Duct SUBARU TRIBECA 2009 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1745 of 2453

GD(H6DO)-133

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

Time Needed for Diagnosis: 30 to 100 seconds

0.02-inch Diagnosis

DTC

P0456 Evaporative Emission Control System Leak Detected (very small leak)

Diagnostic method

The diagnostic method consists of creating a sealed vacuum in the fuel tank and then determining the pres-

ence of leakage from the speed at which the tank internal pressure returns to atmospheric pressure.

Mode A: (0 Point Compensation)

When pressure in tank is high, wait for 0 point 0 kPa (Near 0 mmHg, 0 inHg) to return.Shift to mode B when

0 point returns.

Cancel the diagnosis when 0 point does not return in the specified time.

Mode B: (Negative pressure introduced)

Introduce negative pressure in the intake manifold to the tank.

Approx. 0 → –2.0 kPa (0 mmHg → –15 mmHg, 0 → –0.59 inHg)

When the pressure above (desired negative pressure) is reached, Mode C is entered.

Cancel the diagnosis when the targeted pressure in the tank is not reached.

Mode C: (Negative pressure maintained)

Stop the introduction of negative pressure and wait until the tank pressure returns to the start level of P2 cal-

culation.

Change to Mode D either when the tank pressure returns to the start level of P2 calculation, or when the pre-

determined amount of time has passed.

Mode D: (Calculate the amount of negative pressure change)

Monitor the tank pressure in mode D, calculate (P2) the pressure change in the tank, and measure the time

(evpdset) for the tank pressure to return when calculation of P2 is completed. Shift to mode E when pressure

returns. Make an advance OK judgment using the value of P2, or cancel, when the pressure in the tank does

not return after calculation of P2 is completed even when the predetermined amount of time has passed.

When the following conditions are established, it is OK.

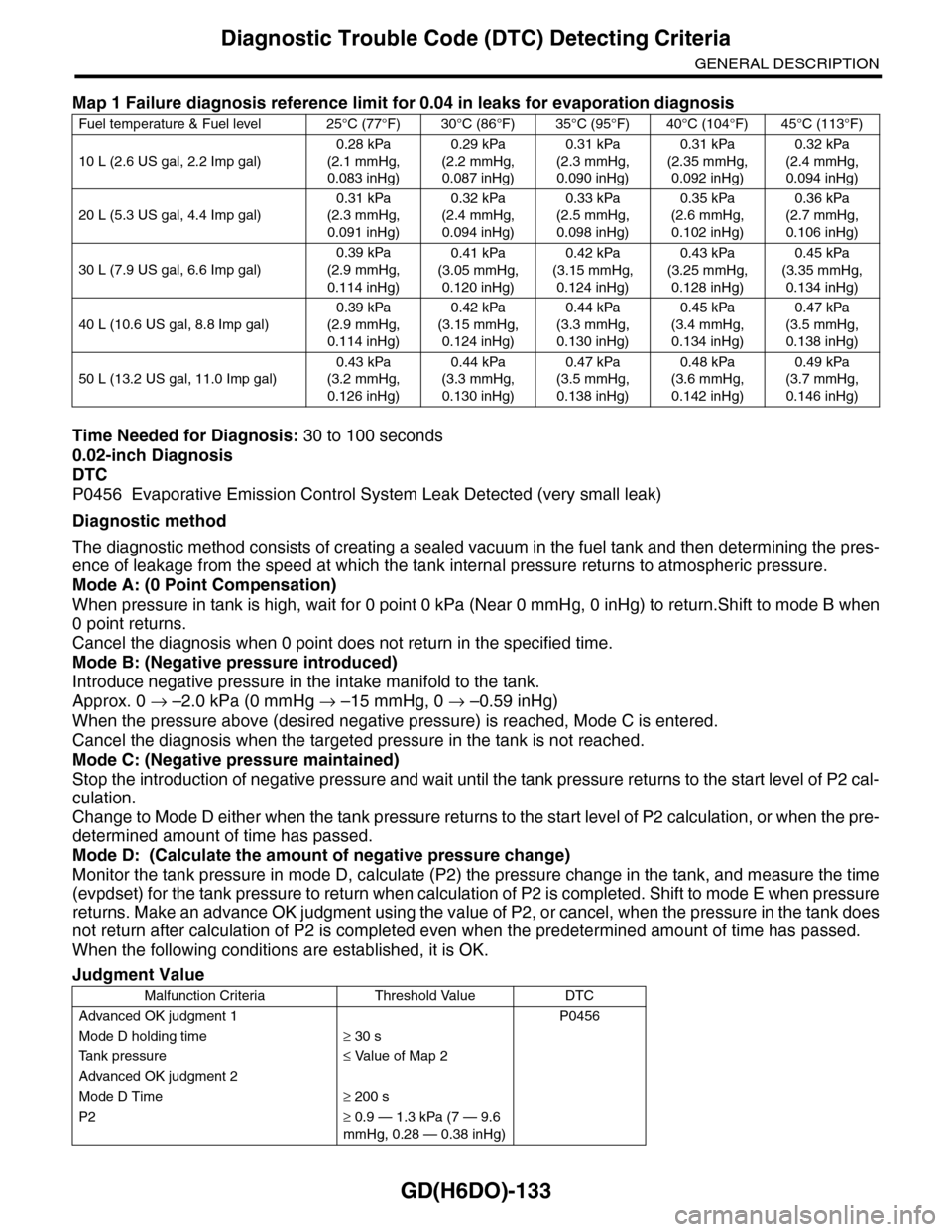

Map 1 Failure diagnosis reference limit for 0.04 in leaks for evaporation diagnosis

