SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 461 of 1456

12) Install stabilizer clamps onto front crossmem-

ber.

Tightening torque:

25

±4 N´m (2.5±0.4 kg-m, 18.1±2.9 ft-lb)

G2M0323

13) Install gear shift rod and stay. (MT vehicles)

(1) Install gear shift rod onto transmission.

G3M0697

(2) Install stay onto transmission.

(3) Install spring.

14) Install shift selector cable onto selector lever.

(AT vehicles)

(1) Install selector cable into selector lever.

(2) Install cable bracket onto body.

NOTE:

Tighten selector cable adjusting and lock nut after

checking selector lever operation.

S3M0013A

15) Install ATF level gauge guide, and ATF cooler

hoses onto pipe. (AT vehicles)

G2M0317

16) Install propeller shaft.

(1) Install propeller shaft into transmission.

(2) Tighten bolts which install propeller shaft

onto companion flange of rear differential.

Tightening torque:

31

±8 N´m (3.2±0.8 kg-m, 23.1±5.8 ft-lb)

G3M0023

(3) Install center bearing bracket on body.

Tightening torque:

52

±5 N´m (5.3±0.5 kg-m, 38.3±3.6 ft-lb)

S2M0219A

17) Install exhaust system.

29

[W2C0]2-11SERVICE PROCEDURE

2. Transmission

Page 462 of 1456

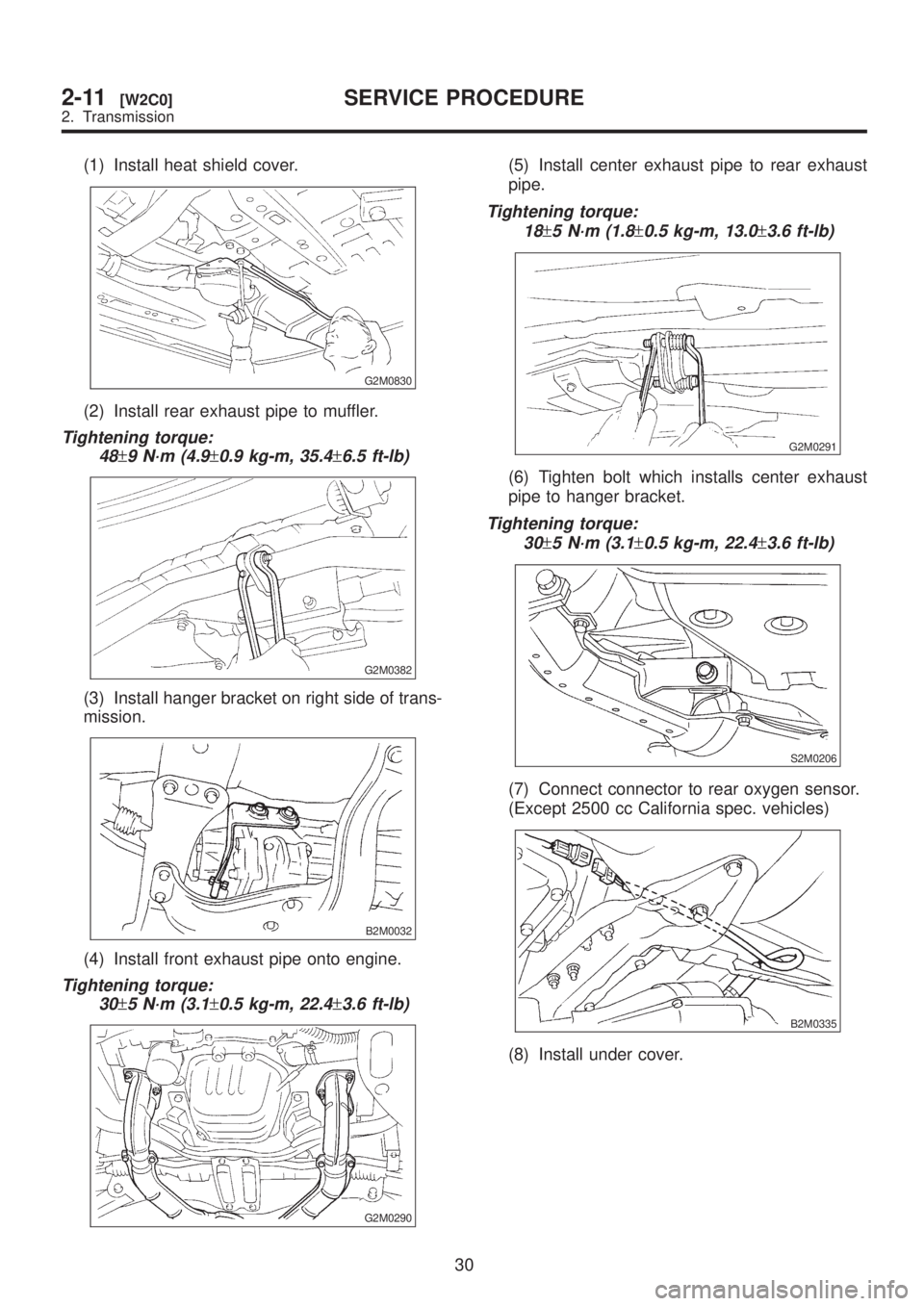

(1) Install heat shield cover.

