SUBARU LEGACY 1999 Service Repair Manual

LEGACY 1999

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/57435/w960_57435-0.png

SUBARU LEGACY 1999 Service Repair Manual

Trending: fold seats, manual transmission, adding oil, ECO mode, wiper assembly, heating system, boot

Page 441 of 1456

10) Remove chamber stay.

IMT vehicles

S2M0210

IAT vehicles

S6M0023

11) Disconnect connectors, cables and hoses.

9

[W1B0]2-11SERVICE PROCEDURE

1. Engine

Page 442 of 1456

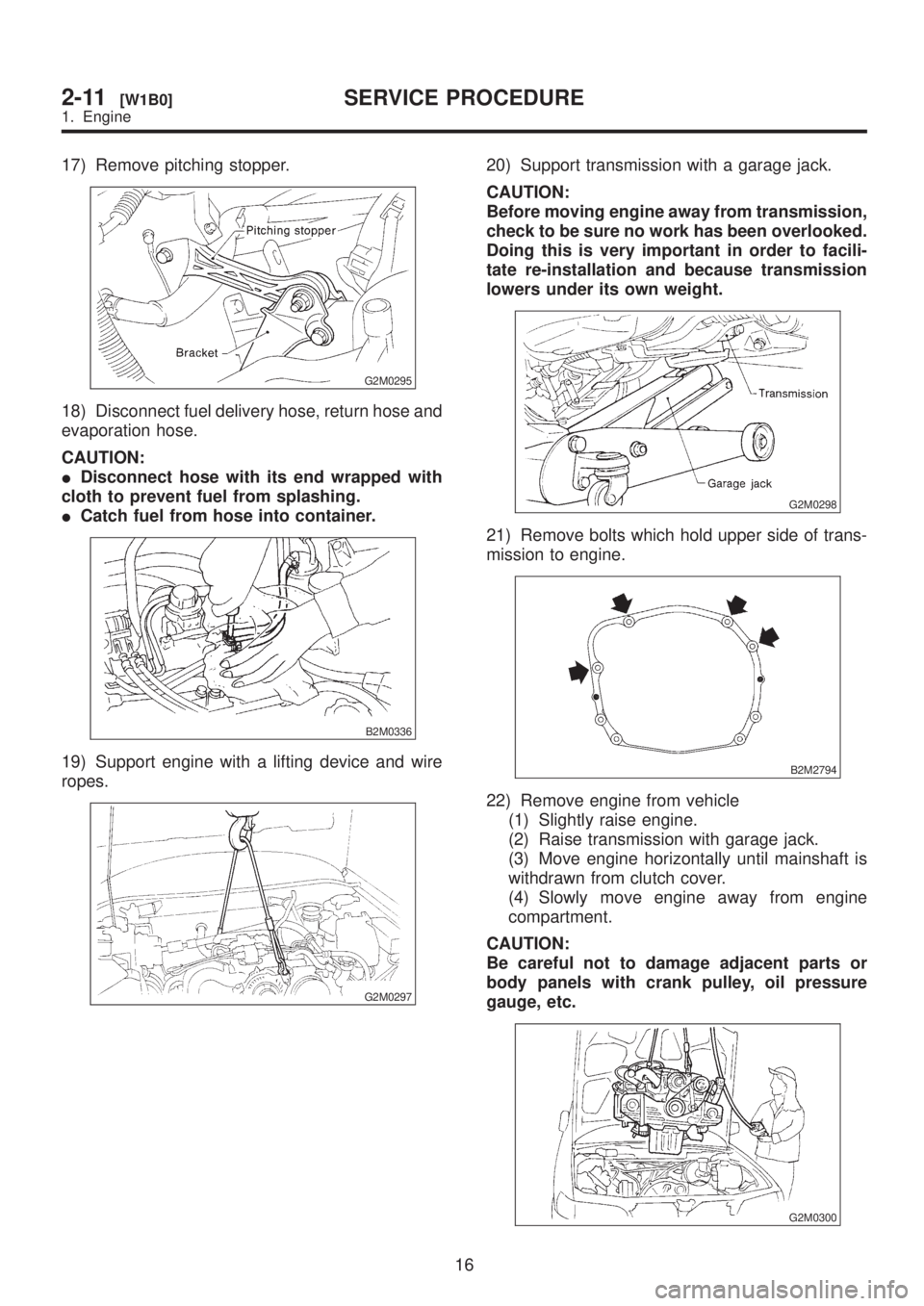

(1) Disconnect the following connectors.

H2M2433A

(1) Front oxygen sensor connector

(2) Rear oxygen sensor connector

(California spec. vehicles)

(3) Engine harness connectors

(4) Engine ground terminal

(5) Alternator connector and termi-

nal

(6) A/C compressor connectors

(With A/C)