Fuel temperature & Fuel level 25°C (77°F) 30°C (86°F) 35°C (95°F) 40°C (104°F) 45°C (113°F)

10 L (2.6 US gal, 2.2 Imp gal)

0.28 kPa

(2.1 mmHg,

0.083 inHg)

0.29 kPa

(2.2 mmHg,

0.087 inHg)

0.31 kPa

(2.3 mmHg,

0.090 inHg)

0.31 kPa

(2.35 mmHg,

0.092 inHg)

0.32 kPa

(2.4 mmHg,

0.094 inHg)

20 L (5.3 US gal, 4.4 Imp gal)

0.31 kPa

(2.3 mmHg,

0.091 inHg)

0.32 kPa

(2.4 mmHg,

0.094 inHg)

0.33 kPa

(2.5 mmHg,

0.098 inHg)

0.35 kPa

(2.6 mmHg,

0.102 inHg)

0.36 kPa

(2.7 mmHg,

0.106 inHg)

30 L (7.9 US gal, 6.6 Imp gal)

0.39 kPa

(2.9 mmHg,

0.114 inHg)

0.41 kPa

(3.05 mmHg,

0.120 inHg)

0.42 kPa

(3.15 mmHg,

0.124 inHg)

0.43 kPa

(3.25 mmHg,

0.128 inHg)

0.45 kPa

(3.35 mmHg,

0.134 inHg)

40 L (10.6 US gal, 8.8 Imp gal)

0.39 kPa

(2.9 mmHg,

0.114 inHg)

0.42 kPa

(3.15 mmHg,

0.124 inHg)

0.44 kPa

(3.3 mmHg,

0.130 inHg)

0.45 kPa

(3.4 mmHg,

0.134 inHg)

0.47 kPa

(3.5 mmHg,

0.138 inHg)

50 L (13.2 US gal, 11.0 Imp gal)

0.43 kPa

(3.2 mmHg,

0.126 inHg)

0.44 kPa

(3.3 mmHg,

0.130 inHg)

0.47 kPa

(3.5 mmHg,

0.138 inHg)

0.48 kPa

(3.6 mmHg,

0.142 inHg)

0.49 kPa

(3.7 mmHg,

0.146 inHg)

Judgment Value

Malfunction Criteria Threshold Value DTC

Advanced OK judgment 1 P0456

Mode D holding time≥ 30 s

Ta n k p r e s s u r e≤ Value of Map 2

Advanced OK judgment 2

Mode D Time≥ 200 s

P2≥ 0.9 — 1.3 kPa (7 — 9.6

mmHg, 0.28 — 0.38 inHg)

