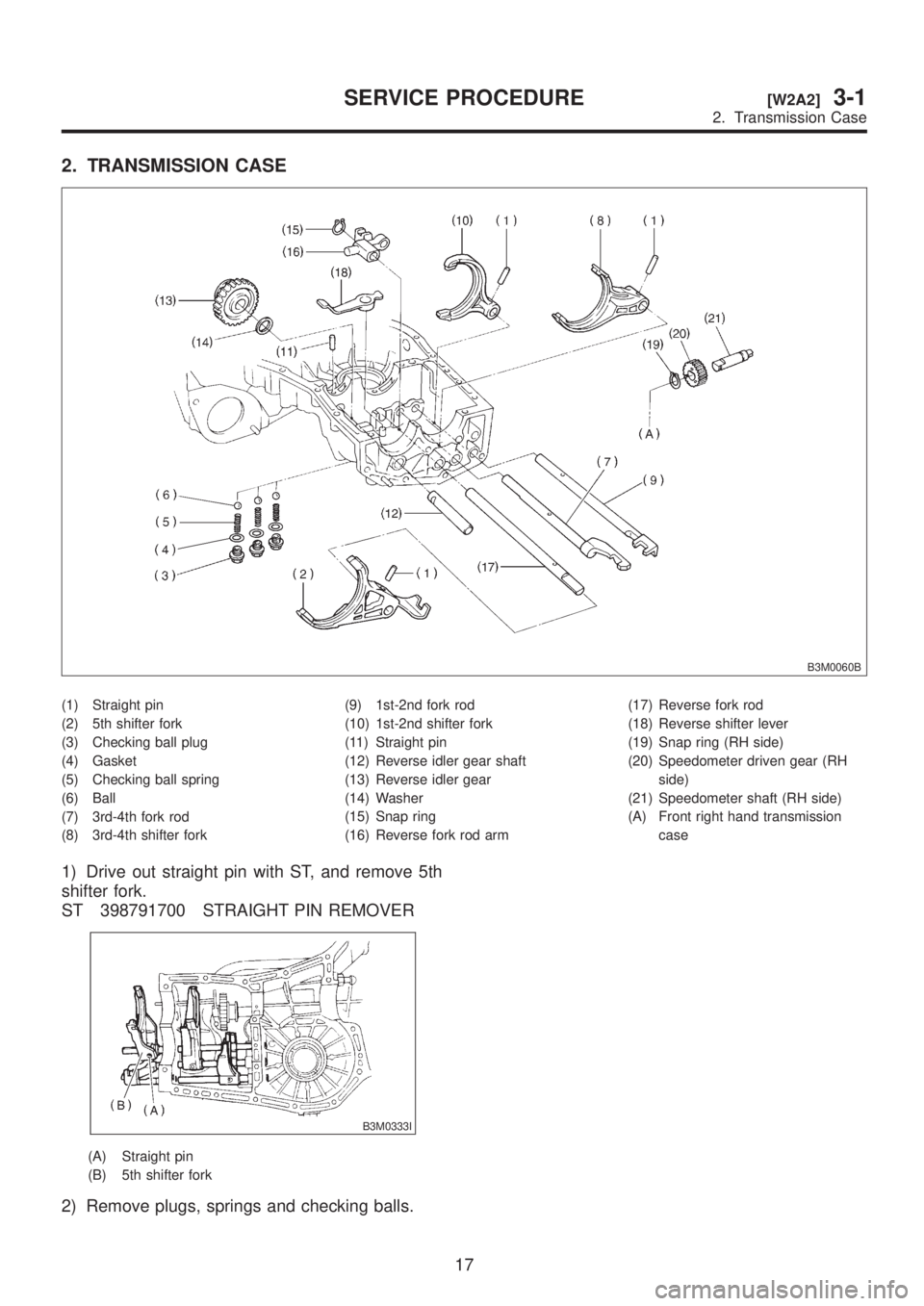

2. TRANSMISSION CASE

B3M0060B

(1) Straight pin

(2) 5th shifter fork

(3) Checking ball plug

(4) Gasket

(5) Checking ball spring

(6) Ball

(7) 3rd-4th fork rod

(8) 3rd-4th shifter fork(9) 1st-2nd fork rod

(10) 1st-2nd shifter fork

(11) Straight pin

(12) Reverse idler gear shaft

(13) Reverse idler gear

(14) Washer

(15) Snap ring

(16) Reverse fork rod arm(17) Reverse fork rod

(18) Reverse shifter lever

(19) Snap ring (RH side)