10

2-11[W1B0]SERVICE PROCEDURE

1. Engine

Page 443 of 1456

S2M0200A

B2M0019E

S2M0201AB2M1291E

11

[W1B0]2-11SERVICE PROCEDURE

1. Engine

Page 444 of 1456

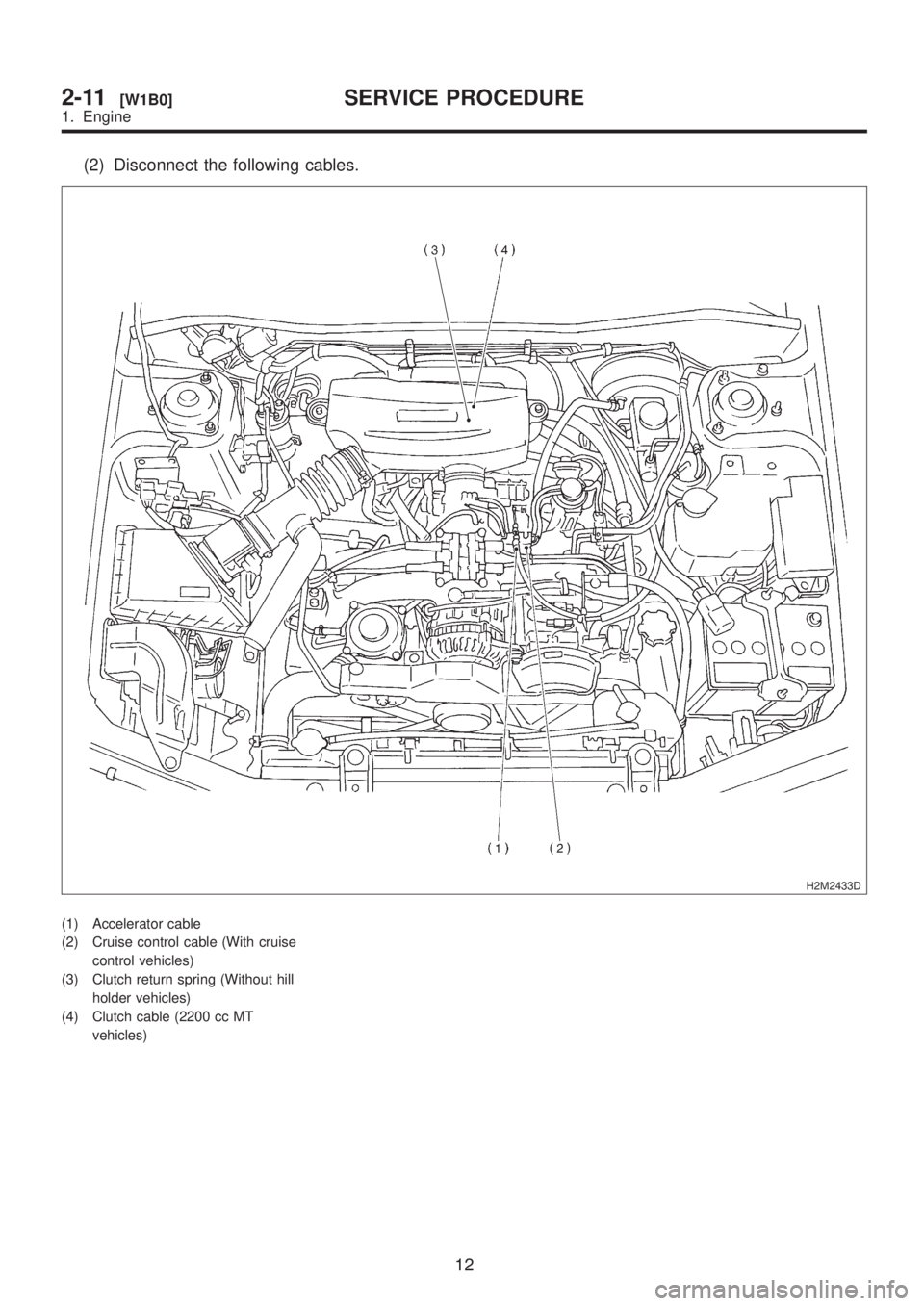

(2) Disconnect the following cables.

H2M2433D

(1) Accelerator cable

(2) Cruise control cable (With cruise

control vehicles)

(3) Clutch return spring (Without hill

holder vehicles)

(4) Clutch cable (2200 cc MT

vehicles)

12

2-11[W1B0]SERVICE PROCEDURE

1. Engine

Page 445 of 1456

B2M2295AB2M1027A

(3) Disconnect the following hoses.

H2M2433C

(1) Brake booster vacuum hose

(2) Heater inlet and outlet hose

13

[W1B0]2-11SERVICE PROCEDURE

1. Engine

Page 446 of 1456

B2M2776AS2M0204A

12) Remove power steering pump from bracket.

(1) Loosen lock bolt and slider bolt, and remove

front side V-belt.

G2M0286

(2) Remove pipe with bracket from intake mani-

fold.

B2M2309

(3) Remove bolts which install power steering

pump from bracket.

S2M0086

(4) Place power steering pump on the right side

wheel apron.

S2M0087

13) Remove front exhaust pipe and center

exhaust pipe.

(1) Lift-up the vehicle.

(2) Disconnect connector from rear oxygen

sensor. (Except 2500cc California spec.

vehicles)