Page 1819 of 2453

GD(H6DO)-207

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

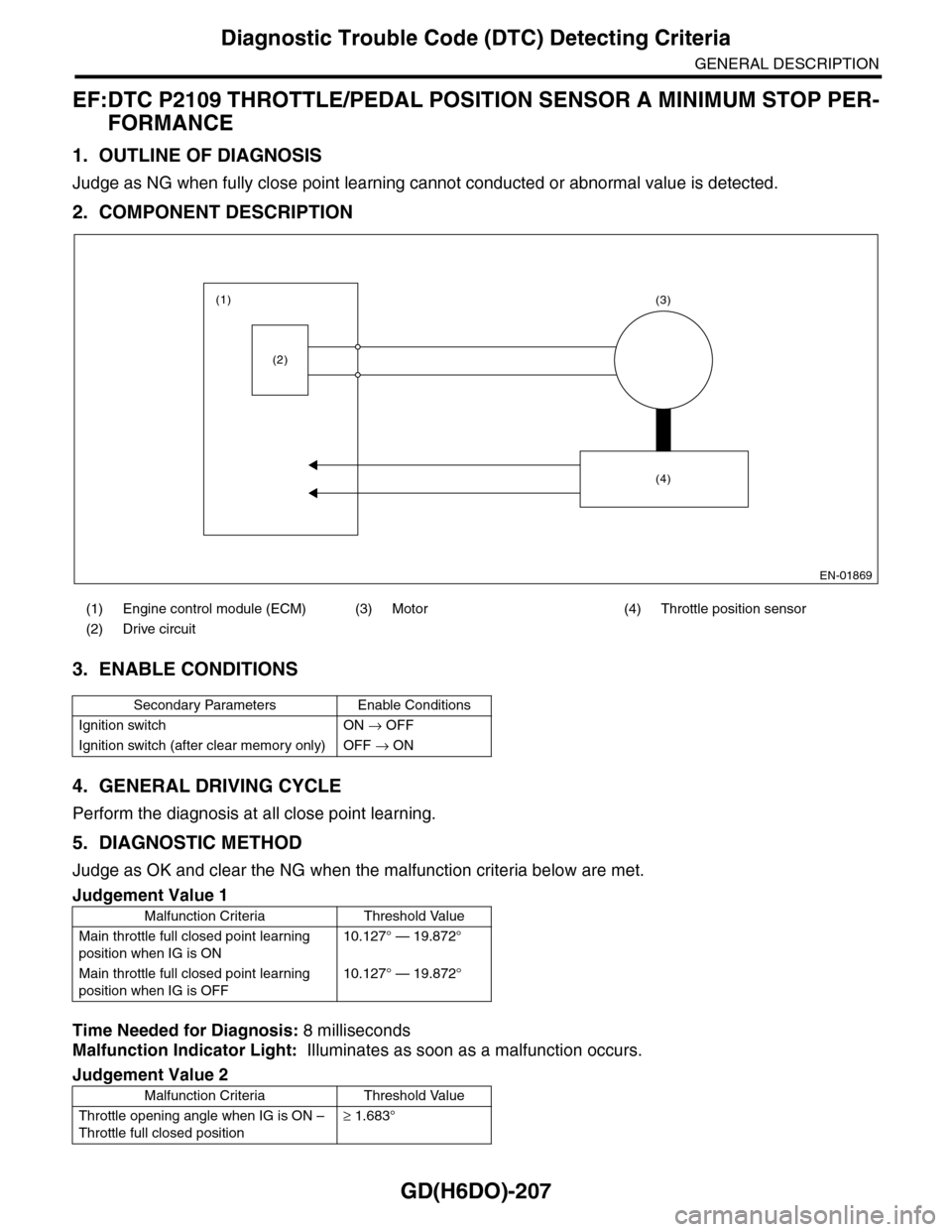

EF:DTC P2109 THROTTLE/PEDAL POSITION SENSOR A MINIMUM STOP PER-

FORMANCE

1. OUTLINE OF DIAGNOSIS

Judge as NG when fully close point learning cannot conducted or abnormal value is detected.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis at all close point learning.

5. DIAGNOSTIC METHOD

Judge as OK and clear the NG when the malfunction criteria below are met.

Time Needed for Diagnosis: 8 milliseconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

(1) Engine control module (ECM) (3) Motor (4) Throttle position sensor

(2) Drive circuit

Secondary Parameters Enable Conditions

Ignition switch ON → OFF

Ignition switch (after clear memory only) OFF → ON

Judgement Value 1

Malfunction Criteria Threshold Value

Main throttle full closed point learning

position when IG is ON

10.127° — 19.872°

Main throttle full closed point learning

position when IG is OFF

10.127° — 19.872°

Judgement Value 2

Malfunction Criteria Threshold Value

Throttle opening angle when IG is ON –

Throttle full closed position

≥ 1.683°

EN-01869

(1)

(2)

(3)

(4)

