SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 491 of 1456

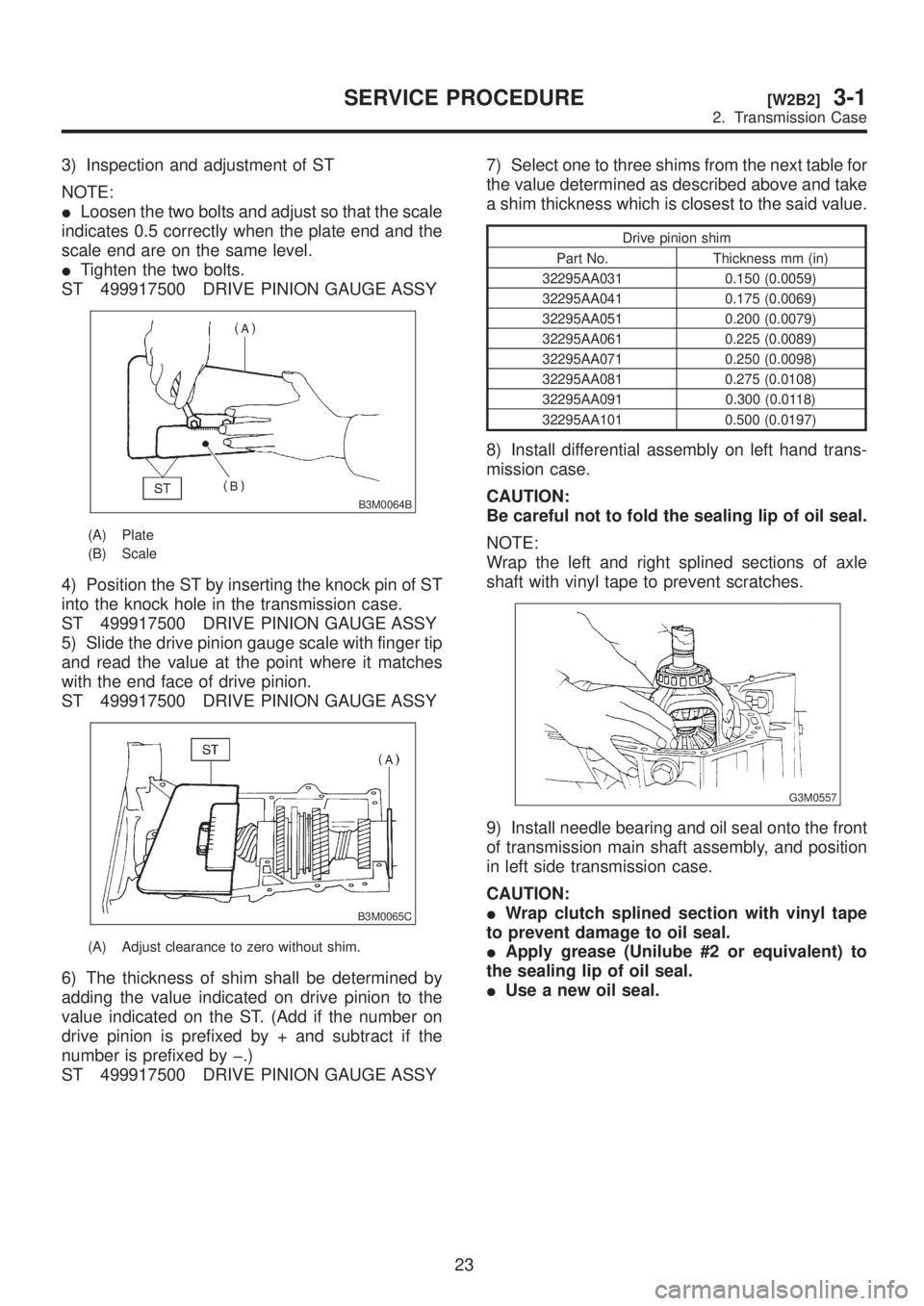

3) Inspection and adjustment of ST

NOTE:

ILoosen the two bolts and adjust so that the scale

indicates 0.5 correctly when the plate end and the

scale end are on the same level.

ITighten the two bolts.

ST 499917500 DRIVE PINION GAUGE ASSY

B3M0064B

(A) Plate

(B) Scale

4) Position the ST by inserting the knock pin of ST

into the knock hole in the transmission case.

ST 499917500 DRIVE PINION GAUGE ASSY

5) Slide the drive pinion gauge scale with finger tip

and read the value at the point where it matches

with the end face of drive pinion.

ST 499917500 DRIVE PINION GAUGE ASSY

B3M0065C

(A) Adjust clearance to zero without shim.

6) The thickness of shim shall be determined by

adding the value indicated on drive pinion to the

value indicated on the ST. (Add if the number on

drive pinion is prefixed by + and subtract if the

number is prefixed by þ.)

ST 499917500 DRIVE PINION GAUGE ASSY7) Select one to three shims from the next table for

the value determined as described above and take

a shim thickness which is closest to the said value.

Drive pinion shim

Part No. Thickness mm (in)

32295AA031 0.150 (0.0059)

32295AA041 0.175 (0.0069)

32295AA051 0.200 (0.0079)

32295AA061 0.225 (0.0089)

32295AA071 0.250 (0.0098)

32295AA081 0.275 (0.0108)

32295AA091 0.300 (0.0118)

32295AA101 0.500 (0.0197)

