SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 601 of 1456

7) Install the oil charge pipe.

CAUTION:

Be careful not to damage the O-ring.

Tightening torque:

41

±3 N´m (4.2±0.3 kg-m, 30.4±2.2 ft-lb)

B3M1052A

8) Install the pitching stopper bracket.

Tightening torque:

41

±3 N´m (4.2±0.3 kg-m, 30.4±2.2 ft-lb)

B3M0629

9) Tighten the drain plugs.

Tightening torque:

Diff.

44

±3 N´m (4.5±0.3 kg-m, 32.5±2.2 ft-lb)

AT F

25

±2 N´m (2.5±0.2 kg-m, 18.1±1.4 ft-lb)

B3M1036A

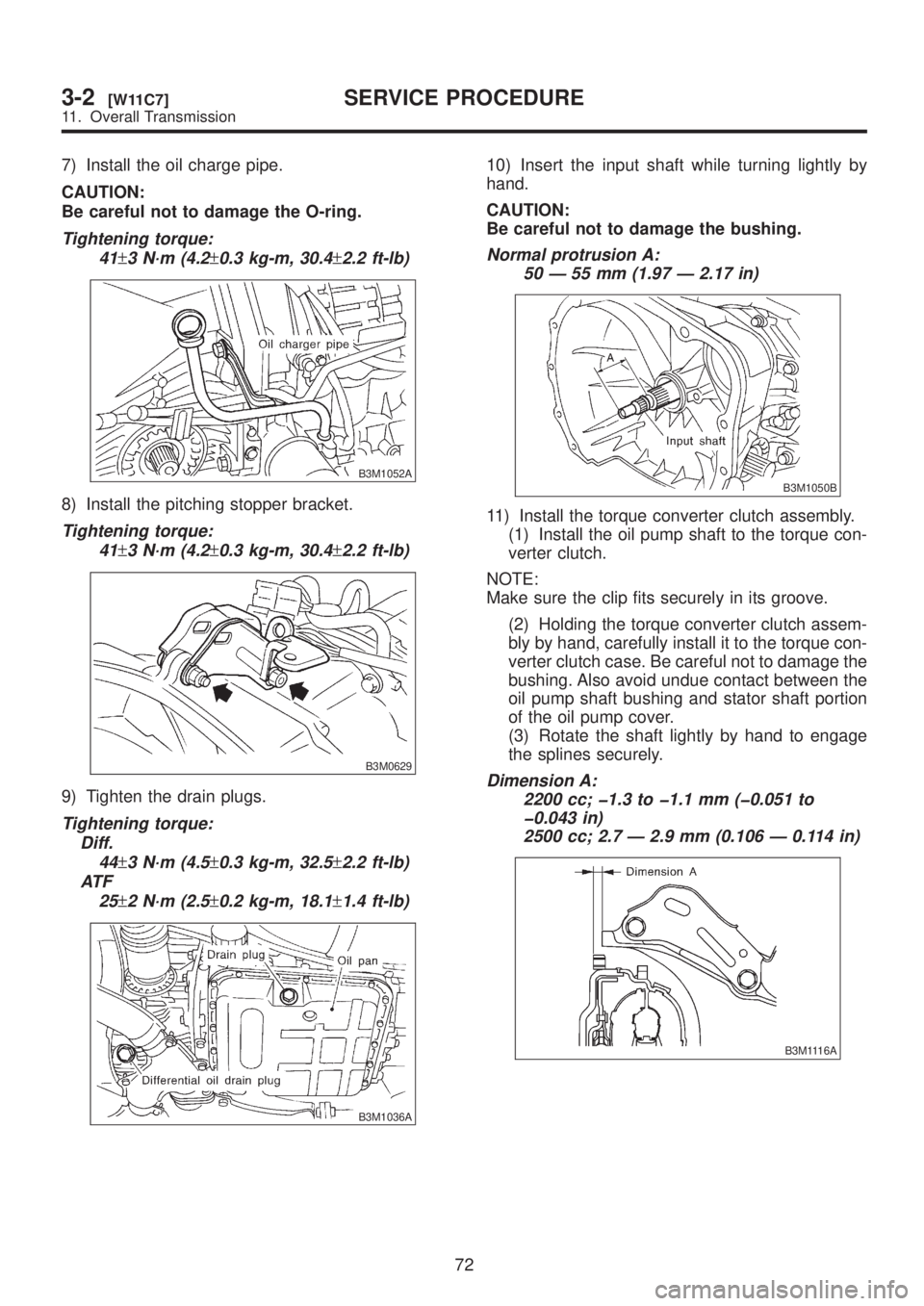

10) Insert the input shaft while turning lightly by

hand.

CAUTION:

Be careful not to damage the bushing.

Normal protrusion A:

50 Ð 55 mm (1.97 Ð 2.17 in)

B3M1050B

11) Install the torque converter clutch assembly.

(1) Install the oil pump shaft to the torque con-

verter clutch.

NOTE:

Make sure the clip fits securely in its groove.

(2) Holding the torque converter clutch assem-

bly by hand, carefully install it to the torque con-

verter clutch case. Be careful not to damage the

bushing. Also avoid undue contact between the

oil pump shaft bushing and stator shaft portion

of the oil pump cover.

(3) Rotate the shaft lightly by hand to engage

the splines securely.