Page 1844 of 2453

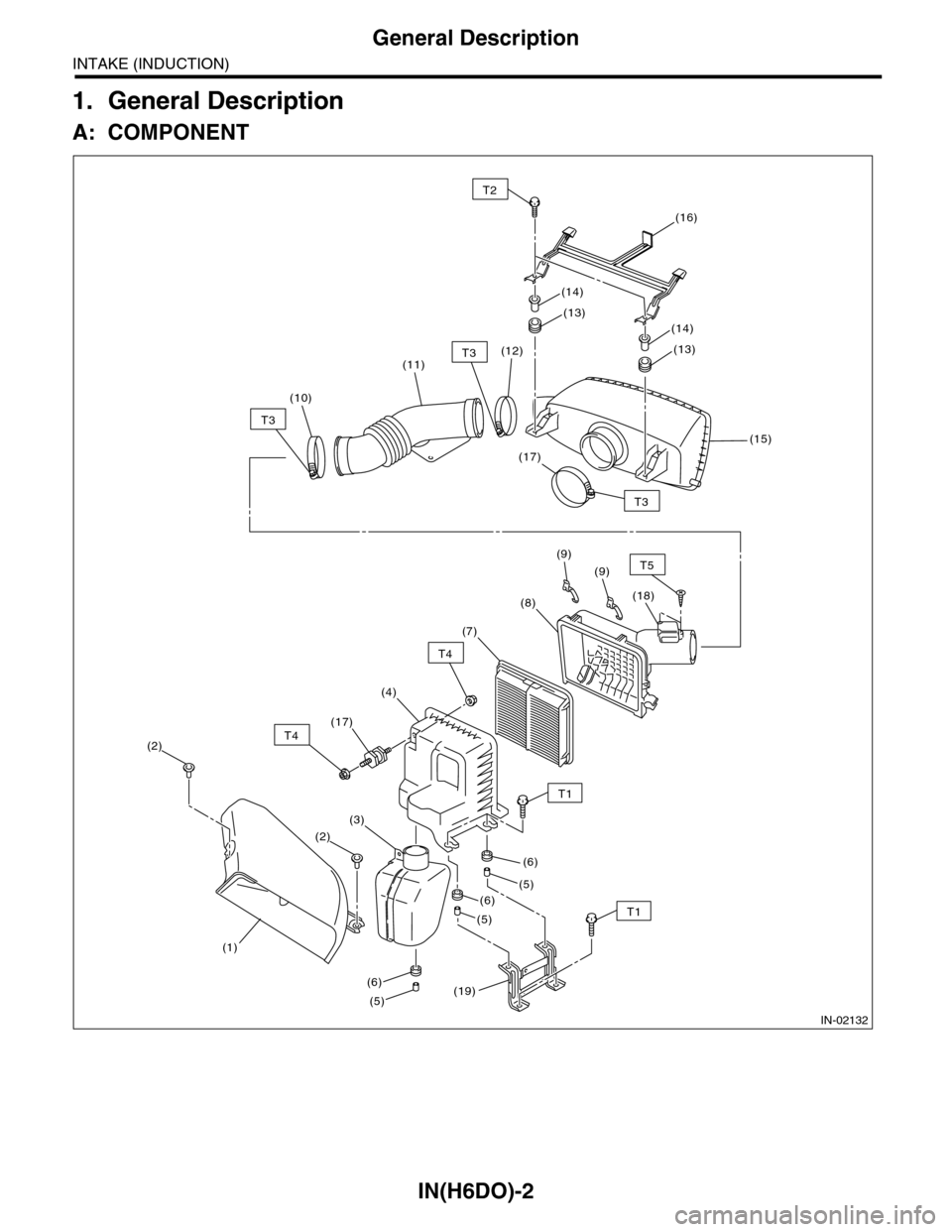

IN(H6DO)-2

General Description

INTAKE (INDUCTION)

1. General Description

A: COMPONENT

(12)

(17)

(16)

(15)

(11)

T1

(6)

(6)

(5)

(5)

(9)

(9)

(8)(18)

(7)

(4)

(17)

(19)

(3)

(1)

(2)

(6)

(5)

T3

T3

(13)

T2

(14)

(13)

(14)

T4

T4

T5

(10)

T3

(2)

IN-02132

T1

Page 1845 of 2453

IN(H6DO)-3

General Description

INTAKE (INDUCTION)

B: CAUTION

•Wear work clothing, including a cap, protective

goggles and protective shoes during operation.

•Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

•Keep the disassembled parts in order and pro-

tect them from dust and dirt.

•Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly and replacement.

•Be careful not to burn yourself, because each

part on the vehicle is hot after running.

•Be sure to tighten fasteners including bolts and

nuts to the specified torque.

•Place shop jacks or rigid racks at the specified

points.

•Before disconnecting connectors of sensors or

units, be sure to disconnect the ground cable from

the battery.

(1) Air intake duct (11) Intake duct (19) Air cleaner bracket

(2) Clip (12) Clamp

(3) Resonator chamber (13) CushionTightening torque: N·m (kgf-m, ft-lb)

(4) Air cleaner case (front) (14) SpacerT1: 6.0 (0.6, 4.4)

(5) Spacer (15) Air intake chamberT2: 6.4 (0.65, 4.7)

(6) Cushion (16) Collector cover bracketT3: 3.0 (0.3, 2.2)

(7) Air cleaner element (17) CushionT4: 7.5 (0.76, 5.5)

(8) Air cleaner case (rear) (18) Mass air flow and intake air tem-

perature sensor

T5: 1.0 (0.10, 0.7)

(9) Clip

(10) Clamp

Page 1846 of 2453

IN(H6DO)-4

Air Cleaner Element

INTAKE (INDUCTION)