B2M0335

14

2-11[W1B0]SERVICE PROCEDURE

1. Engine

Page 447 of 1456

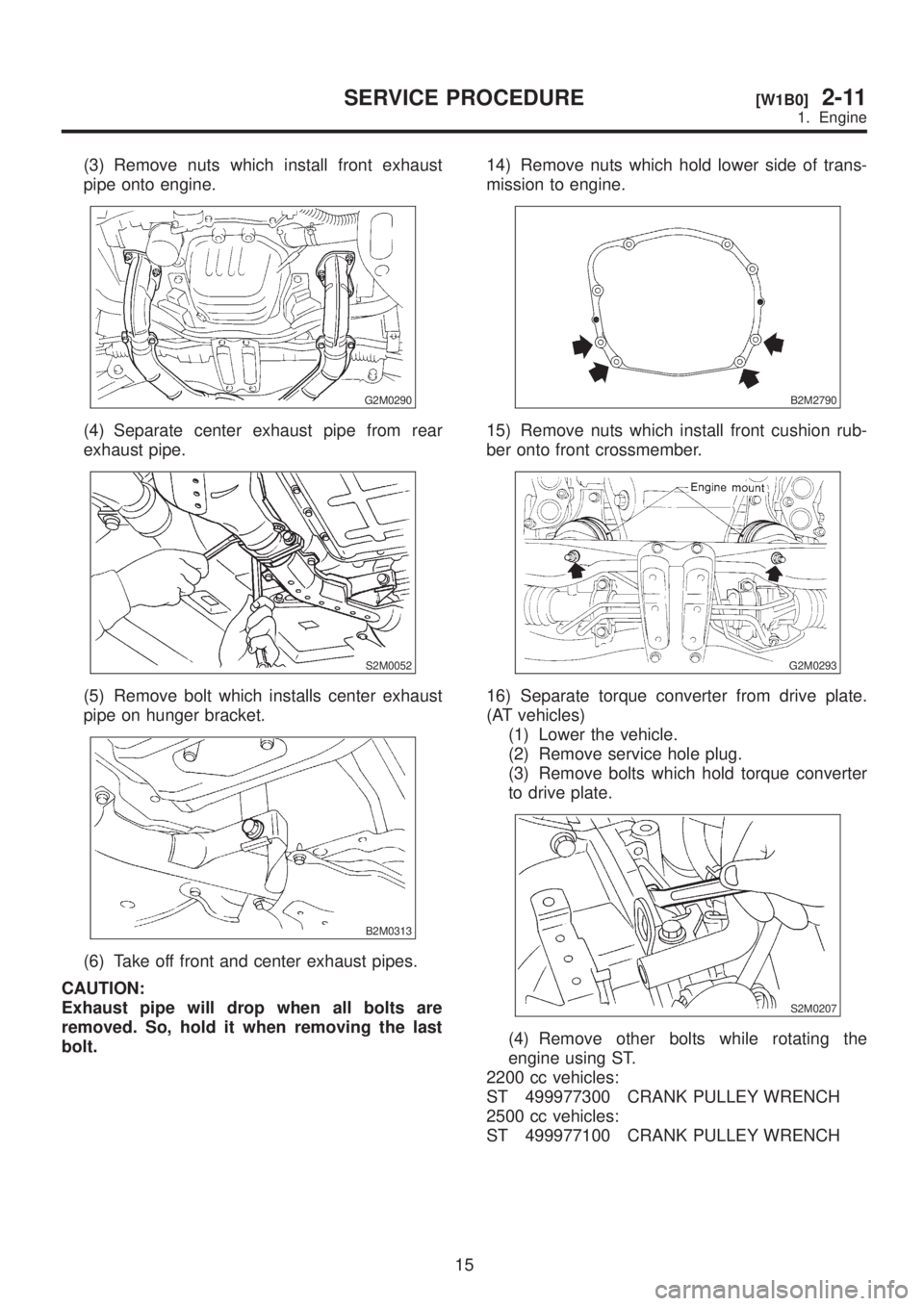

(3) Remove nuts which install front exhaust

pipe onto engine.

G2M0290

(4) Separate center exhaust pipe from rear

exhaust pipe.

S2M0052

(5) Remove bolt which installs center exhaust

pipe on hunger bracket.

B2M0313

(6) Take off front and center exhaust pipes.

CAUTION:

Exhaust pipe will drop when all bolts are

removed. So, hold it when removing the last

bolt.14) Remove nuts which hold lower side of trans-

mission to engine.

B2M2790

15) Remove nuts which install front cushion rub-

ber onto front crossmember.

G2M0293

16) Separate torque converter from drive plate.

(AT vehicles)

(1) Lower the vehicle.

(2) Remove service hole plug.

(3) Remove bolts which hold torque converter

to drive plate.

S2M0207

(4) Remove other bolts while rotating the

engine using ST.

2200 cc vehicles:

ST 499977300 CRANK PULLEY WRENCH

2500 cc vehicles:

ST 499977100 CRANK PULLEY WRENCH

15

[W1B0]2-11SERVICE PROCEDURE

1. Engine

Page 448 of 1456

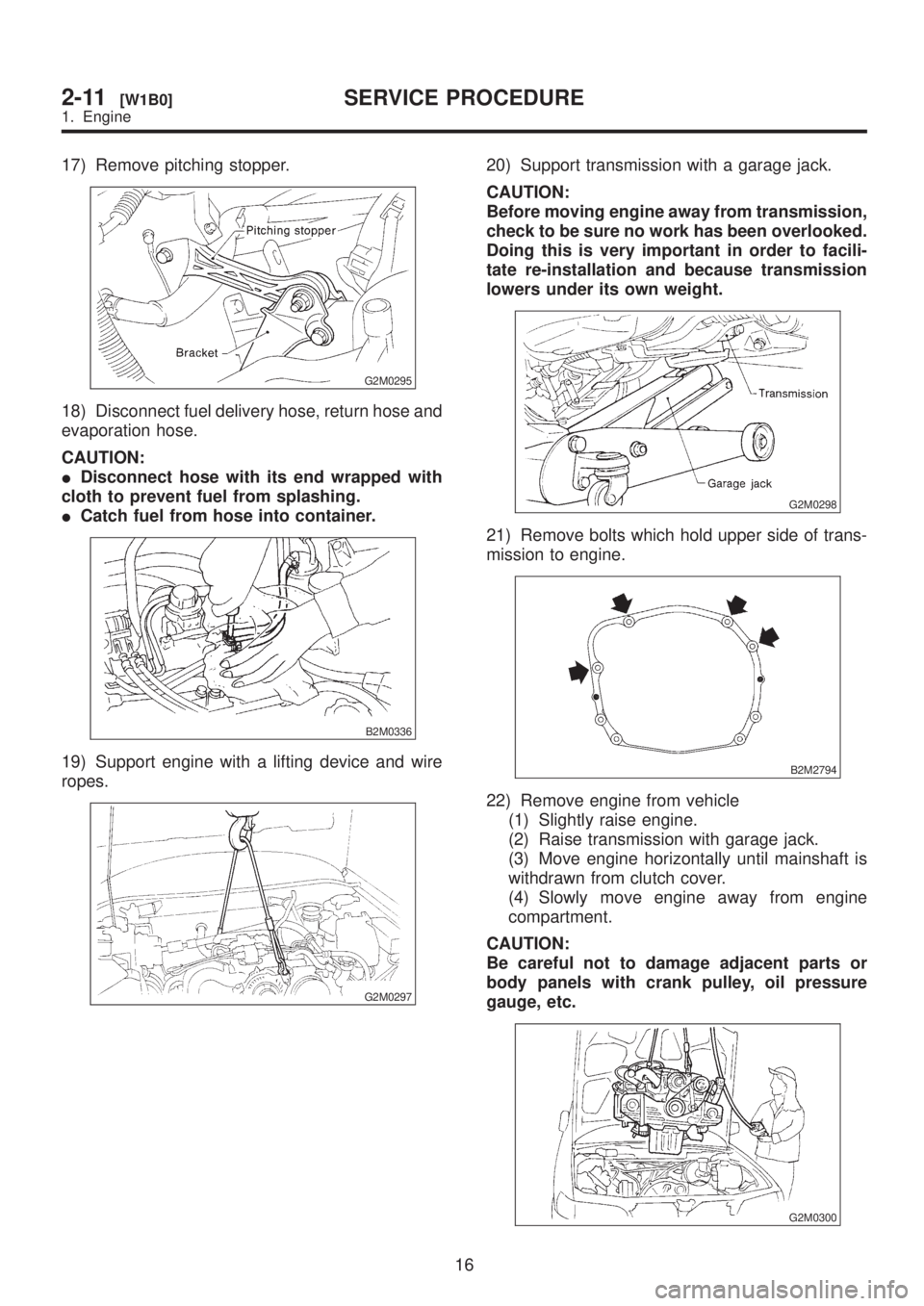

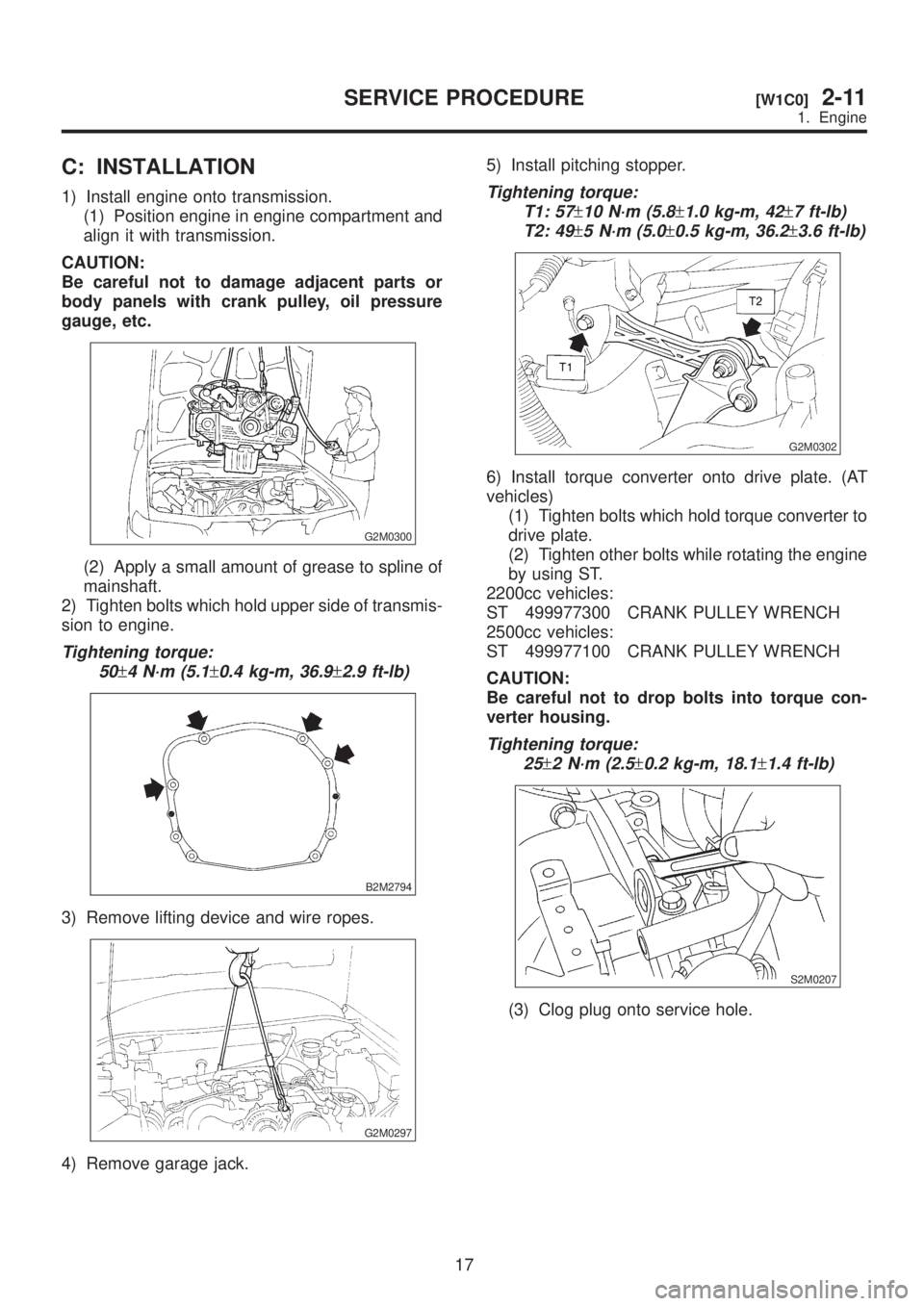

17) Remove pitching stopper.