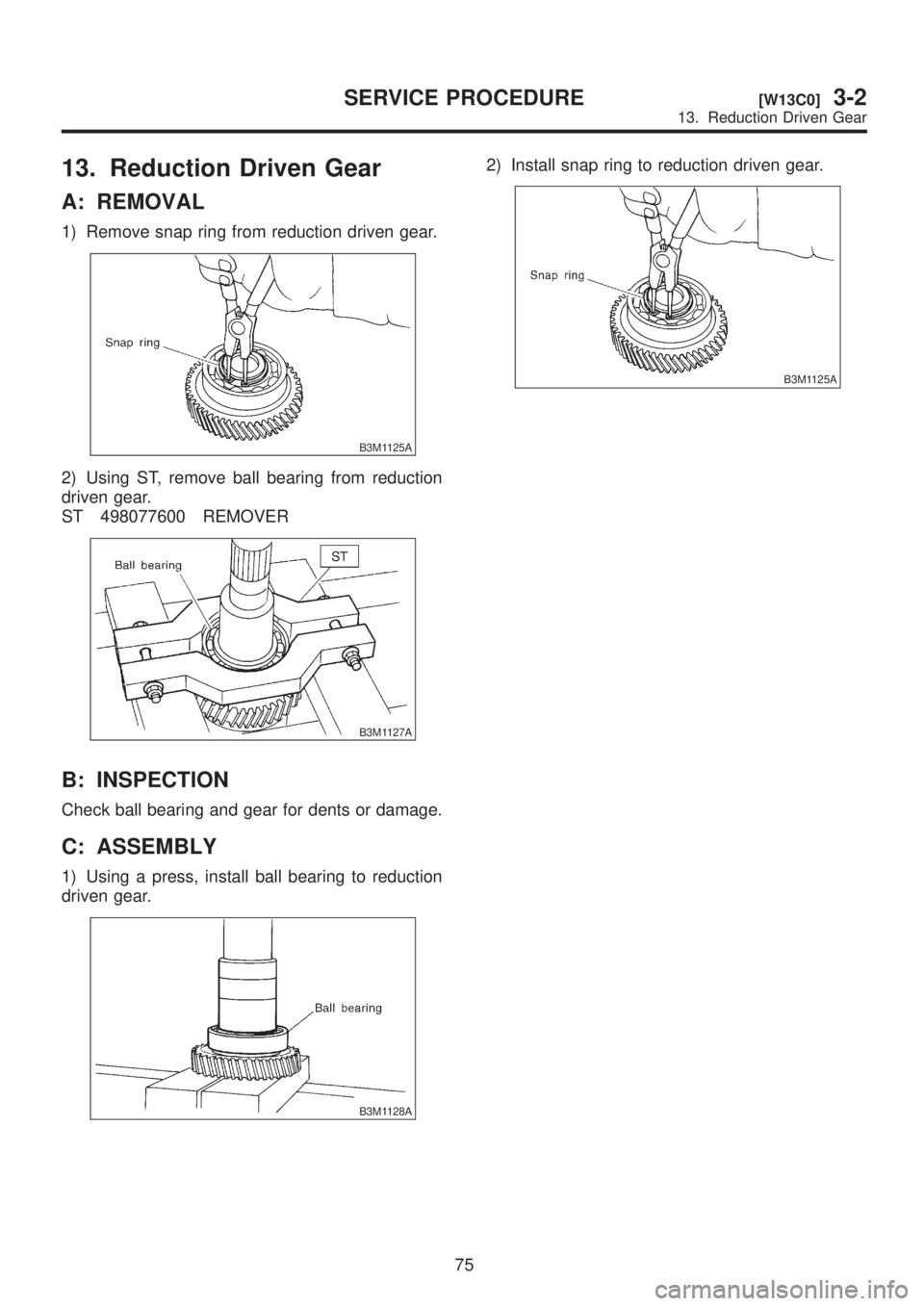

Dimension A:

2200 cc; þ1.3 to þ1.1 mm (þ0.051 to

þ0.043 in)

2500 cc; 2.7 Ð 2.9 mm (0.106 Ð 0.114 in)

B3M1116A

72

3-2[W11C7]SERVICE PROCEDURE

11. Overall Transmission

Page 602 of 1456

12) Fill ATF and differential gear oil.

NOTE:

After filling oil, insert the oil level gauge into the oil

inlet.

Differential gear oil capacity:

1.1 Ð 1.3

(1.2 Ð 1.4 US qt, 1.0 Ð 1.1

Imp qt)

Automatic transmission fluid capacity:

2200 cc; 8.4 Ð 8.7

(8.9 Ð 9.2 US qt, 7.4

Ð 7.7 Imp qt)

2500 cc; 9.3 Ð 9.6

(9.8 Ð 10.1 US qt,

8.2 Ð 8.4 Imp qt)

Recommended fluid:

Dexron II or Dexron III type automatic

transmission

73

[W11C7]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 603 of 1456

12. Reduction Drive Gear

Assembly

A: DISASSEMBLY

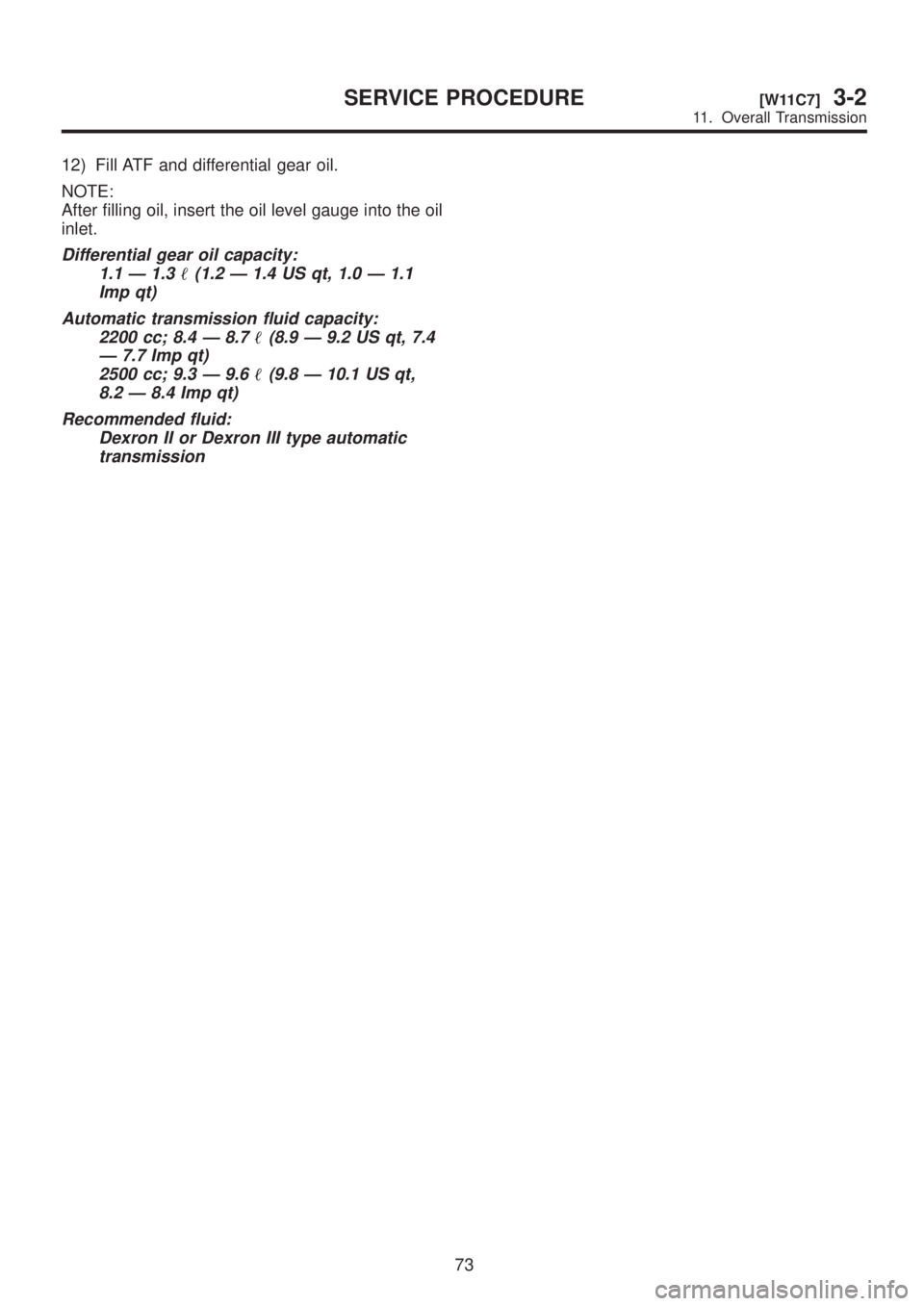

1) Take out the seal rings.