2. Air Cleaner Element

A: REMOVAL

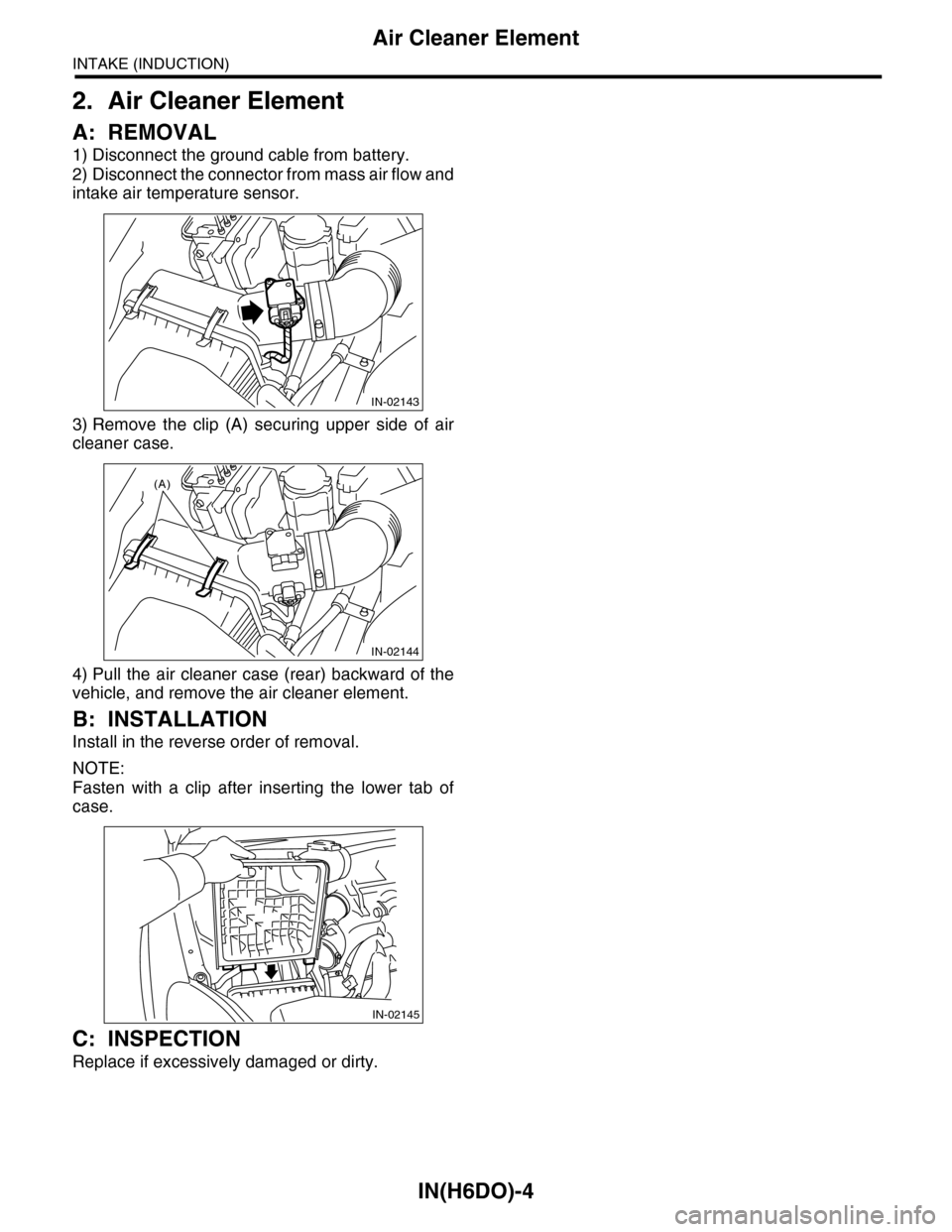

1) Disconnect the ground cable from battery.

2) Disconnect the connector from mass air flow and

intake air temperature sensor.

3) Remove the clip (A) securing upper side of air

cleaner case.

4) Pull the air cleaner case (rear) backward of the

vehicle, and remove the air cleaner element.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Fasten with a clip after inserting the lower tab of

case.

C: INSPECTION

Replace if excessively damaged or dirty.

IN-02143

IN-02144

(A)

IN-02145

Page 1847 of 2453

IN(H6DO)-5

Air Cleaner Case

INTAKE (INDUCTION)

3. Air Cleaner Case

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air intake duct.

3) Disconnect the connector from mass air flow and

intake air temperature sensor.

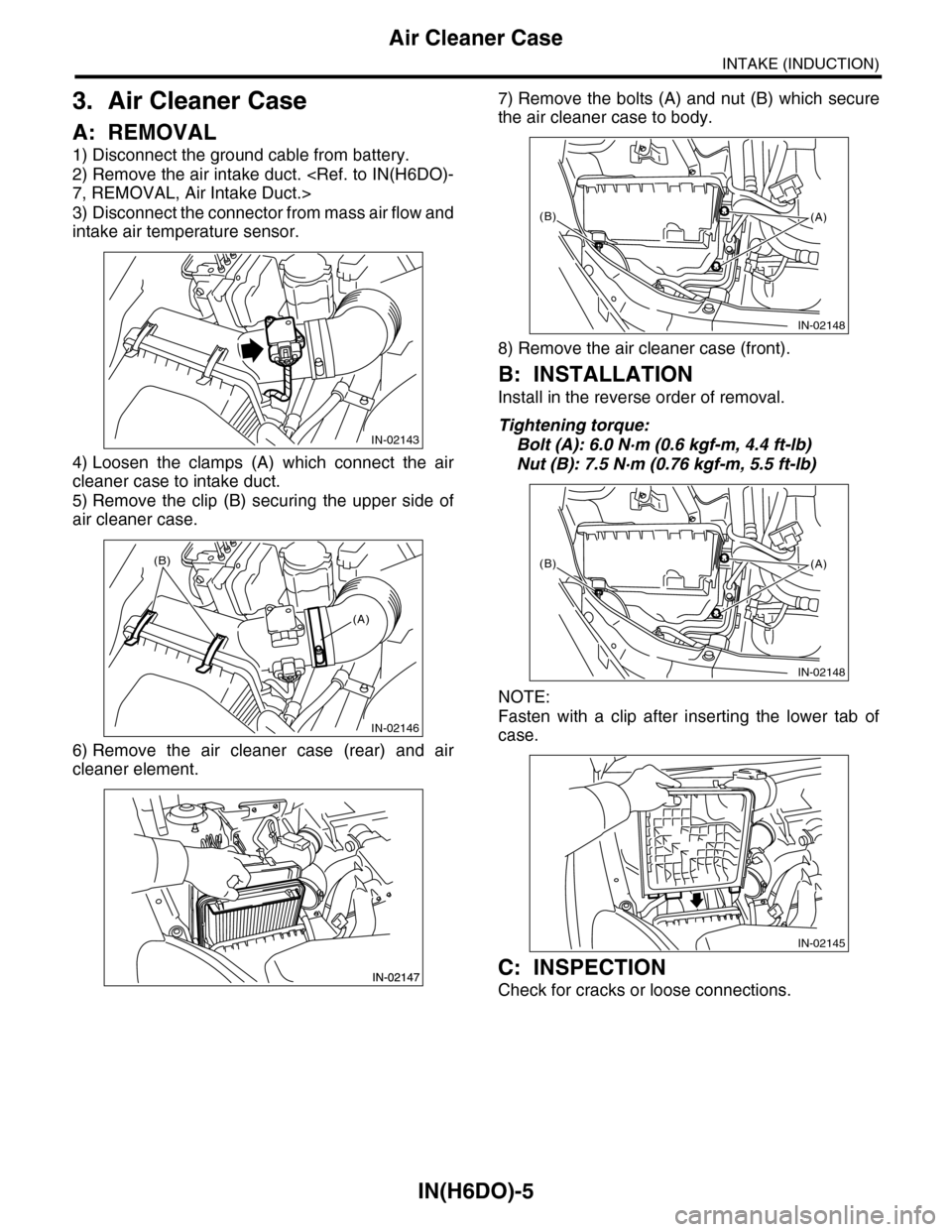

4) Loosen the clamps (A) which connect the air

cleaner case to intake duct.