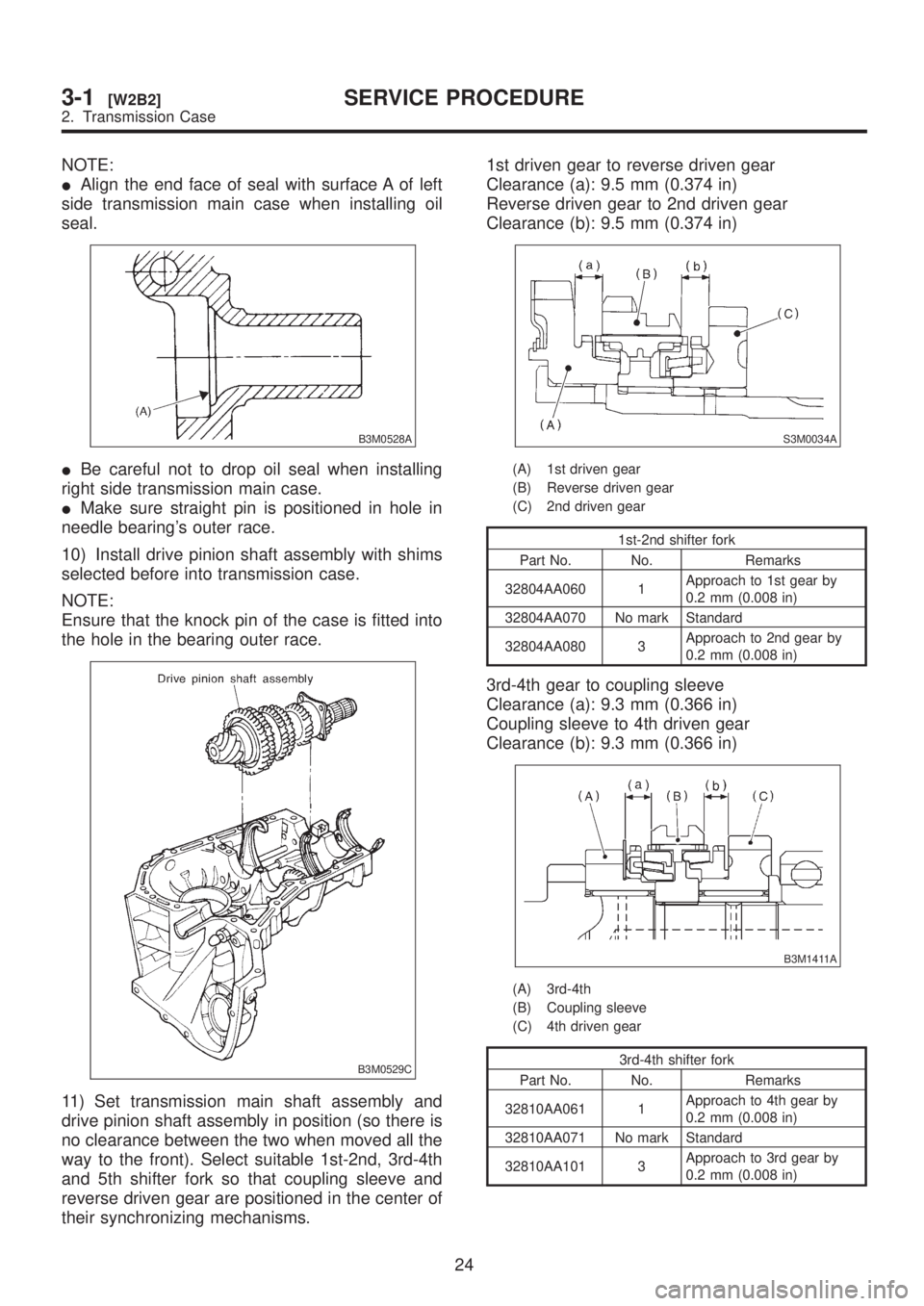

8) Install differential assembly on left hand trans-

mission case.

CAUTION:

Be careful not to fold the sealing lip of oil seal.

NOTE:

Wrap the left and right splined sections of axle

shaft with vinyl tape to prevent scratches.

G3M0557

9) Install needle bearing and oil seal onto the front

of transmission main shaft assembly, and position

in left side transmission case.

CAUTION:

IWrap clutch splined section with vinyl tape

to prevent damage to oil seal.

IApply grease (Unilube #2 or equivalent) to

the sealing lip of oil seal.

IUse a new oil seal.

23

[W2B2]3-1SERVICE PROCEDURE

2. Transmission Case

Page 492 of 1456

NOTE:

IAlign the end face of seal with surface A of left

side transmission main case when installing oil

seal.

B3M0528A

IBe careful not to drop oil seal when installing

right side transmission main case.

IMake sure straight pin is positioned in hole in

needle bearing's outer race.

10) Install drive pinion shaft assembly with shims

selected before into transmission case.

NOTE:

Ensure that the knock pin of the case is fitted into

the hole in the bearing outer race.

B3M0529C

11) Set transmission main shaft assembly and

drive pinion shaft assembly in position (so there is

no clearance between the two when moved all the

way to the front). Select suitable 1st-2nd, 3rd-4th

and 5th shifter fork so that coupling sleeve and

reverse driven gear are positioned in the center of

their synchronizing mechanisms.1st driven gear to reverse driven gear

Clearance (a): 9.5 mm (0.374 in)

Reverse driven gear to 2nd driven gear

Clearance (b): 9.5 mm (0.374 in)

S3M0034A

(A) 1st driven gear

(B) Reverse driven gear

(C) 2nd driven gear

1st-2nd shifter fork

Part No. No. Remarks

32804AA060 1Approach to 1st gear by

0.2 mm (0.008 in)

32804AA070 No mark Standard

32804AA080 3Approach to 2nd gear by

0.2 mm (0.008 in)

3rd-4th gear to coupling sleeve

Clearance (a): 9.3 mm (0.366 in)

Coupling sleeve to 4th driven gear

Clearance (b): 9.3 mm (0.366 in)

B3M1411A

(A) 3rd-4th

(B) Coupling sleeve

(C) 4th driven gear

3rd-4th shifter fork

Part No. No. Remarks

32810AA061 1Approach to 4th gear by

0.2 mm (0.008 in)

32810AA071 No mark Standard

32810AA101 3Approach to 3rd gear by

0.2 mm (0.008 in)

24

3-1[W2B2]SERVICE PROCEDURE

2. Transmission Case

Page 493 of 1456

5th driven gear to coupling sleeve

Clearance (a): 9.3 mm (0.366 in)

B3M1403A

(A) 5th driven gear

(B) Coupling sleeve

5th shifter fork

Part No. No. Remarks

32812AA200 4Approach to 5th gear by

0.2 mm (0.008 in)

32812AA210 No mark Standard

32812AA220 6Become distant from 5th

gear by 0.2 mm (0.008 in)

12) Measure rod end clearances (A) and (B). If

any clearance is not within specifications, replace

rod or fork as required.

(A): 1st-2nd to 3rd-4th 0.4 Ð 1.4 mm (0.016 Ð 0.055 in)

(B): 3rd-4th to 5th 0.5 Ð 1.3 mm (0.020 Ð 0.051 in)

B3M0530A

13) Wipe off grease, oil and dust on the mating

surfaces of transmission cases with white

gasoline, and apply liquid gasket, and then put

case right side and left side together.