(20) Speedometer driven gear (RH

side)

(21) Speedometer shaft (RH side)

(A) Front right hand transmission

case

1) Drive out straight pin with ST, and remove 5th

shifter fork.

ST 398791700 STRAIGHT PIN REMOVER

B3M0333I

(A) Straight pin

(B) 5th shifter fork

2) Remove plugs, springs and checking balls.

17

[W2A2]3-1SERVICE PROCEDURE

2. Transmission Case

Page 486 of 1456

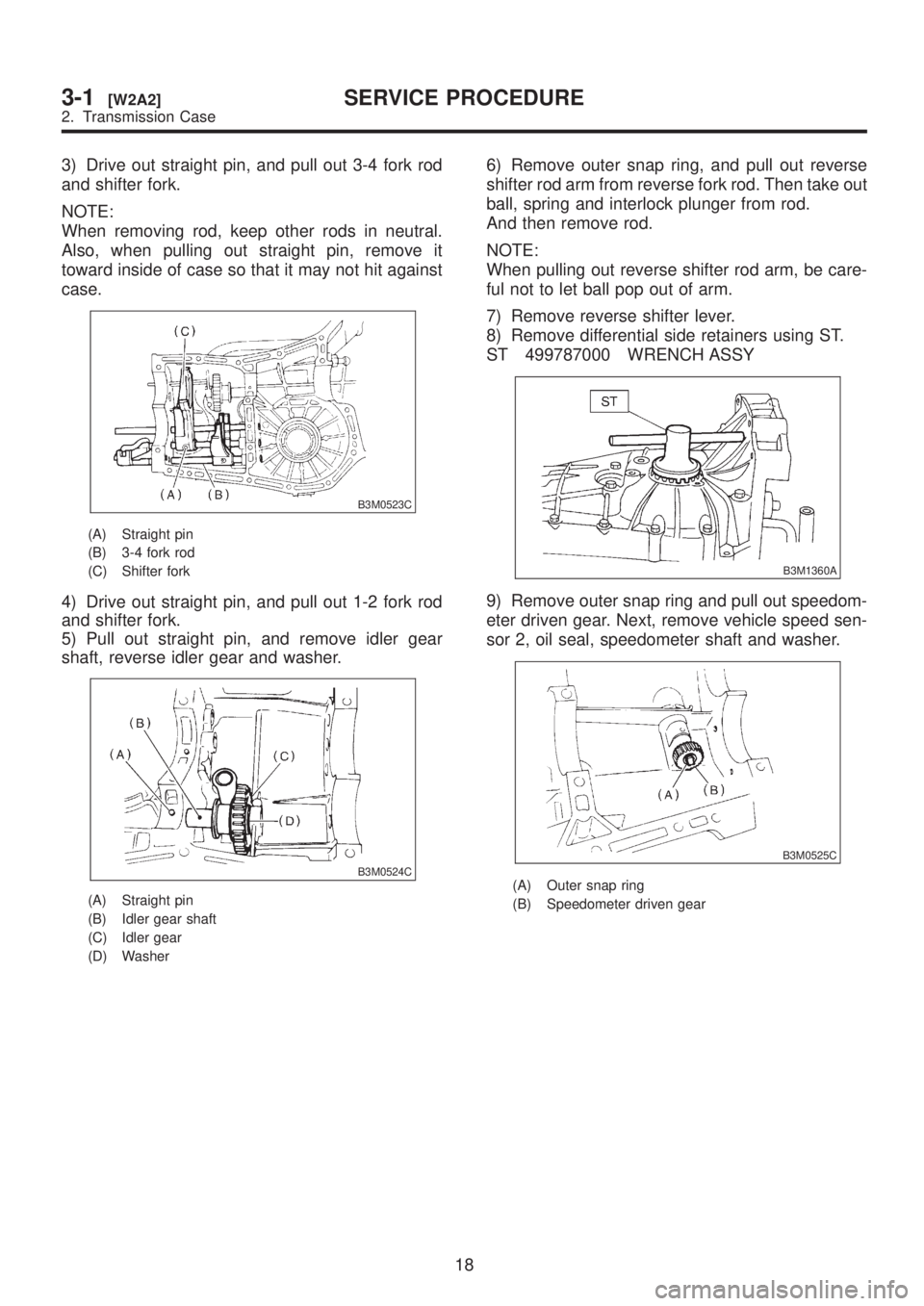

3) Drive out straight pin, and pull out 3-4 fork rod

and shifter fork.

NOTE:

When removing rod, keep other rods in neutral.

Also, when pulling out straight pin, remove it

toward inside of case so that it may not hit against

case.

B3M0523C

(A) Straight pin

(B) 3-4 fork rod

(C) Shifter fork

4) Drive out straight pin, and pull out 1-2 fork rod

and shifter fork.

5) Pull out straight pin, and remove idler gear

shaft, reverse idler gear and washer.

B3M0524C

(A) Straight pin

(B) Idler gear shaft

(C) Idler gear

(D) Washer

6) Remove outer snap ring, and pull out reverse

shifter rod arm from reverse fork rod. Then take out

ball, spring and interlock plunger from rod.

And then remove rod.

NOTE:

When pulling out reverse shifter rod arm, be care-

ful not to let ball pop out of arm.

7) Remove reverse shifter lever.

8) Remove differential side retainers using ST.

ST 499787000 WRENCH ASSY

B3M1360A

9) Remove outer snap ring and pull out speedom-

eter driven gear. Next, remove vehicle speed sen-

sor 2, oil seal, speedometer shaft and washer.