5) Remove the clip (B) securing the upper side of

air cleaner case.

6) Remove the air cleaner case (rear) and air

cleaner element.

7) Remove the bolts (A) and nut (B) which secure

the air cleaner case to body.

8) Remove the air cleaner case (front).

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Bolt (A): 6.0 N·m (0.6 kgf-m, 4.4 ft-lb)

Nut (B): 7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

NOTE:

Fasten with a clip after inserting the lower tab of

case.

C: INSPECTION

Check for cracks or loose connections.

IN-02143

IN-02146

(B)

(A)

IN-02148

(B)(A)

IN-02148

(B)(A)

IN-02145

Page 1848 of 2453

IN(H6DO)-6

Air Intake Chamber

INTAKE (INDUCTION)

4. Air Intake Chamber

A: REMOVAL

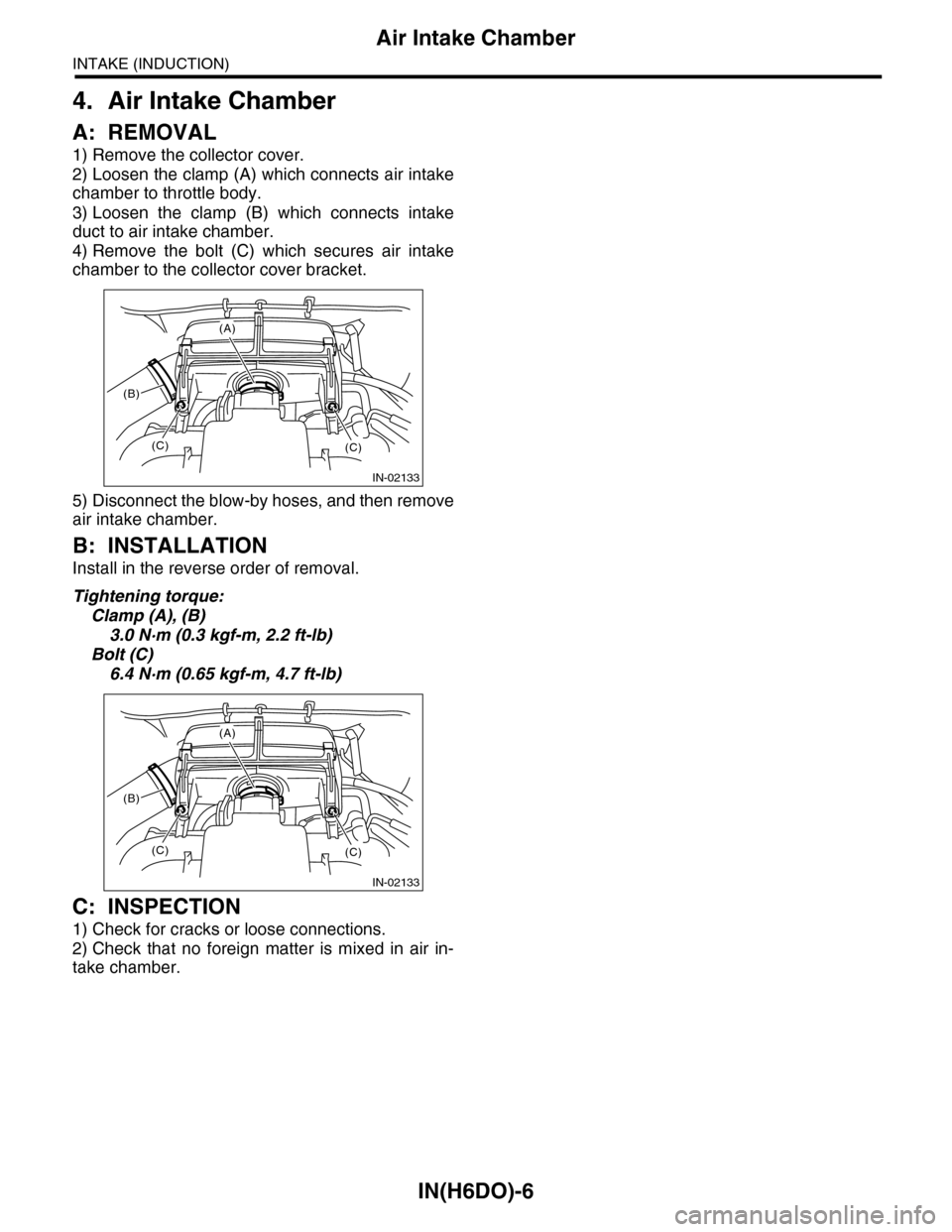

1) Remove the collector cover.

2) Loosen the clamp (A) which connects air intake

chamber to throttle body.

3) Loosen the clamp (B) which connects intake

duct to air intake chamber.

4) Remove the bolt (C) which secures air intake

chamber to the collector cover bracket.