G2M0830

(2) Install rear exhaust pipe to muffler.

Tightening torque:

48

±9 N´m (4.9±0.9 kg-m, 35.4±6.5 ft-lb)

G2M0382

(3) Install hanger bracket on right side of trans-

mission.

B2M0032

(4) Install front exhaust pipe onto engine.

Tightening torque:

30

±5 N´m (3.1±0.5 kg-m, 22.4±3.6 ft-lb)

G2M0290

(5) Install center exhaust pipe to rear exhaust

pipe.

Tightening torque:

18

±5 N´m (1.8±0.5 kg-m, 13.0±3.6 ft-lb)

G2M0291

(6) Tighten bolt which installs center exhaust

pipe to hanger bracket.

Tightening torque:

30

±5 N´m (3.1±0.5 kg-m, 22.4±3.6 ft-lb)

S2M0206

(7) Connect connector to rear oxygen sensor.

(Except 2500 cc California spec. vehicles)

B2M0335

(8) Install under cover.

30

2-11[W2C0]SERVICE PROCEDURE

2. Transmission

Page 463 of 1456

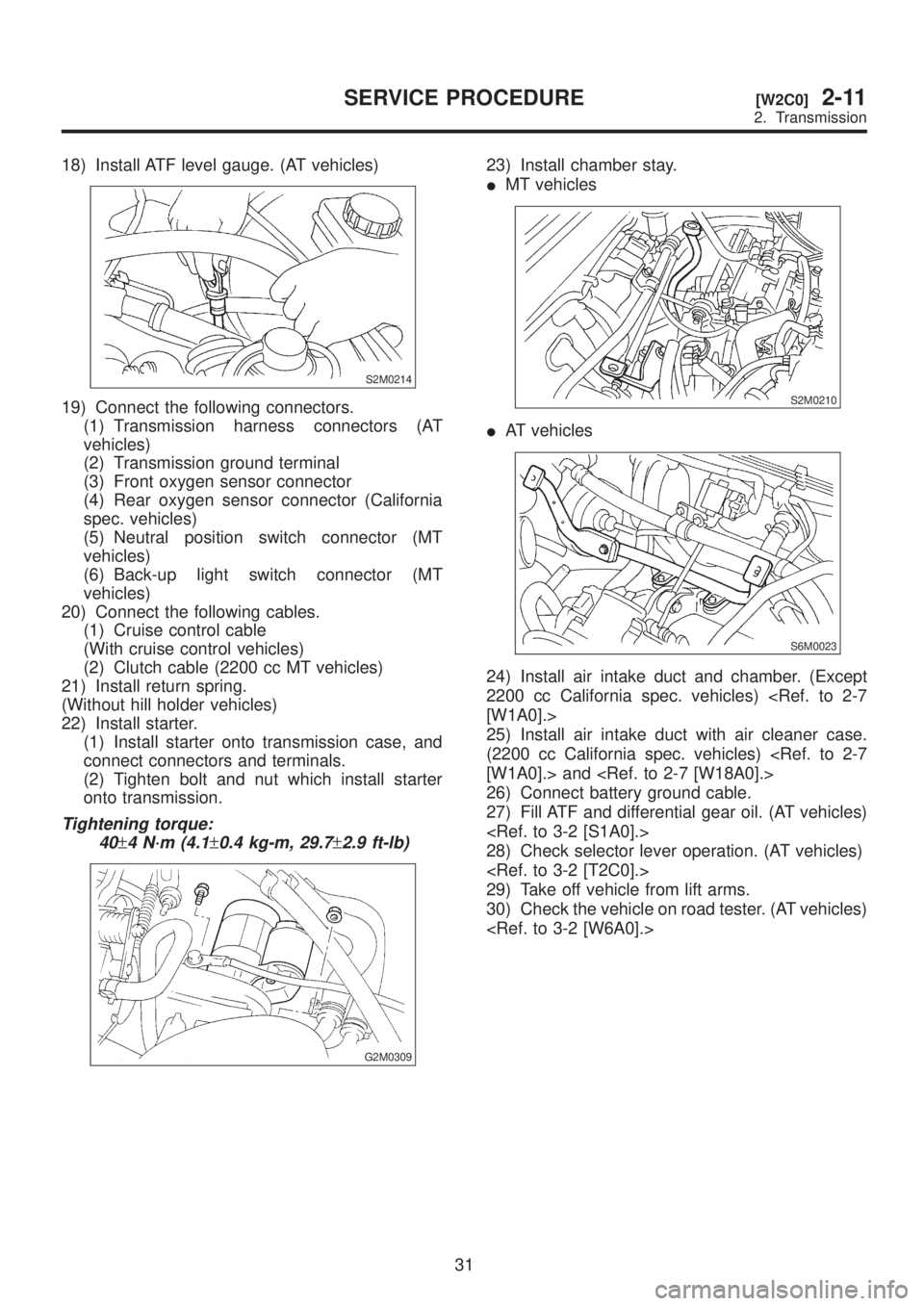

18) Install ATF level gauge. (AT vehicles)

S2M0214

19) Connect the following connectors.