Liquid gasket:

THREE BOND 1215 or equivalent

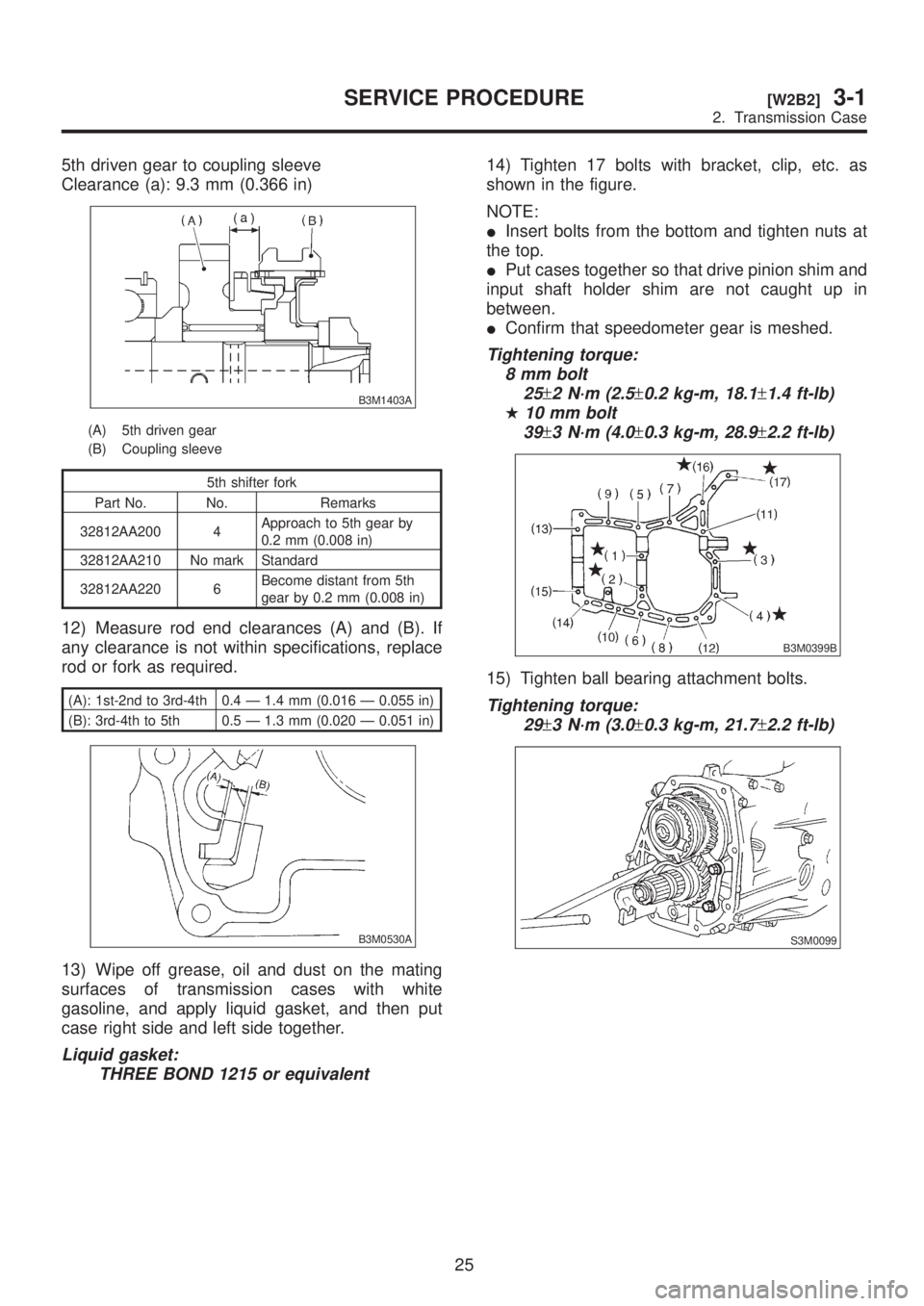

14) Tighten 17 bolts with bracket, clip, etc. as

shown in the figure.

NOTE:

IInsert bolts from the bottom and tighten nuts at

the top.

IPut cases together so that drive pinion shim and

input shaft holder shim are not caught up in

between.

IConfirm that speedometer gear is meshed.

Tightening torque:

8 mm bolt

25

±2 N´m (2.5±0.2 kg-m, 18.1±1.4 ft-lb)

H10 mm bolt

39

±3 N´m (4.0±0.3 kg-m, 28.9±2.2 ft-lb)

B3M0399B

15) Tighten ball bearing attachment bolts.

Tightening torque:

29

±3 N´m (3.0±0.3 kg-m, 21.7±2.2 ft-lb)