G2M0295

18) Disconnect fuel delivery hose, return hose and

evaporation hose.

CAUTION:

IDisconnect hose with its end wrapped with

cloth to prevent fuel from splashing.

ICatch fuel from hose into container.

B2M0336

19) Support engine with a lifting device and wire

ropes.

G2M0297

20) Support transmission with a garage jack.

CAUTION:

Before moving engine away from transmission,

check to be sure no work has been overlooked.

Doing this is very important in order to facili-

tate re-installation and because transmission

lowers under its own weight.

G2M0298

21) Remove bolts which hold upper side of trans-

mission to engine.

B2M2794

22) Remove engine from vehicle

(1) Slightly raise engine.

(2) Raise transmission with garage jack.

(3) Move engine horizontally until mainshaft is

withdrawn from clutch cover.

(4) Slowly move engine away from engine

compartment.

CAUTION:

Be careful not to damage adjacent parts or

body panels with crank pulley, oil pressure

gauge, etc.

G2M0300

16

2-11[W1B0]SERVICE PROCEDURE

1. Engine

Page 449 of 1456

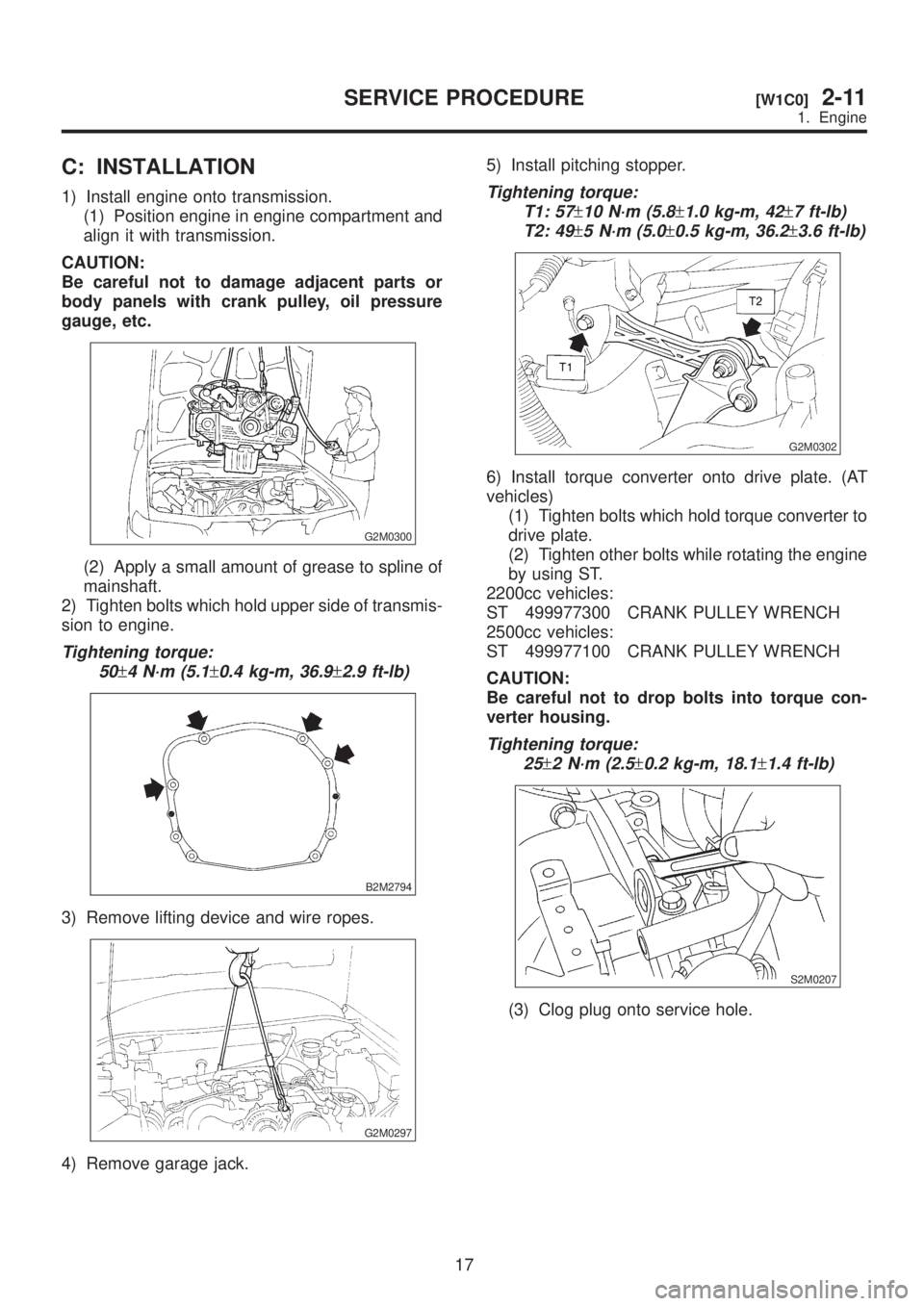

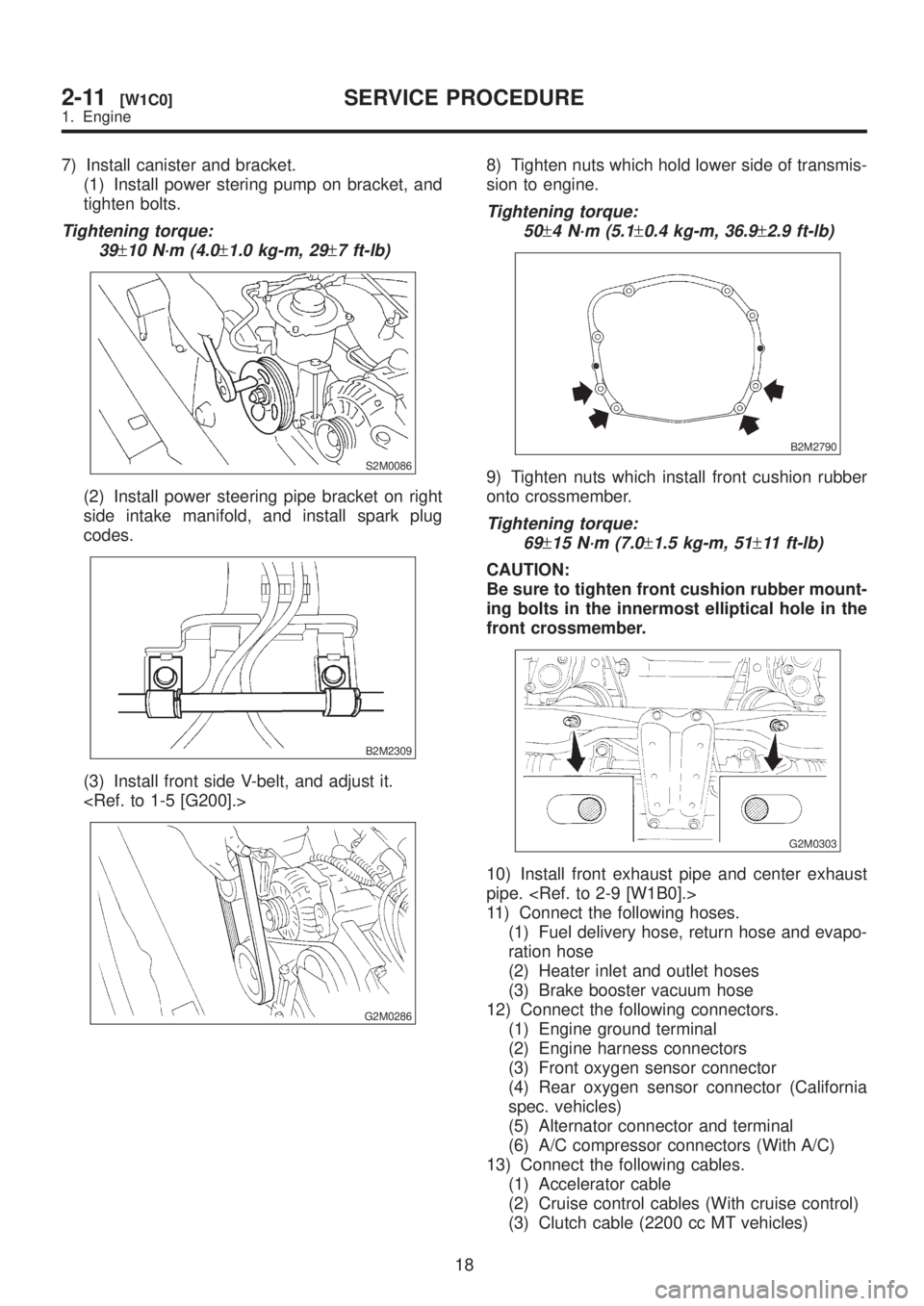

