SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1111 of 2453

WT-5

General Description

WHEEL AND TIRE SYSTEM

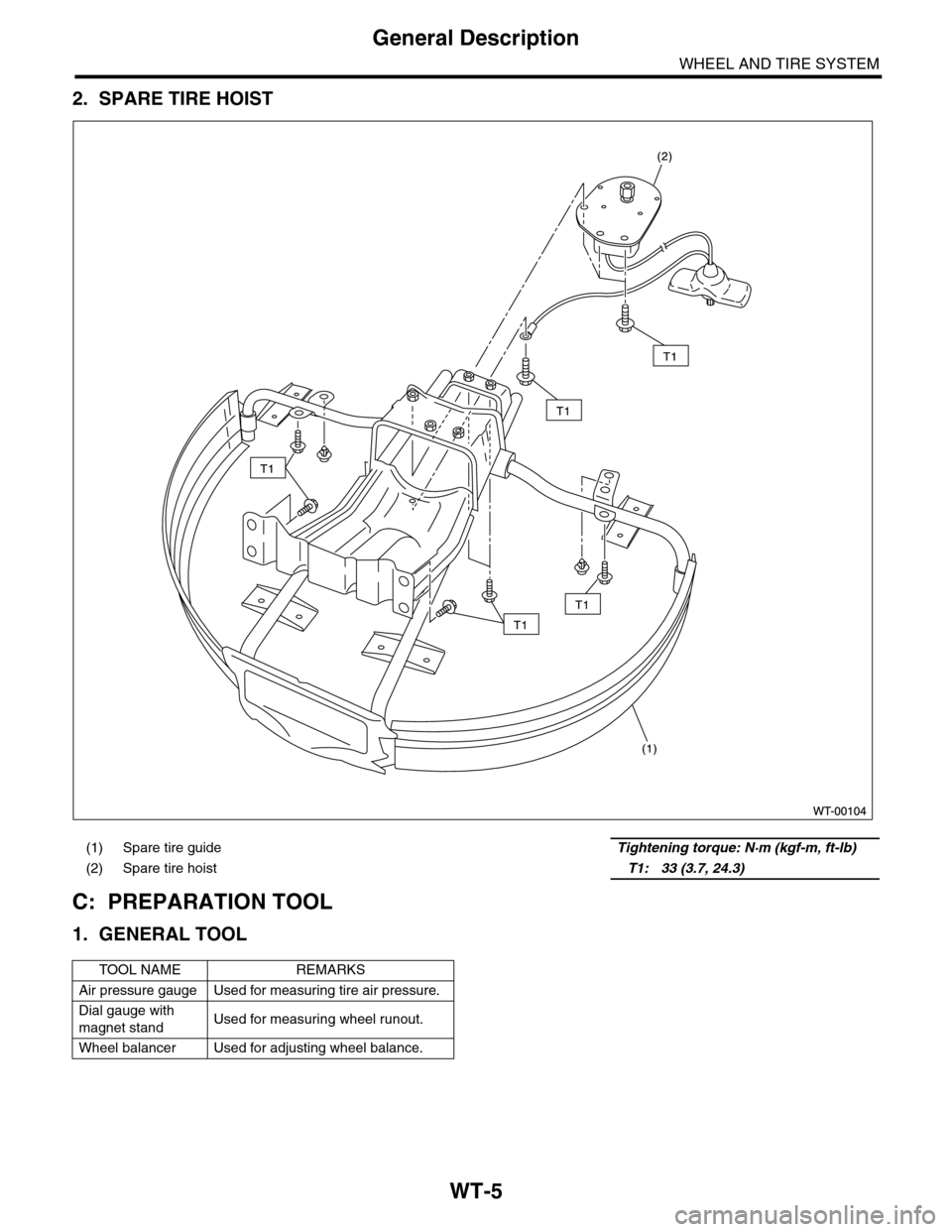

2. SPARE TIRE HOIST

C: PREPARATION TOOL

1. GENERAL TOOL

(1) Spare tire guide Tightening torque: N·m (kgf-m, ft-lb)

(2) Spare tire hoist T1: 33 (3.7, 24.3)

TOOL NAME REMARKS

Air pressure gauge Used for measuring tire air pressure.

Dial gauge with

magnet standUsed for measuring wheel runout.

Wheel balancer Used for adjusting wheel balance.

Page 1112 of 2453

WT-6

Tire

WHEEL AND TIRE SYSTEM

2. Tire

A: INSPECTION

1) Take stones, glass, nails etc. out of the tread

groove.

2) Replace tires in the following cases.

CAUTION:

•When replacing a tire, make sure to use only

tires of the same size, construction and load

range as originally installed.

•Use a tire changer when removing the tire

from the wheel.