5) Disconnect the blow-by hoses, and then remove

air intake chamber.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Clamp (A), (B)

3.0 N·m (0.3 kgf-m, 2.2 ft-lb)

Bolt (C)

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

C: INSPECTION

1) Check for cracks or loose connections.

2) Check that no foreign matter is mixed in air in-

take chamber.

(A)

(C)(C)

(B)

IN-02133

(A)

(C)(C)

(B)

IN-02133

Page 1849 of 2453

IN(H6DO)-7

Air Intake Duct

INTAKE (INDUCTION)

5. Air Intake Duct

A: REMOVAL

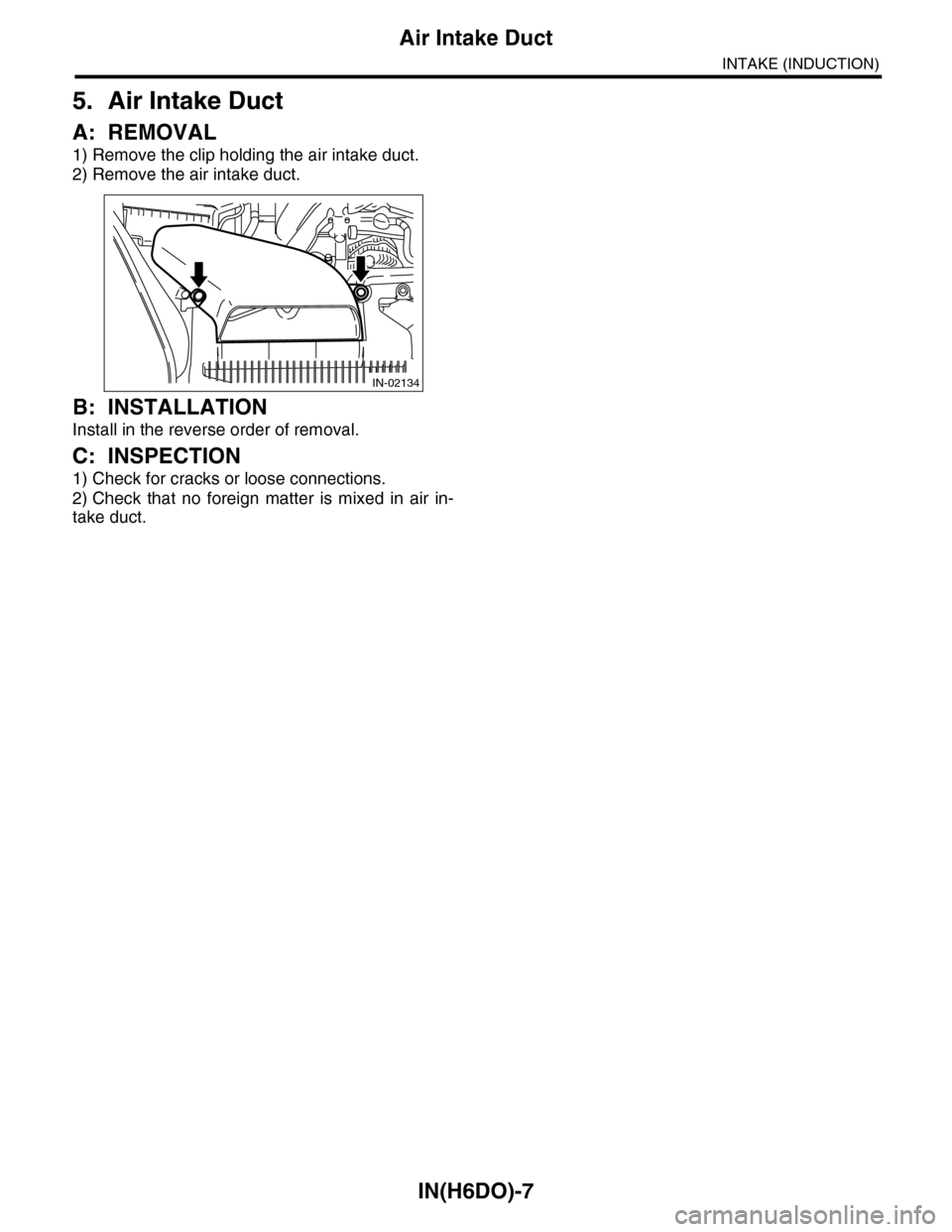

1) Remove the clip holding the air intake duct.

2) Remove the air intake duct.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

1) Check for cracks or loose connections.

2) Check that no foreign matter is mixed in air in-

take duct.

IN-02134

Page 1850 of 2453

IN(H6DO)-8

Resonator Chamber

INTAKE (INDUCTION)

6. Resonator Chamber

A: REMOVAL

The resonator chamber and air cleaner case are in-

tegrated into one unit; therefore, refer to “Air Clean-

er Case” for removal procedure.

B: INSTALLATION

The resonator chamber and air cleaner case are in-

tegrated into one unit; therefore, refer to “Air Clean-

er Case” for installation procedure.

C: INSPECTION

Check for cracks or loose connections.