(1) Transmission harness connectors (AT

vehicles)

(2) Transmission ground terminal

(3) Front oxygen sensor connector

(4) Rear oxygen sensor connector (California

spec. vehicles)

(5) Neutral position switch connector (MT

vehicles)

(6) Back-up light switch connector (MT

vehicles)

20) Connect the following cables.

(1) Cruise control cable

(With cruise control vehicles)

(2) Clutch cable (2200 cc MT vehicles)

21) Install return spring.

(Without hill holder vehicles)

22) Install starter.

(1) Install starter onto transmission case, and

connect connectors and terminals.

(2) Tighten bolt and nut which install starter

onto transmission.

Tightening torque:

40

±4 N´m (4.1±0.4 kg-m, 29.7±2.9 ft-lb)

G2M0309

23) Install chamber stay.

IMT vehicles

S2M0210

IAT vehicles

S6M0023

24) Install air intake duct and chamber. (Except

2200 cc California spec. vehicles)

25) Install air intake duct with air cleaner case.

(2200 cc California spec. vehicles)

26) Connect battery ground cable.

27) Fill ATF and differential gear oil. (AT vehicles)

28) Check selector lever operation. (AT vehicles)

29) Take off vehicle from lift arms.

30) Check the vehicle on road tester. (AT vehicles)

31

[W2C0]2-11SERVICE PROCEDURE

2. Transmission

Page 464 of 1456

MEMO:

32

2-11SERVICE PROCEDURE

Page 465 of 1456

1. Manual Transmission and Differential

ItemModel

AWD

2200 cc 2500 cc 2500 cc OUTBACK

Type 5-forward speeds with synchromesh and 1-reverse

Transmission gear ratio1st 3.545

2nd 2.111

3rd 1.448

4th 1.088

5th 0.780 0.871

Reverse 3.333

Front reduction

gearFinalType of gear Hypoid

Gear ratio 3.900 4.111

Rear reduction

gearTransferType of gear Helical

Gear ratio 1.000

FinalType of gear Hypoid

Gear ratio 3.900 4.111

Front differential Type and number of gear Straight bevel gear (Bevel pinion: 2, Bevel gear: 2)

Center differential Type and number of gearStraight bevel gear (Bevel pinion: 2, Bevel gear: 2 and vis-

cous coupling)

Transmission gear oilGL-5

Transmission oil capacity 3.5(3.7 US qt, 3.1 Imp qt)