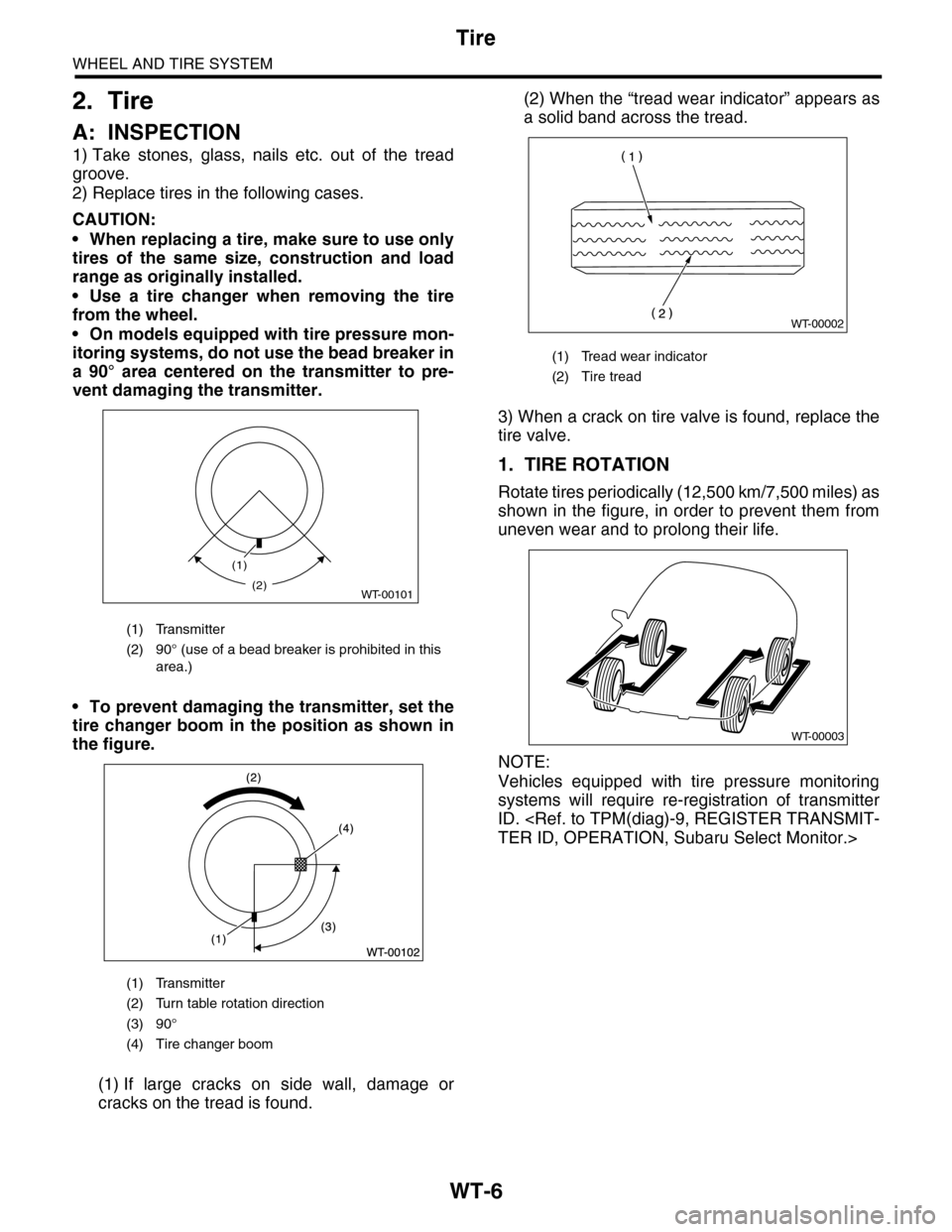

•On models equipped with tire pressure mon-

itoring systems, do not use the bead breaker in

a 90° area centered on the transmitter to pre-

vent damaging the transmitter.

•To prevent damaging the transmitter, set the

tire changer boom in the position as shown in

the figure.

(1) If large cracks on side wall, damage or

cracks on the tread is found.

(2) When the “tread wear indicator” appears as

a solid band across the tread.

3) When a crack on tire valve is found, replace the

tire valve.

1. TIRE ROTATION

Rotate tires periodically (12,500 km/7,500 miles) as

shown in the figure, in order to prevent them from

uneven wear and to prolong their life.

NOTE:

Vehicles equipped with tire pressure monitoring

systems will require re-registration of transmitter

ID.

(1) Transmitter

(2) 90° (use of a bead breaker is prohibited in this

area.)

(1) Transmitter

(2) Turn table rotation direction

(3) 90°

(4) Tire changer boom

(1)

WT-00101(2)

(1) Tread wear indicator

(2) Tire tread

WT-00002

WT-00003

Page 1113 of 2453

WT-7

Aluminum Wheel

WHEEL AND TIRE SYSTEM

3. Aluminum Wheel

A: REMOVAL

1) Apply the parking brake, and position select le-

ver to “P” or “LOW”.

2) Set the shop jacks or a lift to the specified points,

and support the vehicle with its wheels slightly con-

tacting the floor.

3) Loosen the wheel nuts.

4) Raise the vehicle until its wheels are off the

ground using the jack or a lift.

5) Remove the wheel nuts and wheels.

NOTE:

•When removing the wheels, be careful not to

damage the hub bolts.

•Place the wheels with their outer sides facing up-

ward to prevent wheels from being damaged.

B: INSTALLATION

1) Remove dirt from the mating surface of the

wheel and brake rotor.

2) Attach the wheel to the hub by aligning the wheel

bolt holes with the hub bolts.

3) Temporarily attach the wheel nuts to the hub

bolts. (In the case of aluminum wheels, use SUBA-

RU genuine wheel nuts for aluminum wheels.)

4) Tighten the nuts by hand, making sure the wheel

hub hole is aligned correctly to the guide portion of

hub.

5) Tighten the wheel nuts in a diagonal selection to

the specified torque. Use a wheel nut wrench.

Wheel nut tightening torque:

110 N·m (11.2 kgf-m, 81.1 ft-lb)

CAUTION:

•Tighten the wheel nuts in two or three steps

by gradually increasing the torque on opposing

nuts, until they reach the specified torque.

•Do not push the wrench by foot. Always use

both hands when tightening the nuts.

•Make sure the bolt, nut and the nut seating

surface of the wheel are free from oil.

6) If a wheel is removed for replacement or for re-

pair of a puncture, retighten the wheel nuts to the

specified torque after driving 1,000 km (600 miles).