S3M0099

25

[W2B2]3-1SERVICE PROCEDURE

2. Transmission Case

Page 494 of 1456

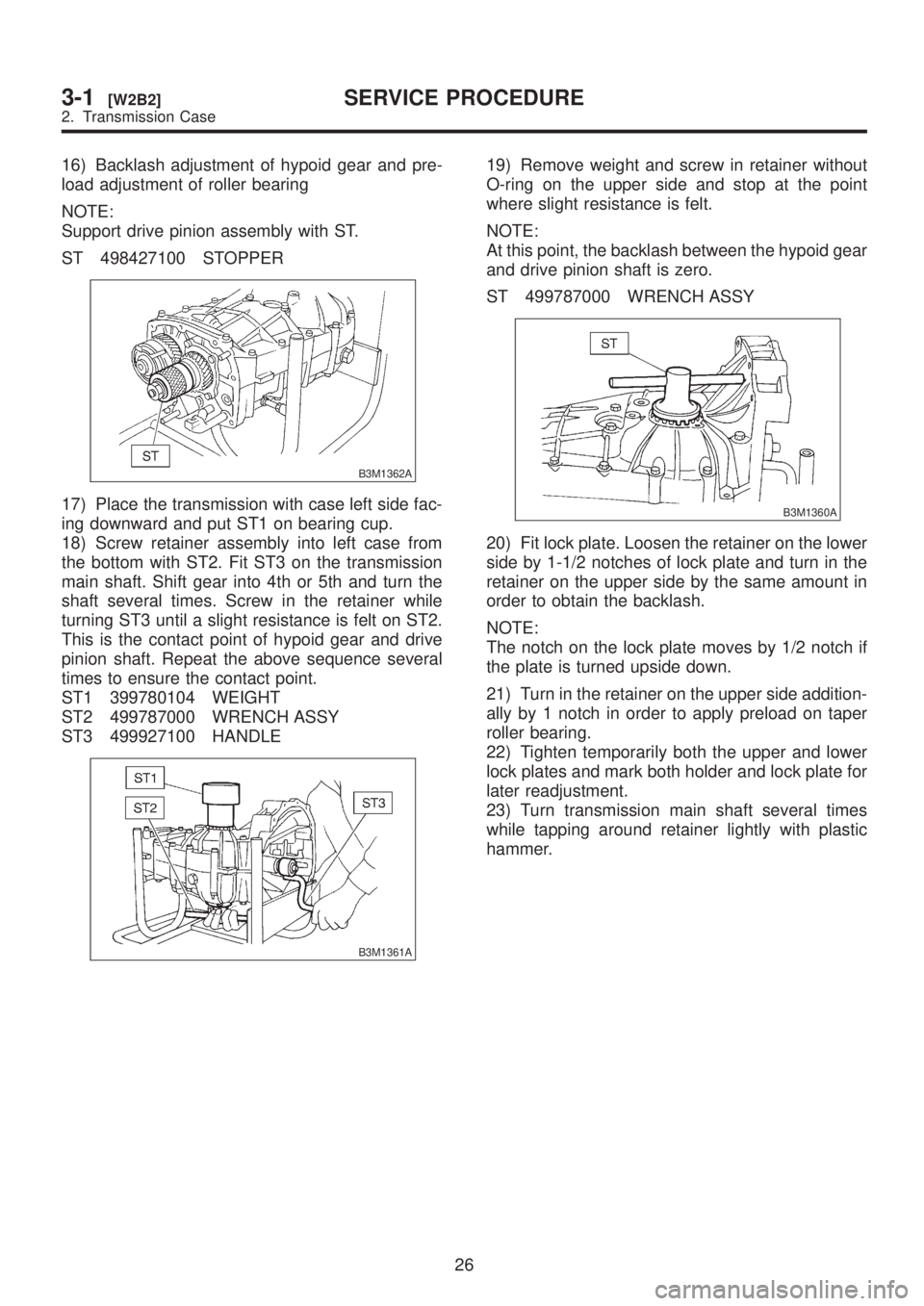

16) Backlash adjustment of hypoid gear and pre-

load adjustment of roller bearing

NOTE:

Support drive pinion assembly with ST.

ST 498427100 STOPPER

B3M1362A

17) Place the transmission with case left side fac-

ing downward and put ST1 on bearing cup.

18) Screw retainer assembly into left case from

the bottom with ST2. Fit ST3 on the transmission

main shaft. Shift gear into 4th or 5th and turn the

shaft several times. Screw in the retainer while

turning ST3 until a slight resistance is felt on ST2.

This is the contact point of hypoid gear and drive

pinion shaft. Repeat the above sequence several

times to ensure the contact point.

ST1 399780104 WEIGHT

ST2 499787000 WRENCH ASSY

ST3 499927100 HANDLE

B3M1361A

19) Remove weight and screw in retainer without

O-ring on the upper side and stop at the point

where slight resistance is felt.

NOTE:

At this point, the backlash between the hypoid gear

and drive pinion shaft is zero.

ST 499787000 WRENCH ASSY

B3M1360A

20) Fit lock plate. Loosen the retainer on the lower

side by 1-1/2 notches of lock plate and turn in the

retainer on the upper side by the same amount in

order to obtain the backlash.

NOTE:

The notch on the lock plate moves by 1/2 notch if

the plate is turned upside down.

21) Turn in the retainer on the upper side addition-

ally by 1 notch in order to apply preload on taper

roller bearing.

22) Tighten temporarily both the upper and lower

lock plates and mark both holder and lock plate for

later readjustment.

23) Turn transmission main shaft several times

while tapping around retainer lightly with plastic

hammer.