CAUTION:

Be careful not to damage the seal rings.

B3M1121A

2) Using ST, remove the ball bearing.

ST 498077600 REMOVER

B3M0962A

3) Using a press, remove the reduction drive gear.

B3M0963A

B: INSPECTION

Make sure that each component is free of harmful

gouges, cuts, or dust.

C: ASSEMBLY

1) Press-fit the reduction drive gear to the shaft.

2) Press-fit the ball bearing to the reduction drive

gear.3) Attach two seal rings.

NOTE:

To make subsequent assembly easier, apply vase-

line to the grooves of the shaft and to the exterior

of the seal ring.

B3M1121A

74

3-2[W12A0]SERVICE PROCEDURE

12. Reduction Drive Gear Assembly

Page 604 of 1456

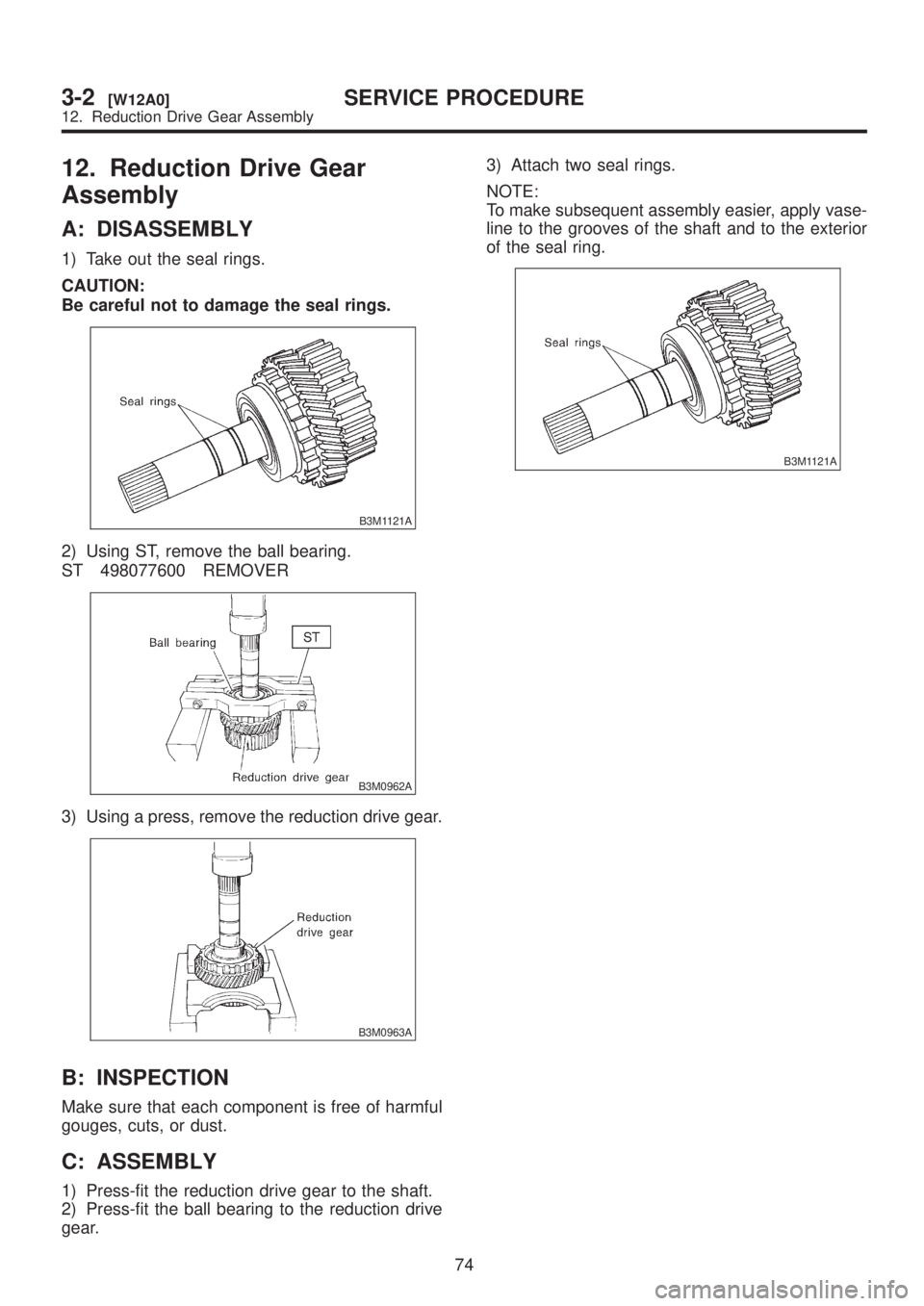

13. Reduction Driven Gear

A: REMOVAL

1) Remove snap ring from reduction driven gear.

B3M1125A

2) Using ST, remove ball bearing from reduction

driven gear.

ST 498077600 REMOVER

B3M1127A

B: INSPECTION

Check ball bearing and gear for dents or damage.

C: ASSEMBLY

1) Using a press, install ball bearing to reduction

driven gear.

B3M1128A

2) Install snap ring to reduction driven gear.