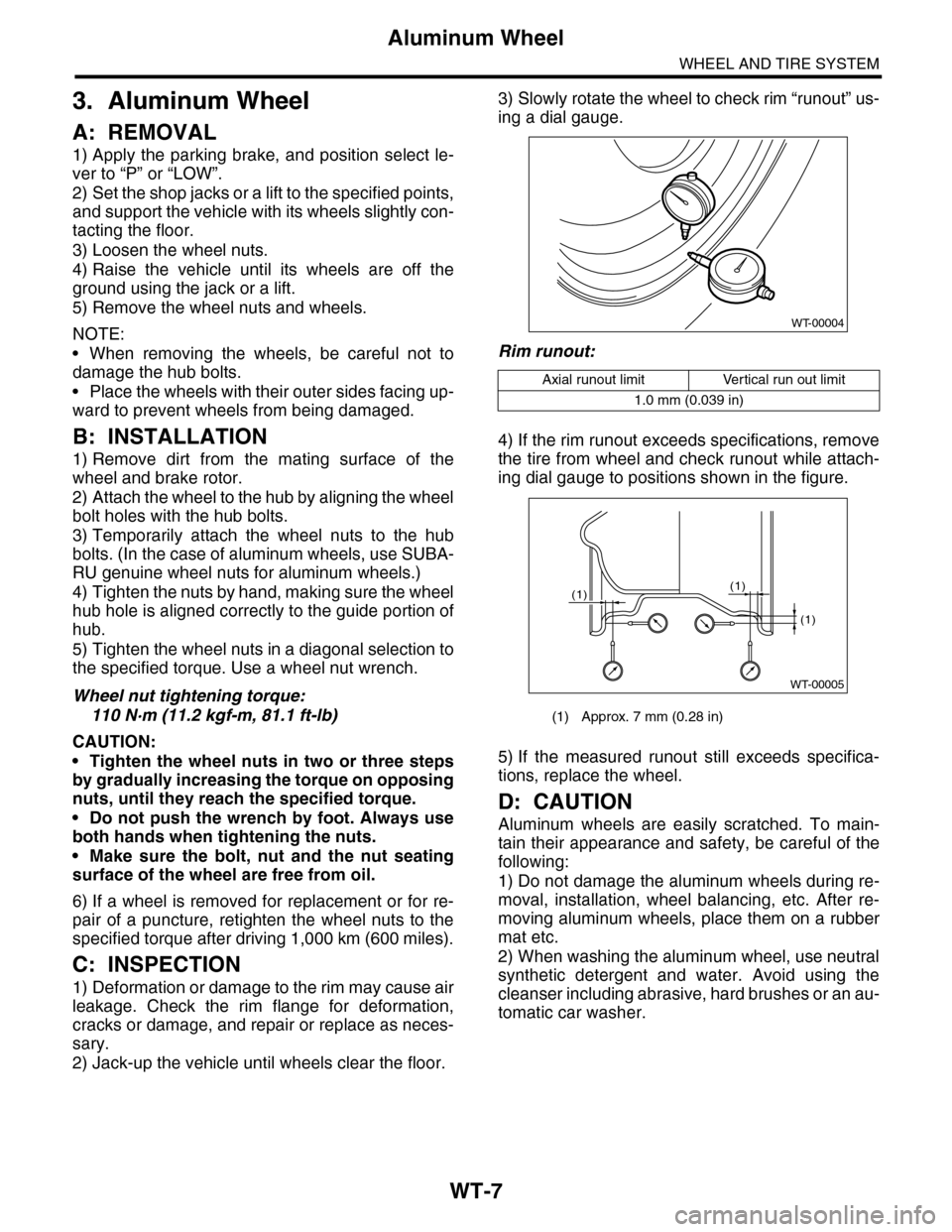

C: INSPECTION

1) Deformation or damage to the rim may cause air

leakage. Check the rim flange for deformation,

cracks or damage, and repair or replace as neces-

sary.

2) Jack-up the vehicle until wheels clear the floor.

3) Slowly rotate the wheel to check rim “runout” us-

ing a dial gauge.

Rim runout:

4) If the rim runout exceeds specifications, remove

the tire from wheel and check runout while attach-

ing dial gauge to positions shown in the figure.

5) If the measured runout still exceeds specifica-

tions, replace the wheel.

D: CAUTION

Aluminum wheels are easily scratched. To main-

tain their appearance and safety, be careful of the

following:

1) Do not damage the aluminum wheels during re-

moval, installation, wheel balancing, etc. After re-

moving aluminum wheels, place them on a rubber

mat etc.

2) When washing the aluminum wheel, use neutral

synthetic detergent and water. Avoid using the

cleanser including abrasive, hard brushes or an au-

tomatic car washer.

Axial runout limit Vertical run out limit

1.0 mm (0.039 in)

(1) Approx. 7 mm (0.28 in)

WT-00004

WT-00005

(1)

(1)

(1)