26

3-1[W2B2]SERVICE PROCEDURE

2. Transmission Case

Page 495 of 1456

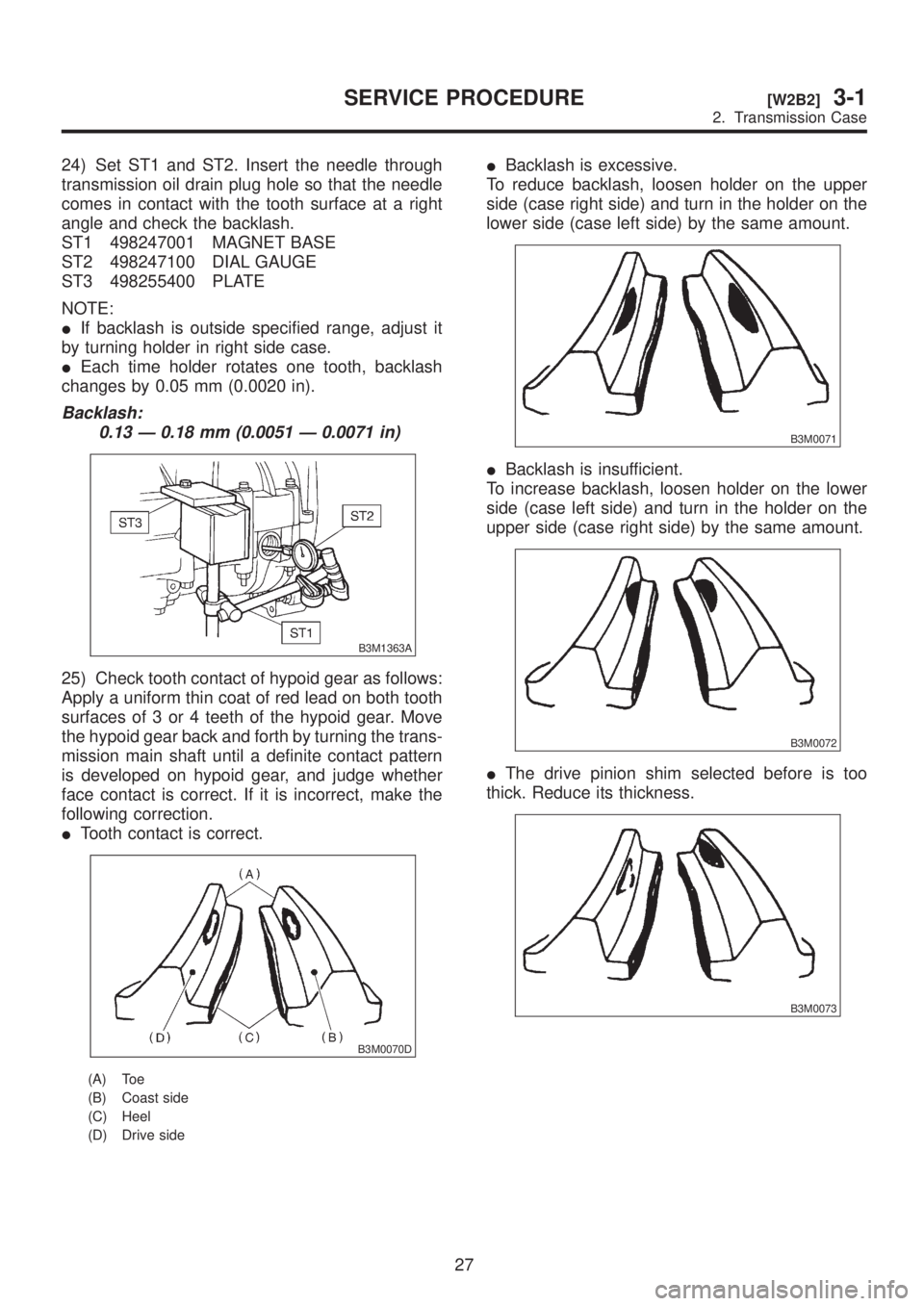

24) Set ST1 and ST2. Insert the needle through

transmission oil drain plug hole so that the needle

comes in contact with the tooth surface at a right

angle and check the backlash.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

ST3 498255400 PLATE

NOTE:

IIf backlash is outside specified range, adjust it

by turning holder in right side case.

IEach time holder rotates one tooth, backlash

changes by 0.05 mm (0.0020 in).

Backlash:

0.13 Ð 0.18 mm (0.0051 Ð 0.0071 in)

B3M1363A

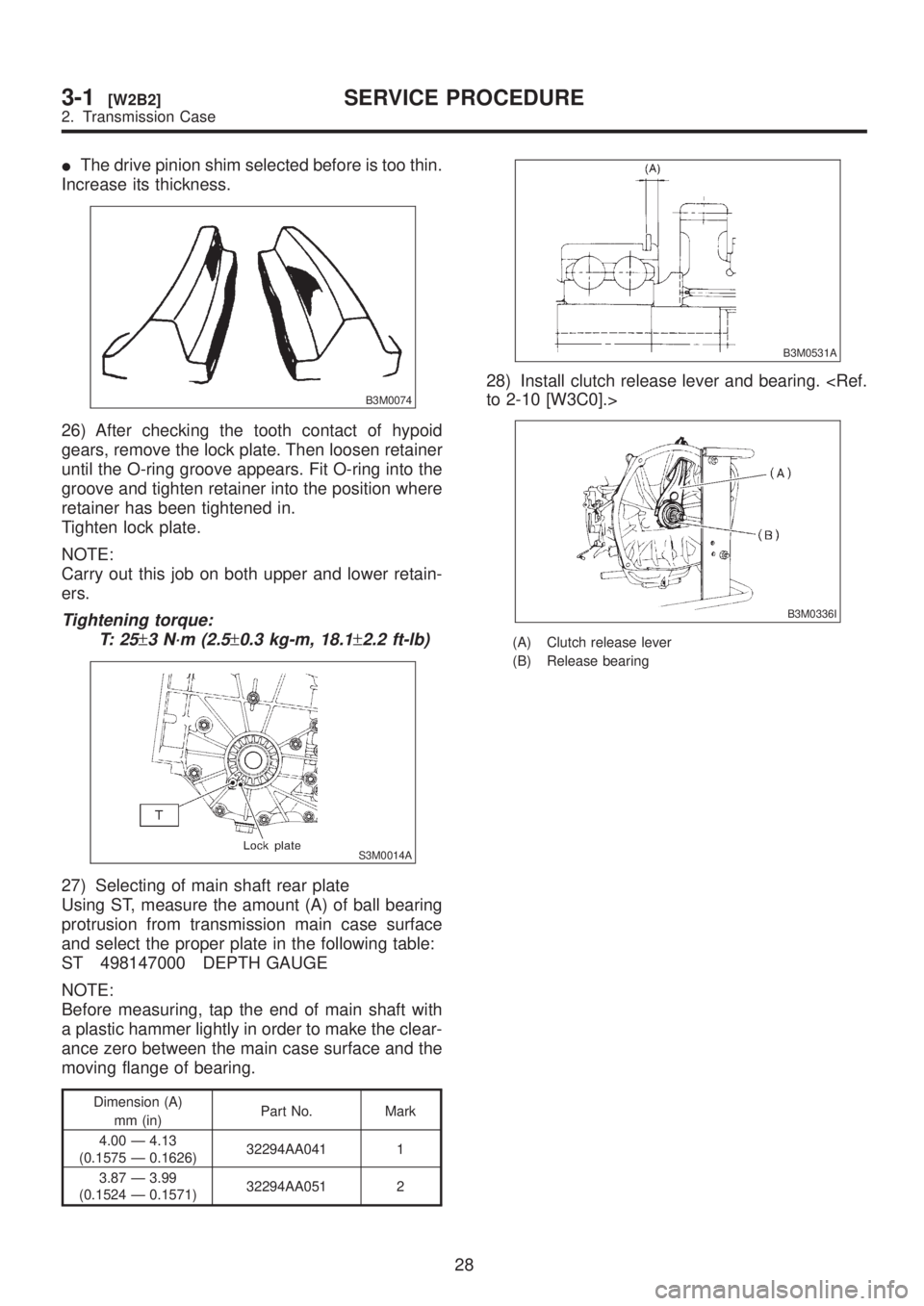

25) Check tooth contact of hypoid gear as follows:

Apply a uniform thin coat of red lead on both tooth

surfaces of 3 or 4 teeth of the hypoid gear. Move

the hypoid gear back and forth by turning the trans-

mission main shaft until a definite contact pattern

is developed on hypoid gear, and judge whether

face contact is correct. If it is incorrect, make the

following correction.

ITooth contact is correct.

B3M0070D

(A) Toe

(B) Coast side

(C) Heel

(D) Drive side

IBacklash is excessive.

To reduce backlash, loosen holder on the upper

side (case right side) and turn in the holder on the

lower side (case left side) by the same amount.

B3M0071

IBacklash is insufficient.