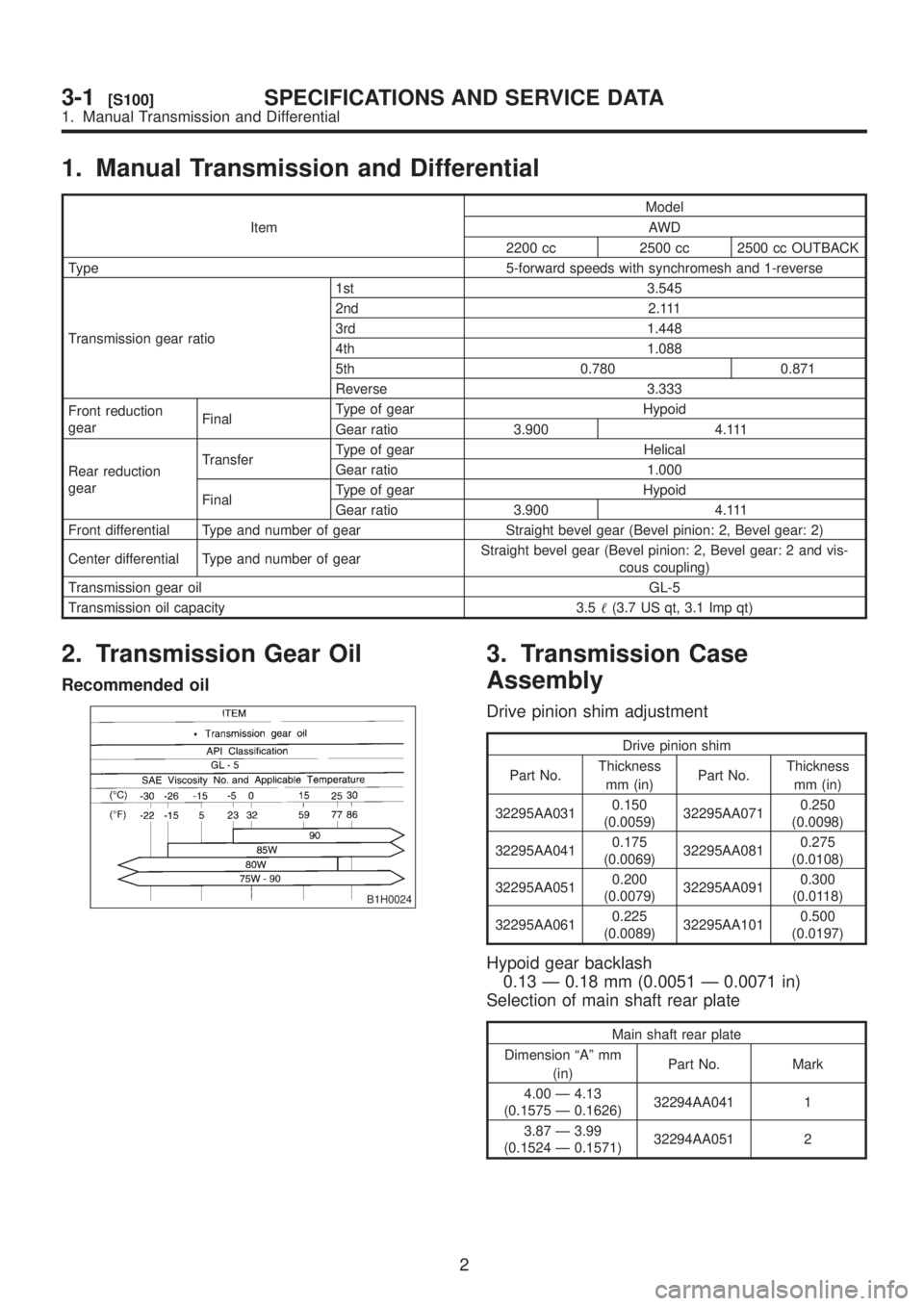

2. Transmission Gear Oil

Recommended oil

B1H0024

3. Transmission Case

Assembly

Drive pinion shim adjustment

Drive pinion shim

Part No.Thickness

mm (in)Part No.Thickness

mm (in)

32295AA0310.150

(0.0059)32295AA0710.250

(0.0098)

32295AA0410.175

(0.0069)32295AA0810.275

(0.0108)

32295AA0510.200

(0.0079)32295AA0910.300

(0.0118)

32295AA0610.225

(0.0089)32295AA1010.500

(0.0197)

Hypoid gear backlash

0.13 Ð 0.18 mm (0.0051 Ð 0.0071 in)

Selection of main shaft rear plate

Main shaft rear plate

Dimension ªAº mm

(in)Part No. Mark

4.00 Ð 4.13

(0.1575 Ð 0.1626)32294AA041 1

3.87 Ð 3.99

(0.1524 Ð 0.1571)32294AA051 2

2

3-1[S100]SPECIFICATIONS AND SERVICE DATA

1. Manual Transmission and Differential

Page 466 of 1456

1. Manual Transmission and Differential

ItemModel

AWD

2200 cc 2500 cc 2500 cc OUTBACK

Type 5-forward speeds with synchromesh and 1-reverse

Transmission gear ratio1st 3.545

2nd 2.111

3rd 1.448

4th 1.088

5th 0.780 0.871

Reverse 3.333

Front reduction

gearFinalType of gear Hypoid

Gear ratio 3.900 4.111

Rear reduction

gearTransferType of gear Helical

Gear ratio 1.000

FinalType of gear Hypoid

Gear ratio 3.900 4.111

Front differential Type and number of gear Straight bevel gear (Bevel pinion: 2, Bevel gear: 2)

Center differential Type and number of gearStraight bevel gear (Bevel pinion: 2, Bevel gear: 2 and vis-

cous coupling)

Transmission gear oilGL-5

Transmission oil capacity 3.5(3.7 US qt, 3.1 Imp qt)

2. Transmission Gear Oil

Recommended oil

B1H0024

3. Transmission Case

Assembly

Drive pinion shim adjustment

Drive pinion shim

Part No.Thickness

mm (in)Part No.Thickness

mm (in)

32295AA0310.150

(0.0059)32295AA0710.250

(0.0098)

32295AA0410.175

(0.0069)32295AA0810.275

(0.0108)

32295AA0510.200

(0.0079)32295AA0910.300

(0.0118)

32295AA0610.225

(0.0089)32295AA1010.500

(0.0197)

Hypoid gear backlash

0.13 Ð 0.18 mm (0.0051 Ð 0.0071 in)