B3M1125A

75

[W13C0]3-2SERVICE PROCEDURE

13. Reduction Driven Gear

Page 605 of 1456

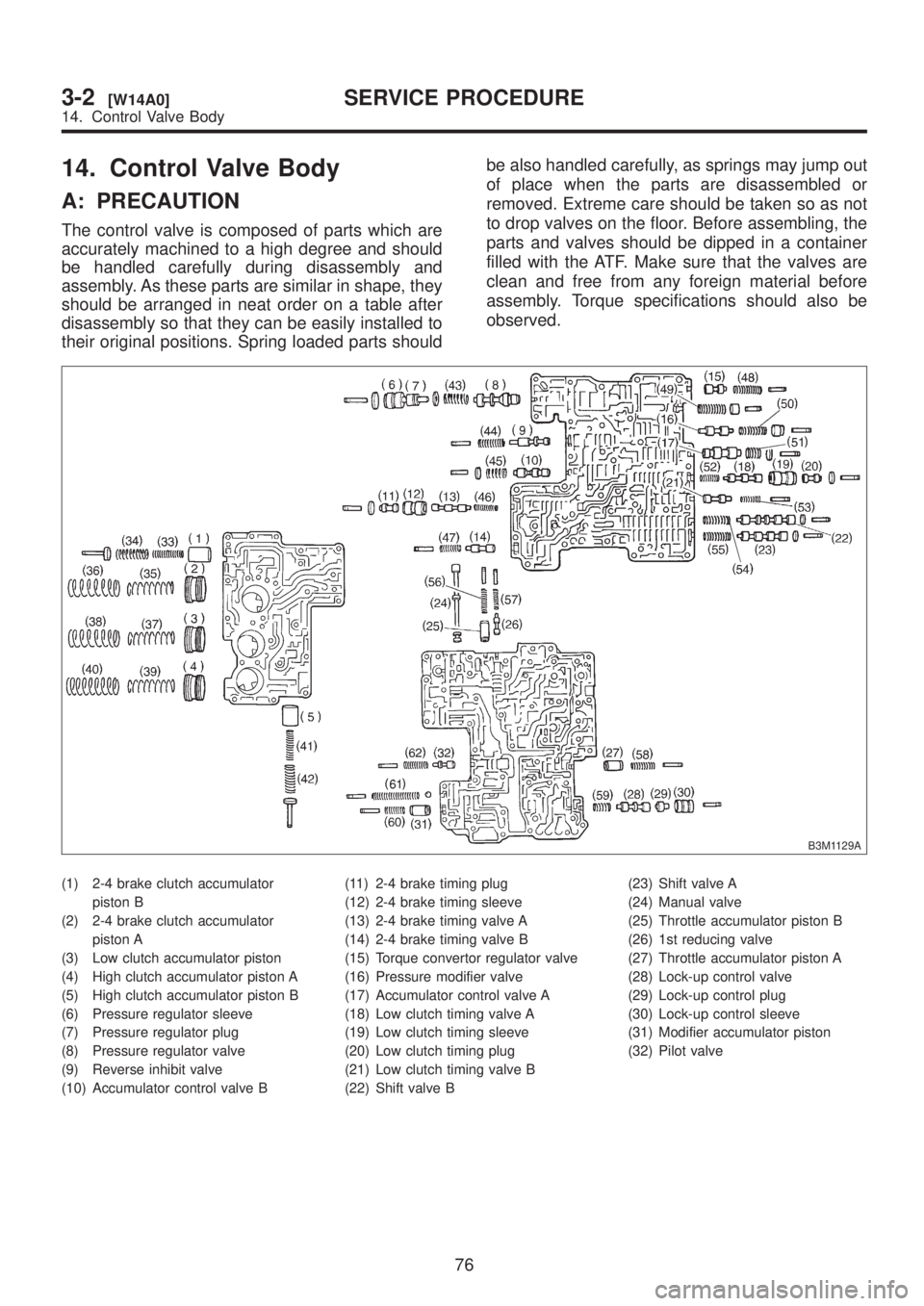

14. Control Valve Body

A: PRECAUTION

The control valve is composed of parts which are

accurately machined to a high degree and should

be handled carefully during disassembly and

assembly. As these parts are similar in shape, they

should be arranged in neat order on a table after

disassembly so that they can be easily installed to

their original positions. Spring loaded parts shouldbe also handled carefully, as springs may jump out

of place when the parts are disassembled or

removed. Extreme care should be taken so as not

to drop valves on the floor. Before assembling, the

parts and valves should be dipped in a container

filled with the ATF. Make sure that the valves are

clean and free from any foreign material before

assembly. Torque specifications should also be

observed.