Page 1114 of 2453

WT-8

Wheel Balancing

WHEEL AND TIRE SYSTEM

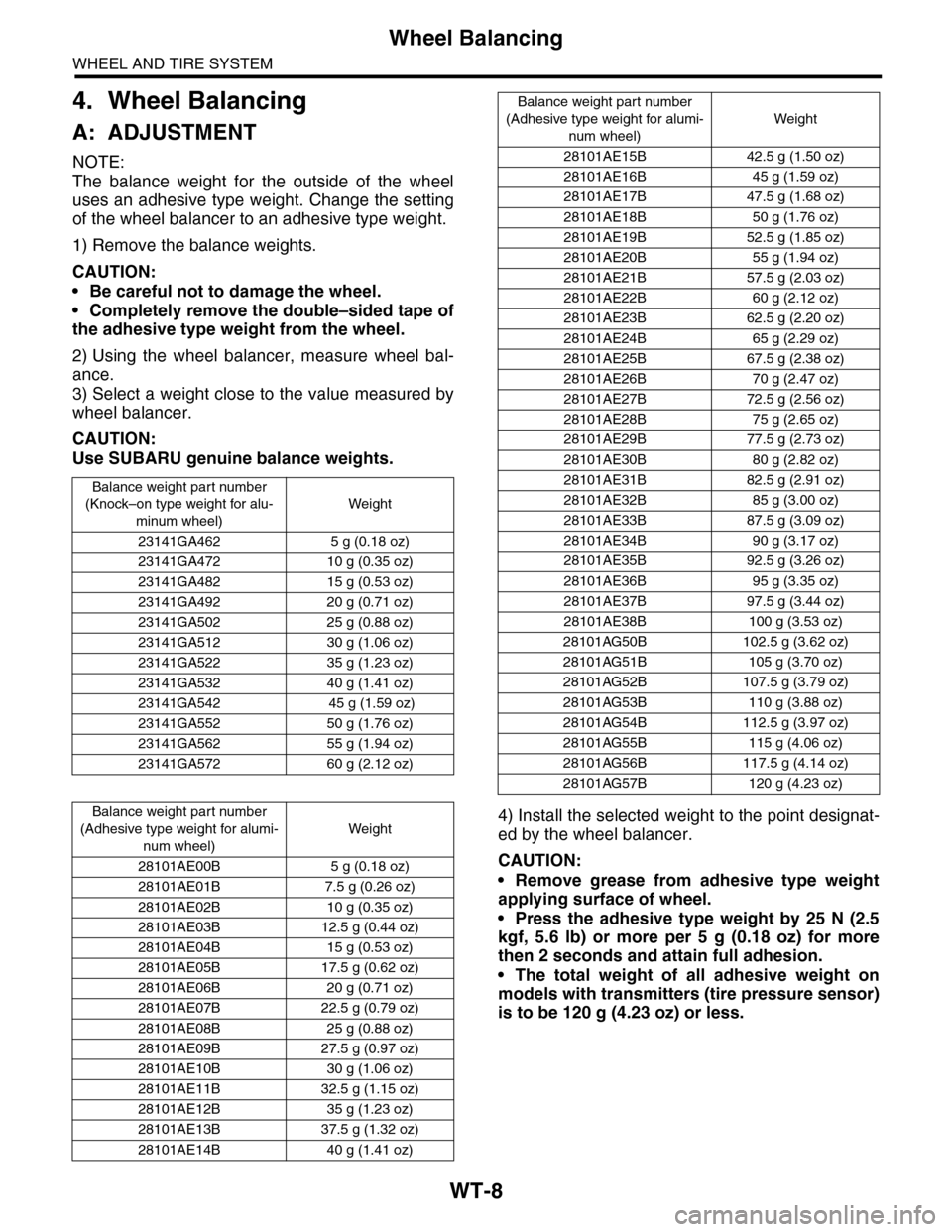

4. Wheel Balancing

A: ADJUSTMENT

NOTE:

The balance weight for the outside of the wheel

uses an adhesive type weight. Change the setting

of the wheel balancer to an adhesive type weight.

1) Remove the balance weights.

CAUTION:

•Be careful not to damage the wheel.

•Completely remove the double–sided tape of

the adhesive type weight from the wheel.

2) Using the wheel balancer, measure wheel bal-

ance.

3) Select a weight close to the value measured by

wheel balancer.

CAUTION:

Use SUBARU genuine balance weights.

4) Install the selected weight to the point designat-

ed by the wheel balancer.

CAUTION:

•Remove grease from adhesive type weight

applying surface of wheel.

•Press the adhesive type weight by 25 N (2.5

kgf, 5.6 lb) or more per 5 g (0.18 oz) for more

then 2 seconds and attain full adhesion.

•The total weight of all adhesive weight on

models with transmitters (tire pressure sensor)

is to be 120 g (4.23 oz) or less.

Balance weight par t number

(Knock–on type weight for alu-

minum wheel)

Weight

23141GA462 5 g (0.18 oz)

23141GA472 10 g (0.35 oz)

23141GA482 15 g (0.53 oz)

23141GA492 20 g (0.71 oz)

23141GA502 25 g (0.88 oz)

23141GA512 30 g (1.06 oz)

23141GA522 35 g (1.23 oz)

23141GA532 40 g (1.41 oz)

23141GA542 45 g (1.59 oz)

23141GA552 50 g (1.76 oz)

23141GA562 55 g (1.94 oz)

23141GA572 60 g (2.12 oz)

Balance weight par t number

(Adhesive type weight for alumi-

num wheel)

Weight

28101AE00B 5 g (0.18 oz)

28101AE01B 7.5 g (0.26 oz)

28101AE02B 10 g (0.35 oz)

28101AE03B 12.5 g (0.44 oz)

28101AE04B 15 g (0.53 oz)

28101AE05B 17.5 g (0.62 oz)

28101AE06B 20 g (0.71 oz)

28101AE07B 22.5 g (0.79 oz)

28101AE08B 25 g (0.88 oz)

28101AE09B 27.5 g (0.97 oz)

28101AE10B 30 g (1.06 oz)

28101AE11B 32.5 g (1.15 oz)

28101AE12B 35 g (1.23 oz)

28101AE13B 37.5 g (1.32 oz)

28101AE14B 40 g (1.41 oz)

28101AE15B 42.5 g (1.50 oz)

28101AE16B 45 g (1.59 oz)

28101AE17B 47.5 g (1.68 oz)

28101AE18B 50 g (1.76 oz)

28101AE19B 52.5 g (1.85 oz)

28101AE20B 55 g (1.94 oz)

28101AE21B 57.5 g (2.03 oz)

28101AE22B 60 g (2.12 oz)

28101AE23B 62.5 g (2.20 oz)

28101AE24B 65 g (2.29 oz)

28101AE25B 67.5 g (2.38 oz)

28101AE26B 70 g (2.47 oz)

28101AE27B 72.5 g (2.56 oz)

28101AE28B 75 g (2.65 oz)

28101AE29B 77.5 g (2.73 oz)

28101AE30B 80 g (2.82 oz)