Selection of main shaft rear plate

Main shaft rear plate

Dimension ªAº mm

(in)Part No. Mark

4.00 Ð 4.13

(0.1575 Ð 0.1626)32294AA041 1

3.87 Ð 3.99

(0.1524 Ð 0.1571)32294AA051 2

2

3-1[S100]SPECIFICATIONS AND SERVICE DATA

1. Manual Transmission and Differential

Page 467 of 1456

1. Manual Transmission and Differential

ItemModel

AWD

2200 cc 2500 cc 2500 cc OUTBACK

Type 5-forward speeds with synchromesh and 1-reverse

Transmission gear ratio1st 3.545

2nd 2.111

3rd 1.448

4th 1.088

5th 0.780 0.871

Reverse 3.333

Front reduction

gearFinalType of gear Hypoid

Gear ratio 3.900 4.111

Rear reduction

gearTransferType of gear Helical

Gear ratio 1.000

FinalType of gear Hypoid

Gear ratio 3.900 4.111

Front differential Type and number of gear Straight bevel gear (Bevel pinion: 2, Bevel gear: 2)

Center differential Type and number of gearStraight bevel gear (Bevel pinion: 2, Bevel gear: 2 and vis-

cous coupling)

Transmission gear oilGL-5

Transmission oil capacity 3.5(3.7 US qt, 3.1 Imp qt)

2. Transmission Gear Oil

Recommended oil

B1H0024

3. Transmission Case

Assembly

Drive pinion shim adjustment

Drive pinion shim

Part No.Thickness

mm (in)Part No.Thickness

mm (in)

32295AA0310.150

(0.0059)32295AA0710.250

(0.0098)

32295AA0410.175

(0.0069)32295AA0810.275

(0.0108)

32295AA0510.200

(0.0079)32295AA0910.300

(0.0118)

32295AA0610.225

(0.0089)32295AA1010.500

(0.0197)

Hypoid gear backlash

0.13 Ð 0.18 mm (0.0051 Ð 0.0071 in)