To increase backlash, loosen holder on the lower

side (case left side) and turn in the holder on the

upper side (case right side) by the same amount.

B3M0072

IThe drive pinion shim selected before is too

thick. Reduce its thickness.

B3M0073

27

[W2B2]3-1SERVICE PROCEDURE

2. Transmission Case

Page 496 of 1456

IThe drive pinion shim selected before is too thin.

Increase its thickness.

B3M0074

26) After checking the tooth contact of hypoid

gears, remove the lock plate. Then loosen retainer

until the O-ring groove appears. Fit O-ring into the

groove and tighten retainer into the position where

retainer has been tightened in.

Tighten lock plate.

NOTE:

Carry out this job on both upper and lower retain-

ers.

Tightening torque:

T: 2 5

±3 N´m (2.5±0.3 kg-m, 18.1±2.2 ft-lb)

S3M0014A

27) Selecting of main shaft rear plate

Using ST, measure the amount (A) of ball bearing

protrusion from transmission main case surface

and select the proper plate in the following table:

ST 498147000 DEPTH GAUGE

NOTE:

Before measuring, tap the end of main shaft with

a plastic hammer lightly in order to make the clear-

ance zero between the main case surface and the

moving flange of bearing.

Dimension (A)

mm (in)Part No. Mark

4.00 Ð 4.13

(0.1575 Ð 0.1626)32294AA041 1

3.87 Ð 3.99

(0.1524 Ð 0.1571)32294AA051 2

B3M0531A

28) Install clutch release lever and bearing.

B3M0336I

(A) Clutch release lever

(B) Release bearing

28

3-1[W2B2]SERVICE PROCEDURE

2. Transmission Case

Page 497 of 1456

3. Drive Pinion Assembly

A: DISASSEMBLY

1. DRIVE PINION SHAFT

1) Straighten lock nut at staked portion. Remove

the lock nut using ST1, ST2 and ST3.

ST1 899884100 HOLDER

ST2 498427100 STOPPER

ST3 899988608 SOCKET WRENCH

G3M0595

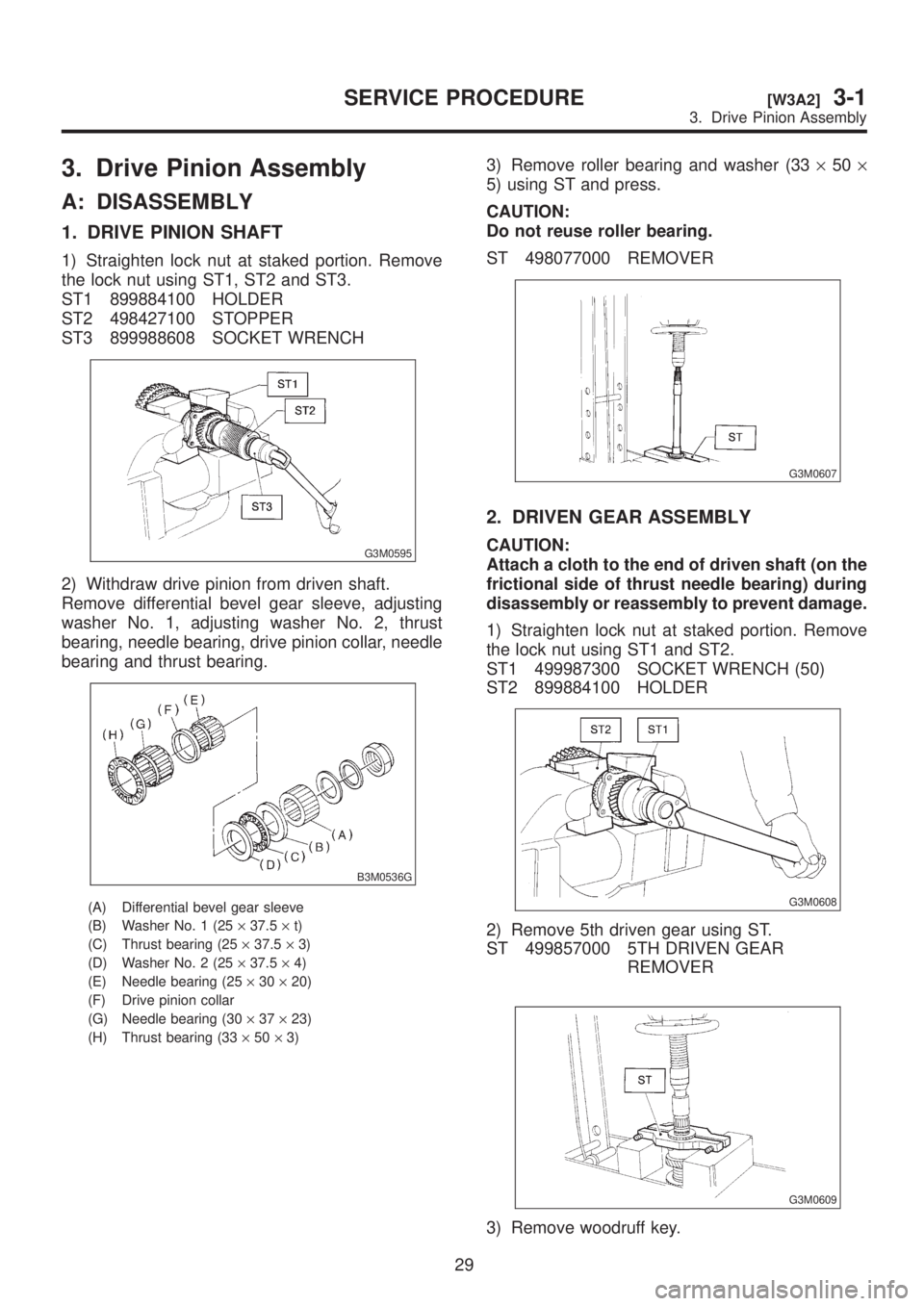

2) Withdraw drive pinion from driven shaft.

Remove differential bevel gear sleeve, adjusting

washer No. 1, adjusting washer No. 2, thrust

bearing, needle bearing, drive pinion collar, needle

bearing and thrust bearing.

B3M0536G

(A) Differential bevel gear sleeve

(B) Washer No. 1 (25´37.5´t)

(C) Thrust bearing (25´37.5´3)

(D) Washer No. 2 (25´37.5´4)

(E) Needle bearing (25´30´20)

(F) Drive pinion collar

(G) Needle bearing (30´37´23)

(H) Thrust bearing (33´50´3)

3) Remove roller bearing and washer (33´50´

5) using ST and press.