28101AE31B 82.5 g (2.91 oz)

28101AE32B 85 g (3.00 oz)

28101AE33B 87.5 g (3.09 oz)

28101AE34B 90 g (3.17 oz)

28101AE35B 92.5 g (3.26 oz)

28101AE36B 95 g (3.35 oz)

28101AE37B 97.5 g (3.44 oz)

28101AE38B 100 g (3.53 oz)

28101AG50B 102.5 g (3.62 oz)

28101AG51B 105 g (3.70 oz)

28101AG52B 107.5 g (3.79 oz)

28101AG53B 110 g (3.88 oz)

28101AG54B 112.5 g (3.97 oz)

28101AG55B 115 g (4.06 oz)

28101AG56B 117.5 g (4.14 oz)

28101AG57B 120 g (4.23 oz)

Balance weight part number

(Adhesive type weight for alumi-

num wheel)

Weight

Page 1115 of 2453

WT-9

Wheel Balancing

WHEEL AND TIRE SYSTEM

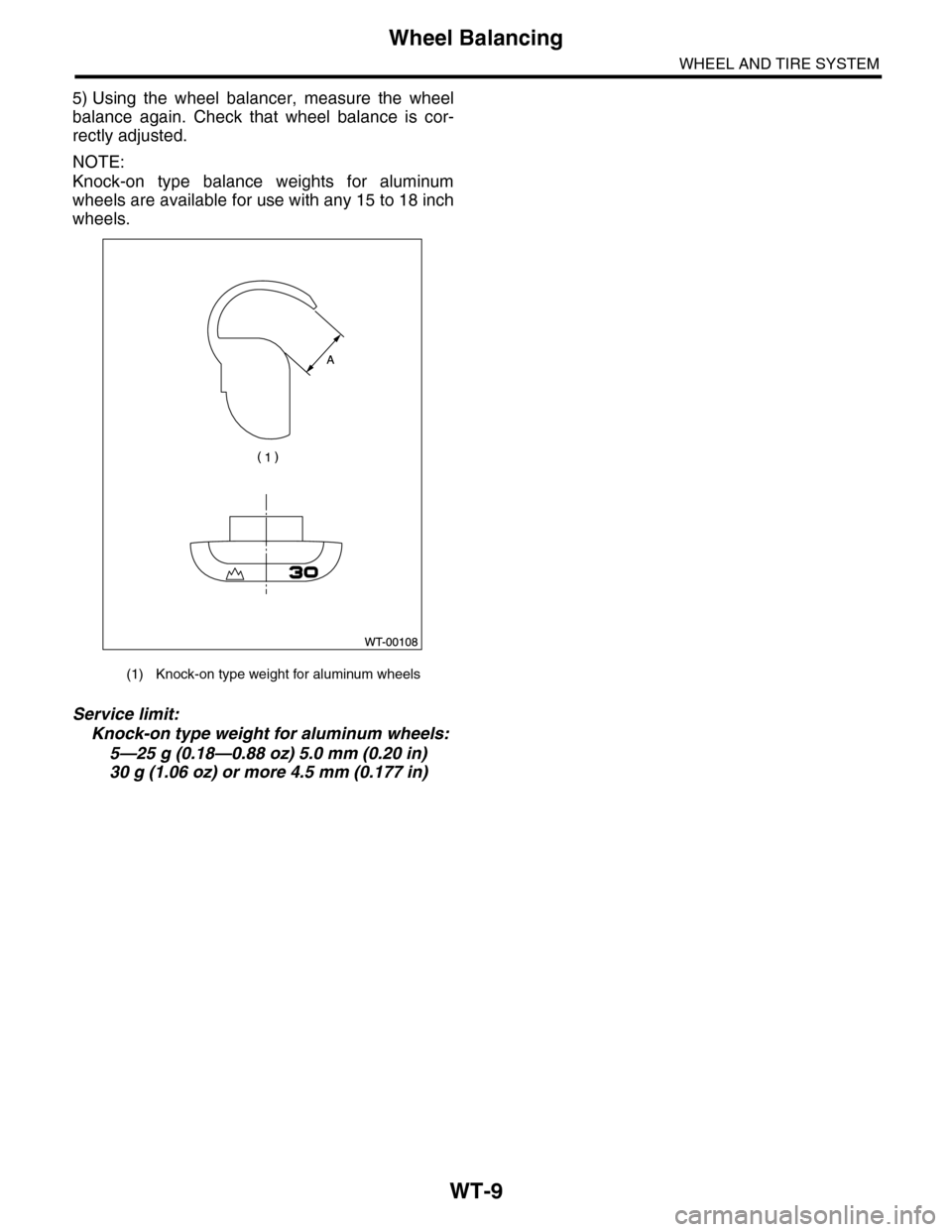

5) Using the wheel balancer, measure the wheel

balance again. Check that wheel balance is cor-

rectly adjusted.

NOTE:

Knock-on type balance weights for aluminum

wheels are available for use with any 15 to 18 inch

wheels.

Service limit:

Knock-on type weight for aluminum wheels:

5—25 g (0.18—0.88 oz) 5.0 mm (0.20 in)

30 g (1.06 oz) or more 4.5 mm (0.177 in)

(1) Knock-on type weight for aluminum wheels

Page 1116 of 2453

WT-10

“T–type” Tire

WHEEL AND TIRE SYSTEM

5. “T–type” Tire

A: NOTE

“T–type” tire for temporary use is equipped as a

spare tire.

CAUTION:

•Do not drive at a speed greater than 100 km/h

(62 MPH).

•For the model with tire pressure monitoring

system, the indicator light may blink when run-

ning with the “T-type” tire.

B: REPLACEMENT

Refer to Aluminum Wheels for removal and instal-

lation procedures of the “T–type”.