B3M1129A

(1) 2-4 brake clutch accumulator

piston B

(2) 2-4 brake clutch accumulator

piston A

(3) Low clutch accumulator piston

(4) High clutch accumulator piston A

(5) High clutch accumulator piston B

(6) Pressure regulator sleeve

(7) Pressure regulator plug

(8) Pressure regulator valve

(9) Reverse inhibit valve

(10) Accumulator control valve B(11) 2-4 brake timing plug

(12) 2-4 brake timing sleeve

(13) 2-4 brake timing valve A

(14) 2-4 brake timing valve B

(15) Torque convertor regulator valve

(16) Pressure modifier valve

(17) Accumulator control valve A

(18) Low clutch timing valve A

(19) Low clutch timing sleeve

(20) Low clutch timing plug

(21) Low clutch timing valve B

(22) Shift valve B(23) Shift valve A

(24) Manual valve

(25) Throttle accumulator piston B

(26) 1st reducing valve

(27) Throttle accumulator piston A

(28) Lock-up control valve

(29) Lock-up control plug

(30) Lock-up control sleeve

(31) Modifier accumulator piston

(32) Pilot valve

76

3-2[W14A0]SERVICE PROCEDURE

14. Control Valve Body

Page 606 of 1456

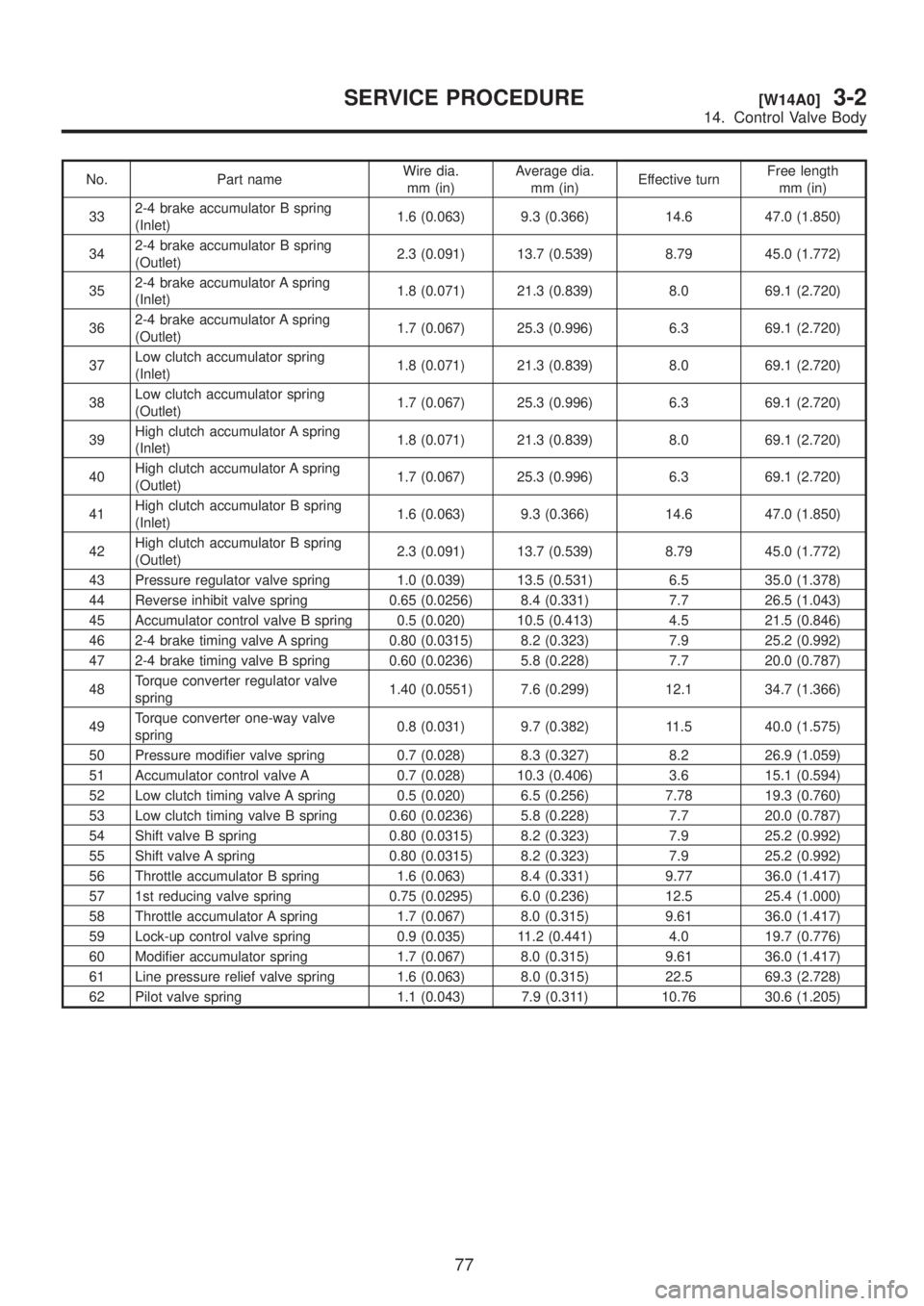

No. Part nameWire dia.

mm (in)Average dia.

mm (in)Effective turnFree length

mm (in)

332-4 brake accumulator B spring

(Inlet)1.6 (0.063) 9.3 (0.366) 14.6 47.0 (1.850)

342-4 brake accumulator B spring

(Outlet)2.3 (0.091) 13.7 (0.539) 8.79 45.0 (1.772)

352-4 brake accumulator A spring

(Inlet)1.8 (0.071) 21.3 (0.839) 8.0 69.1 (2.720)

362-4 brake accumulator A spring

(Outlet)1.7 (0.067) 25.3 (0.996) 6.3 69.1 (2.720)

37Low clutch accumulator spring

(Inlet)1.8 (0.071) 21.3 (0.839) 8.0 69.1 (2.720)

38Low clutch accumulator spring

(Outlet)1.7 (0.067) 25.3 (0.996) 6.3 69.1 (2.720)

39High clutch accumulator A spring

(Inlet)1.8 (0.071) 21.3 (0.839) 8.0 69.1 (2.720)

40High clutch accumulator A spring

(Outlet)1.7 (0.067) 25.3 (0.996) 6.3 69.1 (2.720)

41High clutch accumulator B spring

(Inlet)1.6 (0.063) 9.3 (0.366) 14.6 47.0 (1.850)

42High clutch accumulator B spring

(Outlet)2.3 (0.091) 13.7 (0.539) 8.79 45.0 (1.772)

43 Pressure regulator valve spring 1.0 (0.039) 13.5 (0.531) 6.5 35.0 (1.378)

44 Reverse inhibit valve spring 0.65 (0.0256) 8.4 (0.331) 7.7 26.5 (1.043)

45 Accumulator control valve B spring 0.5 (0.020) 10.5 (0.413) 4.5 21.5 (0.846)

46 2-4 brake timing valve A spring 0.80 (0.0315) 8.2 (0.323) 7.9 25.2 (0.992)

47 2-4 brake timing valve B spring 0.60 (0.0236) 5.8 (0.228) 7.7 20.0 (0.787)

48Torque converter regulator valve

spring1.40 (0.0551) 7.6 (0.299) 12.1 34.7 (1.366)

49Torque converter one-way valve

spring0.8 (0.031) 9.7 (0.382) 11.5 40.0 (1.575)

50 Pressure modifier valve spring 0.7 (0.028) 8.3 (0.327) 8.2 26.9 (1.059)

51 Accumulator control valve A 0.7 (0.028) 10.3 (0.406) 3.6 15.1 (0.594)

52 Low clutch timing valve A spring 0.5 (0.020) 6.5 (0.256) 7.78 19.3 (0.760)

53 Low clutch timing valve B spring 0.60 (0.0236) 5.8 (0.228) 7.7 20.0 (0.787)

54 Shift valve B spring 0.80 (0.0315) 8.2 (0.323) 7.9 25.2 (0.992)

55 Shift valve A spring 0.80 (0.0315) 8.2 (0.323) 7.9 25.2 (0.992)

56 Throttle accumulator B spring 1.6 (0.063) 8.4 (0.331) 9.77 36.0 (1.417)

57 1st reducing valve spring 0.75 (0.0295) 6.0 (0.236) 12.5 25.4 (1.000)