Page 1856 of 2453

LU(H6DO)-7

Engine Oil

LUBRICATION

3. Engine Oil

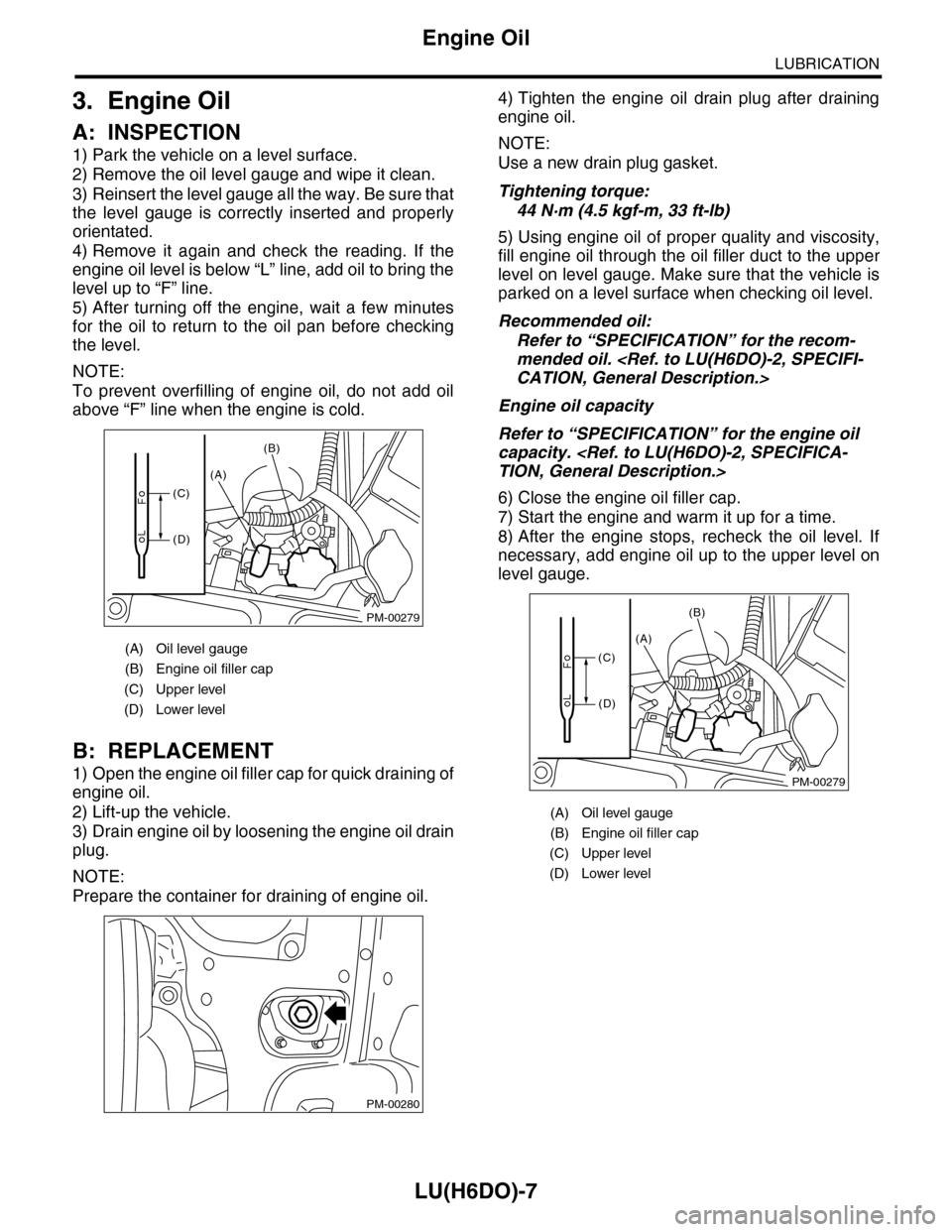

A: INSPECTION

1) Park the vehicle on a level surface.

2) Remove the oil level gauge and wipe it clean.

3) Reinsert the level gauge all the way. Be sure that

the level gauge is correctly inserted and properly

orientated.

4) Remove it again and check the reading. If the

engine oil level is below “L” line, add oil to bring the

level up to “F” line.

5) After turning off the engine, wait a few minutes

for the oil to return to the oil pan before checking

the level.

NOTE:

To prevent overfilling of engine oil, do not add oil

above “F” line when the engine is cold.

B: REPLACEMENT

1) Open the engine oil filler cap for quick draining of

engine oil.

2) Lift-up the vehicle.

3) Drain engine oil by loosening the engine oil drain

plug.

NOTE:

Prepare the container for draining of engine oil.

4) Tighten the engine oil drain plug after draining

engine oil.

NOTE:

Use a new drain plug gasket.

Tightening torque:

44 N·m (4.5 kgf-m, 33 ft-lb)

5) Using engine oil of proper quality and viscosity,

fill engine oil through the oil filler duct to the upper

level on level gauge. Make sure that the vehicle is

parked on a level surface when checking oil level.

Recommended oil:

Refer to “SPECIFICATION” for the recom-

mended oil.

Engine oil capacity

Refer to “SPECIFICATION” for the engine oil

capacity.

6) Close the engine oil filler cap.

7) Start the engine and warm it up for a time.

8) After the engine stops, recheck the oil level. If

necessary, add engine oil up to the upper level on

level gauge.

(A) Oil level gauge

(B) Engine oil filler cap

(C) Upper level

(D) Lower level

PM-00279

(A)

(B)

(C)

(D)

PM-00280

(A) Oil level gauge

(B) Engine oil filler cap

(C) Upper level

(D) Lower level

PM-00279

(A)

(B)

(C)

(D)