CAUTION:

Do not reuse roller bearing.

ST 498077000 REMOVER

G3M0607

2. DRIVEN GEAR ASSEMBLY

CAUTION:

Attach a cloth to the end of driven shaft (on the

frictional side of thrust needle bearing) during

disassembly or reassembly to prevent damage.

1) Straighten lock nut at staked portion. Remove

the lock nut using ST1 and ST2.

ST1 499987300 SOCKET WRENCH (50)

ST2 899884100 HOLDER

G3M0608

2) Remove 5th driven gear using ST.

ST 499857000 5TH DRIVEN GEAR

REMOVER

G3M0609

3) Remove woodruff key.

29

[W3A2]3-1SERVICE PROCEDURE

3. Drive Pinion Assembly

Page 498 of 1456

4) Remove roller bearing (42´74´40), 3rd-4th

driven gear using ST1 and ST2.

ST1 499757002 SNAP RING PRESS

ST2 899714110 REMOVER

G3M0610

5) Remove the key.

6) Remove 2nd driven gear, inner baulk ring, syn-

chro cone and outer baulk ring.

B3M0426C

(A) 2nd driven gear

(B) Inner baulk ring

(C) Synchro coner

(D) Outer baulk ring

7) Remove 1st driven gear, 2nd gear bushing,

gear and hub using ST1 and ST2.

NOTE:

Replace gear and hub if necessary. Do not attempt

to disassemble if at all possible because they must

engage at a specified point. If they have to be

disassembled, mark the engaging point before-

hand.

ST1 499757002 SNAP RING PRESS

ST2 899714110 REMOVER

G3M0611

8) Remove sub gears for 1st and 2nd driven gear.

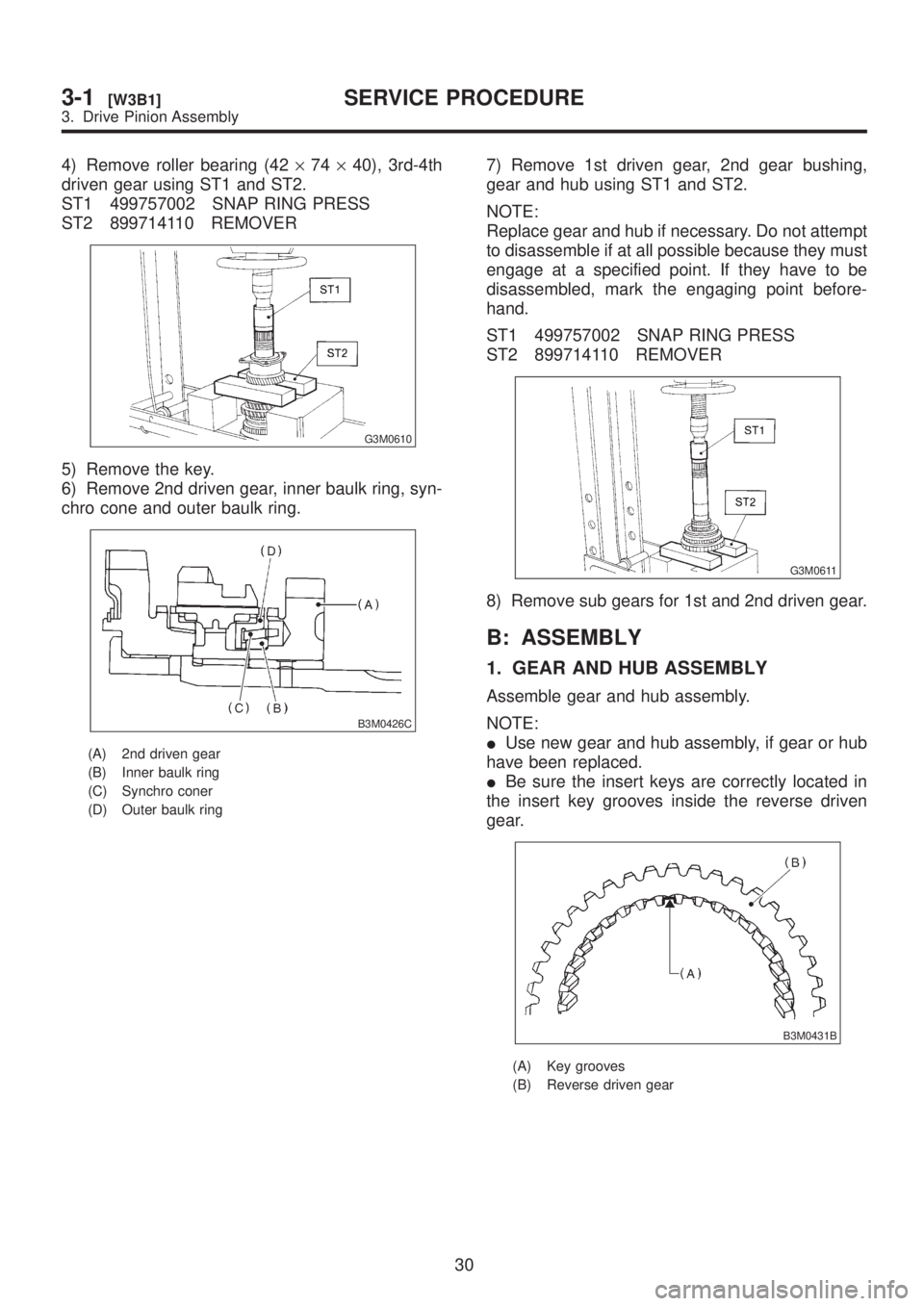

B: ASSEMBLY

1. GEAR AND HUB ASSEMBLY

Assemble gear and hub assembly.

NOTE:

IUse new gear and hub assembly, if gear or hub

have been replaced.

IBe sure the insert keys are correctly located in

the insert key grooves inside the reverse driven

gear.