B3M0525C

(A) Outer snap ring

(B) Speedometer driven gear

18

3-1[W2A2]SERVICE PROCEDURE

2. Transmission Case

Page 487 of 1456

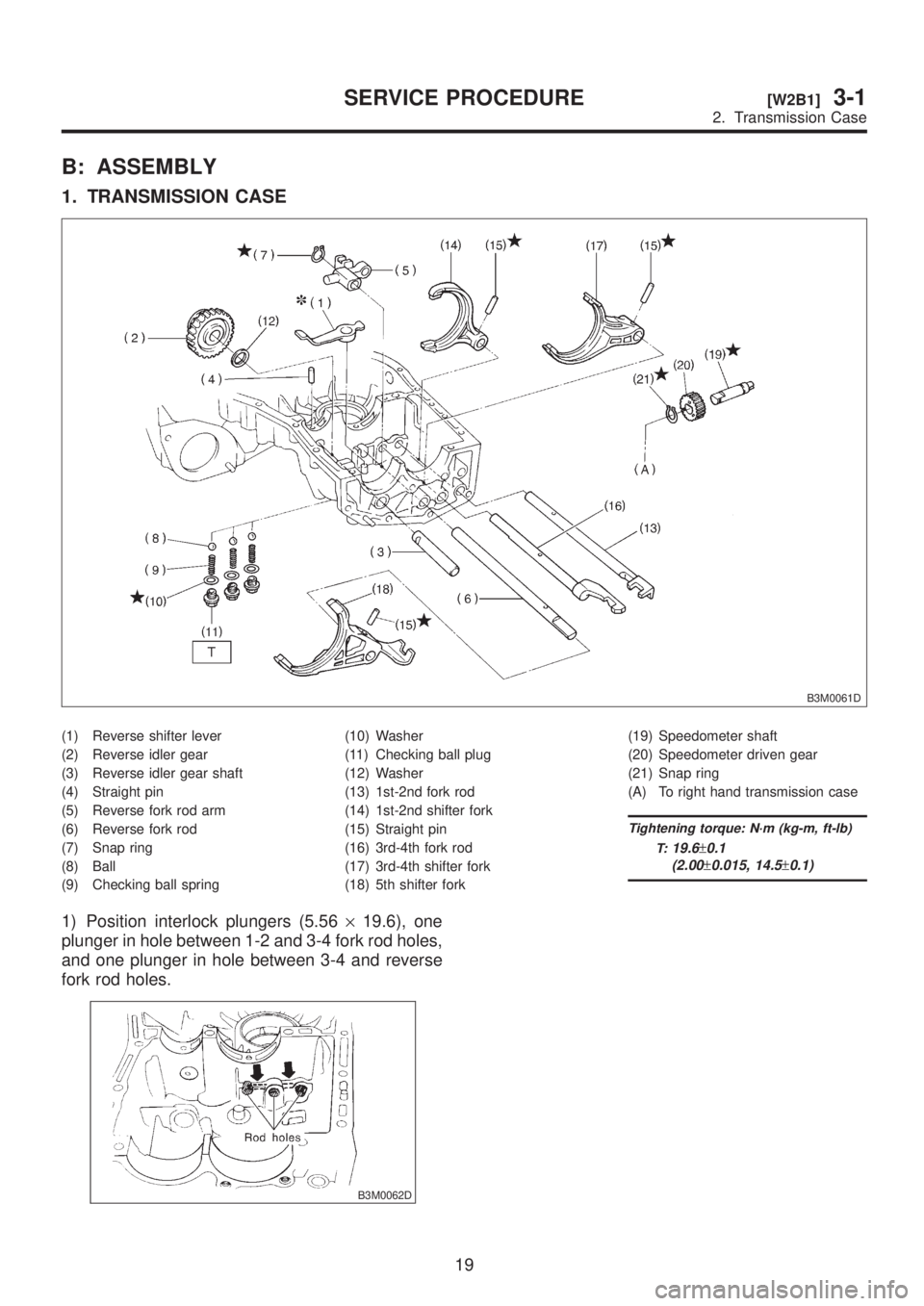

B: ASSEMBLY

1. TRANSMISSION CASE

B3M0061D

(1) Reverse shifter lever

(2) Reverse idler gear

(3) Reverse idler gear shaft

(4) Straight pin

(5) Reverse fork rod arm

(6) Reverse fork rod

(7) Snap ring

(8) Ball

(9) Checking ball spring(10) Washer

(11) Checking ball plug

(12) Washer

(13) 1st-2nd fork rod

(14) 1st-2nd shifter fork

(15) Straight pin

(16) 3rd-4th fork rod

(17) 3rd-4th shifter fork

(18) 5th shifter fork(19) Speedometer shaft

(20) Speedometer driven gear

(21) Snap ring

(A) To right hand transmission case

Tightening torque: N´m (kg-m, ft-lb)

T:

19.6±0.1

(2.00

±0.015, 14.5±0.1)

1) Position interlock plungers (5.56´19.6), one

plunger in hole between 1-2 and 3-4 fork rod holes,

and one plunger in hole between 3-4 and reverse

fork rod holes.