C: INSTALLATION

1) Install engine onto transmission.

(1) Position engine in engine compartment and

align it with transmission.

CAUTION:

Be careful not to damage adjacent parts or

body panels with crank pulley, oil pressure

gauge, etc.

G2M0300

(2) Apply a small amount of grease to spline of

mainshaft.

2) Tighten bolts which hold upper side of transmis-

sion to engine.

Tightening torque:

50

±4 N´m (5.1±0.4 kg-m, 36.9±2.9 ft-lb)

B2M2794

3) Remove lifting device and wire ropes.

G2M0297

4) Remove garage jack.5) Install pitching stopper.

Tightening torque:

T1: 57

±10 N´m (5.8±1.0 kg-m, 42±7 ft-lb)

T2: 49

±5 N´m (5.0±0.5 kg-m, 36.2±3.6 ft-lb)

G2M0302

6) Install torque converter onto drive plate. (AT

vehicles)

(1) Tighten bolts which hold torque converter to

drive plate.

(2) Tighten other bolts while rotating the engine

by using ST.

2200cc vehicles:

ST 499977300 CRANK PULLEY WRENCH

2500cc vehicles:

ST 499977100 CRANK PULLEY WRENCH

CAUTION:

Be careful not to drop bolts into torque con-

verter housing.

Tightening torque:

25

±2 N´m (2.5±0.2 kg-m, 18.1±1.4 ft-lb)

S2M0207

(3) Clog plug onto service hole.