CAUTION:

The “T–type” tire is only for temporary use. Re-

place with a conventional tire as soon as possi-

ble.

C: INSPECTION

1) Check the tire air pressure.

Specifications:

420 kPa (4.2 kg/cm2, 60 psi)

2) Take stones, glass, nails, etc. out of the tread

groove.

3) Check the tires for deformation, cracks, partial

wear, or wear.

CAUTION:

Replace the tire with a new one if defective.

Page 1117 of 2453

WT-11

Tire Pressure Monitoring System

WHEEL AND TIRE SYSTEM

6. Tire Pressure Monitoring

System

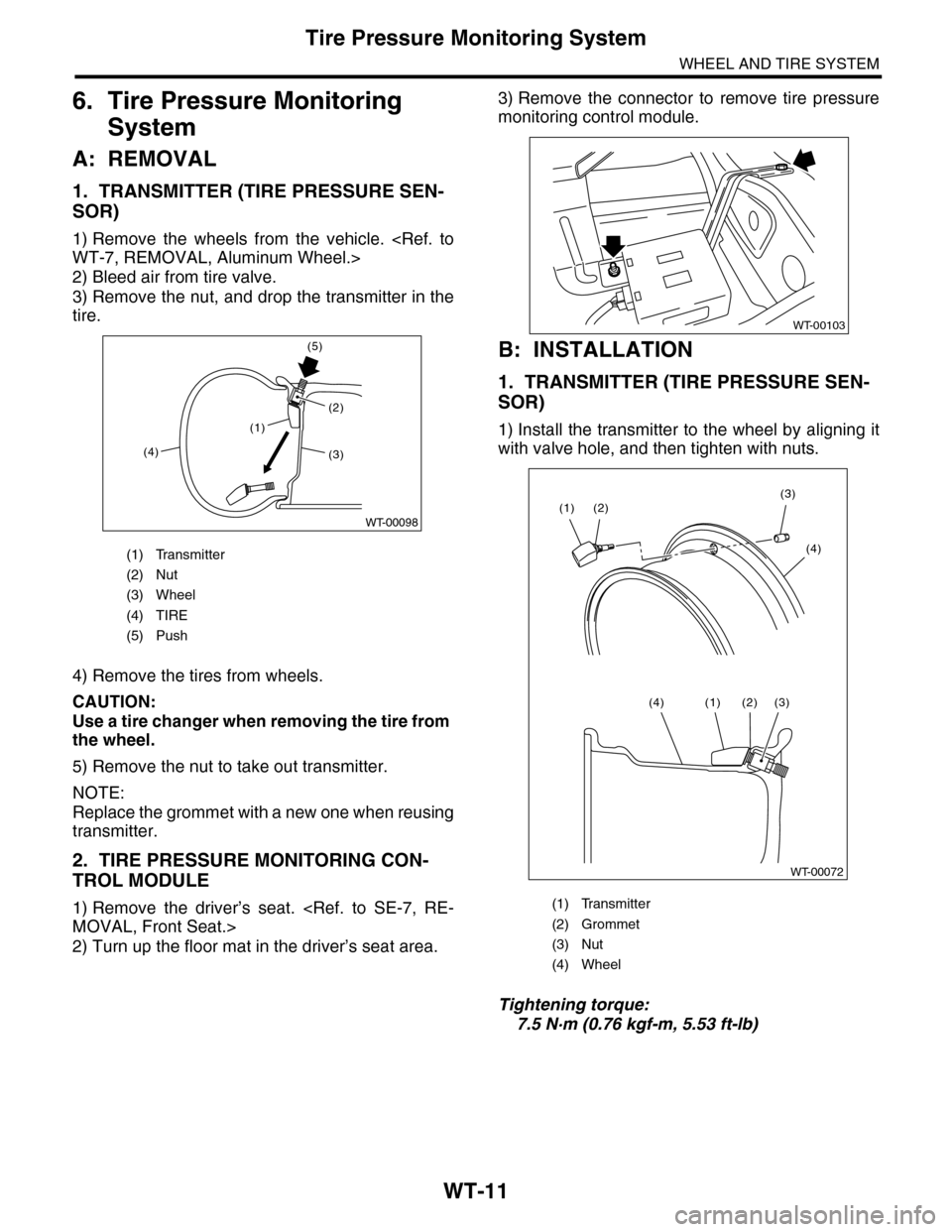

A: REMOVAL

1. TRANSMITTER (TIRE PRESSURE SEN-

SOR)

1) Remove the wheels from the vehicle.

2) Bleed air from tire valve.

3) Remove the nut, and drop the transmitter in the

tire.

4) Remove the tires from wheels.

CAUTION:

Use a tire changer when removing the tire from

the wheel.

5) Remove the nut to take out transmitter.

NOTE:

Replace the grommet with a new one when reusing

transmitter.

2. TIRE PRESSURE MONITORING CON-

TROL MODULE

1) Remove the driver’s seat.

2) Turn up the floor mat in the driver’s seat area.

3) Remove the connector to remove tire pressure

monitoring control module.