B3M0062D

19

[W2B1]3-1SERVICE PROCEDURE

2. Transmission Case

Page 488 of 1456

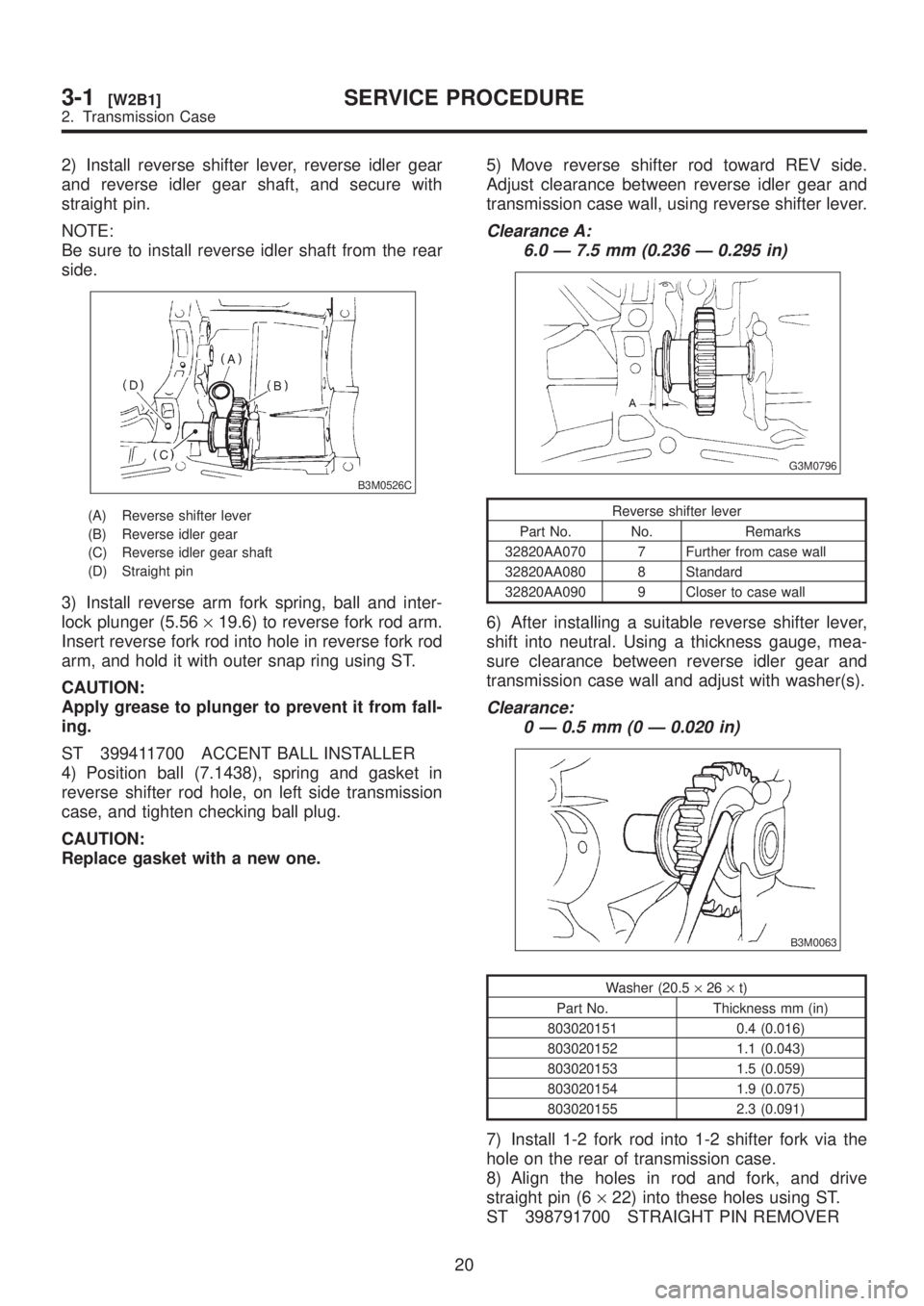

2) Install reverse shifter lever, reverse idler gear

and reverse idler gear shaft, and secure with

straight pin.

NOTE:

Be sure to install reverse idler shaft from the rear

side.

B3M0526C

(A) Reverse shifter lever

(B) Reverse idler gear

(C) Reverse idler gear shaft

(D) Straight pin

3) Install reverse arm fork spring, ball and inter-

lock plunger (5.56´19.6) to reverse fork rod arm.

Insert reverse fork rod into hole in reverse fork rod

arm, and hold it with outer snap ring using ST.

CAUTION:

Apply grease to plunger to prevent it from fall-

ing.

ST 399411700 ACCENT BALL INSTALLER

4) Position ball (7.1438), spring and gasket in

reverse shifter rod hole, on left side transmission

case, and tighten checking ball plug.

CAUTION:

Replace gasket with a new one.5) Move reverse shifter rod toward REV side.