58 Throttle accumulator A spring 1.7 (0.067) 8.0 (0.315) 9.61 36.0 (1.417)

59 Lock-up control valve spring 0.9 (0.035) 11.2 (0.441) 4.0 19.7 (0.776)

60 Modifier accumulator spring 1.7 (0.067) 8.0 (0.315) 9.61 36.0 (1.417)

61 Line pressure relief valve spring 1.6 (0.063) 8.0 (0.315) 22.5 69.3 (2.728)

62 Pilot valve spring 1.1 (0.043) 7.9 (0.311) 10.76 30.6 (1.205)

77

[W14A0]3-2SERVICE PROCEDURE

14. Control Valve Body

Page 607 of 1456

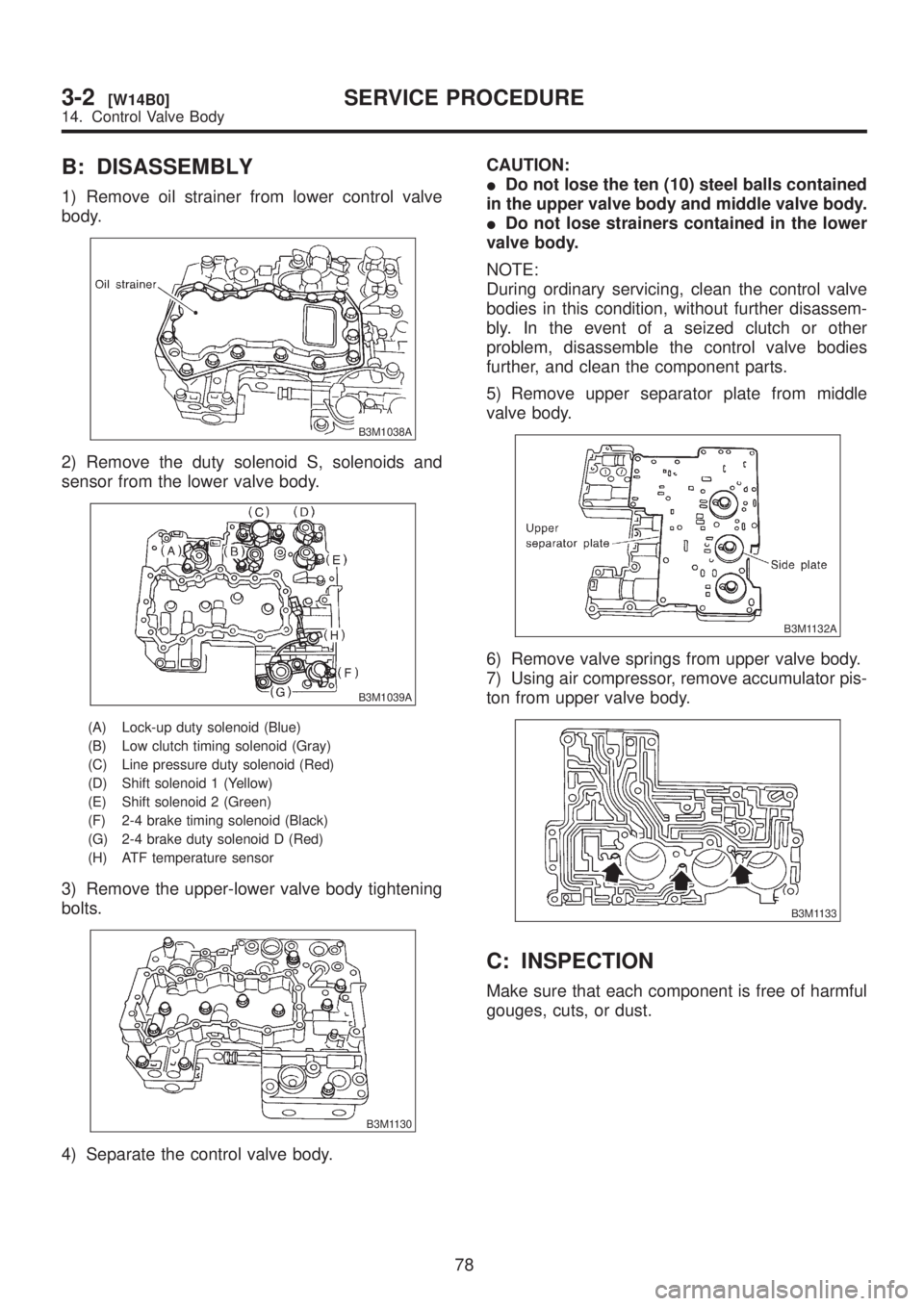

B: DISASSEMBLY

1) Remove oil strainer from lower control valve

body.

B3M1038A

2) Remove the duty solenoid S, solenoids and

sensor from the lower valve body.

B3M1039A

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 1 (Yellow)

(E) Shift solenoid 2 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid D (Red)

(H) ATF temperature sensor

3) Remove the upper-lower valve body tightening

bolts.

B3M1130

4) Separate the control valve body.CAUTION:

IDo not lose the ten (10) steel balls contained

in the upper valve body and middle valve body.

IDo not lose strainers contained in the lower

valve body.

NOTE:

During ordinary servicing, clean the control valve

bodies in this condition, without further disassem-

bly. In the event of a seized clutch or other

problem, disassemble the control valve bodies

further, and clean the component parts.

5) Remove upper separator plate from middle

valve body.

B3M1132A

6) Remove valve springs from upper valve body.

7) Using air compressor, remove accumulator pis-

ton from upper valve body.

B3M1133

C: INSPECTION

Make sure that each component is free of harmful

gouges, cuts, or dust.