B3M0431B

(A) Key grooves

(B) Reverse driven gear

30

3-1[W3B1]SERVICE PROCEDURE

3. Drive Pinion Assembly

Page 499 of 1456

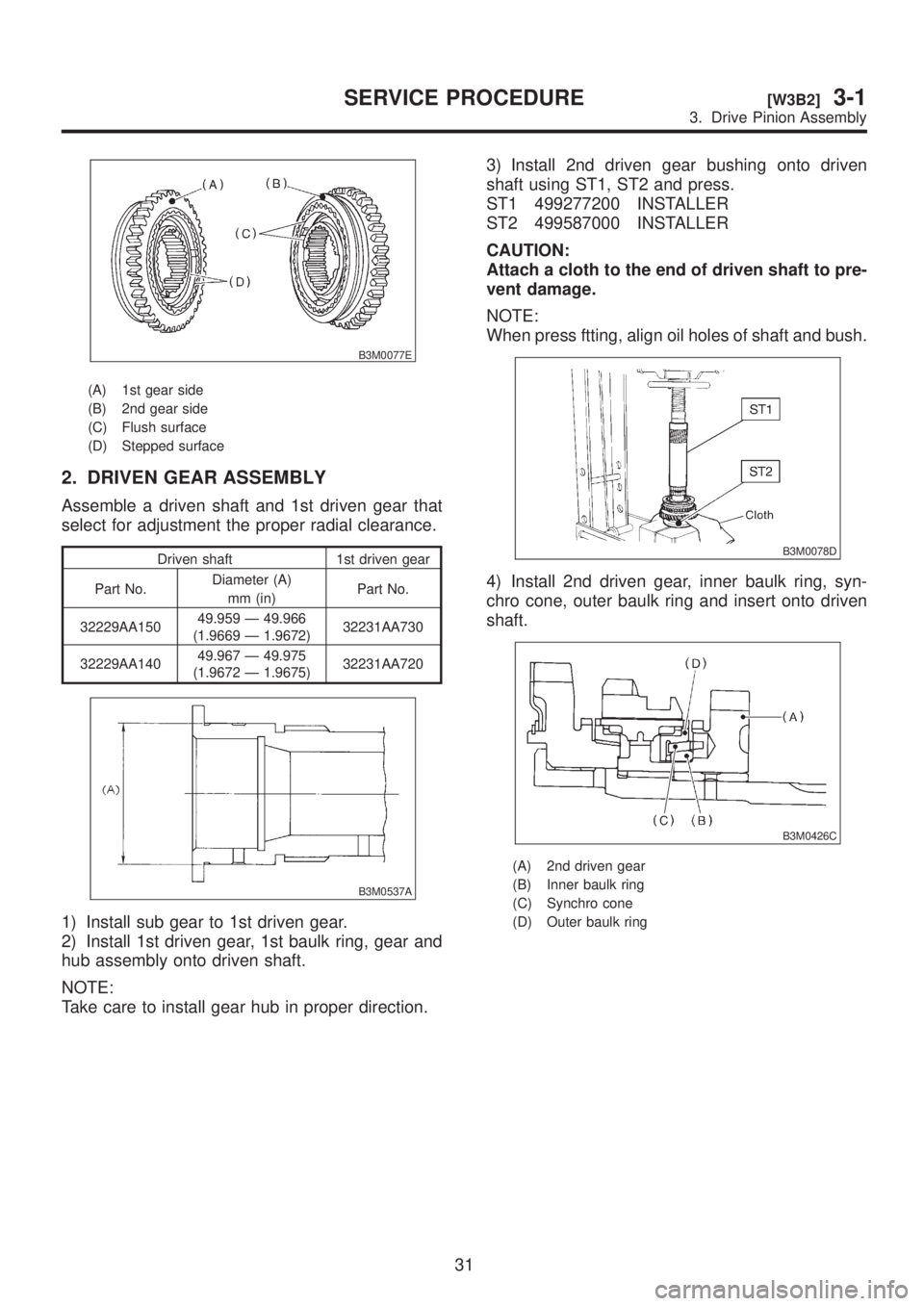

B3M0077E

(A) 1st gear side

(B) 2nd gear side

(C) Flush surface

(D) Stepped surface

2. DRIVEN GEAR ASSEMBLY

Assemble a driven shaft and 1st driven gear that

select for adjustment the proper radial clearance.

Driven shaft 1st driven gear

Part No.Diameter (A)

mm (in)Part No.

32229AA15049.959 Ð 49.966

(1.9669 Ð 1.9672)32231AA730

32229AA14049.967 Ð 49.975

(1.9672 Ð 1.9675)32231AA720

B3M0537A

1) Install sub gear to 1st driven gear.

2) Install 1st driven gear, 1st baulk ring, gear and

hub assembly onto driven shaft.

NOTE:

Take care to install gear hub in proper direction.3) Install 2nd driven gear bushing onto driven

shaft using ST1, ST2 and press.

ST1 499277200 INSTALLER

ST2 499587000 INSTALLER

CAUTION:

Attach a cloth to the end of driven shaft to pre-

vent damage.

NOTE:

When press ftting, align oil holes of shaft and bush.

B3M0078D

4) Install 2nd driven gear, inner baulk ring, syn-

chro cone, outer baulk ring and insert onto driven

shaft.

B3M0426C

(A) 2nd driven gear

(B) Inner baulk ring

(C) Synchro cone

(D) Outer baulk ring

31

[W3B2]3-1SERVICE PROCEDURE

3. Drive Pinion Assembly

Page 500 of 1456

5) After installing key on driven shaft, install 3rd-

4th driven gear using ST and press.

NOTE:

Align groove in baulk ring with insert.

ST 499277200 INSTALLER

G3M0615

6) Install a set of roller bearings (42´74´40)

onto the driven shaft using ST and press.

ST 499277200 INSTALLER

G3M0616

7) Position woodruff key in groove on the rear of

driven shaft. Install 5th driven gear onto drive shaft

using ST and press.

ST 499277200 INSTALLER

G3M0617

8) Install lock washer (42´53´2). Install lock nut

(42´13) and tighten to the specified torque using

ST.

ST 499987300 SOCKET WRENCH (50)

Tightening torque:

265

±10 N´m (27±1 kg-m, 195±7 ft-lb)

G3M0618

NOTE:

IStake lock nut at two points.

IUsing spring balancer, check that starting torque

of roller bearing is 0.1 to 1.5 N´m (0.01 to 0.15

kg-m, 0.07 to 1.1 ft-lb).

B3M0079D

3. DRIVE PINION SHAFT

1) Install roller bearing onto drive pinion. Install

washer (33´50´5) using ST1, ST2 and press.

ST1 499277100 BUSH 1-2 INSTALLER

ST2 499277200 INSTALLER

B3M0080D

32

3-1[W3B3]SERVICE PROCEDURE

3. Drive Pinion Assembly