Selection of main shaft rear plate

Main shaft rear plate

Dimension ªAº mm

(in)Part No. Mark

4.00 Ð 4.13

(0.1575 Ð 0.1626)32294AA041 1

3.87 Ð 3.99

(0.1524 Ð 0.1571)32294AA051 2

2

3-1[S100]SPECIFICATIONS AND SERVICE DATA

1. Manual Transmission and Differential

Page 468 of 1456

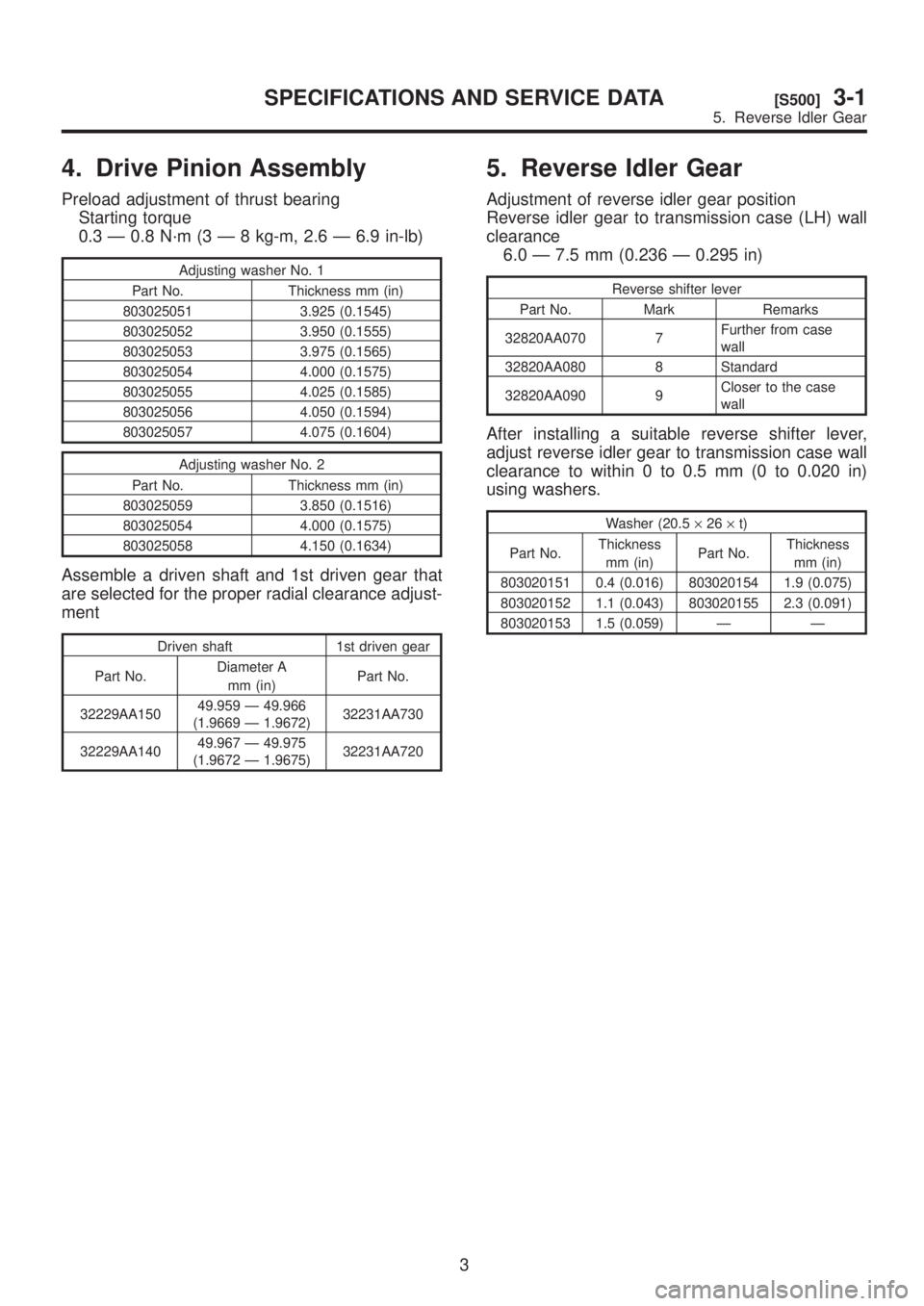

4. Drive Pinion Assembly

Preload adjustment of thrust bearing

Starting torque

0.3 Ð 0.8 N´m (3 Ð 8 kg-m, 2.6 Ð 6.9 in-lb)

Adjusting washer No. 1

Part No. Thickness mm (in)

803025051 3.925 (0.1545)

803025052 3.950 (0.1555)

803025053 3.975 (0.1565)

803025054 4.000 (0.1575)

803025055 4.025 (0.1585)

803025056 4.050 (0.1594)

803025057 4.075 (0.1604)

Adjusting washer No. 2

Part No. Thickness mm (in)

803025059 3.850 (0.1516)

803025054 4.000 (0.1575)

803025058 4.150 (0.1634)

Assemble a driven shaft and 1st driven gear that

are selected for the proper radial clearance adjust-

ment

Driven shaft 1st driven gear

Part No.Diameter A

mm (in)Part No.

32229AA15049.959 Ð 49.966

(1.9669 Ð 1.9672)32231AA730

32229AA14049.967 Ð 49.975

(1.9672 Ð 1.9675)32231AA720

5. Reverse Idler Gear

Adjustment of reverse idler gear position

Reverse idler gear to transmission case (LH) wall

clearance

6.0 Ð 7.5 mm (0.236 Ð 0.295 in)

Reverse shifter lever

Part No. Mark Remarks

32820AA070 7Further from case

wall

32820AA080 8 Standard

32820AA090 9Closer to the case

wall

After installing a suitable reverse shifter lever,

adjust reverse idler gear to transmission case wall

clearance to within 0 to 0.5 mm (0 to 0.020 in)

using washers.

Washer (20.5´26´t)

Part No.Thickness

mm (in)Part No.Thickness

mm (in)

803020151 0.4 (0.016) 803020154 1.9 (0.075)

803020152 1.1 (0.043) 803020155 2.3 (0.091)