Adjust clearance between reverse idler gear and

transmission case wall, using reverse shifter lever.

Clearance A:

6.0 Ð 7.5 mm (0.236 Ð 0.295 in)

G3M0796

Reverse shifter lever

Part No. No. Remarks

32820AA070 7 Further from case wall

32820AA080 8 Standard

32820AA090 9 Closer to case wall

6) After installing a suitable reverse shifter lever,

shift into neutral. Using a thickness gauge, mea-

sure clearance between reverse idler gear and

transmission case wall and adjust with washer(s).

Clearance:

0 Ð 0.5 mm (0 Ð 0.020 in)

B3M0063

Washer (20.5´26´t)

Part No. Thickness mm (in)

803020151 0.4 (0.016)

803020152 1.1 (0.043)

803020153 1.5 (0.059)

803020154 1.9 (0.075)

803020155 2.3 (0.091)

7) Install 1-2 fork rod into 1-2 shifter fork via the

hole on the rear of transmission case.

8) Align the holes in rod and fork, and drive

straight pin (6´22) into these holes using ST.

ST 398791700 STRAIGHT PIN REMOVER

20

3-1[W2B1]SERVICE PROCEDURE

2. Transmission Case

Page 489 of 1456

CAUTION:

Replace straight pin with a new one.

NOTE:

ISet other rods to neutral.

IMake sure interlock plunger (5.56´19.6) is on

the 3-4 fork rod side.

9) Install interlock plunger (3´11.9) onto 3-4 fork

rod.

CAUTION:

Apply a coat of grease to plunger to prevent it

from falling.

10) Install 3-4 fork rod into 3-4 shifter fork via the

hole on the rear of transmission case.

11) Align the holes in rod and fork, and drive

straight pin (6´22) into these holes.

ST 398791700 STRAIGHT PIN REMOVER

CAUTION:

Replace straight pin with a new one.

NOTE:

ISet reverse fork rod to neutral.

IMake sure interlock plunger (installed before) is

on the reverse fork rod side.