17

[W1C0]2-11SERVICE PROCEDURE

1. Engine

Page 450 of 1456

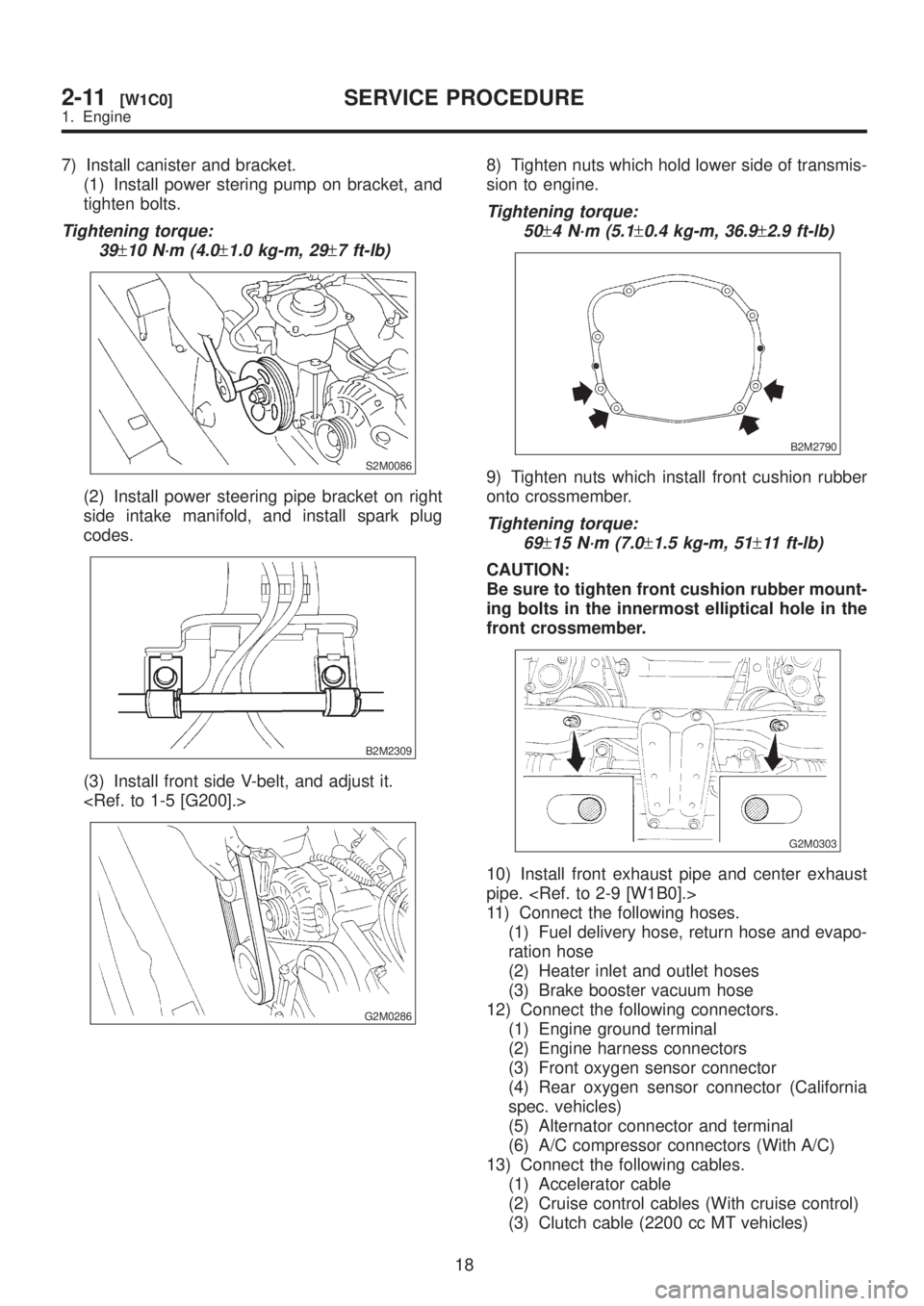

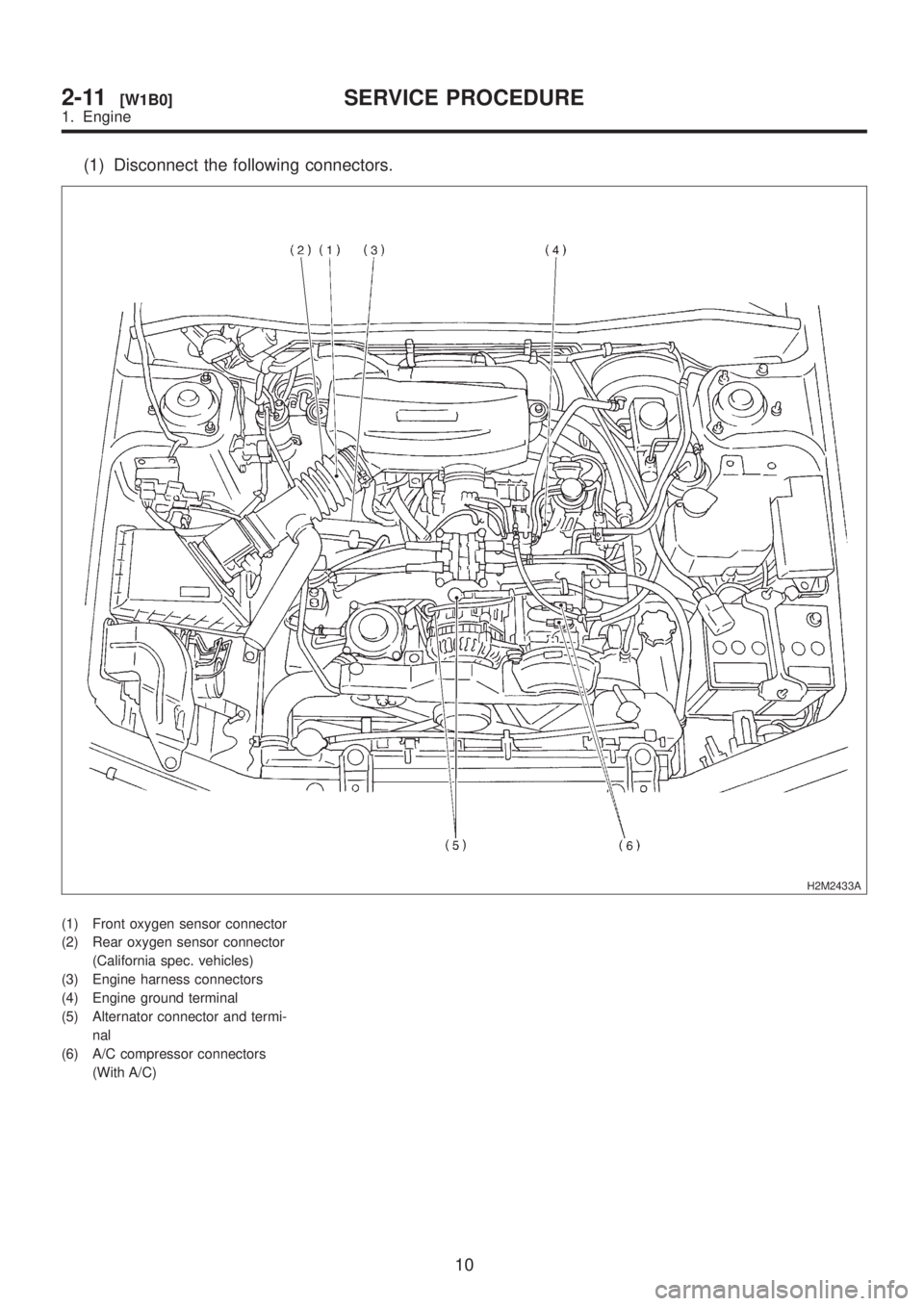

7) Install canister and bracket.

(1) Install power stering pump on bracket, and

tighten bolts.

Tightening torque:

39

±10 N´m (4.0±1.0 kg-m, 29±7 ft-lb)

S2M0086

(2) Install power steering pipe bracket on right

side intake manifold, and install spark plug

codes.

B2M2309

(3) Install front side V-belt, and adjust it.

G2M0286

8) Tighten nuts which hold lower side of transmis-

sion to engine.

Tightening torque:

50

±4 N´m (5.1±0.4 kg-m, 36.9±2.9 ft-lb)

B2M2790

9) Tighten nuts which install front cushion rubber

onto crossmember.

Tightening torque:

69

±15 N´m (7.0±1.5 kg-m, 51±11 ft-lb)

CAUTION:

Be sure to tighten front cushion rubber mount-

ing bolts in the innermost elliptical hole in the

front crossmember.

G2M0303

10) Install front exhaust pipe and center exhaust

pipe.

11) Connect the following hoses.

(1) Fuel delivery hose, return hose and evapo-

ration hose

(2) Heater inlet and outlet hoses

(3) Brake booster vacuum hose

12) Connect the following connectors.

(1) Engine ground terminal

(2) Engine harness connectors

(3) Front oxygen sensor connector

(4) Rear oxygen sensor connector (California

spec. vehicles)

(5) Alternator connector and terminal

(6) A/C compressor connectors (With A/C)

13) Connect the following cables.

(1) Accelerator cable

(2) Cruise control cables (With cruise control)

(3) Clutch cable (2200 cc MT vehicles)

18

2-11[W1C0]SERVICE PROCEDURE

1. Engine

Trending: oil change, tow, oil capacity, oil filter, battery, wheels, brake fluid