803020153 1.5 (0.059) Ð Ð

3

[S500]3-1SPECIFICATIONS AND SERVICE DATA

5. Reverse Idler Gear

Page 469 of 1456

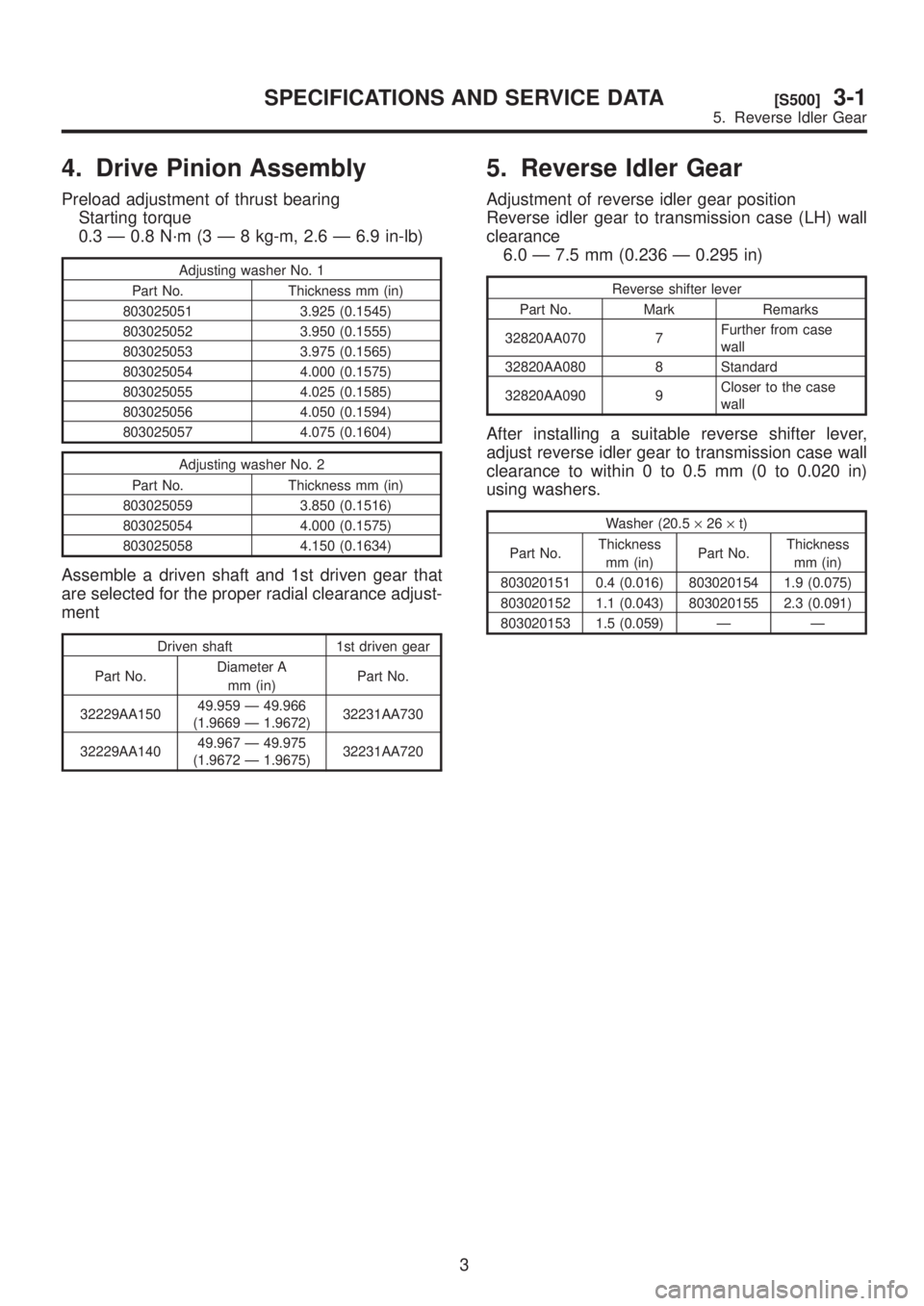

4. Drive Pinion Assembly

Preload adjustment of thrust bearing

Starting torque

0.3 Ð 0.8 N´m (3 Ð 8 kg-m, 2.6 Ð 6.9 in-lb)

Adjusting washer No. 1

Part No. Thickness mm (in)

803025051 3.925 (0.1545)

803025052 3.950 (0.1555)

803025053 3.975 (0.1565)

803025054 4.000 (0.1575)

803025055 4.025 (0.1585)

803025056 4.050 (0.1594)

803025057 4.075 (0.1604)

Adjusting washer No. 2

Part No. Thickness mm (in)

803025059 3.850 (0.1516)

803025054 4.000 (0.1575)

803025058 4.150 (0.1634)

Assemble a driven shaft and 1st driven gear that

are selected for the proper radial clearance adjust-

ment

Driven shaft 1st driven gear

Part No.Diameter A

mm (in)Part No.

32229AA15049.959 Ð 49.966

(1.9669 Ð 1.9672)32231AA730

32229AA14049.967 Ð 49.975

(1.9672 Ð 1.9675)32231AA720

5. Reverse Idler Gear

Adjustment of reverse idler gear position

Reverse idler gear to transmission case (LH) wall

clearance

6.0 Ð 7.5 mm (0.236 Ð 0.295 in)

Reverse shifter lever

Part No. Mark Remarks

32820AA070 7Further from case

wall

32820AA080 8 Standard

32820AA090 9Closer to the case

wall

After installing a suitable reverse shifter lever,

adjust reverse idler gear to transmission case wall

clearance to within 0 to 0.5 mm (0 to 0.020 in)

using washers.

Washer (20.5´26´t)

Part No.Thickness

mm (in)Part No.Thickness

mm (in)

803020151 0.4 (0.016) 803020154 1.9 (0.075)

803020152 1.1 (0.043) 803020155 2.3 (0.091)