78

3-2[W14B0]SERVICE PROCEDURE

14. Control Valve Body

Page 608 of 1456

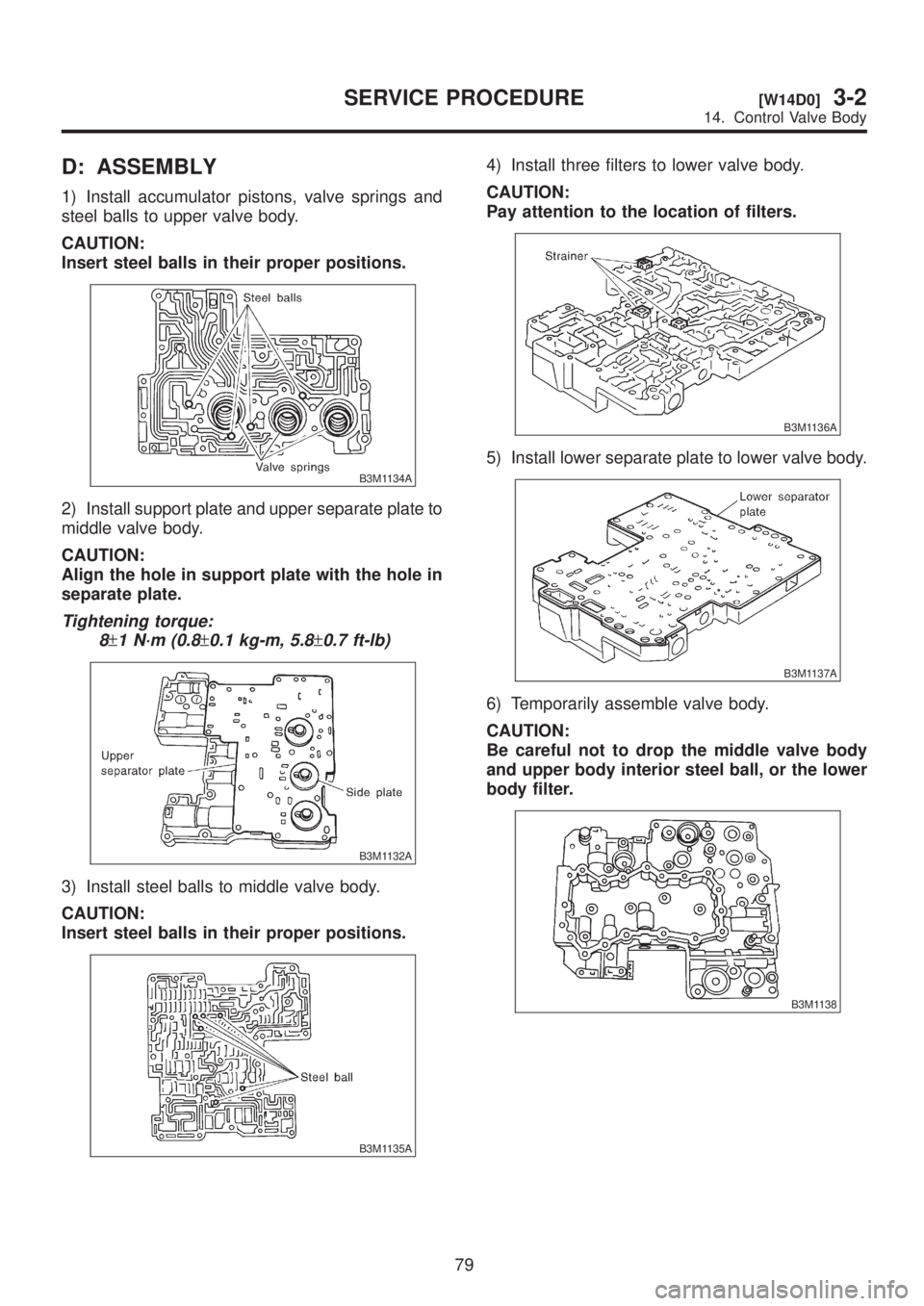

D: ASSEMBLY

1) Install accumulator pistons, valve springs and

steel balls to upper valve body.

CAUTION:

Insert steel balls in their proper positions.

B3M1134A

2) Install support plate and upper separate plate to

middle valve body.

CAUTION:

Align the hole in support plate with the hole in

separate plate.

Tightening torque:

8

±1 N´m (0.8±0.1 kg-m, 5.8±0.7 ft-lb)

B3M1132A

3) Install steel balls to middle valve body.

CAUTION:

Insert steel balls in their proper positions.

B3M1135A

4) Install three filters to lower valve body.

CAUTION:

Pay attention to the location of filters.

B3M1136A

5) Install lower separate plate to lower valve body.

B3M1137A

6) Temporarily assemble valve body.

CAUTION:

Be careful not to drop the middle valve body

and upper body interior steel ball, or the lower

body filter.

B3M1138

79

[W14D0]3-2SERVICE PROCEDURE

14. Control Valve Body

Page 609 of 1456

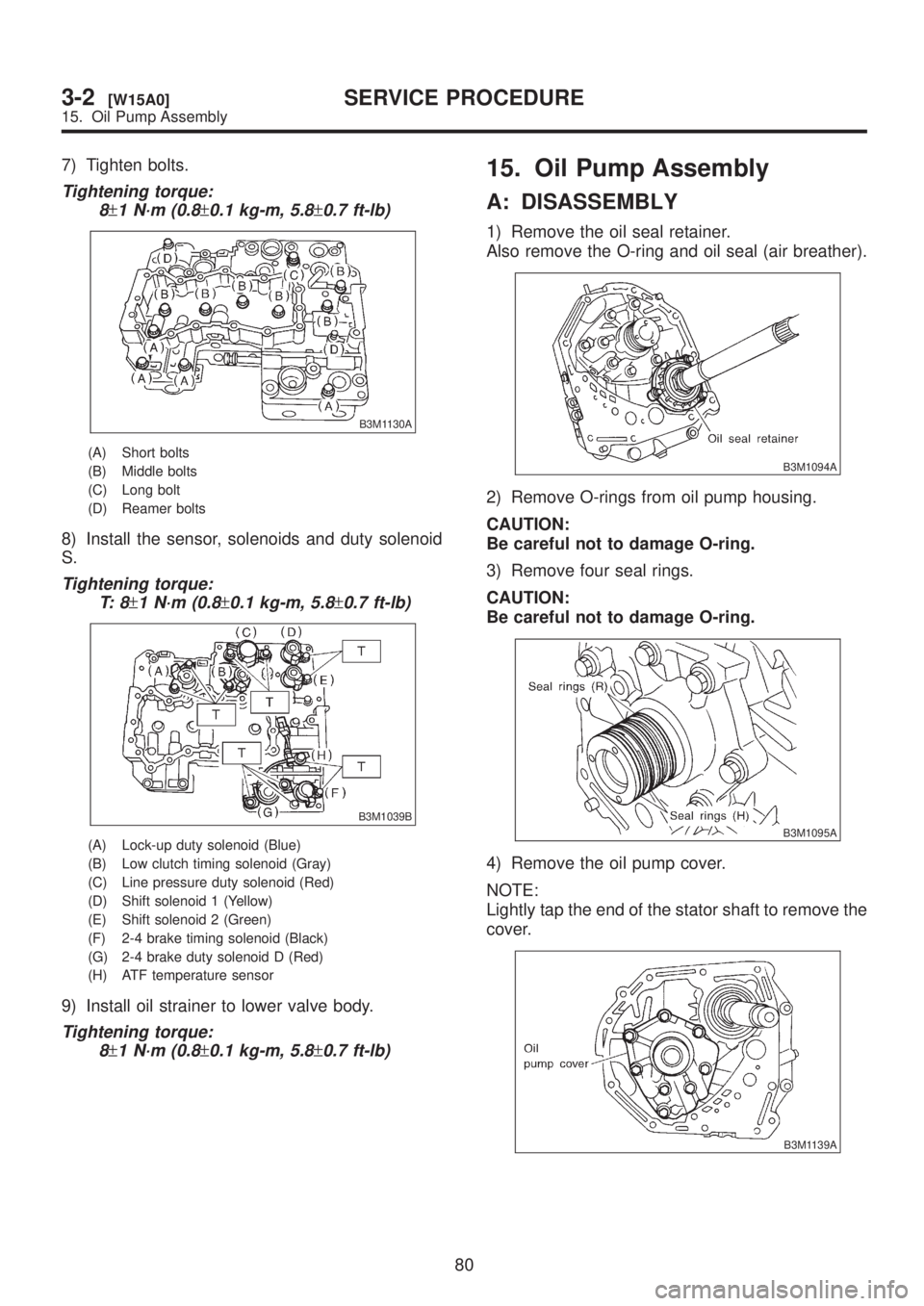

7) Tighten bolts.