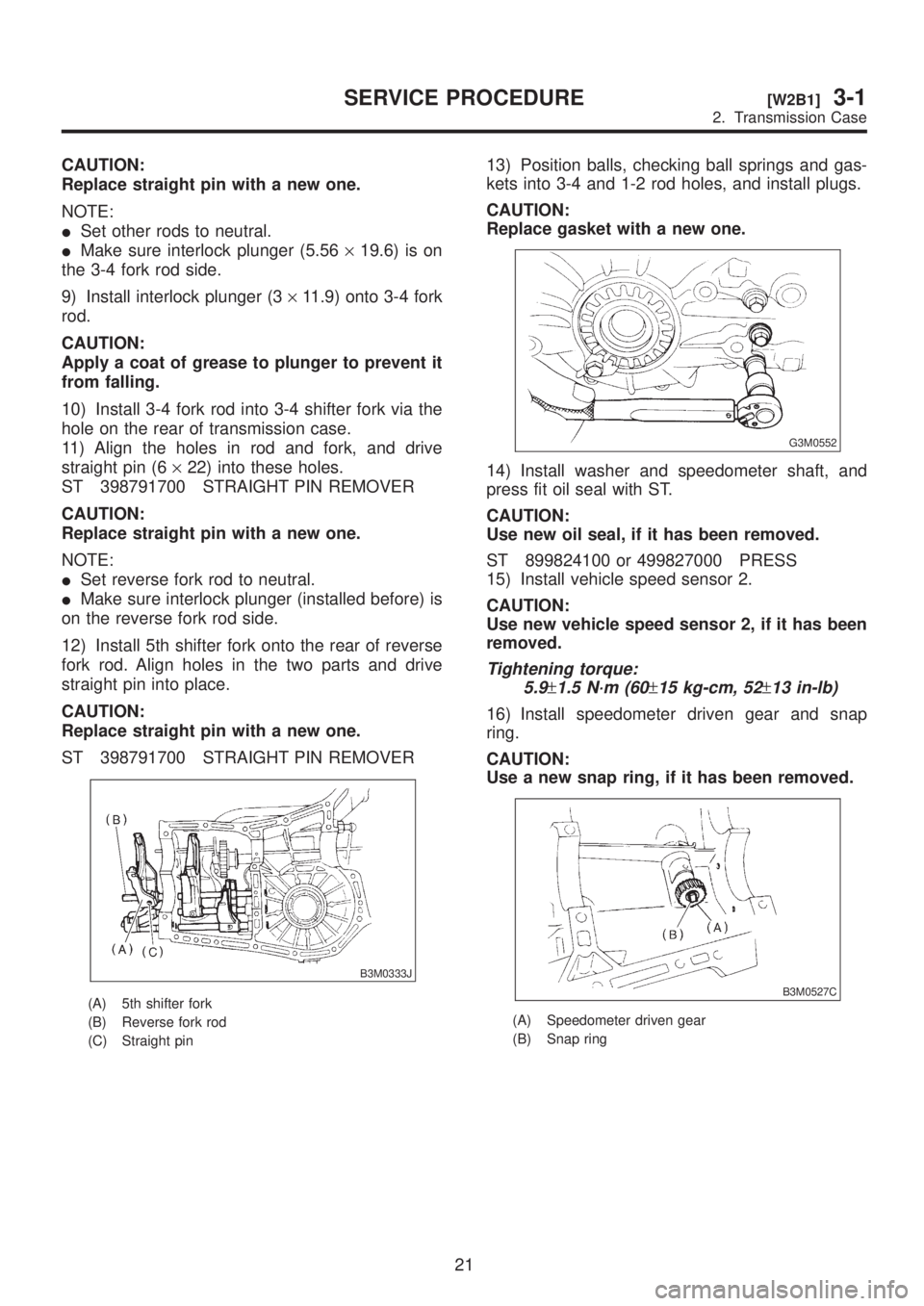

12) Install 5th shifter fork onto the rear of reverse

fork rod. Align holes in the two parts and drive

straight pin into place.

CAUTION:

Replace straight pin with a new one.

ST 398791700 STRAIGHT PIN REMOVER

B3M0333J

(A) 5th shifter fork

(B) Reverse fork rod

(C) Straight pin

13) Position balls, checking ball springs and gas-

kets into 3-4 and 1-2 rod holes, and install plugs.

CAUTION:

Replace gasket with a new one.

G3M0552

14) Install washer and speedometer shaft, and

press fit oil seal with ST.

CAUTION:

Use new oil seal, if it has been removed.

ST 899824100 or 499827000 PRESS

15) Install vehicle speed sensor 2.

CAUTION:

Use new vehicle speed sensor 2, if it has been

removed.

Tightening torque:

5.9

±1.5 N´m (60±15 kg-cm, 52±13 in-lb)

16) Install speedometer driven gear and snap

ring.

CAUTION:

Use a new snap ring, if it has been removed.