803020153 1.5 (0.059) Ð Ð

3

[S500]3-1SPECIFICATIONS AND SERVICE DATA

5. Reverse Idler Gear

Page 470 of 1456

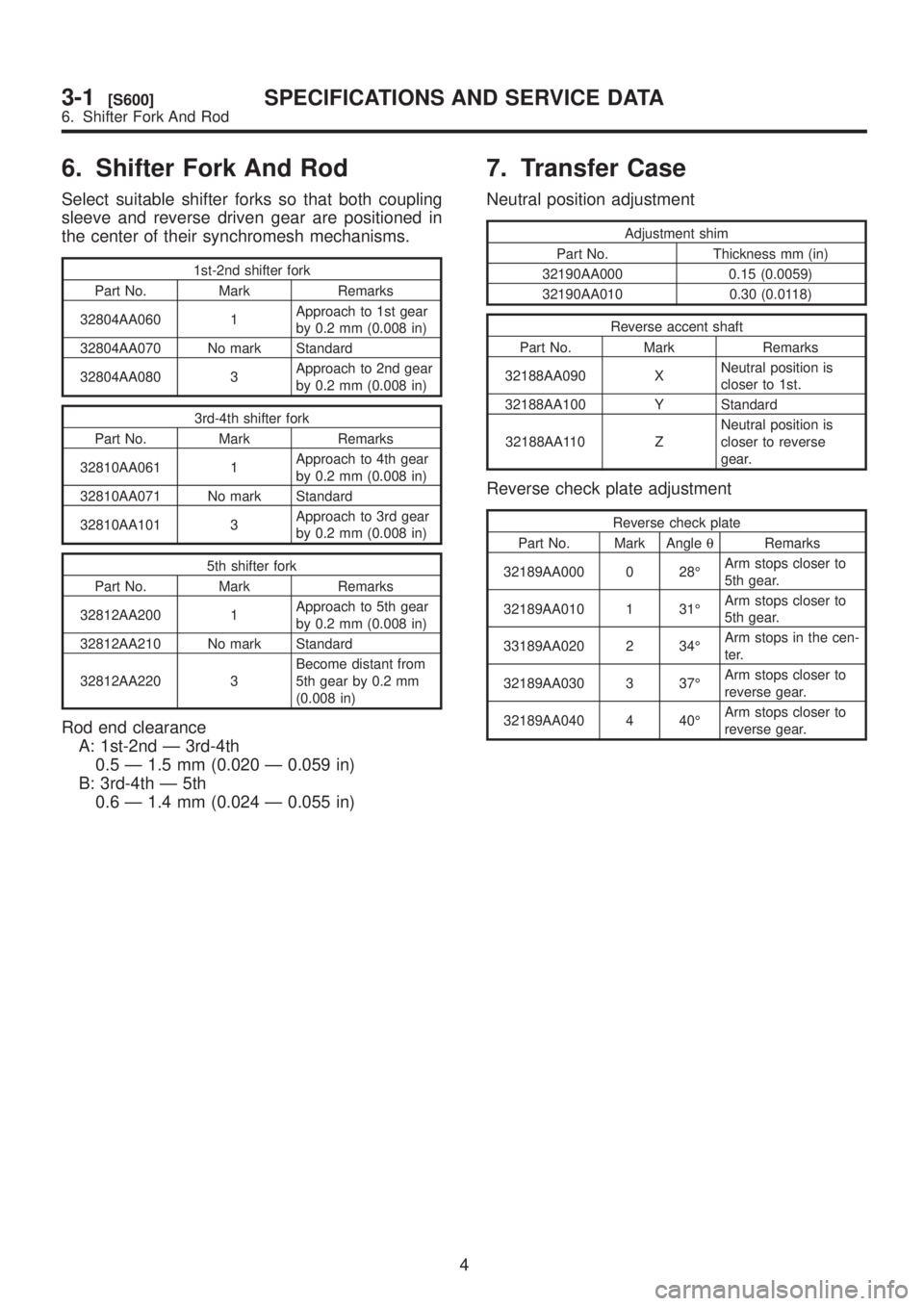

6. Shifter Fork And Rod

Select suitable shifter forks so that both coupling

sleeve and reverse driven gear are positioned in

the center of their synchromesh mechanisms.

1st-2nd shifter fork

Part No. Mark Remarks

32804AA060 1Approach to 1st gear

by 0.2 mm (0.008 in)

32804AA070 No mark Standard

32804AA080 3Approach to 2nd gear

by 0.2 mm (0.008 in)

3rd-4th shifter fork

Part No. Mark Remarks

32810AA061 1Approach to 4th gear

by 0.2 mm (0.008 in)

32810AA071 No mark Standard

32810AA101 3Approach to 3rd gear

by 0.2 mm (0.008 in)

5th shifter fork

Part No. Mark Remarks

32812AA200 1Approach to 5th gear

by 0.2 mm (0.008 in)

32812AA210 No mark Standard

32812AA220 3Become distant from

5th gear by 0.2 mm

(0.008 in)

Rod end clearance

A: 1st-2nd Ð 3rd-4th

0.5 Ð 1.5 mm (0.020 Ð 0.059 in)

B: 3rd-4th Ð 5th

0.6 Ð 1.4 mm (0.024 Ð 0.055 in)

7. Transfer Case

Neutral position adjustment

Adjustment shim

Part No. Thickness mm (in)

32190AA000 0.15 (0.0059)

32190AA010 0.30 (0.0118)

Reverse accent shaft

Part No. Mark Remarks

32188AA090 XNeutral position is

closer to 1st.

32188AA100 Y Standard

32188AA110 ZNeutral position is

closer to reverse

gear.

Reverse check plate adjustment

Reverse check plate

Part No. Mark AngleqRemarks

32189AA000 0 28ÉArm stops closer to

5th gear.

32189AA010 1 31ÉArm stops closer to

5th gear.

33189AA020 2 34ÉArm stops in the cen-

ter.

32189AA030 3 37ÉArm stops closer to

reverse gear.

32189AA040 4 40ÉArm stops closer to

reverse gear.

4

3-1[S600]SPECIFICATIONS AND SERVICE DATA

6. Shifter Fork And Rod