B: INSTALLATION

1. TRANSMITTER (TIRE PRESSURE SEN-

SOR)

1) Install the transmitter to the wheel by aligning it

with valve hole, and then tighten with nuts.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.53 ft-lb)

(1) Transmitter

(2) Nut

(3) Wheel

(4) TIRE

(5) Push

(1)

(4)

(5)

(2)

WT-00098

(3)

(1) Transmitter

(2) Grommet

(3) Nut

(4) Wheel

WT-00103

WT-00072

(2)(3)

(4)

(1)

(3)(2)(1)(4)

Page 1118 of 2453

WT-12

Tire Pressure Monitoring System

WHEEL AND TIRE SYSTEM

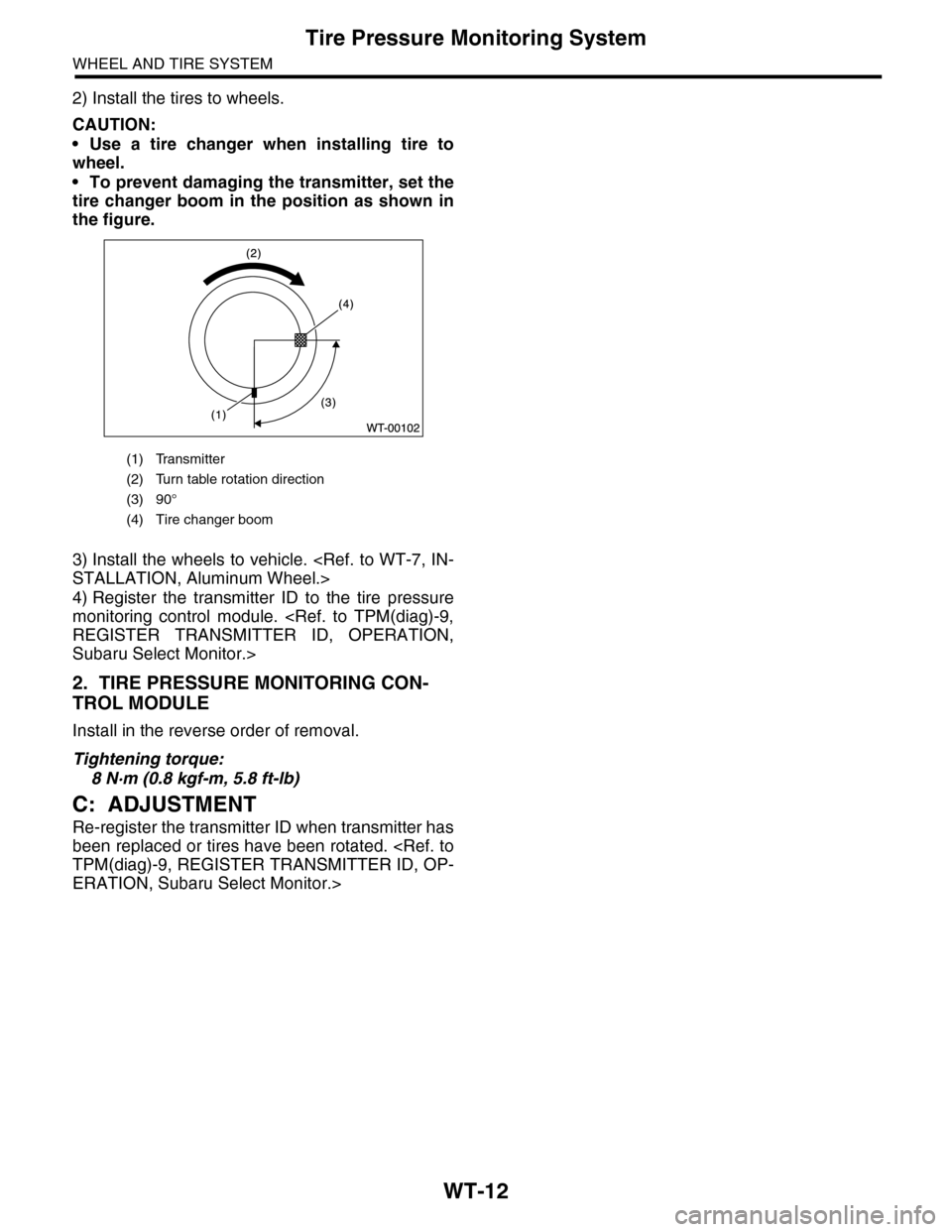

2) Install the tires to wheels.

CAUTION:

•Use a tire changer when installing tire to

wheel.

•To prevent damaging the transmitter, set the

tire changer boom in the position as shown in

the figure.

3) Install the wheels to vehicle.

4) Register the transmitter ID to the tire pressure

monitoring control module.

Subaru Select Monitor.>

2. TIRE PRESSURE MONITORING CON-

TROL MODULE

Install in the reverse order of removal.

Tightening torque:

8 N·m (0.8 kgf-m, 5.8 ft-lb)

C: ADJUSTMENT

Re-register the transmitter ID when transmitter has

been replaced or tires have been rotated.