Tightening torque:

8

±1 N´m (0.8±0.1 kg-m, 5.8±0.7 ft-lb)

B3M1130A

(A) Short bolts

(B) Middle bolts

(C) Long bolt

(D) Reamer bolts

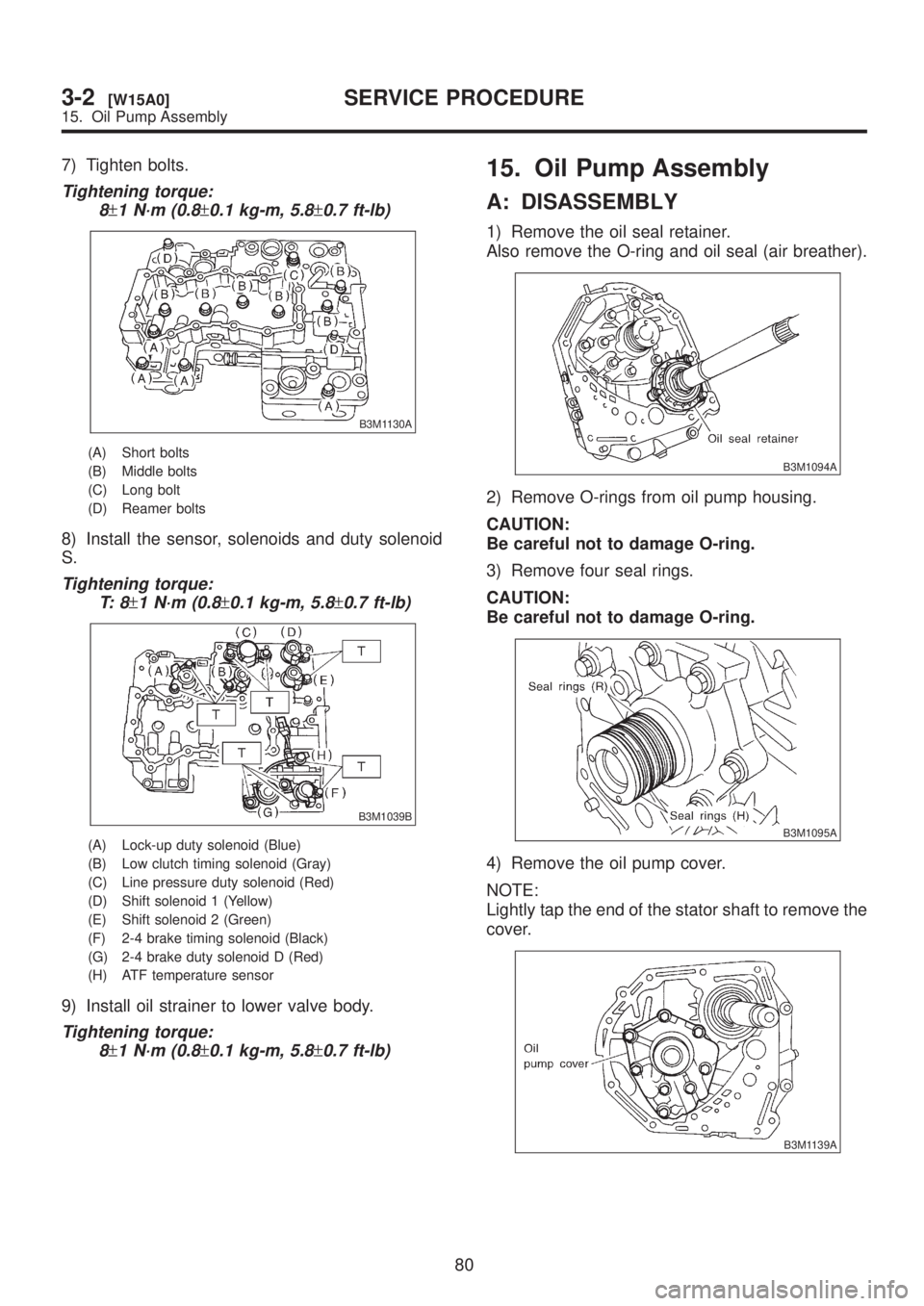

8) Install the sensor, solenoids and duty solenoid

S.

Tightening torque:

T: 8

±1 N´m (0.8±0.1 kg-m, 5.8±0.7 ft-lb)

B3M1039B

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 1 (Yellow)

(E) Shift solenoid 2 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid D (Red)

(H) ATF temperature sensor

9) Install oil strainer to lower valve body.

Tightening torque:

8

±1 N´m (0.8±0.1 kg-m, 5.8±0.7 ft-lb)

15. Oil Pump Assembly

A: DISASSEMBLY

1) Remove the oil seal retainer.

Also remove the O-ring and oil seal (air breather).

B3M1094A

2) Remove O-rings from oil pump housing.

CAUTION:

Be careful not to damage O-ring.

3) Remove four seal rings.

CAUTION:

Be careful not to damage O-ring.

B3M1095A

4) Remove the oil pump cover.

NOTE:

Lightly tap the end of the stator shaft to remove the

cover.

B3M1139A

80

3-2[W15A0]SERVICE PROCEDURE

15. Oil Pump Assembly

Page 610 of 1456

7) Tighten bolts.

Tightening torque:

8

±1 N´m (0.8±0.1 kg-m, 5.8±0.7 ft-lb)

B3M1130A

(A) Short bolts

(B) Middle bolts

(C) Long bolt

(D) Reamer bolts

8) Install the sensor, solenoids and duty solenoid

S.

Tightening torque:

T: 8

±1 N´m (0.8±0.1 kg-m, 5.8±0.7 ft-lb)

B3M1039B

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 1 (Yellow)

(E) Shift solenoid 2 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid D (Red)

(H) ATF temperature sensor

9) Install oil strainer to lower valve body.

Tightening torque:

8

±1 N´m (0.8±0.1 kg-m, 5.8±0.7 ft-lb)

15. Oil Pump Assembly

A: DISASSEMBLY

1) Remove the oil seal retainer.

Also remove the O-ring and oil seal (air breather).

B3M1094A

2) Remove O-rings from oil pump housing.

CAUTION:

Be careful not to damage O-ring.

3) Remove four seal rings.

CAUTION:

Be careful not to damage O-ring.

B3M1095A

4) Remove the oil pump cover.

NOTE:

Lightly tap the end of the stator shaft to remove the

cover.

B3M1139A

80

3-2[W15A0]SERVICE PROCEDURE

15. Oil Pump Assembly