B3M0527C

(A) Speedometer driven gear

(B) Snap ring

21

[W2B1]3-1SERVICE PROCEDURE

2. Transmission Case

Page 490 of 1456

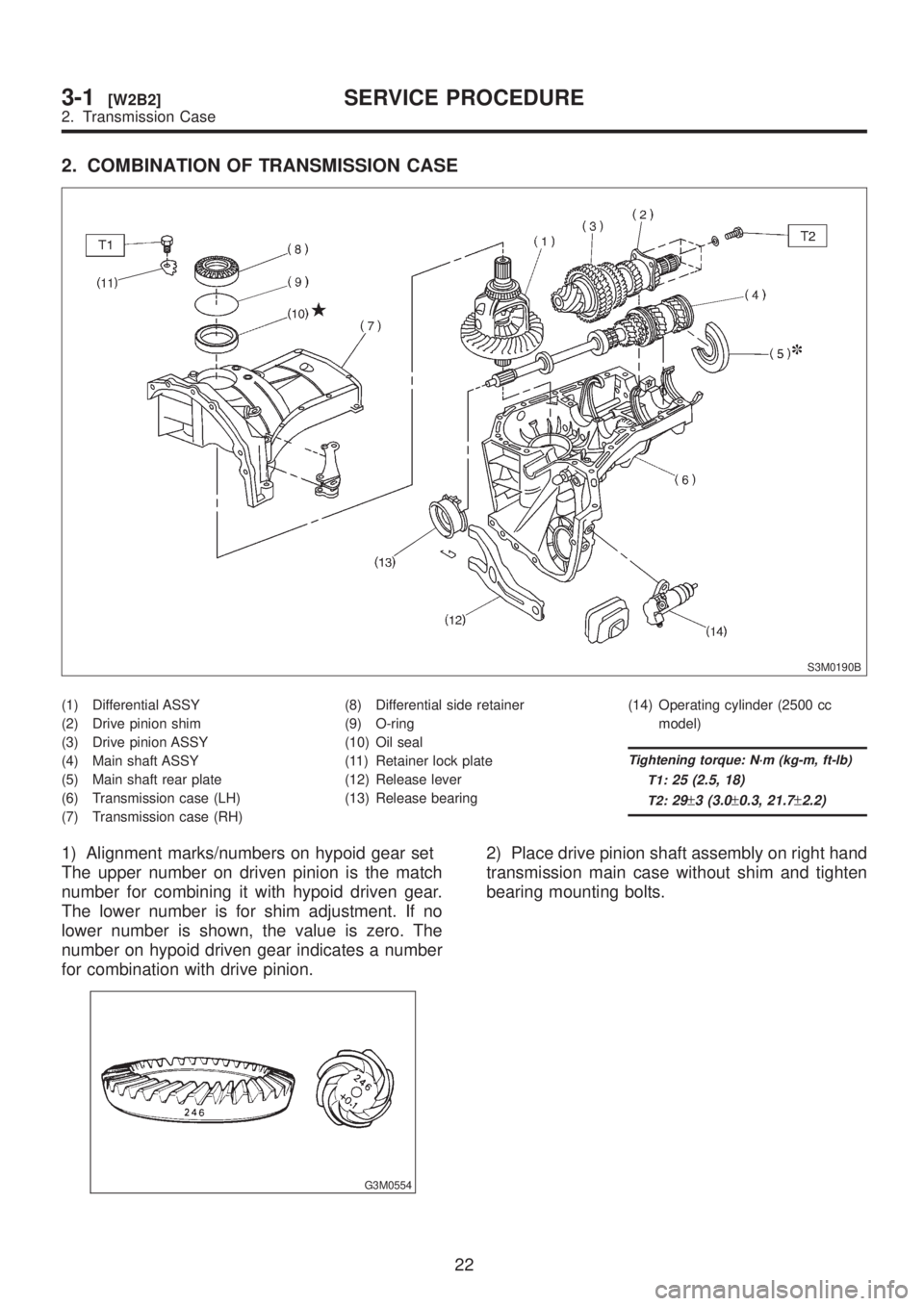

2. COMBINATION OF TRANSMISSION CASE

S3M0190B

(1) Differential ASSY

(2) Drive pinion shim

(3) Drive pinion ASSY

(4) Main shaft ASSY

(5) Main shaft rear plate

(6) Transmission case (LH)

(7) Transmission case (RH)(8) Differential side retainer

(9) O-ring

(10) Oil seal

(11) Retainer lock plate

(12) Release lever

(13) Release bearing(14) Operating cylinder (2500 cc

model)

Tightening torque: N´m (kg-m, ft-lb)

T1:

25 (2.5, 18)

T2:29±3 (3.0±0.3, 21.7±2.2)

1) Alignment marks/numbers on hypoid gear set

The upper number on driven pinion is the match

number for combining it with hypoid driven gear.

The lower number is for shim adjustment. If no

lower number is shown, the value is zero. The

number on hypoid driven gear indicates a number

for combination with drive pinion.

G3M0554

2) Place drive pinion shaft assembly on right hand

transmission main case without shim and tighten

bearing mounting bolts.

22

3-1[W2B2]SERVICE PROCEDURE

2. Transmission Case