ERATION, Subaru Select Monitor.>

(1) Transmitter

(2) Turn table rotation direction

(3) 90°

(4) Tire changer boom

Page 1119 of 2453

WT-13

Spare Tire Hoist

WHEEL AND TIRE SYSTEM

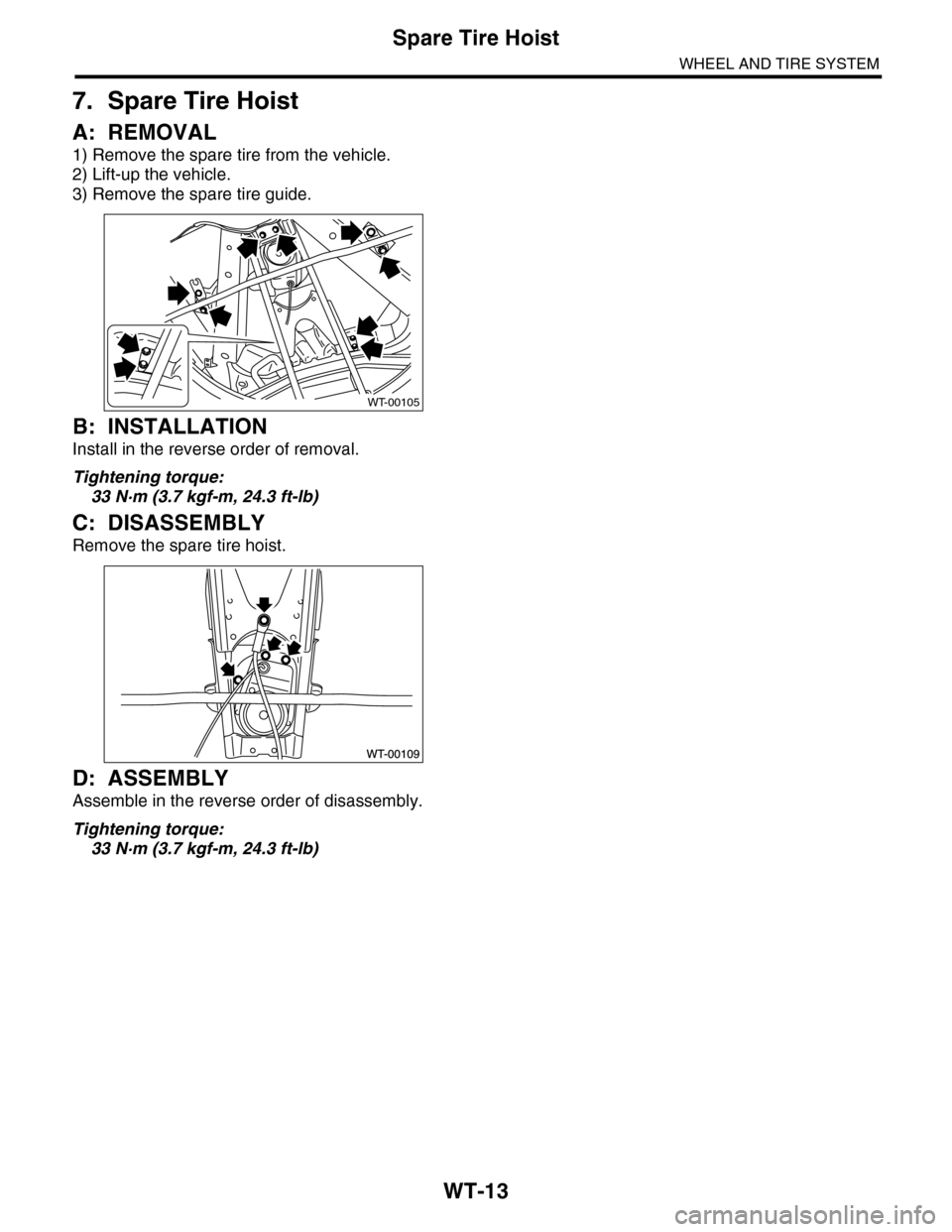

7. Spare Tire Hoist

A: REMOVAL

1) Remove the spare tire from the vehicle.

2) Lift-up the vehicle.

3) Remove the spare tire guide.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

33 N·m (3.7 kgf-m, 24.3 ft-lb)

C: DISASSEMBLY

Remove the spare tire hoist.

D: ASSEMBLY

Assemble in the reverse order of disassembly.

Tightening torque:

33 N·m (3.7 kgf-m, 24.3 ft-lb)

WT-00105

Page 1120 of 2453

WT-14

General Diagnostic Table

WHEEL AND TIRE SYSTEM

8. General Diagnostic Table

A: INSPECTION

Symptom Possible cause Corrective action

Wheel is out of balance. Improperly inflated tire. Adjust the tire pressure.

Uneven wear Check the tire referring to Abnormal tire wear in this table,

carry out the procedure and replace the tire.

Fr o nt w h ee l al ig n me nt Ch eck t he f r on t w he e l a l ig n me nt . < R ef. to F S - 6, I N S P E C -

TION, Wheel Alignment.>

Rear wheel alignment Check the rear wheel alignment.

Fr o nt s tr u t Ch eck th e f r o n t s tr ut .

Rear shock absorber Check the rear shock absorber.

Fr o nt a xl e C h eck th e f r o n t a xl e. < R e f. t o D S - 1 6, I N S P E C T IO N,

Fr o n t A x le. >

Fr o nt h ub un i t b e ar i n g Ch eck th e f r o n t h ub u ni t b e ar i n g. < Re f. t o DS - 2 0,

INSPECTION, Front Hub Unit Bearing.>

Rear hub unit bearing Check the rear hub unit bearing.

Ve h i c l e i s a b n o r m a l l y o u t o f b a l -

ance.

Improperly inflated tire. Adjust the tire pressure.

Uneven wear Check the tire referring to Abnormal tire wear in this table,

carry out the procedure and replace the tire.

Fr o nt s ta b il i ze r I ns p ec t t h e f r o nt st a bi l izer. < R e f. t o F S - 14 , IN SP E C T I ON,

Fr o n t S t a bi l izer. >

Fr o nt w h ee l al ig n me nt Ch eck t he f r on t w he e l a l ig n me nt . < R ef. to F S - 6, I N S P E C -

TION, Wheel Alignment.>

Rear wheel alignment Check the rear wheel alignment.

Abnormal wheel vibration Improperly inflated tire. Adjust the tire pressure.

Uneven wear Check the tire referring to Abnormal tire wear in this table,

carry out the procedure and replace the tire.

Improper wheel balancing Check the wheel balance.

Fr o nt a xl e C h eck th e f r o n t a xl e. < R e f. t o D S - 1 6, I N S P E C T IO N,

Fr o n t A x le. >

Fr o nt h ub un i t b e ar i n g Ch eck th e f r o n t h ub u ni t b e ar i n g. < Re f. t o DS - 2 0,

INSPECTION, Front Hub Unit Bearing.>

Rear hub unit bearing Check the rear hub unit bearing.

Abnormal tire wear Improperly inflated tire. Adjust the tire pressure.

Improper wheel balancing Check the wheel balance.

Fr o nt w h ee l al ig n me nt Ch eck t he f r on t w he e l a l ig n me nt . < R ef. to F S - 6, I N S P E C -

TION, Wheel Alignment.>

Rear wheel alignment Check the rear wheel alignment.