![SUBARU LEGACY 1999 Service Repair Manual 10) Remove chamber stay.

IMT vehicles

S2M0210

IAT vehicles

S6M0023

11) Disconnect connectors, cables and hoses.

9

[W1B0]2-11SERVICE PROCEDURE

1. Engine SUBARU LEGACY 1999 Service Repair Manual 10) Remove chamber stay.

IMT vehicles

S2M0210

IAT vehicles

S6M0023

11) Disconnect connectors, cables and hoses.

9

[W1B0]2-11SERVICE PROCEDURE

1. Engine](/img/17/57435/w960_57435-440.png)

![SUBARU LEGACY 1999 Service Repair Manual S2M0200A

B2M0019E

S2M0201AB2M1291E

11

[W1B0]2-11SERVICE PROCEDURE

1. Engine SUBARU LEGACY 1999 Service Repair Manual S2M0200A

B2M0019E

S2M0201AB2M1291E

11

[W1B0]2-11SERVICE PROCEDURE

1. Engine](/img/17/57435/w960_57435-442.png)

![SUBARU LEGACY 1999 Service Repair Manual B2M2295AB2M1027A

(3) Disconnect the following hoses.

H2M2433C

(1) Brake booster vacuum hose

(2) Heater inlet and outlet hose

13

[W1B0]2-11SERVICE PROCEDURE

1. Engine SUBARU LEGACY 1999 Service Repair Manual B2M2295AB2M1027A

(3) Disconnect the following hoses.

H2M2433C

(1) Brake booster vacuum hose

(2) Heater inlet and outlet hose

13

[W1B0]2-11SERVICE PROCEDURE

1. Engine](/img/17/57435/w960_57435-444.png)

![SUBARU LEGACY 1999 Service Repair Manual B2M2776AS2M0204A

12) Remove power steering pump from bracket.

(1) Loosen lock bolt and slider bolt, and remove

front side V-belt. <Ref. to 1-5 [G200].>

G2M0286

(2) Remove pipe with bracket from intake SUBARU LEGACY 1999 Service Repair Manual B2M2776AS2M0204A

12) Remove power steering pump from bracket.

(1) Loosen lock bolt and slider bolt, and remove

front side V-belt. <Ref. to 1-5 [G200].>

G2M0286

(2) Remove pipe with bracket from intake](/img/17/57435/w960_57435-445.png)